Abstract

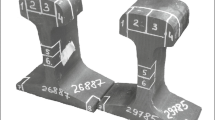

A production technology is developed for converter-steel rail at PAO MK Azovstal’. This technology includes converter casting of steel, treatment in a ladle-furnace unit, vacuum treatment, chill casting of steel, rolling of ingots and blanks, and surface quenching of rail with high-frequency current heating. A batch of R65 rail is produced from K76F steel. Tests show that the rail produced by the proposed technology complies with Ukrainian State Standard DSTU 4344:2004. Heat-treated R65 rail made from K76Φ steel is now in industrial production.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Original Russian Text © D.V. Stalinskii, V.G. Ordin, V.I. Levchenko, A.S. Rudyuk, G.S. Gakheladze, 2012, published in “Stal’,” 2012, No. 6, pp. 19–21.

About this article

Cite this article

Stalinskii, D.V., Ordin, V.G., Levchenko, V.I. et al. Rail production from converter steel. Steel Transl. 42, 513–515 (2012). https://doi.org/10.3103/S0967091212060186

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091212060186