Abstract

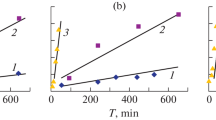

The change in the abrasive resistance under testing composites based on an epoxy matrix filled with sludge originating from cutting tool sharpening exhibits the same character for all compositions, which reflects the process of wear self-organization. A composite filled with abrasive particles originating from grinding wheels has the maximum abrasive wear resistance.

Similar content being viewed by others

REFERENCES

Filin, Yu.I., Epoxy composite for increasing the resource of heat-strengthened plowshares, Sel’sk. Mekh., 2017, no. 5, p. 36.

Mostovoi, A.S. and Kurbatova, E.A., Controlling the properties of epoxy composites filled with brick dust, Russ. J. Appl. Chem., 2017, vol. 90, no. 2, p. 267.

Mikhal’chenkov, A.M., Torikov, V.E., and Filin, Yu.I., The influence of the concentration of components of an epoxy–sandy composite on its abrasive-wear resistance, Polym. Sci., Ser. D, 2018, vol. 11, no. 1, p. 47.

Latypov, R.A., Latypova, G.R., Ageev, E.V., Altukhov, A.Y., and Ageeva, E.V., Properties of the coatings fabricated by plasma-jet hard-facing by dispersed mechanical engineering wastes, Russ. Metall. (Engl. Transl.), 2018, vol. 2018, no. 6, p. 573.

Latypov, R.A., Ageev, E.V., Altukhov, A.Y., and Ageeva, E.V., Effect of temperature on the porosity of the additive products made of the dispersed wastes of cobalt-chromium alloys, Russ. Metall. (Engl. Transl.), 2019, vol. 2019, no. 12, p. 1300.

Perevislov, S.N., Markov, M.A., Motailo, E.S., Vikhman, S.V., and Titov, D.D., Physical and mechanical properties of composite materials in the MoSi2-SiC-TiB2 system, IOP Conf. Ser.: Mater. Sci. Eng., 2020, vol. 848, p. 012067.

Perevislov, S.N., Lysenkov, A.S., Titov, D.D., Omkovich, M.V., Nesmelov, D.D., and Markov, M.A., Materials based on boron carbide obtained by reaction sintering, IOP Conf. Ser.: Mater. Sci. Eng., 2019, vol. 525, p. 012074.

Perevislov, S.N., Lysenkov, A.S., Titov, D.D., Kim, K.A., Tomkovich, M.V., Nesmelov, D.D., and Markov, M.A., Liquid-sintered SiC based materials with additive low oxide oxides, IOP Conf. Ser.: Mater. Sci. Eng., 2019, vol. 525, p. 012073.

Markov, M.A., Combined technologies for obtaining functional coatings for aircraft and marine engineering products, in Aktual’nye problemy prochnosti. Monografiya (Topical Problems of Strength. Monograph), Rubanik, V.V., Ed., Molodechno, 2020, p. 34.

Frolova, M.G., Lysenkov, A.S., Titov, D.D., Istomina, E.I., and Perevislov, S.N., Properties of composites SiC/SiCf obtained by hot pressing of SHS of silicon carbide powder, IOP Conf. Ser.: Mater. Sci. Eng., 2020, vol. 848, no. 1, p. 012113.

Perevislov, S.N., Afanas’eva, L.E., and Baklanov, N.I., Mechanical properties of SiC-fiber-reinforced reaction-bonded silicon carbide, Inorg. Mater., 2020, vol. 56, no. 4, p. 425.

Frolova, M.G., Kargin, Y.F., Lysenkov, A.S., Perevislov, S.N., Titov, D.D., et al., SiC-fiber reinforced silicon carbide-based ceramic composite, Inorg. Mater., 2020, vol. 56, no. 9, p. 987.

Mikhal’chenkov, A.M., Gutsan, A.A., Fes’kov, S.A., Kozarez, M.V., and D’yachenko, A.V., RU Patent 2695867, 2019.

Biryulina, Ya.Yu., Elimination of through wear in paws of Morris cultivators with glue-polymer composites, Tr. GOSNITI, 2015, vol. 119, p. 264.

Mikhalchenkov, A.M., Kozarez, I.V., Tyureva, A.A., and Kuzmin, V.N., Procedure for comparative accelerated testing of materials for resistance to abrasive wear as they move in a loose abrasive environment, Polym. Sci., Ser. D, 2018, vol. 11, no. 1, p. 110.

Mikhalchenkov, A.M., Mikhalchenkova, M.A., Feskov, S.A., and Kononenko, A.S., Effect of concentration and dispersion of filler fractions on adhesive strength and abrasion resistance of an epoxy and sand composite, MATEC Web Conf., 2019, vol. 298, p. 00042.

Mikhal’chenkov, A.M., Torikov, V.E., D’yachenko, A.V., and Anishchenko, A.V., A method for determining the abrasive wear resistance of materials with different properties, Vse Mater., Entsikl. Sprav., 2018, no. 4, p. 40.

Mikhal’chenkov, A.M., Biryulina, Ya.Yu., and Mikhal’chenkova, M.A., Intensity of wear of a coating made of a sludge-epoxy abrasion-resistant composition from the speed of its movement, Materialovedenie, 2016, no. 8, p. 36.

Zelinskyi, V.V. and Borisova, E.A., About the quantum-mechanical nature of wear on magnetized cutting and deforming tools, Proceedings of 2015 International Conference on Mechanical Engineering, Automation and Control Systems, MEACS, 2015, p. 7414978.

Zubarev, Yu.M. and Yur’ev, V.G., Abrazivnye instrumenty. Razrabotka operatsii shlifovaniya (Abrasive Tools: Development of Grinding Operations), St. Petersburg: Lan’, 2018.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by O. Polyakov

About this article

Cite this article

Mikhal’chenkov, A.M., Kozarez, I.V., Fes’kov, S.A. et al. Abrasive Resistance of Epoxy-Based Composites with Fillers Based on Tool Sharpening Sludge. J. Mach. Manuf. Reliab. 50, 269–273 (2021). https://doi.org/10.3103/S1052618821030109

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618821030109