Abstract

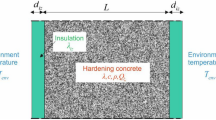

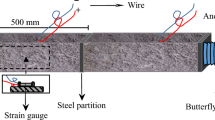

One of the ways to increase economic efficiency of the foundry is to reduce the production cost by reducing scrap, a significant proportion of which is formed due to the formation of hot and cold cracks during solidification and cooling in the casting-mold system. The formation of cracks occurs due to the force interaction of casting with mold. Currently, a number of approaches are used to determine the value of stress state in the casting material and, accordingly, to determine the value of force interaction. The paper considers the developed estimation of stress-strain state of a casting-mold system, which is determined by deformation resistance of the molding mixture. Change in deformation resistance of the molding mixture is complex due to the multi-factor nature of resulting stresses interaction with thermal and component composition of the layer of a sand-clay mixture. We have studied the influence of geometric parameters and thermophysical properties of the casting on deformation resistance of the molding mixture. A mathematical model was developed that considers the following: heat transfer between casting and mold, increase in mold dry layer, and moisture migration in layer of the sand-clay mixture. On the basis of mathematical modeling, we have performed a quantitative analysis of the influence of thermophysical properties of casting (thermal conductivity, volumetric heat capacity, heat of crystallization, geometric parameters) on ductility of raw sand-clay mold with a moisture of 5% expressed in terms of the average resistance to deformation under an obstruction element 100 mm long. It has been established that an increase in the above-mentioned factors at a fixed instant of time increases the average value of deformation resistance. The quantitative relationship is found between the released heat and the growth of the dry layer of the molding mixture. It has been noted that dynamics of changes in the average temperature does not always coincide with the increase in deformation resistance of a molding mixture.

Similar content being viewed by others

REFERENCES

Bochvar, A.A., Rykalin, N.N., Prokhorov, I.I., et al., Hot crystallization cracks at casting and welding, Liteinoe Proizvod., 1960, no. 10, p. 47.

Vable, M., Mechanics of Materials, Houghton, MI: Mich. Technol. Univ., 2014, 2nd ed.

Bochvar, A.A. and Sviderskaya, Z.A., Destruction of castings under action of shrinkage stresses during crystallization depending on composition, Izv. Akad. Nauk SSSR, Otd. Tekh. Nauk, 1947, no. 3, pp. 349–354.

Davidson, C., Viano, D., Lu L., and St. John, D., Observation of crack initiation during hot tearing, Int. J. Cast Met. Res., 2006, vol. 19, no. 1, pp. 59–65.

Hardin, R., Choi, K.K., and Beckermann, C., Reliability-based casting process design optimization, Int. J. Cast Met. Res., 2015, vol. 28, no. 3, pp. 181–192.

Balandin, G.F., Gini, E.I., Matvienko, Yu.P., et al., Technological sample for suppression of hot cracking in panel castings, Izv. Vyssh. Uchebn. Zaved., Mashinostr., 1964, no. 1, pp. 198–203.

Lu, M., Lu, B., Wang, X.-X., Shan, Z.-G., Zhang, Q., and Chen, Y.-S., Research and control on web plate crack of the large type beam blank, Iron Steel (Peking), 2010, vol. 45, no. 7, pp. 99–102.

Liu, J.-H., Bao, Y.-P., Sun, W., Huang, S.-Q., and Zhou, J., Genetic analysis of surface cracks in H beam, Iron Steel (Peking), 2006, vol. 41, no. 8, pp. 37–40.

Aksenov, P.N. and Trukhov, A.P., Unit for testing raw molding mixtures for hot ductility, Liteinoe Proizvod., 1979, no. 3, pp. 20–21.

Shcheglovitov, L.A. and Divavin, A.A., Unit for testing linear shrinkage and crack resistance of foundry steels, Liteinoe Proizvod., 1980, no. 2, pp. 19–20.

Shagalov, V.L. and Popov, S.I., Technological sample for testing steel for crack resistance, Liteinoe Proizvod., 1989, no. 5, pp. 7–8.

Shvetsov, V.I., Kulakov, B.A., and Ivanov, M.A., Osobennosti proizvodstva otlivok iz stali: monografiya (Production Features of Steel Castings: Monograph), Chelyabinsk: Yuzhno-Ural. Gos. Univ., 2014.

Kuliev, V.D. and Cherepanov, G.P., Theory of “hot” cracks, J. Appl. Mech. Tech. Phys., 1974, vol. 15, no. 2, pp. 229–234.

Gulyaev, B.B., Teoriya liteinykh protsessov (Theory of Foundry Processes), Leningrad: Mashinostroenie, 1976.

Stepanov, Yu.A., The role of casting friction on mold in hot cracks formation, Izv. Vyssh. Uchebn. Zaved., Mashinostr., 1960, no. 4, pp. 86–94.

Hojny, M., Physical simulation of steel deformation in the semi-solid state, in Modeling Steel Deformation in the Semi-Solid State, Adv. Struct. Mater. vol. 47, Öchsner, A., da Silva, L.F.M., and Altenbach, H., Eds., Berlin: Springer-Verlag, 2016, pp. 85–119.

Crack Dynamics in Metallic Materials, Klepaczko, J., Ed., Vienna: Springer-Verlag, 1990.

Hills, D., Kelly, P., Dai, D., and Korsunsky, A., Solution of Crack Problems: The Distributed Dislocation Technique, Dordrecht: Springer-Verlag, 1996.

Konstantinov, L.S. and Trukhov, A.P., Napryazheniya deformatsii i treshchiny v otlivkakh (Deformation Stresses and Cracks in Castings), Moscow: Mashinostroenie, 1981.

Choi, H.J., Thermal stresses due to a uniform heat flow disturbed by a pair of offset parallel cracks in an infinite plane with orthotropy, Eur. J. Mech., A, 2017, vol. 63, pp. 1–13.

Savinov, A.S., Sinitskii, E.V., and Tubol’tseva, A.S., Investigation of deformation capacity of sand-clay mixtures, Vestn. Magnitogorsk. Gos. Tekh. Univ. im. G.I. Nosova, 2011, no. 1 (33), pp. 29–32.

Savinov, A.S. and Tubol’tseva, A.S., Determination of boundary conditions when setting the problem of force interaction of cast part with mold, Materialy VIII Vserossiiskoi nauchno-tekhnicheskoi konferentsii s mezhdunarodnym uchastiem “Mekhaniki XXI veka” (Proc. VIII All-Russ. Sci.-Tech. Conf. with Int. Participation “Mechanics of the 21th Century”), Bratsk: Bratsk. Gos. Univ., 2009, pp. 57–60.

Savinov, A.S., Tubol’tseva, A.S., and Sinitskii, E.V., Analysis of force interaction of cast part with mold, Izv. Samar. Nauchn. Tsentra, Ross. Akad. Nauk, 2011, vol. 13, nos. 1–3, pp. 623–626.

Korojy, B., Nassar, H., and Fredriksson, H., Hot crack formation during peritectic reaction in steels, Ironmaking Steelmaking, 2010, vol. 37, no. 1, pp. 63–72.

Kuznetsov, G.V. and Sheremet, M.A., Raznostnye metody resheniya zadach teploprovodnosti (Difference Methods for Solving Heat Transfer Problems), Tomsk: Tomsk. Politekh. Univ., 2007.

Traidi, K., Favier, V., Lestriez, P., Saby, M., and Mangin, P., Thermomechanical steels behaviors at semi-solid state, AIP Conf. Proc., 2016, vol. 1769, art. ID 030002.

Savinov, A.S., Andreev, S.M., Tubol’tseva, A.S., and Sinitskii, E.V., Calculation of temperature field of sand-clay mold-casting system, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2014, no. 4, pp. 10–14.

Savinov, A.S., Postnikova, A.S., and Radomskaya, V.V., Calculation of the specific heat capacity of a layer of raw sand-clay mold with different humidity, Teor. Tekhnol. Metall. Proizvod., 2017, no. 3 (22), pp. 17–21.

Taits, N.Yu., Tekhnologiya nagreva stali (Technology of Steel Heating), Moscow: Metallurgizdat, 1962.

Fuchs, H.U., The Dynamics of Heat, New York: Springer-Verlag, 2010.

Alabi, A.G.F., Ajiboye, T.K., and Olusegun, H.D., Measuring the stress, strain and strain-rate in heat treated medium carbon steel samples and finding the constituted material related properties, Afr. J. Math. Comput. Sci. Res., 2010, vol. 3, no. 3, pp. 38–48.

Lanin, A. and Fedik, I., Thermal Stress Resistance of Materials, Berlin: Springer-Verlag, 2008.

Savinov, A.S., Dzyuba, V.P., and Frolushkina, K.A., Modelirovanie napryazhennogo sostoyaniya syrykh peschano-glinistykh liteinykh form (Modeling of Stress State of Raw Sand-Clay Molds), Magnitogorsk: Magnitogorsk. Gos. Tekh. Univ. im. G.I. Nosova, 2012.

Fredriksson, H., Haddad-Sabzevar, M., Hansson, K., and Kron, J., Theory of hot crack formation, Mater. Sci. Technol., 2005, vol. 21, no. 5, pp. 521–530.

Savinov, A.S., Tubol’tseva, A.S., Dzyuba, V.P., and Frolushkina, K.A., Issledovanie fizicheskikh svoistv sukhikh peschano-glinistykh liteinykh form (Investigation of Physical Properties of Dry Sand-Clay Molds), Magnitogorsk: Magnitogorsk. Gos. Tekh. Univ. im. G.I. Nosova, 2012.

Kuznetsov, S.I., Molekulyarnaya fizika. Termodinamika (Molecular Physics. Thermodynamics), Tomsk: Tomsk. Politekh. Univ., 2006.

Williams, T.J., Hardin, R.A., and Beckermann, C., Thermophysical properties and performance of riser sleeves for steel castings, Int. J. Metalcast., 2016, vol. 10, no. 4, pp. 535–555.

Hojny, M., Multiscale modeling of mechanical properties of steel deformed in semi-solid state-experimental background, Key Eng. Mater., 2014, vols. 622–623, pp. 643–650.

Hentschke, R., Thermodynamics: For Physicists, Chemists and Materials Scientists, Berlin: Springer-Verlag, 2014.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by G. Dedkov

About this article

Cite this article

Kolokol’tsev, V.M., Savinov, A.S., Feoktistov, N.A. et al. Ductility Variation of а Raw Sand-Clay Mold under Influence of Geometric and Thermophysical Properties of the Casting. Steel Transl. 50, 767–772 (2020). https://doi.org/10.3103/S096709122011008X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709122011008X