Abstract

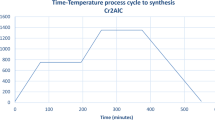

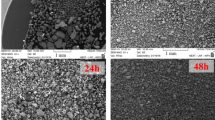

Dense nanocrystalline yttria ceramics without grain growth were obtained within a short densification period by a method combining SHS reaction and quick pressing (SHS-QP). The reactive mixtures consisting of Ni and Al with TiC as a diluent were used as a heat source. An yttria compact was inserted inside the reactants and warmed up by reaction heat at a heating rate of above 1300°C/min. When the temperature reached its maximum, high mechanical pressure was applied to the sample for densification. Dense nanocrystalline yttria was produced when temperature T was 1350°C and pressure P, 120 MPa. The rapid densification process was accomplished in 1 min. Microstructural analysis showed almost no grain growth compared to initial powder. For comparison, the hot pressing (HP) process was also used to densify the same yttria powders. The results prove that the HP process causes grains coarsening even when the sintering temperature is 1250°C.

Similar content being viewed by others

References

Groza, J.R. and Dowding, R.J., Nanoparticulate materials densification, Nanostruct. Mater., 1996, vol. 7, no. 7, pp. 749–768.

Groza, J. R., Nanosintering, Nanostruct. Mater., 1999, vol. 12, nos. 5–8, pp. 987–992.

Luan, W.L., Gao, L., Kawaoka, H., Sekino, T., and Niihara, K., Fabrication and characteristics of finegrained BaTiO3 ceramics by spark plasma sintering, Ceram. Int., 2004, vol. 30, no. 3, pp. 405–410.

Kang, S.-J.L., and Jung, Y.-I., Sintering kinetics at final stage sintering: model calculation and map construction, Acta Mater., 2004, vol. 52, no. 15, pp. 4573–4578.

Meng, F.C., Fu, Z.Y., Zhang, J.Y., Wang, H., Wang, W.M., Wang, Y.C., and Zhang, Q.J., Rapid densification of nano-grained alumina by high temperature and pressure with a very high heating rate, J. Am. Ceram. Soc., 2007, vol. 90, no. 4, pp. 1262–1264.

Munir, Z.A., Anselmi-Tamburini, U., and Ohyanagi, M., The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method, J. Mater. Sci., 2006, vol. 41, no. 3, pp. 763–777.

Merzhanov, A.G., History and recent developments in SHS, Ceram. Int., 1995, vol. 21, no. 5, pp. 371–379.

Chen, I.W. and Wang, X.H., Sintering dense nanocrystalline ceramics without final-stage grain growth, Nature, 2000, vol. 404, no. 6774, pp. 168–171.

Dokko, P.C. and Pask, J.A., Plastic deformation of ceramic materials, Mater. Sci. Eng., 1976, vol. 25, pp. 77–86.

Mitchell, T.E., Application of transmission electron microscopy to the study of deformation in ceramic oxides, J. Am. Ceram. Soc., 1979, vol. 62, nos. 5–6, pp. 254–267.

Ruano, O.A., Wadsworth, J., and Sherby, O.D., Deformation of fine-grained alumina by grain boundary sliding accommodated by slip, Acta Mater., 2003, vol. 51, no. 12, pp. 3617–3634.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Li, B., Zheng, X. & Fu, Z.F. Fast densification of nanocrystalline yttria ceramics without grain growth. Int. J Self-Propag. High-Temp. Synth. 24, 14–20 (2015). https://doi.org/10.3103/S1061386215010069

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1061386215010069