Abstract

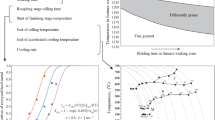

The downtime of ball-rolling mills is largely associated with the replacement of worn rollers. In the present work, the degree and location of critical roller wear are studied: the greatest wear is observed at the flanges in the billet-capture zone. The conditions required for billet capture and successful rolling are determined analytically. Variation in roller speed during billet supply is proposed. Tests are conducted with linear and quadratic variation in roller speed. The familiar formulas for the mean deformation rate are modified for linear and quadratic variation in roller speed. Experiments are conducted on the ball-rolling mill of AO EVRAZ Nizhnetagil’skii Metallurgicheskii Kombinat (NTMK), in rolling 60-mm ШЗГsteel grinding balls on a 40–80 rolling mill. In the experiments, the roller speed is varied manually according to a specified program, with billet capture by the rollers. It is found that speed variation significantly affects the mean pressure at the instant of billet capture. Time dependences of the torque and the mean contact pressure are plotted on the basis of calculation results and experimental data. Empirical characteristics with linear and quadratic variation in roller speed are presented. The permissible agreement of the calculated and empirical results is determined. The installation of a thyristor converter is proposed, so as to decrease the roller speed before billet capture and restore the speed to the rated value in specified fashion after capture. That yields a uniform distribution of the mean contact pressure over the roller length during automatic operation of the mill in different conditions. As a result, the roller wear is decreased, without loss of mill productivity. That reduces roller consumption and the mill downtime for roller replacement.

Similar content being viewed by others

REFERENCES

Kotenok, V.I., Development of theory of profile forming in helical roll passes and creation of high effective processes and equipment for rolling of machines parts, Extended Abstract of Doctoral (Eng.) Dissertation, Moscow, 2005.

Artes, A.E. and Tret’yukhin, V.V., Enhancement of grinding balls production: quality and innovations, Kompetentnost’, 2014, no. 3 (114), pp. 50–53.

Skoblo, T.S., Avtukhov, A.K., and Klimanchuk, V.V., Causes and characteristics of break-down of hot rolling mills rolls, Metall. Mashinostr., 2014, no. 3, pp. 14–17.

Teterin, P.K., Teoriya poperechnoi i vintovoi prokatki (Theory of Cross and Screw Rolling), Moscow: Metallurgiya, 1983.

Bystrov, V.A., D’yakov, P.K., and Umanets, A.G., Operating conditions and wear of hot metal mill rolls, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2014, no. 5, pp. 24–29.

Sinnave, M., New grades of mill rollers and development of their production, Stal’, 2003, no. 7, pp. 48–52.

Romantsev, B.A., Aleshchenko, A.S., Tsyutsyura, V.Yu., and Lube, I.I., Features of wear of working rolls of TPA 159-426 piercing mill at rolling continuous cast billets of large diameter, Proizvod. Prokata, 2016, no 6, pp. 20–27.

Romantsev, B.A., Aleshchenko, A.S., Tsyutsyura, V.Yu., Tyshchuk, I.N., and Lube, I.I., Features of piercing mill TPA 50-200 working roll wear during rolling continuously-cast and hot-rolled billets, Metallurgist, 2017, vol. 60, nos. 9–10, pp. 1062–1069.

Stan TsKBMM 44 dlya prokatki sharov 40-80. Tekhnicheskii proekt (TsKBMM 44 Mill for Rolling the Balls 40-80: Technical Project), Moscow: Tsentr. Nauchno-Issled. Inst. Tekhnol. Mashinostr., 1955.

Peretyat’ko, V.N., Klimov, A.S., and Filippova, M.V., Roller grooving in ball-rolling mills. Part 1, Steel Transl., 2013, vol. 43, no. 4, pp. 168–170.

Filippova, M.V., Smetanin, S.V., and Peretyat’ko, V.N., Computer modeling of rolling balls in screw gage, Trudy IV Vserossiiskoi nauchno-prakticheskoi konferentsii s mezhdunarodnym uchastiem “Modelirovanie i naukoemkie informatsionnye tekhnologii v tekhnicheskikh i sotsial’no-ekonomicheskikh sistemakh” (Proc. 4th All-Russ. Sci.-Pract. Conf. with Int. Participation “Modeling and High-Tech Information Technologies in Technical and Socio-Economic Systems.), Novokuznetsk: Sib. Gos. Ind. Univ., 2016, pp. 290–294.

Filippova, M.V., Peretyat’ko, V.N., and Smetanin, S.V., Stresses and strains during rolling of the ball, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2016, no. 8, pp. 587–588.

Tselikov, A.I. and Barbarich, M.V., Spetsial’nye prokatnye stany (Special Rolling Mills), Moscow: Metallurgiya, 1971.

Tselikov, A.I., Teoriya rascheta usilii v prokatnykh stanakh (Theoretical Calculations of the Forces in Rolling Mills), Moscow: Metallurgiya, 1962.

Grudeev, A.P., Vneshnee trenie pri prokatke (External Friction during Rolling), Moscow: Metallurgiya, 1973.

Gulyaev, Yu.G., Shifrin, E.I., Lube, I.I., Garmashev, D.Yu., and Nikolaenko, Yu.N., Geometry of the deforming region in rotary-rolling mills, Steel Transl., 2013, vol. 43, no. 11, pp. 758–761.

Krasnevskii, S.M., Makushok, E.M., and Shchukin, V.Ya., Razrushenie metallov pri plasticheskoi deformatsii (Metals Fracture by Plastic Deformation), Minsk: Nauka i Tekhnika, 1983.

Novik, F.S. and Arsov, Ya.B., Optimizatsiya protsessov tekhnologii metallov metodami planirovaniya eksperimentov (Optimization of Metal Processing Technology by Experiment Planning Methods), Moscow: Mashinostroenie, 1980.

Belov, V.I. and Razgulin, I.A., Estimation of average values of degree and rate of deformation using Deform 3D software at hot rolling, Model. Razvit. Protsessov OMD, 2014, no. 20, pp. 153–157.

Peretyat’ko, V.N., Klimov, A.S., Filippova, M.V., and Fedorov, A.A., Calibration of rolls of a ball-rolling mill, in Metallurgiya, tekhnologiya, upravlenie, innovatsii, kachestvo (Metallurgy, Technology, Management, Innovations, and Quality), Novokuznetsk: Sib. Gos. Ind. Univ., 2010, pp. 258–265.

Pater, Z., Analysis of helical rolling process of balls formed from a head of a scrapper rail, Adv. Sci. Technol. Res. J., 2016, vol. 10, no. 30, pp. 110–114.

Pater, Z., Tomczak, J., Bartnicki, J., Lovell, M.R., and Menezes, P.L., Experimental and numerical analysis of helical-wedge rolling process for producing steel balls, Int. J. Mach. Tools Manuf., 2013, vol. 67, pp. 1–7.

Chila, P., Pater, Z., Tomczak, J., and Chila, P., Numerical analysis of rolling process for producing steel balls using helical rolls, Arch. Metall. Mater., 2016, vol. 61, no. 2, pp. 485–492.

Pater, Z., FEM analysis of the multi-wedge helical rolling process for a workholding bolt, MATEC Web Conf., 2016, vol. 80, pp. 130–131.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Rubtsov, V.Y., Shevchenko, O.I. & Mironova, M.V. Improvement of Rolling Dynamics to Increase Roller Life in Ball Rolling. Steel Transl. 48, 757–761 (2018). https://doi.org/10.3103/S0967091218120112

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091218120112