Abstract

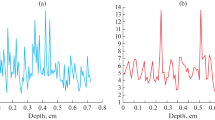

We have studied the structure formation in the strengthened zone under high-temperature thermomechanical treatment and surface plasma quenching of carbon steel with a creation of a gradient-foliate structure under significant crushing of the surface layer. A diffusionless martensitic transformation develops in the surface zone. In the layers lying lower, austenite decays in a diffusive way with the formation of a sheet-like ferrite-carbide mixture with various degree of dispersion, which, if the cooling rate increases, results in enhancement of strength and deterioration of plastic characteristics of steel. It is noted that the formation in the surface layers of a gradient-foliated structure makes it possible to prevent a rapid transition from the martensite structure to troostite-martensite and mixed pearlite structures. This enhances contact-fatigue strength of steel and its crack resistance.

Similar content being viewed by others

REFERENCES

Rybin, V.V., Formation of the structure and properties of low-carbon and low-allyed steel during thermomechanical treatment with accelerated cooling, Vopr. Metalloved., 2007, no. 4 (52), pp. 329–340.

Dombrovskii, Yu.M., Physical principles and technology of plasma surface hardening, Uprochnyayushchie Tekhnol. Pokrytiya, 2007, no. 3, pp. 14–25.

Bernshtein, M.L., Zaimovskii, V.A., and Kaputkina, L.M., Termomekhanicheskaya obrabotka stali (Thermomechanical Processing of Steel), Moscow: Metallurgiya, 1983.

Kovalenko, V.V. and Kozlova, E.V., Fizicheskaya priroda formirovaniya i evolyutsii gradientnykh strukturno-fazovykh sostoyanii v stalyakh i splavakh (Physical Nature of Formation and Evolution of Gradient Structural-Phase States in Steels and Alloys), Novokuznetsk: Sib. Gos. Ind. Univ., 2009.

Kostyrev, V.B., Efimov, O.Yu., and Ivanov, Yu.F., Formation of gradient structural-phase states during thermomechanical hardening, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2011, no. 4, pp. 24–27.

Sidorenko, O.G., Fedorova, I.P., Sukhoi, A.P., et al., Structure formation in rebar strengthened by discontinuous quenching, Steel Transl., 2012, vol. 42, no. 1, pp. 81–83.

Isakaev, M.E., Il’ichev, M.V., Tyuftyaev, A.S., and Filippov, G.A., Structuring and formation of properties during plasma treatment of carbon steel, Materialovedenie, 2003, no. 2, pp. 52–55.

Kanaev, A.T. and Bogomolov, A.V., Formation of a gradient-layered structure during thermal deformation treatment of reinforced steel, Steel Transl., 2020, vol. 50, no. 7, pp. 509–513.

Kanaev, A.T., Sarsembaeva, T.E., Bogomolov, A.V., et al., Structuring and properties of wheel steel during surface plasma hardening, Materiali za XI Mezhdunarodna nauchna praktichna konferentsiya “Achievement of high school-2018” (Proc. XI Int. Sci.-Pract. “Achievement of High School-2018”), Sofia: Bil GRAD-BG, 2018, pp. 41–48.

Akimbekova, Zh.M., Kanaev, A.T., and Omarov, A.K., Quality improvement of reinforced bar steel from rolling heating by deformation-thermal hardening, Vestn. Evraz. Nats. Univ., 2005, no. 4, pp. 91–96.

Dolzhenkov, I.E., Thermal and combined deformation-heat treatment of rolled metal, Fundam. Prikl. Probl. Chern. Metall., 2004, no. 7, pp. 61–71.

Sarsembaeva, T.E., Bogomolov, A.V., Kanaev, A.T., and Topolyansky, P.A., Influence of cooling rate on the characteristics of the strengthened layer at plasma hardening during whole-rolled wheel, Vestn. Kazakh. Agrotekh. Univ. im. S. Seifullina, 2019, no. 4 (103), pp. 154–161.

Brover, A.V., Specific surface hardening of steel by concentrated energy flows, Materialovedenie, 2005, no. 9, pp. 18–23.

Timofeeva, L.A., Timofeev, S.S., Dyomin, A.Y., et al., Surface modification of machine parts made of iron–carbon alloys operating under conditions of friction and wear, J. Frict. Wear, 2018, vol. 39, no. 3, pp. 227–231.

Chinokalov, V.Ya., Dikan’, O.V., Barbashov, D.Yu., et al., Plasma hardening of cast-iron rollers for channel production on a 450 mill at OAO EVRAZ ZSMK, Steel Transl., 2014, vol. 44, no. 7, pp. 543–549.

Efremenko, V.G., Shimizu, K., Pastukhova, T.V., et al., Effect of bulk heat treatment and plasma surface hardening on the microstructure and erosion wear resistance of complex-alloyed cast irons with spheroidal vanadium carbides, J. Frict. Wear, 2017, vol. 38, no. 1, pp. 58–64.

Leshchinskii, L.K., Smotugin, S.S., and Pirch, I.I., Plazmennoe poverkhnostnoe uprochnenie (Plasma Surface Strengthening), Kiev: Tekhnika, 1999.

Cottrell, A.H., Theoretical aspects of fracture, Proc. Int. Symp. on Atomic Mechanisms of Fracture, Swampscott, Washington, DC: Natl. Acad. Sci., 1959, pp. 1–33.

Sarsembaeva, T.E., Kanaev, A.T., Dzhaksymbetova, M.A., et al., Complex volumetric surface hardening of wheel steel, Vestn. Evraz. Nats. Univ. im. L.N. Gumileva, 2017, no. 4 (119), pp. 183–189.

Sarsembaeva, T.E., Kanaev, A.T., and Taimanova, G.K., Differential heat treatment of one-piece freight-car wheels, Steel Transl., 2017, vol. 47, no. 5, pp. 345–348.

Balanovskii, A.E., The theory of surface plasma hardening of metals: a review, Part 3, Uprochnyayushchie Tekhnol. Pokrytiya, 2016, no. 2, pp. 20–30.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by M. Shmatikov

About this article

Cite this article

Kanaev, A.T., Sarsembaeva, T.E. & Saidullaeva, M.A. Formation of Gradient-Foliated Structures under High-Temperature Thermomechanical Treatment and Surface Plasma Quenching of Carbon Steel. Steel Transl. 51, 677–682 (2021). https://doi.org/10.3103/S0967091221090059

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091221090059