Abstract

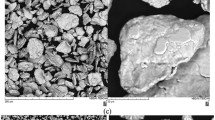

The regularities of oxidation of hard alloys (HA) in the “tungsten carbide-metal binder based on cobalt, nickel, rhenium, and manganese” system are established. It is revealed that the introduction of Ni-Re or Ni-Mn into the cobalt binder increases the temperature of the onset of active oxidation by 20–70°C and decreases its rate in the following order: Co-Ni, Co-Mn → (Co-Ni-Mn, Co-Re, Co-Ni) → Co-Ni-Re → Ni-Re. The character of the temperature dependence of the bending strength of the HA with Co-Ni and Ni-Mn binders is almost indistinguishable from that for the VK alloy, while the addition of Re into the binder abruptly changes this character. The HA strengthens somewhat (up to 20%) up to temperatures of 600°C for the Ni-Re binder and 800°C for the Co-Re binder; then its strength decreases but remains higher than for materials with cobalt and nickel binders. The maximal strength of the HA of the WC-Co-Ni-Re systems is attained in the range t = 600–800°C, which corresponds to the temperature of the working edge of the cutting material.

Similar content being viewed by others

References

Bobrov, V.F., Osnovy teorii rezaniya metallov (Foundations of Cutting Theory of Metals), Moscow: Mashinostroenie, 1975.

Inyutina, I.A., Kuprina, V.V., Sokolovskaya, E.M., and Spasov, N.A., in Issledovanie i primenenie splavov reniya (Investigation and Application of Rhenium Alloys), Moscow: Nauka, 1975, pp. 54–56.

Savitskii, E.M., Tylkina, M.A., and Arskaya, E.P., Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 1989, no. 4, p. 113.

Chaporova, I.N., Sapronova, Z.N., Dezhkina, N.I., and Karasev, G.F., in Svoistva i primenenie spechennykh tverdykh splavov: Sbornik statei (Properties and Application of Sintered Hard Alloys: Collected Articles), Moscow: VNIIPI tugoplavkikh metallov i tverdykh splavov, 1991, p. 30.

Panteleev, I.B., Lukashova, T.V., and Ordan’yan, S.S., Tsvetn. Met., 1997, no. 7, p. 70.

Ordan’yan, S.S., Panteleev, I.B., Lukashova, T.V., and Garabadzhiu, A.A., Tsvetn. Met., 1997, no. 9, p. 62.

Arzamaev, B.N., Sidorin, I.I., Kosolapov, G.F., et al., Materialovedenie: Uchebik dlya vuzov (Materials Science: Textbook for Higher Schools), Moscow: Mashinostroenie, 1986.

Semenov, S.S., Investigation of High-Temperature Mechanical Properties of Ceramic Materials Based on Some Refractory Compounds, Extended Abstract of Cand. Sci. (Eng.) Dissertation, Leningrad: LTI, 1977.

Ordan’yan, S.S., Yuriditskii, B.Yu., and Panteleev, I.B., Poroshk. Metall., 1982, no. 7, pp. 94–97.

S.S. Ordan’yan, S.E. Vinogradov, and I.B. Panteleev, RF Patent no. 2105825, 1998.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © I.B. Panteleev, T.V. Lukashova, S.S. Ordan’yan, 2010, published in Izvestiya VUZ. Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2010, No. 2, pp. 23–25.

About this article

Cite this article

Panteleev, I.B., Lukashova, T.V. & Ordan’yan, S.S. High-temperature strength and refractoriness of doped WC-Co-Ni-Re(Mn) hard alloys. Russ. J. Non-ferrous Metals 52, 295–297 (2011). https://doi.org/10.3103/S1067821211030187

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821211030187