Abstract

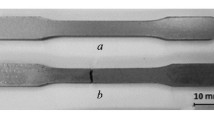

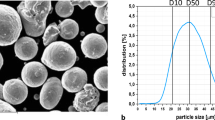

The possibility is shown to decrease the cost of production of powder hot-deformed carbon steels through the use of unconventional carbon-containing components in the charge composition (artificial special low-ash graphite, pyrocarbon, high-temperature coal-tar pitch). The peculiarities of their chemical composition, grain-size distribution, and crystal structure in comparison with the traditionally used pencil lead dictate the increase in blend homogeneity and in density of cold-pressed moldings, and eventually improvement of properties of powder steels.

Similar content being viewed by others

References

Fialkov, A.S., Uglerod, mezhsloevye soedineniya i komposity na ego osnove (Carbon, Interlayer Connections and Composites Based on It), Moscow: Aspect Press, 1997.

Fialkov, A.S., Uglegrafitovye materialy (Electrographite Materials), Moscow: Energiya, 1979.

Privalov, V.E. and Stepanenko, M.A., Kamennougol’nyi pek (Coal-TarPitch), Moscow: Metallurgiya, 1981.

Ubbelode, A.R. and Louis, F.A., Graphite i ego kristallicheskoe stroenie (Graphite and Its Crystal Structure), Moscow: Mir, 1969 (Russian Translation).

Dorofeev, Yu.G., Dinamicheskoe goryachee pressovanie poristykh poroshkovykh zagotovok (Dynamic Hot Pressing of Porous Powder Blanks), Moscow: Metallurgiya, 1977.

Dorofeev, Yu.G., Marinenko, L.G., and Ustimenko, V.I., Konstruktsionnye poroshkovye metally i izdeliya (Construction Powder Materials and Articles), Moscow: Metallurgiya, 1986.

Roman, O.V. and Gabrielov, I.P., Spravochnik po poroshkovoi metallurgii: poroshki, materialy, protsessy (Handbook for Powder Metallurgy: Powders, Materials, Processes), Minsk: Belarus, 1988.

Dorofeev, Yu.G., Gasanov, B.G., Dorofeev, V.Yu., et al., Promyshlennaya tekhnologiya goryachego pressovaniya izdelii (Industrial Technology of Hot Pressing of Powder Articles), Moscow: Metallurgiya, 1990, pp. 108–110.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.I. Kostikov, Yu.G. Dorofeev, Zh.V. Eremeeva, N.N. Zherditskaya, A.P. Ul’yanovskii, G.Kh. Sharipzyanova, 2008, published in Izvestiya VUZ. Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2008, No. 1, pp. 6–9.

About this article

Cite this article

Kostikov, V.I., Dorofeev, Y.G., Eremeeva, Z.V. et al. Specific features of application of nonconventional carbon-containing components in technology of powder steels. Report 1. Russ. J. Non-ferrous Metals 49, 280–282 (2008). https://doi.org/10.3103/S1067821208040135

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821208040135