Abstract

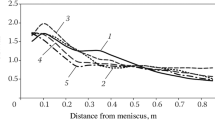

A discrete analog of the differential heat-conduction equation permits the use of nonuniform calculation grids in the simulation of continuous casting. That allows the distribution of the temperature gradients in the model to be taken into account, with corresponding increase in the accuracy of the approximation and the results. A mathematical model is developed for the solidification and shrinkage of continuous-cast slab in the mold. The adoption of a nonuniform grid permits the use of elements measuring 1–2 mm in the simulation. This model is used to study the distortion of the slab cross section at the mold walls. Calculation of the geometric profile permits refinement of the thermal and mechanical interaction of the solidifying shell and the mold walls and determination of the optimal mold taper so as to reduce the risk of surface and subsurface cracking in the slabs.

Similar content being viewed by others

References

Smirnov, A.N., Kuberskii, S.V., and Shtepan, E.V., Nepreryvnaya razlivka stali: uchebnik (Continuous Casting of Steel: Manual), Donetsk: Donetsk. Nats. Tekh. Univ., 2011.

Sengupta, J., Thomas, B.J., Shin, H.J., et al., Mechanism of hook formation during continuous casting of ultra-low carbon steel slabs, Metall. Mater. Trans. A, 2006, vol. 37, no. 5, pp. 1597–1611.

Mills, K.C. and Fox, A.B., The role of mould fluxes in continuous casting-so simple yet so complex, ISIJ Int., 2003, vol. 43, no. 10, pp. 1479–1486.

Shishkin, V.A., Kuznetsova, N.P., and Chugunkova, M.S., Study and improvement of heat work of continuous caster mold, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2010, no. 1, pp. 55–57.

Meng, Y., Li, C., Parkman, J., and Thomas, B.G., Simulation of shrinkage and stress in solidifying steel shells of different grades, in Symp. in Honor of Wilfried Kurz, “Solidification Processes and Microstructures,” Charlotte, NC, March 15–18, 2004, Rappaz, M., Ed., Charlotte, 2004, pp. 33–39.

Ivanova, A.A., Criteria of the quality of the temperature field of a continuous-cast ingot, Metallurgist, 2012, vol. 55, no. 9, pp. 710–719.

Gridin, S.V., Research of shrinkage phenomena at the formation of slab blanks in a crystallizer zone, Metall. Gornorudn. Prom-st, 2004, no. 8, pp. 176–180.

Yoon, J.-K., Applications of numerical simulation to continuous casting technology, ISIJ Int., 2008, vol. 48, no. 7, pp. 879–884.

Thomas, B.G. and Zhang, L., Mathematical modeling of fluid flow in continuous casting, ISIJ Int., 2001, vol. 41, no. 10, pp. 1181–1193.

Wang, Y. and Zhang, L., Transient fluid flow phenomena during continuous casting: Part II Cast speed change, temperature fluctuation, and steel grade mixing, ISIJ Int., 2010, vol. 50, no. 12, pp. 1783–1791.

Schlueter, J., Falkenreck, U., Kempken, J., Odenthal, H.J., Reifferscheid, M., and Vogl, N., Advantageous numerical simulation of the converter blowing process, Iron Steel Technol., 2007, vol. 4, no. 11, pp. 71–89.

Patankar Suhas, V., Computation of Conduction and Duct Flow Heat Transfer, Maple Grove, MN: Innovative Research, 1991.

Zhuravlev, V.A. and Kitaev, E.M., Teplofi zika formirovaniya nepreryvnogo slitka (Thermal Physics of Continuously Cast Ingot Formation), Moscow: Metallurgiya, 1974.

Dyudkin, D.A., Kachestvo nepreryvnolitoi stal’noi zagotovki (Quality of a Continuously Cast Steel Billet), Kiev: Tekhnika, 1988.

Emel’yanov, V.A., Teplovaya rabota mashin nepreryvnogo lit’ya zagotovok (Thermal Operation of CCM), Moscow: Metallurgiya, 1988.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.V. Fedosov, 2016, published in “Izvestiya VUZ. Chernaya Metallurgiya,” 2016, No. 2, pp. 82–87.

About this article

Cite this article

Fedosov, A.V. Simulation of slab formation in a continuous-casting machine. Steel Transl. 46, 83–87 (2016). https://doi.org/10.3103/S0967091216020054

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091216020054