Abstract

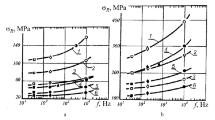

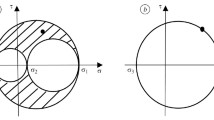

Assessment of the fatigue of test samples on the basis of stress-wave emission is considered. Experiments are conducted on the basis of previously published material regarding the use of synergetically organized acoustic emission. Experimental data for various materials demonstrate that the acoustic-emission signal permits ongoing determination of mechanical characteristics and, in particular, the fatigue. The samples for fatigue tests are prepared from five grades of steel and also from BrAZh9-34 bronze. Five experiments are conducted for each metal. The experimental samples are subjected to loads in small increments. In each step, the emission signal is recorded, and the next series of dislocations is prepared for subsequent loading of the crystal surface and the emission of a stress wave. Thus, energetically prepared dislocations ensuring sufficient power for stable signal recorded are emitted. The experimental data obtained on the basis of the synergetically organized acoustic emission are compared with the fatigue limit of the material determined from empirical formulas in terms of the strength. According to the Fisher test, the experimental results are adequate at the 5% significance level. Assessment of the experimental data for the fatigue limit obtained from the acoustic-emission signal by means of the Cochran test indicates that the dispersion of the experimental measurements is uniform for all the materials considered. The conclusion is that determination of the fatigue limit of a material on the basis of synergetically organized acoustic emission yields real-time experimental data on the fatigue limit, with sufficient precision.

Similar content being viewed by others

REFERENCES

Shkol’nik, L.M., Metodiki ustalostnykh ispytanii (Fatigue Test Methods), Moscow: Metallurgiya, 1978.

Grebennik, V.M., Ustalostnaya prochnost’ i dolgovechnost’ metallurgicheskogo oborudovaniya (Fatigue Strength and Durability of Metallurgical Equipment), Moscow: Mashinostroenie, 1969.

Serensen, S.V., Kogaev, V.P., and Shneiderovich, R.M., Nesushchaya sposobnost’ i raschet detalei mashin na prochnost’ (Carrying Capacity and Structural Analysis of Machine Parts), Moscow: Mashinostroenie, 1975.

Howell, F.M. and Miller, J.L., Axial-stress fatigue strengths of several structural aluminum alloys, Proc. ASTM, 1955, vol. 55, pp. 955–967.

Gavrilov, D.A., Correlation relationships between mechanical characteristics under conditions of static and cyclic loading for constructional steels and alloys, Strength Mater., 1979, vol. 11, no. 5, pp. 515–518.

Savel’ev, A.N., Savel’eva, E.A., and Lokteva, N.A., Strength properties evaluation of materials of technological machines elements based on the synergetically organized signals of acoustic emission, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2017, vol. 60, no. 6, pp. 443–450.

Gur’ev, A.V. and Misharev, G.M., Features of the initial stage of plastic deformation under static and cyclic loading of carbon steel, in Metallovedenie i prochnost’ materialov (Metal Science and Strength of Materials), Tr. Volgogr. Politekh. Inst., Volgograd: Volgogr. Politekh. Inst., 1971, vol. 3, pp. 56–64.

Ivanov, Yu.F., Bessonov, D.A., Vorob’ev, S.V., et al., Ustalostnaya dolgovechnost’ stali martensitnogo klassa, modifitsirovannoi vysokointensivnymi elektronnymi puchkami (Fatigue Service Life of Martensitic Steel Modified with High-Intensity Electron Beams), Novokuznetsk: Inter-Kuzbass, 2011.

Ivanova, V.S., Balankin, A.S., Bunin, I.Zh., and Okhsotoev, A.A., Sinergetika i fraktaly v materialovedenii (Synergetics and Fractals in Materials Science), Moscow: Nauka, 1995.

Koneva, N.A., Lychagin, D.V., Zhukovskii, S.P., and Kozlov, E.V., Evolution of the dislocation structure and stages of plastic flow of a polycrystalline iron-nickel alloy, Phys. Met. Metallogr., 1985, vol. 60, no. 1, pp. 157–166.

Zuev, L.B. and Barannikova, S.A., Fizika prochnosti i eksperimental’naya mekhanika: uchebnoe posobie (Physics of Strength and Experimental Mechanics: Manual), Novosibirsk: Nauka, 2011, 350 p.

Savel’eva, E.A. and Savel’ev, A.N., RF Patent 2555506, Bull. Izobret., 2014, no. 19.

Bolotin, Yu.I., Greshnikov, V.A., Gusakov, A.A, and Drobot, Yu.B., Ispol’zovanie emissii voln napryazhenii dlya ispytanii materialov izdelii (Using Emission of Stress Waves for Testing the Products Materials), Moscow: Izd. Standartov, 1976.

Greshnikov, V.A. and Drobot, Yu.V., Akusticheskaya emissiya. Primenenie dlya ispytanii materialov i izdelii (Acoustic Emission: Application for Testing of Materials and Products), Moscow: Izd. Standartov, 1976.

Natsik, V.D., Radiation of sound by a dislocation that emerges on the surface of a crystal, Pis’ma Zh. Tekh. Fiz., 1968, vol. 8, no. 6, pp. 324–328.

Frederick, J.R. and Felbeck, D.K., Dislocation motion as a source of acoustic emission, in ASTM STP505: Acoustic Emission, West Conshohocken, PA: ASTM Int., 1972, pp. 129–139.

Pollock, A.A., Stress-wave emission a new tool for industry, Ultrasonics, 1969, vol. 6, no. 2, no. 32, pp. 88–92.

Gillis, P.P., Dislocation motions and acoustic emission, in ASTM STP505: Acoustic Emission, West Conshohocken, PA: ASTM Int., 1972, pp. 20–29.

Boiko, V.S., Garber, R.I., and Krivenko, L.F., Sound emission at annihilation of a dislocation cluster, Fiz. Tverd. Tela, 1974, vol. 16, no. 4, pp. 1233–1235.

Haken, H., Synergetics: An Introduction. Nonequilibrium Phase Transitions and Self-organization in Physics, Chemistry, and Biology, Berlin: Springer-Verlag, 1978, 2nd ed.

Koneva, N.A., Self-organization and phase transition in dislocation structure, Proc. 9th ICSMA, Israel, Haifa 1991, London: Fruid, 1991, pp. 157–164.

Glasov, M., Llanes, L.M., and Laird, C., Self-organized dislocation structures (SODS) in fatigue metals, Phys. Status Solidi A, 1995, vol. 149, p. 297.

Davidson, D.L. and Lankford, J., Fatigue crack growth in metals and alloys: mechanism and micromechanism, Int. Mater. Rev., 1992, vol. 37, no. 2, pp. 45–76.

Ivanova, V.S. and Terent’ev, V.F., Priroda ustalosti metallov (Nature of Metal Fatigue), Moscow: Metallurgiya, 1975.

Mecke, K., Blochwítz, G., and Kremling, U., The development of the dislocation structures during the fatigue process of F.C.C. single crystals, Cryst. Res. Technol., 1982, vol. 17, no. 12, pp. 1557–1570.

Mugrabi, H., Dislocations in fatigue, Proc. Conf. Celebrate the Fiftieth Anniversary of the Concept of Dislocation in Crystals “Dislocation and Properties of Real Materials,” London: Inst. Met., 1985, no. 323, pp. 244–262.

Grebennik, V.M. and Tsapko, V.K., Nadezhnost’ metallurgicheskogo oborudovaniya. Spravochnik (Reliability of Metallurgical Equipment: Handbook), Moscow: Metallurgiya, 1980.

Kogaev, V.P. and Drozdov, Yu.N., Prochnost’ i iznosostoikost’ detalei mashin (Strength and Wear Resistance of Machine Parts), Moscow: Mashinostroenie, 1991.

Adler, Yu.P., Vvedenie v planirovanie eksperimenta (Introduction to Experiment Planning), Moscow: Metallurgiya, 1969.

Gorbatenko, N.I., Lankin, M.V., and Shaikhutdinov, D.V., Planirovanie eksperimenta: Uchebnoe posobie (Experiment Planning: Manual), Novocherkassk: Oniks+, 2007.

Rogov, V.A. and Pozdnyak, G.G., Metodika i praktika tekhnicheskikh eksperimentov: Uchebnoe posobie (Method and Practice of Engineering Experiments: Manual), Moscow: Akademiya, 2005.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Savel’ev, A.N., Savel’eva, E.A., Anisimov, D.O. et al. Determining the Fatigue Characteristics of Material on the Basis of Stress-Wave Emission. Steel Transl. 49, 91–96 (2019). https://doi.org/10.3103/S096709121902013X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709121902013X