Abstract

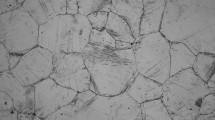

Titanium aluminide alloys with unique properties as well as high strength to weight ratio, excellent oxidation resistance and acceptable high temperature mechanical properties can be used as a high temperature structural material and a competitor for super-alloys. In this research, production process of Ti-48Al-2Cr (numbers indicate atomic percent) intermetallic in an induction furnace with argon atmosphere, alumina crucibles with different purities and several ingot casting time, were investigated. Microstructure of produced ingots was studied by optical microscope and scanning electron microscope (SEM) with EDX analyzer and phase analysis were studied by XRD method. Results show that microstructures are completely lamellar and by increasing cooling rate, interlamellar space will decrease. In the structure, three morphologies of alumina particles could be seen that are: spherical, cluster and lathed. Volume fraction of Al2O3 particles will increase by increasing the holding time of melt and crucibles with higher SiO2 content will react more severe with melt.

Similar content being viewed by others

References

Knippscheer, S. and Frommeyer, G., Us Patent, Advanced Engineering Materials, 1999, vol. 4, pp. 187–191.

Yang, R., Cui, Y.Y., and Dong, L.M., Journal of Materials Processingn Technology, 2003, vol. 135, pp. 179–188.

Rishel, L.L., Biery, N.E., Raban, R., Intermetallics, 1998, vol. 6, pp. 629–639.

Kobayashi, Y. and Tsukihashi, F., Metallurgical and Materials transaction. Ser. B, 1998, pp. 1037–1048.

Kuang, J.P., Harding, R.A. and Campbell, J., Materials Science and Engineering. Ser. A, 2002, vol. 329, pp. 31–37.

Lapin, J., Ondrus, L. and Bajana, Materials Science and Engineering. Ser. A, 2003, vol. 360, pp. 85–95.

Author information

Authors and Affiliations

Additional information

The article is published in the original.

About this article

Cite this article

Eatesami, D., Hadavi, M.M. & Habibollahzade, A. Melting of γ-TiAl in the alumina crucible. Russ. J. Non-ferrous Metals 50, 363–367 (2009). https://doi.org/10.3103/S1067821209040105

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821209040105