Abstract

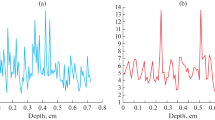

The processes of structure formation during plasma hardening of samples made of 65G grade low-alloy structural steel have been studied using optical metallography. It is shown that the structure formation during quenching after exposure to a highly concentrated energy flux obeys general structure formation features described by the iron–carbon phase diagram. The depth of the hardened structural zones in occurring under plasma quenching depends on the parameters of heating and cooling and is determined by the mechanisms and kinetics of α → γ phase transformations under nonequilibrium conditions. By changing the heating parameters (heating rate, holding time), one can control the level of homogeneity and the size of austenite grains at the beginning of the γ → α transformation, and, by changing the cooling rate, one can control the dispersion level of martensite in the reverse γ → α transformation, therefore, the properties of steel. The study results show the fact that in order to obtain the maximum possible hardening, it is necessary to carry out a preliminary heat treatment, which could provide fine austenite grains by the beginning of the α → γ transformation with a more stable structural state of the initial phase in combination with the crystal structure defects.

Similar content being viewed by others

REFERENCES

Safronov, E.N., Plazmennaya zakalka detalei mashin (Plasma Hardening of Machine Parts), Nizhny Tagil: Nizhnetagil’sk. Fil., Ural. Fed Univ., 2014.

Korotkov, V.A., Wear resistance of plasma-hardened materials, J. Frict. Wear, 2011, vol. 32, no. 1, pp. 17–22.

Kanaev, A.T., Zhusin, B.T., Sarsembaeva, T.E., and Gulyarenko, A.A., Plasma hardening of replaceable parts of working units of soil-cutting machines, Tekhnol. Mashinostr., 2017, no. 10, pp. 31–36.

Timofeeva, L.A., Timofeev, S.S., Dyomin, A.Y., et al., Surface modification of machine parts made of iron–carbon alloys operating under conditions of friction and wear, J. Frict. Wear, 2018, vol. 39, no. 3, pp. 227–231.

Samoilovich, Yu.A., Thermophysical model of plasma hardening of a plow share of agricultural machines, Uprochnyayushchie Tekhnol. Pokrytiya, 2018, vol. 14, no. 12, pp. 557–565.

Kokoreva, O.G., Development of a method for processing of heavily loaded surfaces of machine parts, Uprochnyayushchie Tekhnol. Pokrytiya, 2015, no. 10, pp. 8–10.

Gurinovich, V.I., Influence of the initial structural state on the hardening of 38KhGSA steel by a plasma jet, in Sovremennye metody i tekhnologii sozdaniya i obrabotki materialov (Modern Methods and Technologies for Creation and Processing of Materials), Minsk, 2010, pp. 185–189.

Chernikovich, V.N., Golubev, V.S., Gurinovich, V.I., et al., Hardening of working surfaces of parts of tillage machines during complex use of highly concentrated energy flows, in Tekhnologiya remonta, vosstanovleniya i uprochneniya detalei mashin, mekhanizmov, oborudovaniya, instrumenta i tekhnologicheskoi osnastki (Technology of Reparation, Restoration, and Hardening of Machine Parts, Mechanisms, Equipment, Tools and Technological Accessories), St. Petersburg, 2008, part 2, pp. 127–131.

Kilov, A.S., Combination of high-speed heating and cooling of products, Uprochnyayushchie Tekhnol. Pokrytiya, 2013, no. 1, pp. 20–22.

Kovalenko, V.V. and Kozlova, E.V., Fizicheskaya priroda formirovaniya i evolyutsii gradientnykh strukturno-fazovykh sostoyanii v stalyakh i splavakh (Physical Nature of Formation and Evolution of Gradient Structural-Phase States in Steels and Alloys), Novokuznetsk: Sib. Gos. Ind. Univ., 2009.

Kiselev, L.A., Bulushev, V.R., and Topolyanskii, P.A., Reparation tehcnology of plaw share, in Tekhnologiya uprochneniya, nanesenie pokrytii i remonta: teoriya i praktika (Hardening Technology, Coating, and Reparation: Theory and Practice), St. Petersburg: S.-Peterb. Politekh. Univ., 2016, ch. 1, pp. 36–39.

Krukovich, M.G., Analysis of structuring during surface treatment of steels, Vestn. Vseross. Nauchno-Issled. Inst. Zheleznodorozhn. Transp., 2012, no. 3, pp. 36–39.

Balanovskii, A.E., Surface plasma hardening of metals, Uprochnyayushchie Tekhnol. Pokrytiya, 2016, no. 2, pp. 20–30.

Funding

The work was financially supported in the scope of Project no. AP08052699 “Development of an experimental workshop for the strengthening of heavily loaded parts of soil-cutting machines with the use of innovative plasma technologies”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Polyakov

About this article

Cite this article

Kanaev, A.T., Gulyarenko, A.A., Sarsembaeva, T.E. et al. Structure Formation under Plasma-Assisted Hardening of Thin-Walled Low-Weight Parts. Steel Transl. 51, 582–586 (2021). https://doi.org/10.3103/S0967091221080064

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091221080064