Abstract

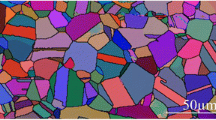

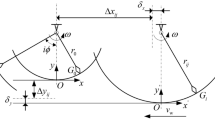

The surface topography’s subsurface layer condition and the wear elements of balls operated in the mills using wet and dry grinding are studied. The factors that determine the tendency for products to increase its level of wear and cracking during operation have been revealed. Measures have been developed, and its implementation made it possible to manufacture grinding balls at a new quality level with high performance characteristics according to wear resistance and impact resistance.

Similar content being viewed by others

REFERENCES

Duda, W.H., Cement Data Book, Berlin: Bauverlag, 1976.

Artes, A.E. and Tret’yukhin, V.V., Production improvement of grinding balls: quality and innovations, Kompetentnost’, 2014, no. 3, pp. 50–54.

Vavilkin, N.M. and Chelnokov, V.V., Material selection for production of grinding balls, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2002, no. 1, pp. 41–46.

Stalinskii, D.V., Rudyuk, A.S., and Solenyi, V.K., Production of grinding balls resistant to abrasive wear, Steel Transl., 2017, vol. 47, no. 6, pp. 421–427.

Stalinskii, D.V., Rudyuk, A.S., Solenyi, V.K., and Yudin, A.V., Improving the quality of steel grinding balls, Steel Transl., 2017, vol. 47, no. 2, pp. 130–136.

Tkachenko, F.K., Tikhonyuk, S.L., Efremenko, V.G., et al., Quality improvement of steel grinding balls by a regulated increase of hardenability, Stal’, 1999, no. 1, pp. 56–58.

Efremenko, V.G., Ganoshenko, I.V., Tkachenko, F.K., et al., Effect of macrostructural state of ball blank on the quality of steel products for the milling equipment, Met. Lit’e Ukr., 2002, nos. 9–10, pp. 40–43.

Tkachenko, F.K. and Efremenko, V.G., Iron-carbon alloys for grinding bodies in wet grinding conditions, Metall. Gornorudn. Prom-st., 2009, no. 5, pp. 75–80.

Ignatov, V.A., Solenyi, V.K., Zhuk, V.L., et al., Basic principles for the selection of materials for the manufacture of grinding bodies operating under conditions of impact-abrasive, shock-corrosive abrasive, and impact-fatigue wear, Met. Lit’e Ukr., 2001, nos. 10–11, pp. 31–34.

GOST (State Standard) 7524–2015. Grinding Steel Balls for ball Mills, Specifications, Moscow: Standartinform, 2016.

Lam, M.M., Serov, A.I., Smyrnov, Y.N., et al., Production of hard (class V) grinding balls at PJSC “DMPZ,” Steel Transl., 2017, vol. 47, no. 5, pp. 325–329.

Efremenko, V.G., Tkachenko, F.K., and Eremenko, T.A., Influence of structural and technological factors on propensity of rolled grinding balls to destruction by fragmentation, in Zakhist metalurgiinikh mashin vid polomok (Protection of Metallurgical Machines from Breakdowns), Mariupol: Priazov. Derzh. Tekh. Univ., 2003, no. 7, pp. 52–56.

Efremenko, V.G., Metallographic analysis of the causes of destruction of rolled steel bodies for drum mills, Visn. Priazov. Derzh. Tekh. Univ., 2000, no. 9, pp. 89–91.

Efremenko, V.G., Specific wear of the working parts of drum mills, in Zakhist metalurgiinikh mashin vid polomok (Protection of Metallurgical Machines from Breakdowns), Mariupol: Priazov. Derzh. Tekh. Univ., 2000, no. 5, pp. 67–71.

Prokhorenko, E.M., Klepikov, V.F., Litvinenko, V.V., et al., Diagnostics of wear processes of materials of ball drum mills, Vost.-Evrop. Zh. Peredovykh Tekhnol., 2015, no. 1-5 (73), pp. 14–19.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Polyakov

About this article

Cite this article

Stalinskii, D.V., Rudyuk, A.S. & Solenyi, V.K. Topography of the Surface and Subsurface Layers of Grinding Balls Operating in Dry and Wet Grinding Modes. Steel Transl. 51, 135–143 (2021). https://doi.org/10.3103/S0967091221020091

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091221020091