Abstract

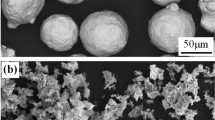

For the example of PRFBKh6-2 alloy and P6M5 steel powders, the structure of plasma coatings after electromechanical treatment is investigated by scanning probe microscopy. After such treatment, ultradisperse and nano hardening phases are formed in the coating. These phases are formed by the decomposition of the coating’s initial fast-quenched structure in high-speed treatment. The formation of characteristic structural zones hardened by nanoparticles and ultradisperse particles is analyzed; the proportions of nanoparticles and ultradisperse particles are determined by the parameters of the sprayed powder and the conditions of plasma spraying and subsequent electromechanical treatment.

Similar content being viewed by others

References

Stoica, V., Ahmed, R., Itsukaichi, T., et al., Sliding wear evaluation of hot isostatically pressed (HIPed) thermal spray cermet coatings, Proceedings of the 2003 International Thermal Spray Conference, Orlando, 2003, pp. 459–466.

Povarova, K.B., Burmistrov, V.I., Antonova, A.V., et al., Metally, 2006, no. 3, pp. 83–90.

Shaw, L., Goerman, D., Ren, R., and Gell, M., J. Surf. Coat. Technol., 2000, no. 130, pp. 1–8.

Gell, M., Jordan, E.H., Sohn, Y.H., et al., J. Surf. Coat. Technol., 2001, nos. 146–147, pp. 48–54.

Skandan, G., Yao, R., Kear, B.H., et al., J. Scripta Mater., 2001, no. 44, pp. 1699–1702.

Jordan, E.H., Gell, M., Shaw, L., and Jiang, S., J. Mater. Sci. Eng. A, 2001, no. 301, pp. 80–89.

Bagmutov, V.P., Kalita, V.I., Zakharov, I.N., and Komlev, D.I., Fund. Prob. Sovrem. Materialov., 2007, vol. 4, no. 1, pp. 18–23.

Bagmutov, V.P., Kalita, V.I., Parshev, S.N., and Zakharov, I.N., Russian patent 2338005, Izobret., Polezn. Modeli, 2008, no. 31, p. 8.

Bagmutov, V.P., Kalita, V.I., Zakharov, I.N., et al., Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2009, no. 10, pp. 62–68.

Kalita, V.I. and Komlev, D.I., Metally, 2003, no. 6, pp. 30–37.

Kalita, V.I., Bagmutov, V.P., Zakharov, I.N., et al., Fiz. Khim. Obrab. Mater., 2008, no. 1, pp. 38–42.

Bagmutov, V.P., Kalita, V.I., Zakharov, I.N., and Parshev, S.N., Fiz. Khim. Obrab. Mater., 2007, no. 3, pp. 22–28.

Kalita, V.I., Yarkin, V.V., Kasimtsev, A.V., et al., Fiz. Khim. Obrab. Mater., 2006, no. 5, pp. 29–40.

Kalita, V.I. and Komlev, D.I., Plazmennye pokrytiya s nanokristallicheskoi i amorfnoi strukturoi (Plasma Coatings with Nanocrystalline and Amorphous Structure), Moscow: Lider M, 2008.

Author information

Authors and Affiliations

Additional information

Original Russian Text © V.P. Bagmutov, V.I. Kalita, E.B. Zakharova, D.I. Komlev, A.Yu. Ivannikov, I.N. Zakharov, A.V. Kosogorov, 2013, published in “Izvestiya VUZ. Chernaya Metallurgiya,” 2013, No. 6, pp. 51–55.

About this article

Cite this article

Bagmutov, V.P., Kalita, V.I., Zakharova, E.B. et al. Ultradisperse and nano structures in plasma coatings hardened by electromechanical treatment. Steel Transl. 43, 351–355 (2013). https://doi.org/10.3103/S0967091213060028

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091213060028