Abstract

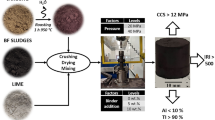

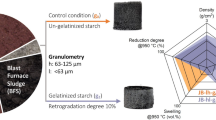

The wastes of corundum production in the form of porous alumina sludge is a promising material to provide ferrous metallurgy with cheap alumina-containing slag-formers. However, the direct feeding of the pulverized materials to the steelmaking furnace leads, as a rule, to a significant carryover of such materials together with waste gases. In this paper, the potential for making briquettes based on porous corundum production sludge by cold briquetting using various common binders (molasses, cement, polyacrylamide-based powder, polyvinyl acetate-based emulsion) is discussed. The features of cold briquetting have been compared for the case of powdered porous materials (the sludge originating from the production of electrocorundum) and for the case of dispersed crystalline materials (chromium ore fines). Experiments have been carried out in order to determine the impact strength of briquettes based on different binders (so-called cold strength) and to determine so-called hot strength (via thermal shock testing). The binder consumption required for obtaining satisfactory characteristics of briquettes made of corundum sludge and made of chromium ore fines has been determined. A technique has been developed and a mechanism for the binding of loose and crystalline particles has been determined during briquetting with the use of polyacrylamide powder. It is shown that the destruction of the briquettes made of loose materials occurs mainly along the grains of the most porous material, whereas the briquettes made of crystalline materials are destroyed along the grain boundaries glued with a binder. Upon briquetting, in the case of porous materials, the binder consumption is twice greater as compared to the binder consumption in the case of fine crystalline fraction with the use of the same binder. Thus, the binder should necessarily impregnate the entire volume of a porous material.

Similar content being viewed by others

REFERENCES

Ravich, B.M., Briketirovanie v tsvetnoi i chernoi metallurgii (Briquetting in Non-Ferrous and Ferrous Metallurgy), Moscow: Metallurgiya, 1975.

Nazimko, E.I., Materials sintering as a method of using various waste, Materialy II Natsional’noi nauchno-prakticheskoi konferentsii, posvyashchennoi 20-letiyu kafedry ekologii morya FGBOU KGMTU “Aktual’nye problemy biorazoobraziya i prirodopol’zovaniya,” Kerch’, 15–17 maya 2019 g. (Proc. II Natl. Sci.-Pract. Conf. Dedicated to the 20th Anniversary of the Department of Marine Ecology at the Kerch State Marine Technology University “Actual Problems of Biodiversity and Nature Management,” Kerch, May 15–17, 2019), Simferopol: Arial, 2019, pp. 367–373.

Diez, M.A., Alvarez, R., and Cimadevilla, J.L.G., Briquetting of carbon-containing wastes from steelmaking for metallurgical coke production, Fuel, 2013, vol. 114, pp. 216–223. https://doi.org/10.1016/j.fuel.2012.04.018

Brožová, S., Pustějovská, P., Bilík, J., Jursová, S., Zbranková, M., and Havránek, J., Innovated technologies of recycling of metallic wastes- modification of existing industrial processes, New Trends Prod. Eng., 2019, vol. 2, no. 2, pp. 361–367. https://doi.org/10.2478/ntpe-2019-0100

Murthy, Y.R., Kapure, G.U., Tripathy, S.K., and Sahu, G.P., Recycling of ferromanganese gas cleaning plant (GCP) sludge by novel agglomeration, Waste Manage., 2018, vol. 80, pp. 457–465. https://doi.org/10.1016/j.wasman.2018.06.023

Ozhogin, V.V., Tomash, A.A., Kovalevskii, I.A., et al., Briquetting as a full-fledged method of agglomeration of metallurgical raw materials, Metall. Protsessy Oborud., 2005, no. 2, pp. 54–58.

Shaik, A.A., Pal, S., and Jha, R., Briquetting: A new approach to recycle the waste iron-bearing materials generated in steel plants, J. Metall. Mater. Sci., 2005, vol. 47, no. 4, pp. 199–206.

Taulbee, D., Patil, D.P., Honaker, R.Q., and Parekh, B.K., Briquetting of coal fines and sawdust Part I: Binder and briquetting-parameters evaluations, Int. J. Coal Prep. Util., 2009, vol. 29, no. 1, pp. 1–22. https://doi.org/10.1080/19392690802628705

Zhang, G., Sun, Y., and Xu, Y., Review of briquette binders and briquetting mechanism, Renewable Sustainable Energy Rev., 2018, vol. 82, pp. 477–487. https://doi.org/10.1016/j.rser.2017.09.072

Kuskov, V., Kuskova, Y., and Udovitsky, V. Effective processing of the iron ores, E3S Web Conf., 2017, vol. 21, art. ID 02010. https://doi.org/10.1051/e3sconf/20172102010

Alimbaev, S.A., Almagambetov, M.S., Nurgali, N.Z., and Pavlov, A.V., The use of extrusion briquettes for smelting carbon ferrochrome, Chern. Met., 2020, no. 5, pp. 4–8.

Kurunov, I. and Bizhanov, A., Stiff Extrusion Briquetting in Metallurgy, New York: Springer-Verlag, 2018.

Steele, R.B. and Bizhanov, A., Stiff extrusion agglomeration of arc furnace dust and ore fines for recovery at a ferroalloy smelter, Proc. 32nd Biennial Conf. of the Institute of Briquetting and Agglomeration, New Orleans, Louisiana, Red Hook, NY: Curran Assoc., 2011, pp. 41–53.

Yulenkov, N.S., Muravskii, A.A., Litosov, G.E., et al., Properties of polyacrylamide and pentanpentaol compositions, Materialy Mezhdunarodnoi nauchno-prakticheskoi konferentsii “Nauka segodnya: zadachi i puti ikh resheniya,” Vologda, 29 maya 2019 g. (Proc. Int. Sci.-Pract. Conf. “Science Today: Problems and Solutions,” Vologda, May 29, 2019), Vologda: Marker, 2019, pp. 52–53.

Khadyev, Ya.A. and Antonova, M.V., Influence of binder composition on properties of composite material, Materialy X Mezhdunarodnoi molodezhnoi nauchnoi konferentsii “Molodezh’ i XXI vek–2020,” Kursk, 19–20 fevralya 2020 g. (Proc. X Int. Youth Sci. Conf. “Youth and the 21st Century–2020,” Kursk, February 19–20, 2020), Kursk: Yugo-Zap. Gos. Univ., 2020, pp. 411–413.

Zhang, G., Sun, Y., and Xu Y., Review of briquette binders and briquetting mechanism, Renewable Sustainable Energy Rev., 2018, vol. 82, pp. 477–487. https://doi.org/10.1016/j.rser.2017.09.072

Sunde, M., Organic binder as a substitute for bentonite in ilmenite pelletization, MSc Thesis, Trondheim: Norw. Univ. Sci. Technol., 2012.

Shabanov, E.Zh., Izbembetov, D.D., Baisanov, S.O., and Shadiev, M.F., Technology for the production of high-carbon ferrochromium using mono-briquettes, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2018, vol. 61, no. 9, pp. 702–707. https://doi.org/10.17073/0368-0797-2019-9-702-707

Bizhanov, A.M., Steele, R.B., Podgorodetskyi, G.S., Kurunov, I.F., Dashevskyi, V.Ya., and Korovushkin, V.V., Extruded briquettes (bricks) for ferroalloy production, Metallurgist, 2013, vol. 56, nos. 11–12, pp. 925–932. https://doi.org/10.1007/s11015-013-9676-2

Kosturkiewicz, B., The use of cement as a binder in the process of industrial waste briquetting, Przem. Chem., 2019, vol. 98, no. 9, pp. 1420–1422. https://doi.org/10.15199/62.2019.9.13

Manyuchi, M.M., Mbohwa, C., and Muzenda, E., Value addition of coal fines and sawdust to briquettes using molasses as a binder, S. Afr. J. Chem. Eng., 2018, vol. 26, pp. 70–73. https://doi.org/10.1016/j.sajce.2018.09.004

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by O. Polyakov

About this article

Cite this article

Aksenova, V.V., Alimbaev, S.A., Pavlov, A.V. et al. Briquetting of Porous Alumina-Containing Materials Using Organic Binders. Steel Transl. 51, 291–295 (2021). https://doi.org/10.3103/S0967091221050028

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091221050028