Abstract—When studying the microstructure of carbon steel by the example of steel 10 and steel 45, inclusions of gold and silver were found on the surface hardened by shockwave deformation, which were confirmed by experimental and quantitative studies. The formation hypothesis of synthetic gold and silver in the structure of deformed steel is proposed on the basis of cold nuclear fusion (CNF) or low-energy nuclear reactions (LENR) in the deformation core zone. It is shown that the CNF nuclear chain reaction is triggered only when an amorphous core emerges in the deformation zone. The splitting of the amorphous steel structure into iron clusters and degenerate electron gas leads to a collapsing self-compression of the system due to the pressure of the degenerate electron gas and electromagnetic interaction of iron clusters. As a result of the collapse of iron clusters, the CNF of the gold and silver proceeds in them. The leading stage of iron-silver transmutation is shown. It was proved that in the process of silver CNF, an additional proton flux is introduced into the system that leads to their recombination with free electrons and the formation of a significant amount of hydrogen. Hydrogen saturation of the steel causes the well-known effect of anomalous spontaneous deformation of iron, which activates amorphization of steel in the core deformation zone accelerating the CNF process. The development of experimental studies to confirm the course of CNF in the processes of the shockwave deformation of steel during its surface hardening is shown.

Similar content being viewed by others

Notes

Degenerate gases are the gases, which consist of fermions, such as electrons, protons, neutrons rather than molecules of common matter.

Amorphous and nanocrystalline magnetosoft alloys based on iron “Mstator”, series AMAG: amorphous—AMAG170, AMAG172, AMAG179, AMAG180, AMAG183, AMAG186A, AMAG186B, AMAG186C, AMAG202, AMAG223, AMAG225, AMAG245, AMAG254, AMAG321, AMAG324, AMAG492; nanocrystalline—AMAG200, AMAG202C, AMAG201, AMAG204, AMAG211.

REFERENCES

Davydov, S.V. and Gorlenko, A.O., Deposition of coatings for raising the wear resistance of friction surfaces of spherical sliding bearings, Metalloved. Term. Obrab. Met., 2017, no. 9, pp. 36–40.

Gorlenko, A.O. and Davydov, S.V., Deposition of coatings for raising the wear resistance of friction surfaces of spherical sliding bearings, Met. Sci. Heat Treat., 2018, vol. 59, nos. 9–10, pp. 579–583. https://doi.org/10.1007/s11041-018-0193-6

Davydov, S.V., Gorlenko, A.O., Skantsev, V.M., and Kurakin, M.Yu., Structure of wear-resistant surface layers with implanted nanodiamonds of detonation synthesis, Metalloved. Term. Obrab. Met., 2014, no. 5, pp. 46–50.

Davydov, S.V., Gorlenko, A.O., Skantsev, V.M., and Kurakin, M.Yu., Structure of wear-resistant surface layers with implanted detonation-synthesized nanodiamonds, Met. Sci. Heat Treat., 2014, vol. 56, nos. 5–6, pp. 274–278. https://doi.org/10.1007/s11041-014-9745-6

Gorlenko, A.O. and Davydov, S.V., Material implantation techniques based on tungsten carbide to increase friction surface durability, Naukoemkie Tekhnol. Mashinostr., 2016, no. 9, pp. 3–9.

Davydov, S.V. and Gorlenko, A.O., Composite gradient structures in functional tungsten coatings of carbon steels, Naukoemkie Tekhnol. Mashinostr., 2020, no. 2, pp. 28–31. https://doi.org/10.30987/2223-4608-2020-2020-2-28-31

Davydov, S.V. and Gorlenko, A.O., Nanostructured gradient coating based on carbide of tungsten in carbon steel, Int. J. Nanotechnol., 2019, vol. 16, nos. 1–3, pp. 60–68. https://doi.org/10.1504/IJNT.2019.102392

Gorlenko, A.O., Davydov, S.V., Shevtsov, M.Yu., and Boldyrev, D.A., Creation of a wear-resistant tungsten-carbide surface layer on carbon steels by implantation and electromechanical machining, Steel Transl., 2019, vol. 49, no. 3, pp. 212–216. https://doi.org/10.3103/S0967091219030045

Gorlenko, A.O., Davydov, S.V., Shevtsov, M.Yu., and Boldyrev, D.A., Wear-resistance increase of friction surfaces of steel machine parts by electro-mechanical hardening, Steel Transl., 2019, no. 11, pp. 800–805. https://doi.org/10.3103/S0967091219110044

Shevchuk, D.M., Davydov, S.V., and Boldyrev, D.A., Improvement in the wear resistance of knife shafts of steel grade 40Kh by means of manual arc surfacing, Stal’, 2021, no. 4, pp. 29–30.

Davydov, S.V., Foundations of thermodynamics and technology of generation of high-disperse carbide phases of globular morphology in iron–carbon alloys, Metall. Mashinostr., 2021, no. 6, pp. 5–15.

Davydov, S.V. and Petrov, E.V., Spinodal decomposition of tungsten-containing phases in functional coatings obtained via high-energy implantation processes, Tech. Phys., 2017, vol. 62, no. 8, pp. 1207–1213. https://doi.org/10.1134/S1063784217080060

Berberov, S.A., Blyumenshtein, V.Yu., Boldyrev, A.I., et al., Spravochnik po protsessam poverkhnostnogo plasticheskogo deformirovaniya (Reference Book on Processes of Surface Plastic Deformation), Zaides, S.A., Ed., Irkutsk: Irkutskii Nats. Issled. Tekh. Univ., 2021, vol. 1.

Kirichek, A.V., Solov’ev, D.L., and Lazutkin, A.G., Tekhnologiya i oborudovanie statiko-impul’snoi obrabotki poverkhnostnym plasticheskim deformirovaniem (Technology and Equipment of Static-Pulse Processing by Surface Plastic Deformation), Moscow: Mashinostroenie, 2004.

Lazutkin, A.G., Kirichek, A.V., Stepanov, Yu.S., and Solov’ev, D.L., Mekhanika nagruzheniya poverkhnosti volnoi deformatsii (Mechanics of Surface Loading by Deformation Wave), Moscow: Mashinostroenie-1, 2005.

Kirichek, A.V., Barinov, S.V., Yashin, A.V., and Ryzhkova, M.N., Finite-element modeling of hardening process by deformation wave of aluminum–magnesium alloys, Sb. tezisov. IV Vseros. molodezhnoi nauch.-prakt. shkoly “Uprochnyayushchie tekhnologii i funktsional’nye pokrytiya v mashinostroenii” (Proc. 4th All-Russian Young Scientists’ Sci.-Pract. School on Hardening Technologies and Functional Coatings in Mechanical Engineering), 2018, pp. 17.1–17.5.

Kirichek, A.V., Altuhov, A.Yu., and Soloviev, D.L., Deformation wave hardening of metallic materials, Zh. Nano- Elektron. Fiz., 2014, vol. 6, no. 3, p. 03069.

Kirichek, A.V., Solov’ev, D.L., and Silant’ev, S.A., Impact of modes of static-pulse treatment on uniformity of hardening of surface layer, Kuznechno-Shtampovochnoe Proizvod.–Obrab. Mater. Davleniem, 2004, no. 2, pp. 13–17.

Khomskaya, I.V., Phase and structural transformations in alloys based on iron and copper at intense impact-wave and deformation actions, Doctoral (Eng.) Dissertation, Yekaterinburg, 2014.

Babichev, A.P. and Babichev, I.A., Osnovy vibratsionnoi tekhnologii (Foundations of Vibration Technology), Rostov-on-Don: Don. Gos. Tekh. Univ., 2008.

Babichev, A.P., Motrenko, P.D., and Babichev, I.A., Otdelochno-uprochnyayushchaya obrabotka detalei mnogokontaktnym vibroudarnym instrumentom, Rostov-on-Don: Don. Gos. Tekh. Univ., 2003.

Kirichek, A.V., Barinov, S.V., Yashin, A.V., Zaycev, A.A., and Konstantinov, A.M., Wave deformation multi-contact loading, Vestn. Bryanskogo Gos. Tekh. Univ., 2017, no. 7, pp. 18–26.

Kirichek, A.V., Soloviev, D.L., Silantiev, S.A., and Fedonina, S.O., Technological support of quality and operational properties by wave deformation hardening, Vestn. Irkutskogo Gos. Tekh. Univ., 2018, vol. 22, no. 12, pp. 46–55. https://doi.org/10.21285/1814-3520-2018-12-46-55

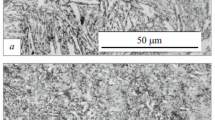

Kirichek, A.V., Barinov, S.V., Davydov, S.V., Yashin, A.V., Zaycev, A.A., and Konstantinov, A.M., Micro-structural changes in steel 45 caused by wave strain strengthening, Vestn. Bryanskogo Gos. Tekh. Univ., 2017, no. 8, pp. 79–85. https://doi.org/10.12737/article_5a3779ff9bec74.56692716

Kirichek, A.V., Barinov, S.V., and Yashin, A.V., Strength increase in steel 45, 40Kh, and 35KhGSA by deformation wave strengthening, Vestn. Bryanskogo Gos. Tekh. Univ., 2017, no. 2, pp. 69–75. https://doi.org/10.12737/article_59353e2965a8c6.82426503

Kirichek, A.V. and Barinov, S.V., Study of methods relating to increase of contact pitting resistance in 45, 40H, 35HGSA steel due to development of heterogeneous structure involving mechanical hardening technique, Appl. Mech. Mater., 2015, vol. 756, pp. 65–69. https://doi.org/10.4028/www.scientific.net/AMM.756.65

Kirichek, A.V., Barinov, S.V., Yashin, A.V., Zaycev, A.A., and Konstantinov, A.M., Real product size accounting problem at wave deformation hardening, Vestn. Bryanskogo Gos. Tekh. Univ., 2020, no. 1, pp. 4–10. https://doi.org/10.30987/1999-8775-2020-2020-1-4-10

Gusev, A.I., Nanomaterialy, nanostruktury, nanotekhnologii (Nanomaterials, Nanostructures, and Nanotechnologies), Moscow: Fizmatlit, 2007.

Lovshenko, G.F., Lovshenko, F.G., and Khina, B.B., Nanostrukturnye mekhanicheski legirovannye materialy na osnove metallov. Monografiya (Nanostructural Mechanical Alloyed Materials Based on Metals: Monograph), Lovshenko, F.G., Ed., Mogilev: Belorussko-Ross. Univ., 2008.

Barinov, V.A., Tsurin, V.A., Kazantsev, V.A., and Surikov, V.T., Carbonization of α-Fe upon mechanical alloying, Phys. Met. Metallogr., 2014, vol. 115, no. 1, pp. 53–68. https://doi.org/10.1134/S0031918X14010025

Barinov, V.A., Kazantsev, V.A., and Surikov, V.T., Temperature investigations of mechanosynthesized cementite, Phys. Met. Metallogr., 2014, vol. 115, no. 6, pp. 576–585. https://doi.org/10.1134/S0031918X14060027

Barinov, V.A. and Protasov, A.V., Studying mechanosynthesized Hägg carbide (χ-Fe5C2), Phys. Met. Metallogr., 2015, vol. 116, no. 8, pp. 791–801. https://doi.org/10.1134/S0031918X15080025

Barinov, V.A., Tsurin, V.A., and Surikov, V.T., Study of mechanically synthesized carbide Fe7C3, Phys. Met. Metallogr., 2010, vol. 110, no. 5, pp. 474–484. https://doi.org/10.1134/S0031918X10110074

Chen, B., Lai, X., Li, J., Liu, J., Zhao, J., Bi, W., Ercan Alp, E., Hu, M.Y., and Xiao, Yu., Experimental constraints on the sound velocities of cementite Fe3C to core pressures, Earth Planet. Sci. Lett., 2018, vol. 494, pp. 164–171. https://doi.org/10.1016/j.epsl.2018.05.002

Khmel’nitskii, R.A., Talipov, N.Kh., and Chucheva, G.V., Sinteticheskii almaz dlya elektroniki i optiki (Synthetic Diamond for Electronics and Optics), Moscow: Ikar, 2017.

Novikov, N.V. and Klimenko, S.A., Synthetic diamond, in Instrumenty iz sverkhtverdykh materialov (Tools from Superhard Materials), Moscow: Mashinostroenie, 2014, 2nd ed.

Chepurov, A.I., Fedorov, I.I., and Sonin, V.M., Eksperimental’noe modelirovanie protsessov almazoobrazovaniya (Experimental Modeling of Processes of Diamond Generation), Cherupov, A.I., Ed., Novosibirsk: Ob”edinennyi Inst. Geologii, Geofiziki i Mineralogii, Sib. Otd. Ross. Akad. Nauk, 1997.

Binnewies, M., Glaum, R., Schmidt, M., and Schmidt, P., Chemical vapor transport reactions—A historical review, Z. Anorg. Allgemeine Chem., 2013, vol. 639, no. 2, pp. 219–229. https://doi.org/10.1002/zaac.201300048

Smorodov, E.A., Galiakhmetov, R.N., and Il’ga-mov, M.A., Fizika i khimiya kavitatsii (Physics and Chemistry of Cavitation), Moscow: Nauka, 2008.

Taubes, G., Bad Science: The Short Life and Weird Times of Cold Fusion, New York: Random House, 1993.

Simon, B., Undead Science: Science Studies and the Afterlife of Cold Fusion, Rutgers Univ. Press, 2002.

Schiffer, M.B., Draw the Lightning Down: Benjamin Franklin and Electrical Technology in the Age of Enlightenment, Univ. of California Press, 2003. https://doi.org/10.1525/9780520939851

Vysotskii, V.I. and Adamenko, S.V., Correlated states of interacting particles and problems of the coulomb barrier transparency at low energies in nonstationary systems, Tech. Phys., 2010, vol. 55, no. 5, pp. 613–621. https://doi.org/10.1134/S106378421005004X

Vysotskii, V.I. and Vysotskyy, M.V., The formation of correlated states and tunneling at low energy at controlled pulse action on particles, J. Exp. Theor. Phys., 2017, vol. 125, no. 2, pp. 195–209. https://doi.org/10.1134/S106377611707024X

Vysotskii, V.I., Vysotskyy, M.V., and Bertalucci, S., Features of the formation of correlated coherent states and nuclear fusion induced by the interaction of slow particles with crystals and free molecules, J. Exp. Theor. Phys., 2018, vol. 127, no. 3, pp. 479–480. https://doi.org/10.1134/S1063776118080253

Ratis, Yu.L., Upravlyaemyi “termoyad” ili kholodnyi sintez? Drama idei (Controlled Thermonuclear Reaction or Cold Synthesis? Drama of Ideas), Samara: Izd-vo Samarskogo Nauchnogo Tsentra Ross. Akad. Nauk, 2009.

Bagulya, A.V., Dalkarov, O.D., Negodaev, M.A., and Rusetskii, A.S., Low-energy nuclear reactions in crystal structures, Phys. Part. Nuclei, 2017, vol. 48, no. 5, pp. 691–697. https://doi.org/10.1134/S1063779617050045

Suzdalev, I.P., Nanotekhnoloiya: fiziko-khimiya nanoklasterov, nanostruktur i nanomaterialov (Nanotechnology: Physics and Chemistry of Nanoclusters, Nanostructures, and Nanomaterials), Moscow: KomKniga, 2006.

Mazalova, V.L., Kravtsova, A.N., and Soldatov, A.V., Nanoklastery. Rentgenospektral’nye issledovaniya i komp’yuternoe modelirovanie (Nanoclusters: X-Ray Spectral Studies and Computer Modeling), Moscow: Fizmatlit, 2012.

Erlebach, A., Kurland, H-D., Grabow, J., Müller, F.A., and Sierka, M., Structure evolution of nanoparticulate Fe2O3, Nanoscale, 2015, vol. 7, no. 7, pp. 2960–2969. https://doi.org/10.1039/C4NR06989G

Farkaš, B. and de Leeuw, N.H., A perspective on modelling metallic magnetic nanoparticles in biomedicine: From monometals to nanoalloys and ligand-protected particles, Materials, 2021, vol. 14, pp. 3611–3662. https://doi.org/10.3390/ma14133611

Bochicchio, D. and Ferrando, R., Morphological instability of core–shell metallic nanoparticles, Phys. Rev. B, 2013, vol. 87, p. 165435. https://doi.org/10.1103/PhysRevB.87.165435

Antone, A.J., Sun, Z., and Bao, Yu., Preparation and application of iron oxide nanoclusters, Magnetochemistry, 2019, vol. 5, no. 3, pp. 45–61. https://doi.org/10.3390/magnetochemistry5030045

Morachevskii, A.G., Smirnova, N.A., Piostrovskii, E.M., et al., Termodinamika ravnovesiya zhidkost’-par (Thermodynamics of Liquid–Vapor Equilibrium), Morachevskii, A.G., Ed., Leningrad: Khimiya, 1989.

Kirillin, V.A., Sychev, V.V., and Sheindlin, A.E., Tekhnicheskaya termodinamika. Uchebnik dlya vuzov (Engineering Thermodynamics: Textbook for Universities), Moscow: Energoatomizdat, 1983, 4th ed.

Babichev, A.P., Babushkina, N.A., Bratkovskii, A.M., et al., Fizicheskie velichiny. Spravochnik (Physical Quantities: Reference Book), Grigor’ev, I.S. and Meilikhov, E.Z., Eds., Moscow: Energoatomizdat, 1991.

Shapovalov, V.I. and Karpov, V.Yu., Phenomenon of appearance of hydrogen-containing metastable zones at polymorphous transformation of metals, Otkrytiya, Izobret., 1986, no. 31, p. 13.

Bannykh, O.A., Budberg, P.B., Alisova, S.P., et al., Diagrammy sostoyaniya dvoinykh i mnogokomponentnykh sistem na osnove zheleza (Diagrams of State of Iron-Based Double and Multicomponent Systems), Moscow: Metallurgiya, 1986.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by F. Baron

About this article

Cite this article

Davydov, S.V. A New Type of Phase Transformations in the Process of Shockwave Deformation of Low-Carbon Steel. Steel Transl. 52, 536–552 (2022). https://doi.org/10.3103/S0967091222050035

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091222050035

- Keywords: surface hardening

- plastic deformation

- cold nuclear fusion (CNF)

- low-energy nuclear reactions (LENR)

- mechanosynthesis

- shockwave deformation

- deformation wave hardening (DWH)

- synthetic gold and silver

- iron-to-gold-silver transmutation

- anomalous spontaneous deformation of iron

- low-carbon steel

- amorphous state of steel

- hydrogen amorphization of iron

- nanocluster