Abstract

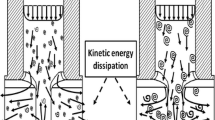

The flow of steel melt into a mold has not been adequately studied. In general, analysis of the melt flow is a complex mathematical problem, and accordingly numerical modeling is employed. The present work employs Odinokov’s numerical method, which is based on a finite-difference form of the initial system of equations. This method has been successfully employed in continuum mechanics; in casting to determine the stress–strain state of shell-type molds; and in solving other technological problems. That suggests its universality. In the present work, it is applied to the hydrodynamic fluxes of liquid metal when steel is cast in a mold of rectangular cross section. The use of a submerged nozzle with eccentric holes for steel supply requires a three-dimensional mathematical model describing the metal fluxes into the mold. Odyssey software is used to simulate the processes in the mold. The calculation is based on the fundamental hydrodynamic equations and the proposed numerical model. The solution is obtained numerically and takes the form of a system of differential equations. The region of interest is divided into finite elements, and the system of equations is written in difference form for each element. The result obtained is the field of metal flow velocities into the mold. A numerical approach and a corresponding algorithm are developed for solution of the system of algebraic equations obtained and are incorporated in a computation program written in Fortran-4. By means of the mathematical model, the geometric dimensions of the mold and the cross section of the exit holes in the submerged nozzle may be varied. The model clarifies the pattern of metal flows, which affects the heat transfer by the mold walls, and permits determination of the optimal parameters of metal exit from the submerged nozzle in different casting conditions. As an example, the model is applied to steel casting in a mold of rectangular cross section (height 100 cm, horizontal dimensions 2000 × 40 cm). Steel flow from the submerged nozzle is eccentric in two directions within the horizontal plane. The results of solution are presented in graphic form. The pattern of metal fluxes into the mold is shown, and the magnitude and intensity of the fluxes is determined.

Similar content being viewed by others

References

Ho, K. and Pehlke, R., Modeling of steel solidification using the general finite difference method, Proc. 6th Process Technologic Conf. and 5th Int. Iron and Steel Congr., April 6–9, 1986, Warrendale, 1986, vol. 6, pp. 853–866.

Kohn, A. and Morillon, Y., Étude mathématique de la solidification des lingots en acier mi-dur, Rev. Metall., 1966, vol. 63, no. 10, pp. 779–790.

Mizikar, E., Mathematical heat transfer model for solidification of continuous cast steel slabs, Trans. Metall. Soc. AIME, 1967, vol. 239, no. 11, p. 1747.

Szekely, J. and Stanek, V., On heat transfer and liquid mixing in the continuous casting of steel, Metall. Trans., 1970, vol. 1, no. 1, p. 119.

Ozava, M., Okano, S., and Matsuno, J., Influence des contitions du jet de coulee sur la formation de la peau solidifiee eulingotiere de brames de colee continue, Tensu Hagane, 1976, vol. 62, no. 4, p. 86.

Larreq, M., Sagues, C., and Wanin, M., Vodele mathematique de la solidifica-tioneu coulee continue tenant compte de la solidificationeu al`interfacesolide-liquide, Rev. Metall., 1978, vol. 75, no. 6, pp. 337–352.

Tsaplin, A.I., Galyagin, K.S., and Selyaninov, Yu.A., et al., Modes of electromagnetic mixing and quality of continuously cast slabs, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1987, no. 8, pp. 55–60.

Shestakov, N.I., Kalyagin, Yu.A., Man’ko, O.V., et al., Calculation of temperature field of a continuously cast ingot, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2004, no. 3, pp. 59–61.

Abramov, N.B. and Ermokhin, F.K., State of continuous casting of steel in Russia and the competitiveness of the material for molds, Instrum. Tekhnol., 2001, no. 5, pp. 135–138.

Narzt, H.-P., Köllerer, S., Stachelberger, C., Mörwald, K., Federspiel, C., and Wahl, H., Innovative developments and practical results in continuous casting technology, Stahl Eisen, 2003, vol. 123, no. 5, pp. 77–82.

Lukin, S.V., Mukhin, V.V., Osipov, E.B., Shestakov, G.N., and Polushin, E.G., Heat transfer of ingot with mold of continuous bar-casting machine, Steel Transl., 2008, vol. 38, no. 5, pp. 366–369.

Chichko, A.N., Andrianov, N.V., and Yatskevich, Yu.V., The ProNPS-1 computer system and modeling the continuous casting, Stal’, 2005, no. 4, pp. 77–80.

Ohler, C., Odenthal, H.-J., Pfeifer, H., and Lemanowicz, I., Numerische simulation der strömungs-und erstarrungsprozeßse in einer dünnbrammen-stranggießanlage, Stahl Eisen, 2002, vol. 122, no. 3, pp. 55–63.

Razumov, S.D., Rodionov, V.E., and Zaveryukha, A.A., Defects of continuously cast steel and their elimination, Stal’, 2002, no. 11, pp. 26–29.

Odinokov, V.I., Kaplunov, B.G., Peskov, A.V., and Bakov, A.A., Matematicheskoe modelirovanie slozhnykh tekhnologicheskikh protsessov (Mathematical Modeling of Complex Technological Processes), Moscow: Nauka, 2008.

Odinokov, V.I., Dmitriev, E.A., Evstigneev, A.I., Metal flow in the mold of a continuous-casting machine, Steel Transl., 2017, vol. 47, no. 6, pp. 383–388.

Gornakov, A.I., Modeling of liquid metal flow in CCM crystallizer, Extended Abstract of Cand. Sci. (Eng.) Dissertation, Komsomolsk-on-Amur, 2013.

Stulov, V.V., Matysik, V.A., Novikov, T.V., et al., Razrabotka novogo sposoba razlivki slyabovykh zagotovok na MNLZ (A New Method for Casting Slab Blanks on CCM), Vladivostok: Dal’nauka, 2008.

Evstigneev, A.I., Odinokov, V.I., Sviridov, A.V., Dmitriev, E.A., and Petrov, V.V., Mathematical modeling of stress-strain state of multilayer shell molds, Int. Conf. on Advanced Material Engineering and Technology 2015, Kaohsiung City, Taiwan, December 4–5, 2015, Kangar: Univ. Malaysia Perlis, 2016, vol. 857, pp. 565–572.

Sevast’yanov, G.M., Simulation of the stress-strain state during casting and solidification of metal in a ceramic shell mold, Extended Abstract of Cand. Sci. (Eng.) Dissertation, Komsomolsk-on-Amur, 2011.

Odinokov, V.I., Lovizin, N.S., and Sklyar, S.Yu., Modeling of the process of metal deformation on the casting-forging module, Matem. Model., 2010, vol. 22, no. 9, pp. 129–145.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.I. Odinokov, E.A. Dmitriev, A.I. Evstigneev, 2018, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2018, No. 8, pp. 606–612.

About this article

Cite this article

Odinokov, V.I., Dmitriev, E.A. & Evstigneev, A.I. Steel Flow into a Mold from a Submerged Nozzle with Eccentric Outputs. Steel Transl. 48, 489–494 (2018). https://doi.org/10.3103/S0967091218080119

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091218080119