Abstract

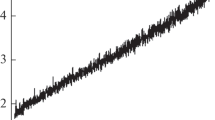

In the H2–O2–C system, in the general case, two reversible reactions of carbon gasification and the water gas reaction, the gas mixture H2–H2O–CO–CO2 is formed at high temperatures. In this mixture, the very low content of oxygen formed by the dissociation of H2O and CO2 is represented by the oxygen potential log (\({p_{{O_2}}}\), atm). Thus, the redox properties may be assessed in terms of the oxygen potential. In any gas mixture containing H2O and/or CO2, it may be calculated from the equations

;

. In the present work, possible compositions of the H2–O2–C system at 700–1500 K and a total pressure of 1 atm are considered: H2–H2O, CO–CO2, CO–CO2–C, H2O–CO2–O2, H2–CO–C, H2–H2O–CO–CO2, and H2–H2O–CO–CO2–C. Analysis yields two nomograms in the following coordinates: log(\({x_{{H_2}O}}\)/\({x_{{H_2}}}\))–log\({p_{{O_2}}}\)–T and log(\({x_{C{O_2}}}\)/xCO)–log\({p_{{O_2}}}\)–T. Using the nomograms and reference information regarding the dissociation pressure of metal oxides, the redox properties of the gas mixtures with respect to those oxides may be assessed. In CO–CO2 systems without hydrogen that are obtained in the combustion of CO, carbon may be formed as soot. This explains the existence of a limited region of gas-phase compositions and log\({p_{{O_2}}}\) in the corresponding nomogram and hence the limited potential for the reduction of some metal oxides in CO–CO2–C systems. The introduction of hydrogen permits the creation of gas mixtures with extremely low oxygen pressure and hence increases the thermodynamic probability of reduction for any metal oxide. Hydrogen may be introduced in the system by methods that differ in economic expediency: from the use of pure hydrogen to the production of gas mixtures as a result of the reaction between water vapor and carbon. In the first case, the reduction of the oxide by hydrogen in the MeO–C–H2 system activates the gasification of carbon by water vapor, the water gas reaction, the reduction of carbon monoxide, and the gasification of carbon dioxide. In the second case, practically pure H2–CO mixture may be obtained above 1300 K. The utility of representing the results on a three-dimensional diagram based on the H2–O2–C concentration triangle is analyzed. If methane formation is taken into account, the equilibrium parameters of gas mixtures are changed markedly only at temperatures below about 900 K.

Similar content being viewed by others

References

Grachev, V.A., Thermodynamic characteristics of phase interaction during melting of cast iron affected by temperature fluctuations, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2017, vol. 60, no. 5, pp. 391–397.

Kalistov, S.V., Andreev, I.A., and Plokhov, S.V., Physicochemical model of metal melt carburization process in synthetic cast iron production, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2010, no. 5, pp. 27–30.

Donskov, E.G., Lyalyuk, V.P., and Donskov, D.E., Influence of blast-furnace conditions on the direct reduction of iron, Steel Transl., 2014, vol. 44, no. 2, pp. 132–135.

Shakirov, M.K., Zhibinova, I.A., Shakirov, K.M., and Protopopov, E.V., Oxygen-converter reduction of iron and manganese from their oxides by components dissolved in liquid iron, Steel Transl., 2009, vol. 39, no. 6, pp. 445–449.

Abzalov, V.M., Gorbachev, V.A., Evstyugin, S.N., et al., Fiziko-khimicheskie i teplofizicheskie osnovy proizvodstva zhelezorudnykh okatyshei (Physicochemical and Thermophysical Basis for the Production of Iron Ore Pellets), Yekaterinburg: Molodezhnyi Inf. Tsentr, 2015.

Strakhov, V.M., Anikin, A.E., Strokina, I.V., Yakushevich, N.F., and Pheoktistov, A.V., Production of reduced pellets from lignite semicoke, Coke Chem., 2015, vol. 58, no. 1, pp. 18–22.

Nokhrina, O.I., Rozhikhina, I.D., Rybenko, I.A., and Khodosov, I.E., Energy-efficient reduction of iron from its ores, Steel Transl., 2016, vol. 46, no. 4, pp. 245–250.

Amdur, A.M., Lkhamsuren, M., Blagin, D.V., and Pavlov, V.V., The behavior of sulfur during metallization of iron-ore concentrates by coal, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2013, no. 8, pp. 8–11.

Melamud, S.G., Yur’ev, B.P., and Gol’tsev, V.A., Study of the oxidation process in iron–ore materials at temperate and high temperatures, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2017, vol. 60, no. 6, pp. 474–480.

Matyukhin, V.I., Dudko, V.A., and Zhuravlev, S.Ya., Study of siderites firing in a shaft furnace, Chern. Metall., Byull. Nauchno-Tekh. Ekon. Inf., 2017, no. 4 (1408), pp. 26–33.

Digonskii, S.V. and Ten, V.V., Role of hydrogen in the reduction of metal oxides by solid carbon, Al’tern. Energet. Ekol., 2009, no. 11 (79), pp. 45–55.

Digonskii, S.V., Carbothermic reduction of the oxide raw material in chemical nonequilibrium systems, Tekhnol. Met., 2008, no. 8, pp. 3–7.

Digonskii, S.V., Dubinin, N.A., and Kravtsov, E.D., RF Patent 2111271, 1998.

Digonskii, V.V., Digonskii, S.V., and Gorbovskii, V.E., RF Patent 2033431, 1991.

Teplov, O.A., Kinetics of the low-temperature hydrogen reduction of magnetite concentrates, Russ. Metall. (Engl. Transl.), 2012, vol. 2012, no. 1, pp. 8–21.

Dubinin, A.M. and Mavrin, S.P., Coal gasification in a system with a damped circulating fluidized bed, Steel Transl., 2016, vol. 46, no. 11, pp. 764–770.

Podgorodetskii, G.S., Tretyak, A.A., Gorbunov, V.B., and Polulyakh, L.A., Using a multifuel gas generator in blast-furnace shops, Steel Transl., 2016, vol. 46, no. 12, pp. 841–846.

Grishin, A.M., Simonov, V.K., and Shcheglova, I.S., The disparity of kinetic laws to thermodynamics preconditions of reactions of carbon gasification by H2O and CO2, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2013, no. 7, pp. 64–67.

Strokina, I.V. and Yakushevich, N.F., Changes of redox properties of gaseous phase of C–O2–H2 system, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2011, no. 6, pp. 3–5.

Yakushevich, N.F., Strokina, I.V., and Polyakh, O.A., Determining redox parameters in the Fe–C–O2–H2 system, Steel Transl., 2011, vol. 41, no. 8, pp. 631–635.

Mikhailov, G.G., Leonovich, B.I., and Kuznetsov, Yu.S., Termodinamika metallurgicheskikh protsessov i sistem (Thermodynamics of Metallurgical Processes and Systems), Moscow: Mosk. Inst. Stali Splavov, 2009.

Kazachkov, E.A., Raschety po teorii metallurgicheskikh protsessov (Calculations on the Theory of Metallurgical Processes), Moscow: Metallurgiya, 1988.

Muan, A. and Osborn, E.F., Phase Equilibria among Oxides in Steelmaking, New York: Pergamon, 1965.

Kuznetsov, Yu.S. and Kachurina, O.I., Equilibrium of water gas and carbon, Vestn. Yuzhno-Ural. Gos. Univ., Ser. Metall., 2015, vol. 14, no. 2, pp. 5–11.

Vyatkin, G.P., Mikhailov, G.G., Kuznetsov, Yu.S., and Kachurina, O.I., System analysis of reduction of iron oxides in the water gas in the presence of carbon, Vestn. Yuzhno-Ural. Gos. Univ., Ser. Metall., 2012, vol. 18, no. 15, pp. 53–59.

Mikhailov, G.G., Kuznetsov, Yu.S., and Kachurina, O.I., System analysis of the reduction of iron oxides, Russ. Metall. (Engl. Transl.), 2014, vol. 2014, no. 2, pp. 179–184.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Yu.S. Kuznetsov, O.I. Kachurina, 2018, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2018, No. 1, pp. 69–79.

About this article

Cite this article

Kuznetsov, Y.S., Kachurina, O.I. Redox Properties of Gas Phases. Steel Transl. 48, 25–33 (2018). https://doi.org/10.3103/S0967091218010084

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091218010084