Abstract

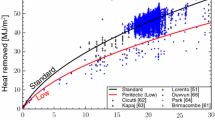

The influence of continuous casting of steel on the high-temperature plasticity of microalloyed steel is investigated. The Gleeble-3800 system is used for the physical modeling of the steel’s hot plasticity. The temperature ranges of plasticity are determined in different conditions of slab cooling in the continuouscasting machine. In all the simulations, a trough is seen on the temperature dependence of the steel’s plasticity. With enlargement of the grain boundaries (decrease in grain size), the high-temperature plasticity increases.

Similar content being viewed by others

References

Crowther, D.N., The effects of microalloying elements on cracking during continuous casting, in Proc. 2001 Int. Symp. on Vanadium Application Technology, Beijing, China, Westerham: Vanitec, 2001, pp. 99–131.

Crown, L.H., The influence of continuous casting parameters on hot tensile behaviour in low carbon, niobium, and boron steels, Ph.D. Thesis, Johannesburg: Univ. of Witwatersrand, 2008.

Kolbasnikov, N.G., Matveev, M.A., Zotov, O.G., Mishin, V.V., Mishnev, P.A., and Nikonov, S.V., Hot plasticity of microalloyed pipe steel in continuous casting and hot rolling, Steel Transl., 2014, vol. 44, no. 2, pp. 149–155.

Matveev, M.A., Physical and mechanical analysis of the reasons of formation of near-edge breaks in the hot rolling pipe steel sheets, Extended Abstract of Cand. Sci. (Tech.) Dissertation, St. Petersburg: S.-Peterb. Politech. Univ., 2015.

Kim, S.K., Kim, N.J., and Kim, J.S., Effect of boron on the hot ductility of Nb-containing steel, Metall. Mater. Trans. A, 2002, vol. 33, pp. 701–704.

Sautkin, N.I., Tarasova, L.P., and Larin, A.V., Analysis of the defects on the surface of continuously cast billets, Stal’, 1983, no. 2, pp. 22–39.

Sarrak, V.I., Zabil’skii, V.V., and Razumov, D.A., Surface cracks of continuous-cast ingot and their prevention: a review, in Staleplavil’noe proizvodstvo (Steel Production), Moscow: Chermetinformatsiya, 1984, no. 1, pp. 23–32.

Kazakov, A.A., Kovalev, P.V., and Zanchenko, S.D., Defects of hot-rolled pipe-steel sheet. Part 2: Defects formed in rolling, Chern. Met., 2008, no. 12, pp. 10–14.

Matveev, M.A., Mishin, V.V., Shishov, I.A., et al., Evaluation of possible metal destruction at the hot rolling using physical and mathematical modeling, Chern. Met., 2014, no. 4, pp. 55–60.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.A. Matveev, N.G. Kolbasnikov, 2016, published in Stal’, 2016, No. 4, pp. 47–51.

About this article

Cite this article

Matveev, M.A., Kolbasnikov, N.G. High-temperature plasticity of microalloyed steel. Steel Transl. 46, 285–289 (2016). https://doi.org/10.3103/S0967091216040069

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091216040069