Abstract

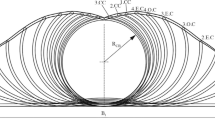

The analysis of the quality of large diameter welded pipes (LDP) was carried out and a method was proposed in the form of algorithms and mathematical models based on the finite-element method (FEM), which allows calculating the boundaries of the deformation zone, the width and radius of the billet to be formed at each step of the step forming press and obtaining profile of “spline” pipe, which, upon subsequent deformation and welding on the equipment of the TESA 1420 line, ensures the production of finished pipes of the required dimensions in accordance with regulatory documents and without defects.

Similar content being viewed by others

REFERENCES

Ushakov, A.S. and Kondratov, L.A., Manufacturing of steel pipes, Stal’, 2019, no. 7, pp. 33–43.

SNiP 2.05.06–85. Magistral’nye truboprovody (SNiP 2.05.06–85. Main Pipelines), Moscow: Gosstroi SSSR, 1985; TU 1381-001-00186654–2012: Truby stal’nye elektrosvarnye pryamoshovnye iz stali klassa prochnosti K60 dlya magistral’nykh gazoprovodov na rabochee davlenie 11.8 MPa i promyslovykh gazoprovodov na rabochee davlenie 12.9 MPa (TU 1381-001-00186654–2012: Steel Electrically Welded Pipes of K60 Durability Class for Main Gas Pipelines and Working Pressure 11.8 MPa and Industrial Gas Pipelines with Working Pressures 12.9 MPa), Chelyabinsk, 2012.

Osadchii, V.Ya. and Kolikov, A.P., Prozivodstvo i kachestvo stal’nykh trub (Production and Quality of Steel Pipe), Moscow: Mosk. Gos. Univ. Priborostr. Inf., 2012.

Efron, L.D., Metallovedenie v bol’shoi metallurgii. Trubnye stali (Physical Metallurgy in Industrial Practice: Pipe Steels), Moscow: Metallurgiya, 2012.

Zvonarev, D.Yu., Improvement of the edge hemming and gradual forming of large welded pipes to ensure the high precision of sizes and shapes, Cand. Sci. (Eng.) Dissertation, Chelyabinsk: Southern Ural State Univ., 2015.

Deriks, V. and Genzer, B., New technologies for economical and flexible production of large diameter pipes, Trudy XIII Mazhdunarodnoi nauchno-praktichekoi konferentsii “Truby–2005” (Proc. XIII Int. Sci.-Pract. Conf. “Pipes–2005”), Chelyabinsk: Ross. Nauchno-Issled. Inst. Trubnoi Prom-ti, 2005, part 1, pp. 105–108.

Seleznev, V.E., Aleshin, V.V., and Pryalov, S.N., Osnovy chislennogo modelirovaniya magistral’nykh truboprovodov (Principles of Numerical Modeling of Mine Pipelines), Seleznev, V.E., Ed., Moscow: MAKS-Press, 2009, 2nd ed.

Barykov, A.M., Stepanov, P.P., Ringinen, A.A., et al., Development of technology and manufacture of rolled products and pipes of Kh100 strength class, in Razvitie tekhnologii proivodstva stali, prokata i trub na Vyksunskoi proizvodstvennoi plashchadke (Development of Production Technology of Steel, Rolling Products, and Pipes at the Vyksunskaya Industrial Site), Moscow: Metallurgizdat, 2016, pp. 425–437.

Samusev, S.V. and Fadeev, V.A., Continuous shaping of welded straight-seam pipe in the open stands of a pipe-welding system, Steel Transl., 2019, vol. 49, no. 7, pp. 447–453.

Fan, L., Gao, Y., and Xu, Q.L.H., Quality control on crimping of large diameter welding pipe, Chin. J. Mech. Eng., 2012, vol. 25, no. 6, pp. 1264–1274.

Kishiguchi, T., Hosoda, H., Ikuno, Y., et al., Pipe end round equipment and control system (perfects), Chin-Niittetsu-Sumikin Eng. Gino, 2013, no. 4, pp. 39–45.

Kolikov, A.P., Romantsev, B.A., and Aleshchenko, A.S., Obrabotka metallov davleniem. Teoriya protsessov trubnogo proizvodstva. Uchbnik (Metal Pressure. Theory of Pipe Manufacturing Processes: Manual), Moscow: Mosk. Inst. Stali Splavov, 2019.

Shinkin, V.N. and Kolikov, A.P., Engineering calculations for processes involved in the production of large-diameter pipes by the SMS Meer technology, Metallurgist, 2012, vol. 55, nos. 11–12, pp. 833–840.

Shinkin, V.N., Calculation of technological parameters of O-forming press for manufacture of large-diameter steel pipes, CIS Iron Steel Rev., 2017, vol. 13, pp. 33-37.

Stepanskii, L.G., Prognozirovanie nadezhnosti tekhnologicheskikh protsessov, instrumenta i mahsin v obrabotke metallov davleniem (Prediction of Reliability of Tehcnological Processes, Tools, and Machines for Metal Pressure), Moscow: Moderat, 2015.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by S. Avodkova

About this article

Cite this article

Kolikov, A.P., Zvonarev, D.Y. Quality Improvement for Large Diameter Welded Pipes Using a Modeling Method for the Shape Change Processes of Sheet Billet. Steel Transl. 50, 801–807 (2020). https://doi.org/10.3103/S0967091220110078

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220110078