Abstract

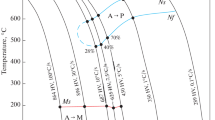

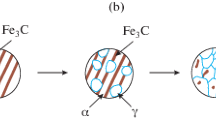

During contact flash welding of rails, the metal in the area of thermal impact is heated and continuously cooled. Accelerated heating and subsequent intensive cooling during pulse flash welding lead to the formation of quenching structures, which subsequently leads to cracking and to brittle destruction upon operation of rail weld joint. This work studies capabilities of contact heating after welding in order to eliminate formation of quenching structures in metal weld joint of R350LHT rail steel. Thermal cycles during welding and subsequent contact heating have been recorded. The regularity of structure formation of metal weld joint (including the area of thermal impact) was determined during pulse contact heating for R350LHT rail steel. It is demonstrated that the contact pulse heating allows to prevent the formation of quenching structures and decelerates cooling of weld joint. In the case of non-optimum modes, the contact pulse heating can result in reverse effect. It has been determined that upon significant contribution of heat by contact heating, the metal cooling rate exceeds critical value and the transformation runs according to diffusion free mechanism with formation of coarse grain martensite structure. The use of thermal kinetic and isothermal diagrams of austenite decomposition with known thermal welding cycles allows to restrict significantly the search ranges of optimum modes of electric welding of railroad rails and subsequent contact heating. The use of optimum modes of contact heating allows to obtain minimum length of areas of thermal impact without the formation of quenching structures in weld joint of railroad rails.

Similar content being viewed by others

REFERENCES

Shtaiger, M.G. and Balanovskii, A.E., Analysis of technologies for welding high-strength rails according to the structure formation at construction and reconstruction of high-speed railways. Part 1, Vestn. Irkutskogo Gos. Tekh. Univ., 2018, no. 6, pp. 48–73. https://doi.org/10.21285/1814-3520-2018-6-48-74

Dahl, B., Mogard, B., Gretoft, B., and Ulander, B., Repair of rails on-site by welding, Svetsaren, 1995, vol. 50, no. 2, pp. 10–14.

Tachikawa, H., Uneta, T., Nishimoto, H., Sasaki, Y., and Yanai, J., Steel welding technologies for civil construction applications, Nippon Steel Tech. Rep., 2000, vol. 82, no. 7, pp. 35–41.

Okumura, M., Karimine, K., Uchino, K., and Yurioka, N., Development of field fusion welding technology for railroad rails, Nippon Steel Tech. Rep., 1995, vol. 65, no. 4, pp. 41–49.

Myers, J., Geiger, G.H., and Poirier, D.R., Structure and properties of thermite welds in rails, Weld. J., 1982, vol. 258, no. 8, pp. 258–268.

Wang, Y., Zhou, H., Shi, Y., and Feng, B., Mechanical properties and fracture toughness of rail steels and thermite welds at low temperature, Int. J. Miner., Metall. Mater., 2012, vol. 19, no. 5, pp. 409–420. https://doi.org/10.1007/s12613-012-0572-8

Kavunichenko, A.V., Shvets, V.I., and Antipin, E.V., Peculiarities of flash-butt welding of rail frogs with rail ends, Paton Weld. J., 2018, no. 4, pp. 14–18. https://doi.org/10.15407/tpwj2018.04.03

Tikhomirova, L.B., Il’inykh, A.S., Galai, M.S., and Sidorov, E.S., Investigation of the structure and mechanical properties of aluminumthermal welded joints of rails, Vestn. Yuzhno-Ural. Gos. Univ., 2016, vol. 16, no. 3, pp. 90–95. https://doi.org/10.14529/met160313

Saita, K., Karimine, K., Ueda, M., Iwano, K., Yamamoto, T., and Hiroguchi, K., Trends in rail welding technologies and our future approach, Nippon Steel Sumitomo Met. Tech. Rep., 2013, no. 105, pp. 84–92.

Weingrill, L., Krutzler, J., and Enzinger, N., Temperature field evolution during flash butt welding of railway rails, Mater. Sci. Forum, 2017, vol. 879, pp. 2088–2093. https://doi.org/10.4028/www.scientific.net/MSF.879.2088

Shtaiger, M.G. and Balanovskii, A.E., Analysis of technologies for welding high-strength rails according to the structure formation at construction and reconstruction of high-speed railways (review). Part 2, Vestn. Irkutskogo Gos. Tekh. Univ., 2018, no. 7, pp. 41–68.

Bajic, D., Kuzmenko, G.V., and Samardžić, I., Welding of rails with new technology of arc welding, Metalurgija, 2013, vol. 52, no. 3, pp. 399–402.

Takimoto, T., Latest welding technology for long rail and its reliability, Tetsu-to-Hagane, 1984, vol. 70, no. 10, pp. 40–45. https://doi.org/10.2355/tetsutohagane1955.70.10_1348

Kozyrev, N.A., Shevchenko, R.A., Usol’tsev, A.A., Prudnikov, A.N., and Bashchenko, L.P., Welding of differentially heat-strengthened rails. Modeling of processes during welding and local thermal processing, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2020, vol. 63, no. 2, pp. 93–101. https://doi.org/10.17073/0368-0797-2020-2-93-101

Karkhin, V.A., Khomich, P.N., and Ivanov, S.Yu., Calculation of temperature field during continuous flash contact welding of steel, Izv. Tul’skogo Gos. Univ. Tech. Nauki, 2008, no. 2, pp. 211–218.

Karkhin, V.A., Khomich, P.N., Fedotov, B.V., and Rayamyaki, P., Analysis of thermal cycles in contact flash welding of steel, Svarochnoe Proizvod., 2008, no. 1, pp. 12–17.

Shur, E.A. and Rezanov, V.A., Complex method of rails contact welding, Vestn. Vseross. Nauchn.-Issled. Inst. Zheleznodorozhnogo Transp., 2012, no. 3, pp. 20–22.

Rezanov, V.A., Fedin, V.M., Bashlykov, A.V., Fimkin, A.I., and Zeman, S.K., Differentiated hardening of rails welded joints, Vestn. Vseross. Nauchno-Issled. Inst. Zheleznodorozhnogo Transp., 2013, no. 2, pp. 28–34.

Kuchuk-Yatsenko, S.I., Bogorskii, M.V., and Goronkov, N.D., Contact butt welding of high-strength rails, Avtom. Svarka, 1994, no. 3, pp. 34–40.

Shevchenko, R.A., Kozyrev, N.A., Shishkin, P.E., Kryukov, R.E., and Usol’tsev, A.A., Calculation of optimal modes of electric contact welding of railway rails, Vestn. Gorno-Metall. Sektsii Ross. Akad. Estestv. Nauk. Otd. Metall., 2016, no. 37, pp. 175–180.

Funding

The work was supported by the Russian Foundation for Basic Research and Kemerovo Oblast, the project no. 20-48-420003 р_а “Development of Physicochemical and Technological Foundations of Cardinally New Welding Method of Differentially Thermally Strengthened Railroad Rails”.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by I. Moshkin

About this article

Cite this article

Polevoi, E.V., Simonov, Y.N., Kozyrev, N.A. et al. Studying Phase and Structural Transformation Upon Formation of Weld Joint of Rail Steel. Report 3. Using Thermal Kinetic and Isothermal Diagrams of Austenite Decomposition while Selecting Optimum Modes of Electric Welding. Steel Transl. 52, 203–207 (2022). https://doi.org/10.3103/S096709122202019X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709122202019X