Abstract

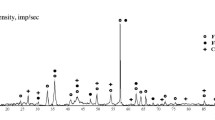

Dust formation in the plasma-arc heating of zinc-plated steel in argon is studied, when the current is 170–190 A, the argon flow rate is 0.06 m3/h, and the pressure in the furnace chamber is 0.1 MPa. Zinc evaporates practically completely in the first 30 s of heating. The structure of the trapped zinc-bearing dust is heterogeneous: the particles are of different shape (spherical, acicular, or membranous particles), different size, and different composition. The composition of individual dust particles is analyzed on an iCAP 6300 spectrometer (Thermo Electron, United States). On that basis, their oxide composition is estimated by means of Terra software. The dust includes particles consisting of ZnO, Fe2O4, carbon, and pure iron. The results indicate that, in the plasma heating of zinc-plated steel, the zinc-bearing dust may be captured separately from the other dust in the initial smelting period.

Similar content being viewed by others

References

Global zinc market. http://www.cmmarket.ru/markets/znworld.htm. Accessed August 15, 2013.

International Lead and Zinc Study Group. http://www.ilzsg.org/static/statistics.aspx?from=20.

Overtaking is completed, Rusmet. http://metaldaily.ru/news/news50255.html.

Doronin, I.E. and Svjazhin, A.G., Thermodynamic study of carbon reaction with steel-smelting dust components, Metallurgist (Moscow), 2013, vol. 57, nos. 1–2, pp. 41–48.

Trusov, B.G., Software system “Terra” for phase and chemical equilibrium modeling, in Trudy XXIV mezhd. konf. po khimicheskoi termodinamike (Proc. XXIV Int. Conf. on Chemical Thermodynamics), St. Petersburg: 2002.

Isakova, N.Sh., Simonyan, L.M., and Khil’ko, A.A., The research of dust formation during the arc heating of metals, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2014, no. 3, pp. 3–9.

Popielska-Ostrowska, P., Siwka, J., Sorek, A., and Niesler, M., Dust arising during steelmaking processes, J. Achiev. Mater. Manuf. Eng., 2012, vol. 55, no. 2, pp. 772–776.

Pereskoka, V.V., Kamkina, L.V., Proidak, Yu.S., Stovpchenko, A.P., and Kvichanskaya, M.I., Restorative heat treatment dust of EAF electrofilters, Visn. Priazov. Derzhavn. Tekh. Univ., Tekh. Nauki, 2010, no. 21, pp. 13–16.

Guezennec, A.G., Huber, J.Ch., Patisson, F., Sessiecq, P., Birat, J.P., and Ablitzer, D., Dust formation in electric arc furnace: birth of the particles, Powder Technol., 2005, vol. 157, no. 1–3, pp. 2–11.

Stovpchenko, A.P., Kamkina, L.V., Proidak, Yu.S., Derevyanchenko, I.V., Kucherenko, O.L., and Bondarenko, M.Yu., Theoretical and experimental studies of the composition and reducibility of the dust from arc steel-melting furnaces, Russ. Metall. (Metally), 2010, vol. 2010, no. 6, pp. 572–579.

Khil’ko, A.A., Simonyan, L.M., Lysenko, A.A., Astashkina, O.V., and Mikhalchan, A.A., Morphology of steel electrofurnace dust, Steel Transl., 2013, vol. 43, no. 5, pp. 254–257.

Simonyan, L.M., Khil’ko, A.A., Lysenko, A.A., Mikhalchan, A.A., and Sel’nikova, P.Yu., Iron and steel electrometallurgical dust as disperse system, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2010, no. 11, pp. 68–75.

Sekula, R., Wnek, M., Selinger, A. and Wrobel, M., Electric arc furnace dust treatment: Investigation on mechanical and magnetic separation methods, Waste Manage. Res., 2001, vol. 19, no. 4, pp. 271–275.

Kukurugya, F., Havlik, T., Kekki, A., and Forsen, O., Chemical and structural characterization of different steelmaking dusts from stainless steel production, Proc. 6th European Metallurgical Conference 2011 (EMC 2011), Düsseldorf, Germany, June 26–29, 2011, Harre, J. and Waschki, U., Eds., Clausthal-Zellerfeld: GDMB Soc. Mining, Metall., Resour. Environ. Technol., 2011, vol. 4, pp. 1171–1184.

Korneev, V.P., Sirotinkin, V.P., Petrakova, N.V., Dyubanov, V.G., and Leont’ev, L.I., Physicochemical properties of the zinc-containing dusts of electric furnace steelmaking, Russ. Metall. (Metally), 2013, vol. 2013, no. 7, pp. 507–512.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.A. Alpatova, L.M. Simonyan, N.Sh. Isakova, 2016, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2016, No. 5, pp. 293–299.

About this article

Cite this article

Alpatova, A.A., Simonyan, L.M. & Isakova, N.S. Dust formation in the arc heating of zinc-plated steel. Steel Transl. 46, 303–308 (2016). https://doi.org/10.3103/S096709121605003X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709121605003X