Abstract

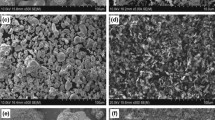

Pure carbon phases formed in samples of soot-alloyed powder steel produced by mechanical activation were investigated using transmission electron microscopy and Auger-electron energy loss fine spectroscopy. A theoretical approach was proposed that considers the escape depth of the signal under analysis when modelling the functions of the radial distribution of atoms in the crystal lattice. The approach proposed allowed for the identification of the nano-crystalline pure carbon phase as a structure similar to natural diamond. The presence of nanosized diamond particles will allow for noticeable enhancement of the consumer qualities of powder steel used to manufacture blades.

Similar content being viewed by others

REFERENCES

Verhoeven, J.D., Steel Metallurgy for Non-Metallurgists, New York: ASM Int., 2007.

Novozhonov, V.I., Polyakov, P.V., Gil’manshina, T.R., et al., Mekhanoaktivatsiya oksidnykh i sloistykh materialov: monografiya (Mechanical Activation of Oxide and Layered Materials: Monograph), Krasnoyarsk: Sib. Fed. Univ., 2015.

Eletskii, A.V. and Smirnov, B.M., Fullerenes and carbon structures, Phys.-Usp., 1995, vol. 38, no. 9, pp. 935–964.

Ageev, V.S., Nikitina, A.A., Potapenko, M.M., et al., Evaluation of the deformation ability of EP450 DUO steel and the production of specific thin-walled pipes from it, Vopr. At. Nauki Tekh., Ser.: Materialoved. Nov. Mater., 2008, no. 2 (71), pp. 14–20.

Hirsch, P.B., Howie, A., Nicholson, R.B., et al., Electron Microscopy of Thin Crystals, London: Butterworths, 1965.

Kovalev, A.I., Mishina, V.P., Stsherbedinsky, G.V., and Wainstein, D.L., EELFS method for investigation of equilibrium segregations on surfaces in steel and alloys, Vacuum, 1990, vol. 41, nos. 7–9, pp. 1794–1795.

Seah, M.P., Quantification of AES and XPS, in Practical Surface Analysis by Auger and X-Ray Photoelectron Spectroscopy, Seah, M.P. and Briggs, D., Eds., Chichester: Wiley, 1983.

Filippova, V.P., Kunavin, S.A., and Pugachev, M.S., Calculation of the parameters of the Lennard–Jones potential for pairs of identical atoms based on the properties of solid substances, Inorg. Mater.: Appl. Res., 2015, vol. 6, no. 1, pp. 1–4.

Penkala T., Zarys Krystalografii, Warsaw: Pan. Wyd. Nauk., 1972.

Emsley, J., The Elements, Oxford: Clarendon, 1989.

Funding

This work was supported by the Russian Foundation for Basic Research, project no. 19-08-00959.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Lotova

About this article

Cite this article

Zhukov, O.P., Filippova, V.P., D’yakonov, D.L. et al. The Prospects of Applying the Mechanical Activation Method to the Manufacturing of Powder Steel Blades. Steel Transl. 50, 277–282 (2020). https://doi.org/10.3103/S0967091220040130

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220040130