Abstract

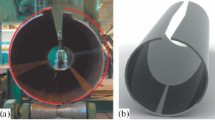

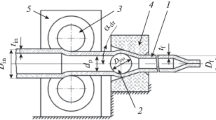

The quality of welded pipe (diameter 508–1420 mm; wall thickness 8–48 mm) of strength class up to K80 (X100) is investigated. Plastic shaping is simulated, with quantitative estimation of the stress–strain state of thick-walled pipe blanks in TESA 1420 presses during edge bending and stepwise shaping. The corresponding computer program permits calculation of the setup of the equipment and determination of the geometric parameters of the pipe blank specified in the standards. Theoretical results are presented for a range of large-diameter pipe produced on the TESA 1420 system.

Similar content being viewed by others

References

Efron, L.I., Metallovedenie v bol’shoi metallurgii. Trubnye stali (Physical Metallurgy in Large-Scale Production: Pipe Steel), Moscow: Metallurgizdat, 2012.

Katsumi, M. and Kenji, O., Steel products for energy industries, JFE Tech. Rep., 2013, vol. 43, no. 18, pp. 1–11.

Osadchii, V.Ya. and Kolikov, A.P., Proizvodstvo i kachestvo stal’nykh trub (Production and Quality of Steel Pipe), Moscow: Mosk. Gos. Univ. Priborostr. Inform., 2012.

Deriks, V. and Genzer, B., New technologies of economic and flexible production of large diameter pipes, Tr. XIII mezhd. nauchno-prakt. konf. “Truby-2005” (Proc. XIII Int. Int. Sci.-Pract. Conf. “Pipes-2005”), Chelyabinsk: Ross. Nauchno-Issled. Inst. Trubnoi Prom., 2005, part 1, pp. 105–108.

Shinkin, V.N. and Kolikov, A.P., Elastoplastic shaping of metal in an edge-bending press in the manufacture of large-diameter pipe, Steel Transl., 2011, vol. 41, no. 6, p. 528.

Wen, S.W., Hilton, P., and Farrugia, D.C.J., Finite element modeling of a submerged arc welding process, J. Mater. Process. Technol., 2001, vol. 119, pp. 203–209.

Kishiguchi, T., Hosoda, H., Ikuno, Y., et al., Pipe end round equipment and control system (PERFECTS), Nippon Steel Sumikin Eng., 2013, no. 4, pp. 39–45.

Chernyavskii, A.O., Metody konechnykh elementov. Osnovy prakticheskogo primeneniya (The Method of Finite Elements: Fundamentals of Practical Implementation), Moscow: Mashinostroenie, 2007.

Seleznev, V.E., Aleshin, V.V., and Pryalov, S.N., Osnovy chislennogo modelirovaniya magistral’nykh truboprovodov (Fundamentals of Numerical Modeling of Pipelines), Seleznev, V.E., Ed., Moscow: MAKS-Press, 2009, 2nd ed.

Zvonarev, D.Yu., Osadchii, V.Ya., Romashov, A.N., and Kolikov, A.P., Development of mathematical model for strip billet forming aimed on quality improvement of large-diameter welded tubes, Chern. Met., 2015, no. 4, pp. 34–39.

Romanovskii, V.P., Spravochnik po kholodnoi shtampovke (Handbook on the Cold Punching), Leningrad: Mashinostroenie, 1979.

Zvonarev, D.Yu., RF Inventors Certificate no. 2013660023, 2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © D.Yu. Zvonarev, V.Ya. Osadchii, A.I. Romantsov, A.P. Kolikov, 2016, published in Stal’, 2016, No. 6, pp. 45–48.

About this article

Cite this article

Zvonarev, D.Y., Osadchii, V.Y., Romantsov, A.I. et al. Shaping of sheet to produce large-diameter welded pipe. Steel Transl. 46, 443–446 (2016). https://doi.org/10.3103/S0967091216060140

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091216060140