Abstract

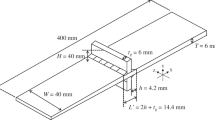

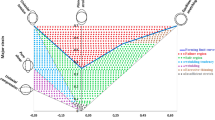

The forging of high-alloy 13Kh17N14M3 and 08Kh18N10T steel ingots (mass 5.3, 1.5, and 1.2 t) is considered. Five forging technologies based on microshear are considered: natural shear in forging by traditional tools, insertion hammers; and hybrid hammers; and applied shear in forging by hammers with working surfaces that cross in the transverse vertical plane. In forging with macroshear, the reduction is 1.78, while the total reduction in the ingot is 2.44. For all the forgings, the deformation of the metal is satisfactory, with no residual cast structure. The mechanical properties of the metal considerably exceed the standard requirements.

Similar content being viewed by others

References

Tyurin, V.A., Teoriya i protsessy kovki slitkov na pressakh (Theory and Forging Processes of Ingots on Presses), Moscow: Mashinostroenie, 1979.

Tyurin, V.A., Phenomenology of macroshifts during deformation by strikes with crossing working surfaces, Kuznechno-Shtampovochnoe Proizvod.-Obrab. Mater. Davleniem, 2017, no. 12, pp. 36–41.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.A. Tyurin, A.L. Sapunov, A.A. Chuchkov, 2018, published in Stal’, 2018, No. 10, pp. 27–29.

About this article

Cite this article

Tyurin, V.A., Sapunov, A.L. & Chuchkov, A.A. Forging of High-Alloy Steel Ingots. Steel Transl. 48, 659–662 (2018). https://doi.org/10.3103/S0967091218100121

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091218100121