Abstract

Based on literature and our own data, the effect of boron on the characteristics of all stages of metallurgical processes (from sintering, smelting of cast iron and ferroalloys, to steel production) and on the properties of the resulting slag and metal was studied. To intensify hardening of the pellets at the stage of liquid-phase sintering and to improve their metallurgical properties, it is sufficient to have 0.20–0.35% of boron oxide in them. According to laboratory studies, the presence of boron oxide in pellets increases their compressive strength by 1.5–1.7 times and hot strength by 3–4 times. While studying the mechanism and kinetics of sulfur removal, it was shown that the presence of boric anhydride significantly intensifies processes of ±pellets desulfurization. Their intensive progress goes to the zones of lower temperatures of 1050–1100°C. To increase the sinter strength characteristics, it is possible to add B2O3 to the charge. The introduction of 0.44% of B2O3 does not affect the sinter abrasion. The content of fines (0–5 mm) in comparison with the base sample is reduced by 1.5 times. The use of boron pellets in blast-furnace smelting makes it possible to increase the basicity of the final slag from 1.10 to 1.16. In this regard, the sulfur distribution coefficient increases from 48 to 74. The sulfur content in cast iron decreases by 0.005%. The possibility of using boron and its compounds to improve the technical and economic indicators of production and pellet quality, sinter and cast iron is shown on the base of the presented theoretical, laboratory-experimental and industrial data.

Similar content being viewed by others

REFERENCES

Eremin, N.I., Nemetallicheskie poleznye iskopaemye (Nonmetallic Minerals), Moscow: Moscow State Univ., 2004.

Romanyuk, T.V. and Tkachev, A.V., Geodinamicheskii stsenarii formirovaniya krupneishikh mirovykh miotsen-chetvertichnykh borlitievykh provintsii (Geodynamic Case of Formation of the World’s Largest Miocene-Quaternary Boron-Lithium-Bearing Provinces), Moscow: Svetoch-Plyus, 2010.

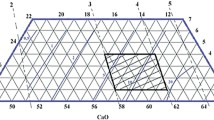

Flethcer, J.G. and Glasser, F.P., Phase relations in system CaO–B2O3–SiO2, J. Mater. Sci., 1993, vol. 28, no. 10, pp. 2677–2686. https://doi.org/10.1007/BF00356203

Ghose, A., Chopra, S., and Young, J.F., Microstructural characterization of doped dicalcium silicate polymorphs, J. Mater. Sci., 1983, vol. 18, no. 10, pp. 2905–2914. https://doi.org/10.1007/BF00700771

Zayakin, O.V. and Kel’, I.N., Promising directions for the stabilization of ferroalloy production slags, Mater. Sci. Forum, 2019, vol. 946, pp. 401–405. https://doi.org/10.4028/www.scientific.net/MSF.946.401

Zayakin, O.V., Statnykh, R.N., and Zhuchkov, V.I., Study of the possibility of obtaining non-decomposing slag during low-carbon ferrochrome production, Metallurgist, 2019, vol. 62, nos. 9–10, pp. 875–881. https://doi.org/10.1007/s11015-019-00744-8

Murari, F.D., da Costa e Silva, A.L.V., and de Avillez, R.R., Cold-rolled multiphase boron steels: microstructure and mechanical properties, J. Mater. Res. Technol., 2015, vol. 4, no. 2, pp. 191–196. https://doi.org/10.1016/j.jmrt.2014.12.001

Mejia, I., Bedolla-Jacuinde, A., Maldonado, C., and Cabrera, J.M., Hot ductility behavior of a low carbon advanced high strength steel (AHSS) microalloyed with boron, Mater. Sci. Eng., A, 2011, vol. 528, nos. 13–14, pp. 4468–4474. https://doi.org/10.1016/j.msea.2011.02.040

Chown, L.H. and Cornish, L.A., Investigation of hot ductility in Al-killed boron steels, Mater. Sci. Eng., A, 2008, vol. 494, nos. 1–2, pp. 263–275. https://doi.org/10.1016/j.msea.2008.04.026

Asahi, H., Overview of development and commercialization of X120 ultra-high strength UOE linepipe, Proc. Int. Symp. on Microalloyed Steels for the Oil and Gas Industry, Chichester: Wiley, 2007, pp. 281–293.

Upadhyay, N., Pujar, M.G., Sakthivel, T., Mallika, C., Laha, K., and Mudali, U.K., Effect of addition of boron and nitrogen on the corrosion resistance of modified 9Cr-1Mo ferritic steel, Procedia Eng., 2014, vol. 86, pp. 606–614. https://doi.org/10.1016/j.proeng.2014.11.086

Fujishiro, T., Hara, T., Terada, E., et al., Application of B-added low carbon bainitic steels to heavy wall X80 UOE line pipe ultra-low temperature use, Dzairo Prosesu, 2009, no. 22, p. 640.

Asahi, H., Development of high grade OCTG and linepipe by utilizing boron addition, Zairyo Prosesu, 2009, no. 22, p. 639.

Kim, A.S., Zayakin, O.V., Akberdin, A.A., and Kontsevoi, Yu.V., Production and application of new complex boron-containing ferroalloys, Russ. Metal., 2010, vol. 2010, no. 12, pp. 1148–1150. https://doi.org/10.1134/S0036029510120165

Zhuchkov, V.I., Akberdin, A.A., Vatolin, N.A., Leont’ev, L.I., Zayakin, O.V., Kim, A.S., and Konu-rov, U.K., Application of boron-containing materials in metallurgy, Russ. Metal., 2011, vol. 11, no. 12, pp. 1134–1137. https://doi.org/10.1134/S003602951112024X

Naderi, M., Ketabchi, M., Abbasi, M., and Bleck, W., Analysis of microstructure and mechanical properties of different hot stamped B-bearing steels, Steel Res. Int., 2010, vol. 81, no. 3, pp. 216–223. https://doi.org/10.1002/srin.200900125

Fletcher, J.G. and Glasser, F.P., Phase relations in the system CaO–B2O3–SiO2, J. Mater. Sci., 1993, vol. 28, no. 10, pp. 2677–2686. https://doi.org/10.1007/BF00356203

Durinck, D., Arnout, S., Mertens, G., Boydens, E., Jones, P.T., Elsen, J., Blanpain, B., and Wollants, P., Borate distribution in stabilized stainless-steel slag, J. Am. Ceram. Soc., 2008, vol. 91, no. 2, pp. 548–554. https://doi.org/10.1111/j.1551-2916.2007.02147.x

Seki, A., Aso, Y., Okubo, M., Sudo, F., and Ishizaka, K., Development of dusting prevention stabilizer for stainless steel slag, Kawasaki Steel Tech. Rep., 1986, vol. 15, pp. 16–21.

Pontikes, Y., Jones, P. T., Geysen, D., and Blanpain, B., Options to prevent dicalcium silicate-driven disintegration of stainless steel slags, Arch. Metall. Mater., 2010, vol. 55, no. 4, pp. 1169–1172. https://doi.org/10.2478/v10172-010-0020-6

Efimenko, G.G. and Kovalev, D.A., State, problems and prospects for the preparation of iron ore raw materials for metallurgical processing, Trudy Mezhdunarodnoi konferentsii “Teoriya i praktika proizvodsta chuguna” (Proc. Int. Conf. “Theory and Practice of Iron Production”), Krivoi Rog, 2004, pp. 27–37.

Utkov, V.A., Vysokoosnovnoi aglomerat (Highly Basic Sinter), Moscow: Metallurgiya, 1977.

Esenzhulov, A.B., Ostrovskii, Ya.I., Afanas’ev, V.I., Zayakin, O.V., and Zhuchkov, V.I., Russian chromium ore in smelting high-carbon ferrochrome at OAO SZF, Steel Transl., 2008, vol. 38, no. 4, pp. 315–317. https://doi.org/10.3103/S096709120804013X

Tlegabulov, B.S., Influence of magnesium-containing additives on technical and economic indicators of sinter-blast furnace production, Materialy Vsesoyuznoi konferentsii “Intensifikatsiya metallurgicheskikh protsessov i povyshenie kachestva metallov i splavov,” Tula, 19–27 marta 1990 g., Tezisy dokladov (Abstracts of Papers, All-Union Conf. “Intensification of Metallurgical Processes and Improvement of the Quality of Metals and Alloys,” Tula, March 19–27, 1990), Tula, 1990, pp. 25–27.

Akberdin, A.A. and Kim, A.S., Reserves of blast-furnace process for production of high-quality rolled steel, Trudy Mezhdunar. konf. “Nauchno-tekhnicheskii progress v metallugii” (Proc. Int. Conf. “Scientific and Technical Progress in Metallurgy”), Temirtau, 2005, pp. 148–156.

Funding

The work was as part of the governmental contract of the Institute of Metallurgy, Ural Branch of the Russian Academy of Science included in the Program for Basic Research at State Universities.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by K. Gumerov

About this article

Cite this article

Zhuchkov, V.I., Zayakin, O.V. & Akberdin, A.A. Prospects for Using Boron in Metallurgy. Report 1. Steel Transl. 51, 423–427 (2021). https://doi.org/10.3103/S0967091221070111

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091221070111