Abstract

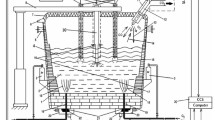

The material balance in six series of melts is investigated to determine the losses of metal and the yield of liquid steel from a 120-t Consteel arc furnace installed at OAO Ashinskii Metallurgicheskii Zavod in September 2010. In each melt, the mass of scrap and slag-forming material introduced is recorded, and the mass of the slabs produced, together with offcuts, scrap, slag, conveyer spillage, and dust in the gas-purification bunkers. Most of the metal-bearing components of the batch are lost with the furnace slag, whose quantity (116–210 kg/t of steel) depends on the quality of the scrap. The quantity of dust is 7.1–20.4 kg/t. The chemical composition of the slag and dust is determined. The results of the balance melts indicate that the yield of liquid steel from the 120-t Consteel arc furnace is the same as for furnaces with melt-intensification systems and with bucket delivery of the scrap throughout the working space. Recommendations are made to reduce the quantity of slag and increase the yield of liquid steel.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Original Russian Text © V.G. Evstratov, G.P. Uryupin, Z.Kh. Shakirov, A.M. Shumakov, I.Yu. Zinurov, 2013, published in “Stal’,” 2013, No. 6, pp. 25–29.

About this article

Cite this article

Evstratov, V.G., Uryupin, G.P., Shakirov, Z.K. et al. Material balance of melts in the Consteel 120-t arc furnace at OAO Ashinskii Metallurgicheskii Zavod. Steel Transl. 43, 374–378 (2013). https://doi.org/10.3103/S0967091213060077

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091213060077