Abstract

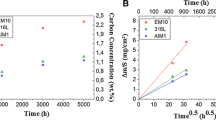

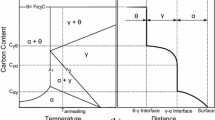

Existing systems for diffusional saturation with molybdenum have numerous problems. The use of microarc treatment for this purpose is investigated. A steel sample is immersed in coal powder and heated by current transmission. Ammonium molybdate is the source of the molybdenum. The pyrolysis of coal is accompanied by the emission of hydrogen, methane, carbon dioxide, and carbon monoxide, which form a protective atmosphere and may reduce molybdenum to the atomic state. To identify the most likely chemical reactions, we calculate the standard change in Gibbs energy. The temperature ranges in which molybdenum trioxide is reduced to obtain molybdenum dioxide and atomic molybdenum are determined. The calculation results are verified experimentally. Simultaneous diffusion of carbon and molybdenum leads to the formation of a carbide coating (thickness 80–150 μm), with microhardness 13.5–15.0 GPa.

Similar content being viewed by others

References

Borisenok, G.V., Vasil’ev, L.A., and Voroshnin, L.G., Khimiko-termicheskaya obrabotka metallov i splavov (Chemical Thermal Treatment of Metals and Alloys), Lyakhovich, L., Ed., Moscow: Metallurgiya, 1981.

Lakhtin, Yu.M. and Arzamasov, B.N., Khimiko-termicheskaya obrabotka metallov (Chemical Thermal Treatment of Metals), Moscow: Metallurgiya, 1985.

Loskutov, V.F., Khizhnyak, V.G., Kunitskii, Yu.A., and Kindrachuk, M.V., Diffuzionnye karbidnye pokrytiya (Diffused Carbide Coatings), Kiev: Tekhnika, 1991.

Voroshnin, L.G., Mendeleeva, O.L., and Smetkin, V.A., Teoriya i tekhnologiya khimiko-termicheskoi obrabotki (Theory and Technology of Chemical Thermal Treatment), Moscow: Novoe Znanie, 2010.

Voroshnin, L.G., Bashlak, S.D., Khina, B.B., and Shmatov, A.A., Mnogokomponentnye diffuzionnye karbidnye pokrytiya na zhelezouglerodistykh splavakh (Multicomponent Diffused Carbide Coatings on IronCarbon Alloys), Minsk: Beloruss. Nats. Tekhn. Univ., 2007.

Dombrovskii, Yu.M. and Stepanov, M.S., Microarc carburizing of steel items in powder media, Uprochnyayushchie Tekhnol. Pokrytiya, 2013, no. 12, pp. 25–29.

Dombrovskii, Yu.M. and Stepanov, M.S., Microarc chrome plating: analysis of main reactions, in Mater. 3-i mezhd. nauchno-prakt. konf. “Innovatsionnye materially i tekhnologii v mashinostroitel’nom proizvodstve,” Novotroitsk, 25 aprelya 2014 g. (Proc. Third Int. Sci.Pract. Conf. “Innovative Materials and Technologies in Machine-Building Production,” Novotroitsk, April 25, 2014), Novotroitsk: Mosk. Inst. Stalei Splavov, 2014, pp. 57–58.

Stepanov, M.S., Formation of carbide coating at microarc chrome plating of steel, Uprochnyayushchie Tekhnol. Pokrytiya, 2015, no. 1, pp. 35–38.

Makarov, G.N., Kharlampovich, G.D., Korolev, Yu.G., et al., Khimicheskaya tekhnologiya tverdykh goryuchikh iskopaemykh (Chemical Technology of Solid Fossil Fuels), Moscow: Khimiya, 1986.

Lipovich, V.G., Kalabin, G.A., Kalechits, I.V., et al., Khimiya i pererabotka uglya (Chemistry and Conversion of Coal), Moscow: Khimiya, 1988.

Glushchenko, I.M., Teoreticheskie osnovy tekhnologii goryuchikh iskopaemykh (Theoretical Technological Basis of Fossil Fuels), Moscow: Metallurgiya, 1990.

Gyul’maliev, A.M., Golovin, G.S., and Gladun, T.G., Teoreticheskie osnovy khimii uglya (Theoretical Basis of Coal Chemistry), Moscow: Mosk. Gos. Gorn. Univ., 2003.

Morachevskii, A.G. and Sladkov, I.B., Termodinamicheskie raschety v metallurgii (Thermodynamic Calculations in Metallurgy), Moscow: Metallurgiya, 1985.

Morachevskii, A.G., Fiziko-khimicheskie svoistva molekulyarnykh neorganicheskikh soedinenii (eksperimental’nye dannye i metody rascheta) (Physical and Chemical Properties of Molecular Inorganic Compounds: Experimental Data and Calculation Methods), St. Petersburg: Khimiya, 1996.

Kazachkov, E.A., Raschety po teorii metallurgicheskikh protsessov (Calculations of the Theory of Metallurgical Processes), Moscow: Metallurgiya, 1988.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.S. Stepanov, Yu.M. Dombrovskii, 2016, published in “Izvestiya VUZ. Chernaya Metallurgiya,” 2016, No. 2, pp. 77–81.

About this article

Cite this article

Stepanov, M.S., Dombrovskii, Y.M. Thermodynamic analysis of carbide-layer formation in steel with microarc saturation by molybdenum. Steel Transl. 46, 79–82 (2016). https://doi.org/10.3103/S0967091216020169

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091216020169