Abstract

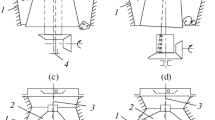

Crushing machines are part of the charge departments of blast-furnace and steel-making shops of metallurgical enterprises. One of the main indicator of the crushing process is its energy efficiency. It is determined by the mass of crushed material when consuming a unit of electricity. The article considers various methods of crushing brittle materials and the design of crushing machines for their implementation. The analysis of the crushers has shown that impact crushers are the most energy-efficient. However, due to a significant drawback (the yield of a suitable product is very small), they are practically not used in the metallurgical industry, in which high requirements are imposed on the finished product fractional composition. In the metallurgical industry, compression crushers are widely used with approximately the same specific energy intensity, that is, with the same energy consumption for the destruction of a unit volume of material of equal strength. Compression fracture is the most energy-intensive crushing method known. In single-roll crushers, a piece of material is fed into the gap between a roll and a solid, stationary plate. During the operation, a complex stress state is generated in the destructed material. Compressive forces act on a piece of crushed material, causing normal compressive stresses in it, as well as an internal torque causing shear stresses. This is achieved by the reduction in energy on crushing by 20–30% in comparison with crushers operating in compression (all other things are equal). The authors describe the design of a crusher, in which the destruction of the processed material occurs due to the forces acting on the crushed piece in one plane towards each other. In this case, only shear stresses arise in the processed piece. The use of crushers, in which the destruction of the processed material occurs due to generation of only tangential stresses in a piece, can reduce the energy consumption per unit of finished product by almost a half. The design of such crushers is a promising direction in the development of machines intended for crushing.

Similar content being viewed by others

REFERENCES

Lynch, A.J., Mineral Crushing and Grinding Circuits: Their Simulation, Optimization, Design and Control, Amsterdam: Elsevier, 1977.

de la Vergne, J., Hard Rock Miner’s Handbook, Edmonton, AB: Stantec Consult., 2008.

Tselikov, A.I., Mashiny i agregaty metallugicheskikh zavodov (Machines and Units of Metallurgical Plants), Moscow: Mashinostroenie, 1987, vol. 1.

Klushantsev, B.V., Kosarev, A.I., and Muizemnek, Yu.A., Drobilki. Konstruktsiya, raschet, osobennosti ekspluatatsii (Crushers: Design, Calculation, and Specific Operation), Moscow: Mashinostroenie, 1990.

Telsmith, Jaw-crushers. http://telsmith.com/products/ crushing-equipment/jaw-crushers. Accessed September 7, 2020.

Lindstrom, A., US Patent 105682804, 2016.

Egbe, E.A.P. and Olugboji, O.A., Design, fabrication and testing of a double roll crusher, Int. J. Eng. Trends Technol., 2016, vol. 35, no. 11, pp. 511–515. https://doi.org/10.14445/22315381/IJETT-V35P303

Lieberwirth, H., Hillmann, Ph., and Hesse, M., Dynamics in double roll crushers, Miner. Eng., 2017, vols. 103–104, pp. 60–66. https://doi.org/10.1016/j.mineng.2016.08.009

Evertsson, M., Output prediction of cone crushers, Miner. Eng., 1998, vol. 11, no. 3, pp. 215–231. https://doi.org/10.1016/S0892-6875(98)00001-6

Johanssson, M., Quist, J., Evertsson, M., and Hulthen, E., Cone crusher performance evaluation using DEM simulations and laboratory experiments for model validation, Miner. Eng., 2017, vols. 103–104, pp. 93–101. https://doi.org/10.1016/j.mineng.2016.09.015

Nikitin, A.G. and Sakharov, D.F., Comparative analysis of compression crushes energy consumption, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2011, no. 4, pp. 56–57.

Maslennikov, V.A., Compression crushers, Izv. Vyssh. Uchebn. Zaved., Gorn. Zh., 1996, nos. 10–11, pp. 124–138.

Zhao, L.L., Zang, F., and Wang, Z.B., Multi-object optimization design for differential and grading toothed roll crusher using a genetic algorithm, J. China Univ. Min. Technol., 2008, vol. 18, no. 2, pp. 316–320. https://doi.org/10.1016/S1006-1266(08)60067-X

BEDESCHI, Production of heavy machinery and equipment. https://www.bedeschi.com. Accessed September 7, 2020.

Lagunova, Yu.A., Crushability of brittle materials at compression destruction, Izv. Vyssh. Uchebn. Zaved., Gorn. Zh., 1996, nos. 10–11, pp. 121–124.

Fishman, M.A., Drobilki udearnogo deistviya (Impact Crushers), Moscow: Gosgortekhizdat, 1960.

Nikitin, A.G., Epifantsev, Yu.A., Medvedeva, K.S., and Gerike, P.B., Power analysis of the process of brittle materials destruction in universal crushing machine with roll locker, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2019, vol. 62, no. 4, pp. 303–307. https://doi.org/10.17073/0368-0797-2019-4-303-307

Goulet, J., Résistance des Matériaux, Paris: Dunod, 1976.

Nikitin, A.G., Lyulenkov, V.I., Mochalov, S.P., and Matekhina, A.N., RF Patent 2526738, Byull. Izobret., 2014, no. 24.

Stepin, P.A., Soprotivlenie materialov (Strength of Materials), St. Petersburg: Lan’, 2014.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Sh. Galyaltdinov

About this article

Cite this article

Nikitin, A.G., Fastykovskii, A.R., Shabunov, M.E. et al. Prospects for Energy-Saving Methods of Crushing Brittle Materials. Steel Transl. 51, 379–381 (2021). https://doi.org/10.3103/S0967091221060073

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091221060073