Abstract

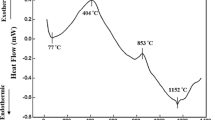

A cobalt-containing high-entropy alloy (HEA) system with varying tungsten content, CoCrFeNiWx (x = 0.1, 0.2, 0.4, 1.0), is studied, with the focus on the influence of tungsten content on the microstructural morphology, formation of strengthening phases, entropy, hardness and wear resistance of the HEA. The powders for fabricating the bulk specimens are prepared via mechanical alloying (MA), and the phase transformation behavior of the elemental powders during the MA process is investigated with XRD. It is found that the mixed elemental powders can be alloyed in the milling process. The MAed powders are subjected to differential scanning calorimetry (DSC) analysis to determine the melting points and also to obtain cast-like bulk samples. The MAed CoCrFeNiW0.2 powder is also consolidated via spark plasma sintering (SPS). The experimental results show that increasing W content can promote formation of strengthening phase and enhance entropy of CoCrFeNiWx HEA, thereby resulting in the increase of hardness. The SPS specimens have higher hardness than the bulk samples from the DSC tests. The SPS CoCrFeNiW0.2 HEA exhibits comparable wear resistance to wear-resistant Stellite 6 and much better wear resistance than the cobalt-containing HEA, HE6, fabricated via the same processing route.

Similar content being viewed by others

References

M.H. Tsai, J.W. Yeh, High-entropy alloys: a critical review. Mater. Res. Lett. 2(3), 107–123 (2014)

J.W. Yeh, Alloy design strategies and future trends in high-entropy alloys. JOM. 65(12), 1759–1771 (2013)

J.R. Davis, Cobalt-Base Alloys in Nickel, Cobalt, and Their Alloys (ASM International, Materials Park, 2000), pp.362–406

C.M. Cao, J.X. Fu, T.W. Tong, Y.X. Hao, P. Gu, H. Hao, L.M. Peng, Intermediate-temperature creep deformation and microstructural evolution of an equiatomic FCC-structured CoCrFeNiMn high-entropy alloy. Entropy. 20(960), 1–13 (2018)

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, E.P. George, The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 61(15), 5743–5755 (2013)

M.G. Poletti, G. Fiore, F. Gili, D. Mangherini, L. Battezzati, Development of a new high entropy alloy for wear resistance: FeCoCrNiW0.3 and FeCoCrNiW0.3 + 5 at.% of C. Mater. Des. 115, 247–254 (2017)

C.D. Dai, T.L. Zhao, C.W. Du, Z.Y. Liu, D.W. Zhang, Effect of molybdenum content on the microstructure and corrosion behavior of FeCoCrNiMox high-entropy alloys. J. Mater. Sci. Technol. 46, 64–73 (2020)

S. Varalakshmi, M. Kamaraj, B.S. Murty, Synthesis and characterization of nanocrystalline AlFeTiCrZnCu high entropy solid solution by mechanical alloying. J. Alloy. Comp. 460, 253–257 (2008)

B.S. Murty, S. Ranganathan, Novel materials synthesis by mechanical alloying/milling. Int. Mater. Rev. 43, 101–141 (1998)

S. Praveen, B.S. Murty, R.S. Kottada, Alloying behavior in multicomponent AlCoCrCuFe and NiCoCrCuFe high entropy alloys. Mater. Sci. Eng. A. 534, 83–89 (2012)

M. Omori, Sintering, consolidation, reaction and crystal growth by the spark plasma system (SPS). Mater. Sci. Eng. A. 287(2), 183–188 (2000)

S. Sivasankaran, F.A. Al-Mufadi, H.R. Ammar, Influence of V and Zn in FeCrCuMnTi high-entropy alloys on microstructures and uniaxial compaction behavior prepared by mechanical alloying. Crystals. 11(1413), 1–28 (2021)

Z.Y. Lyu, C.H. Lee, S.Y. Wang, X.S. Fan, J.W. Yeh, P.K. Liaw, Effects of constituent elements and fabrication methods on mechanical behavior of high-entropy alloys: a review. Metall. Mater. Trans. A. 50, 1–28 (2019)

M. Murali, S.P.K. Babu, J. Majhi, A. Vallimanalan, R. Mahendran, Processing and characterization of nano crystalline AlCoCrCuFeTix high-entropy alloy. Powder Metall. 61(2), 139–148 (2018)

S. Praveen, B.S. Murty, R.S. Kottada, Alloying behavior in multi-component AlCoCrCuFe and NiCoCrCuFe high entropy alloys. Mater. Sci. Eng. A. 534, 83–89 (2012)

M.C. Gao, P.K. Liaw, J.W. Yeh, Y. Zhang, Phase Formation Rules in High-Entropy Alloys: Fundamentals and Applications (Springer, Switzerland, 2016), pp.21–49

ASTM G 99-17, Standard Test Method for Wear Testing with a Pin-on-Disc Apparatus. American Society for Testing and Materials, West Conshohocken, Pennsylvania (2017), pp. 1–6

S. Praveen, J. Basu, S. Kashyap, R.S. Kottada, Exceptional resistance to grain growth in nanocrystalline CoCrFeNi high entropy alloy at high homologous temperatures. J. Alloy. Comp. 662, 361–367 (2016)

L. Zhang, X. Guo, Microstructural evolution, thermal stability and microhardness of the Nb–Ti–Si-based alloy during mechanical alloying. Metals (Basel). 8, 403 (2018)

B.R. Chen, A.C. Yeh, J.W. Yeh, Effect of one-step recrystallization on the grain boundary evolution of CoCrFeMnNi high entropy alloy and its subsystems. Sci. Rep. 6(1), 22306 (2016)

Z.Z. Niu, J. Xu, T. Wang, N.R. Wang, Z.H. Han, Y. Wang, Microstructure, mechanical properties and corrosion resistance of CoCrFeNiWx (x = 0, 0.2, 0.5) high entropy alloys. Intermetallics (Barking). 112, 106550 (2019)

X.Y. Wu, X.Z. Zhang, R. Liu, M.X. Yao, Microstructure and performance characterization of a novel cobalt high-entropy alloy. Metall. Mater. Trans. A. 52, 4066–4089 (2021)

Acknowledgement

The authors are grateful for financial support from the Natural Science & Engineering Research Council of Canada (NSERC), both financial and in-kind support of Kennametal Stellite Group.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, X.Y., Liu, R., Zhang, X.Z. et al. Influence of Tungsten Content on Microstructural Evolution of Cobalt-Containing High-Entropy Alloy via Mechanical Alloying. Metallogr. Microstruct. Anal. 12, 760–778 (2023). https://doi.org/10.1007/s13632-023-01000-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-023-01000-x