Abstract

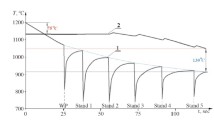

This article discusses possible approaches to increase the capacity of a finishing train using strip rolling with an inverse temperature wedge. One calendar year of operation of a continuous wide-strip hot-rolling mill (NShSGP) is considered. Analysis of plant data demonstrated that the rolling time is by 7–10% lower in the case of rolling with an inverse temperature wedge, which allows increasing overall mill capacity. The obtained results can be applied during rolling of low carbon steels for cold pressing, and their fraction in mill production prevails; thus, it is possible to significantly increase mill capacity without making additional capital investments.

Similar content being viewed by others

REFERENCES

Strategiya razvitiya chernoi metallurgii Rossii na 2014–2020 gg. i na perspektivu do 2013 g. (utverzhdennaya prikazom Ministerstva promyshlennosti i torgovli RF ot 5 maya 2014 g. no. 839) (The Strategy of Development of Ferrous Metallurgy in Russia for 2014–2020 and until 2030 Approved by the Order of the Ministry of Industry and Trade of the Russian Federation No. 839 of May 5, 2014), Moscow, 2014.

Chuprov, V.B., Karetnyi, Z.P., Mazur, S.I., and Tret’yakova, N.Z., Rekonstruktsiya metallurgicheskikh proizvodstv. Shirokopolosnye stany goryachei prokatki: uchebnoe posobie (Reconstruction of Metallurgical Plants. Broadband Hot-Rolling Mills: Manual), Lipetsk: Novolipetsk. Metall. Kombinat, 2006.

Novolipetsk Steel renews the heating furnace of the hot rolled shop in Lipetsk, Metallosnabzhenie Sbyt, 2019, no. 3. http://www.metalinfo.ru.

Millionth ton of hot rolled steel was produced at Novolipetsk Steel, Nov. Predpriyatii, 2017, May 26. https://nlmk.com/ru/media-center/news-companies/ 250-millionnuyu-tonnu-goryachegoprokata-vypustili-na- novolipetskom-kombinate-/?sphrase_id=118429. Accessed May 13, 2019.

Kaputkina, L.M., Marmulev, A.V., Shchetinin, I.V., et al., Nonuniform structure and properties in hot-rolled low-carbon steel coils, Steel Transl., 2013, vol. 43, no. 9, pp. 561–565.

Stulov, V.V. and Aldunin, A.V., Production of hot-rolled sheet of specified quality by a new slab-casting technology, Steel Transl., 2017, vol. 47, no. 10, pp. 645–649.

Mukhin, Yu.A., Solov’ev, V.N., Shunin, A.V., and Makarov, E.V., Stabilization of the structure and mechanical properties along the strip during hot rolling of large-mass slabs, Trudy rashirennogo nacuhnogo seminara “Problemy fundamental’noi mekhaniki v teorii obrabotki metallov davleniem” (Proc. Extended Sci. Seminar “Fundamental Mechanics in the theory of Metal Pressure”), Moscow: Mosk. Gos. Mashinostr. Univ., MAMI, 2008, pp. 117–126.

Mukhin, Yu.A., Solov’ev, V.N., and Bobkov, E.B., The influence of the deformation-speed regime of hot rolling in the finishing group of broadband mills on the structure of St3 steel, Chern. Met., 2018, no. 11 (1043), pp. 12–15.

Mukhin, Yu.A., Solov’ev, V.N., and Shunin, A.V., Improvement of the production of low-carbon hot-rolled strips during rolling with higher acceleration, Proizvod. Prokata, 2012, no. 10, pp. 9–15.

Mukhin, Yu.A., Mazur, S.I., Bel’skii, S.M., and Shunin, A.V., Hot rolling with a reverse temperature wedge and the stability of the structure and mechanical properties of the finished strips, Proizvod. Prokata, 2013, no. 11, pp. 15–18.

Mukhin, Yu.A., Bel’skii, S.M., and Pogodaev, A.K., Accelerated rolling of low-carbon steels with a reverse temperature wedge, Izv. Yugo-Zap. Gos. Univ., Ser. Tekh. Tekhnol., 2016, no. 3 (20), pp. 42–47.

Muhin, U., Belskij, S., Makarov, E., and Koinov, T., Application of between-stand cooling in the production of hot-rolled strips, J. Chem. Technol. Metall., 2014, vol. 49, no. 1, pp. 65–70.

Muhin, U., Belskij, S., Makarov, E., and Koinov, T., Application of between-stand cooling in the production of hot-rolled strips, Fratt. Integr. Strutt., 2016, vol. 10, no. 37, pp. 312–317.

Mukhin, Yu.A., Pimenov, V.A., Galin, P.V., and Chernikov, O.V., RF Patent 2398641, Byull. Izobret., 2010, no. 25.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by I. Moshkin

About this article

Cite this article

Solov’ev, V.N., Bobkov, E.B., Zhovnodii, N.N. et al. Experience of Rolling Patterns with an Inverse Temperature Wedge on the NShSGP 2000 Continuous Wide-Strip Hot-Rolling Mill. Steel Transl. 49, 874–878 (2019). https://doi.org/10.3103/S0967091219120118

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091219120118