Abstract—

The hard film/soft substrate systems are widely found in production and life. In order to better understand the indentation response of those systems, a closed-form indentation model is established based on the theory of plates and the assumption of Hertz contact stress distribution. Inspired by the model, a new method of measuring the mechanical properties of nanofilms by indentation on hard film/soft substrate system is proposed. Then, with the help of finite element method (FEM), the effectiveness of the model and the method is systematically verified. The results show that compared with the Xu-Pharr model which established by the perturbation method, our model can better describe the compliance of the hard film/soft substrate system in a lager range of modulus ratio of the film to the substrate. In order to obtain the modulus of the nanofilms more accurately by our method, the optimum indentation depth for testing is 0.5 times the film thickness to 1 times the film thickness, and it is best to use a softer substrate to make the modulus ratio of the film to the substrate greater than 103. In addition, the radius of the AFM tip is preferably more than 1 times the film thickness and less than 4 times the film thickness, and a smooth surface of the sample is most preferred. Compared with free standing indentation test or bulge test, our research provides a more convenient and cheaper method for measuring the nanofilms’ modulus in laboratory.

Similar content being viewed by others

REFERENCES

C. Lee, X. Wei, J. W. Kysar, et al., “Measurement of the elastic properties and intrinsic strength of monolayer graphene,” Science 321 (5887), 385–388 (2008). https://doi.org/10.1126/science.1157996

A. C. Ferrari, J. C. Meyer, V. Scardaci, et al., “Raman spectrum of graphene and graphene layers,” Phys. Rev. Lett. 97, 187401 (2006). https://doi.org/10.1103/PhysRevLett.97.187401

A. K. Geim, “Graphene: status and prospects,” Science 324 (5934), 1530–1534 (2009). https://doi.org/10.1126/science.1158877

A. A. Balandin, “Thermal properties of graphene and nanostructured carbon materials,” Nature Materials 10 (8), 569–581 (2011). https://doi.org/10.1038/nmat3064

C. N. R. Rao, A. K. Sood, K. S. Subrahmanyam, et al. “Graphene: the new two-dimensional nanomaterial,” Angew. Chem. Int. Ed. 48 (42), 7752–7777 (2009). https://doi.org/10.1002/anie.200901678

D. A. Dikin, S. Stankovich, E. J. Zimney, et al., “Preparation and characterization of graphene oxide paper,” Nature 448 (7152), 457–460 (2007). https://doi.org/10.1038/nature06016

M. Fang, Z. Zhang, J. Li, et al. “Constructing hierarchically structured interphases for strong and tough epoxy nanocomposites by amine-rich graphene surfaces,” J. Mater. Chem. 20 (43), 9635 (2010). https://doi.org/10.1039/C0JM01620A

Z. Chen and H. Lu, “Constructing sacrificial bonds and hidden lengths for ductile graphene/polyurethane elastomers with improved strength and toughness,” J. Mater. Chem. 22, 12479–12490 (2012). https://doi.org/10.1039/C2JM30517H

C. Hou, H. Wang, Q. Zhang, et al., “Highly conductive, flexible, and compressible all-graphene passive electronic skin for sensing human touch,” Adv. Mater. 26 (29), 5018–5024 (2014). https://doi.org/10.1002/adma.201401367

D. H. Ho, Q. Sun, S. Y. Kim, et al., “Stretchable and multimodal all graphene electronic skin,” Adv. Mater. 28 (13), 2601–2608 (2016). https://doi.org/10.1002/adma.201505739

H. Liu, A. T. Neal, Z. Zhu, et al., “Phosphorene: an unexplored 2D semiconductor with a high hole mobility,” ACS Nano 8 (4), 4033–4041 (2014). https://doi.org/10.1021/nn501226z

A. Castellanos-Gomez, M. Poot, G. A. Steele, et al., “Elastic properties of freely suspended MoS2 nanosheets,” Adv. Mater. 24 (6), 772–775 (2012). https://doi.org/10.1002/adma.201103965

J. Tao, W. Shen, S. Wu, et al., “Mechanical and electrical anisotropy of few-layer black phosphorus,” ACS Nano 9 (11), 11362–11370 (2015). https://doi.org/10.1021/acsnano.5b05151

J. J. Vlassak and W. D. Nix, “A new bulge test technique for the determination of Young’s modulus and Poisson’s ratio of thin films,” J. Mater. Res. 7, 3242–3249 (1992). https://doi.org/10.1557/JMR.1992.3242

P. A. Gruber, J. Böhm, F. Onuseit, et al., “Size effects on yield strength and strain hardening for ultra-thin Cu films with and without passivation: A study by synchrotron and bulge test techniques,” Acta Mater. 56 (10), 2318–2335 (2008). https://doi.org/10.1016/j.actamat.2008.01.027

K. Chen, M. Scales, and S. Kyriakides, “Material hardening of a high ductility aluminum alloy from a bulge test,” Int. J. Mech. Sci. 138–139, 476–488 (2018). https://doi.org/10.1016/j.ijmecsci.2018.02.002

Y. Zhang and C. Pan, “Measurements of mechanical properties and number of layers of graphene from nano-indentation,” Diamond Relat. Mater. 24, 1–5 (2012). https://doi.org/10.1016/j.diamond.2012.01.033

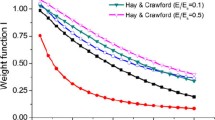

J. Hay and B. Crawford, “Measuring substrate-independent modulus of thin films,” J. Mater. Res. 26, 727–738 (2011). https://doi.org/10.1557/jmr.2011.8

G. Cao, Y. Liu, and T. Niu, “Indentation response of two-dimensional materials mounted on different substrates,” Int. J. Mech. Sci. 137, 96–104 (2018). https://doi.org/10.1016/j.ijmecsci.2018.01.018

L. Yang, T. Niu, H. Zhang, et al., “Self-assembly of suspended graphene wrinkles with high pre-tension and elastic property,” 2D Materials 4 (4), 041001 (2017). https://doi.org/10.1088/2053-1583/aa833c

Q. Y. Lin, G. Jing, Y. B. Zhou, et al., “Stretch-induced stiffness enhancement of graphene grown by chemical vapor deposition,” ACS Nano 7 (2), 1171–1177 (2013). https://doi.org/10.1021/nn3053999

J. U. Lee, D. Yoon, and H. Cheong, “Estimation of Young’s modulus of graphene by Raman spectroscopy,” Nano Lett. 12 (9), 4444–4448 (2012). https://doi.org/10.1021/nl301073q

T. Niu, G. Cao, and C. Xiong, “Indentation behavior of the stiffest membrane mounted on a very compliant substrate: Graphene on PDMS,” Int. J. Solids Sturct. 132–133, 1–8 (2018). https://doi.org/10.1016/j.ijsolstr.2017.05.038

H. Gao, C. Cheng-Hsin, and L. Jin, “Elastic contact versus indentation modeling of multi-layered materials,” Int. J. Solids Sturct. 29 (20), 2471–2492, (1992).

H. Xu and G. M. Pharr, “An improved relation for the effective elastic compliance of a film/substrate system during indentation by a flat cylindrical punch,” Scr. Mater. 55 (4), 315–318, (2006).

P. M. Ramsey, H. W. Chandler, and T. F. Page, “Modelling the contact response of coated systems,” Surface Coatings Techn. 49 (1–3), 504–509 (1991). https://doi.org/10.1016/0257-8972(91)90108-9

G. M. Pharr and W. C. Oliver, “Measurement of thin film mechanical properties using nanoindentation,” MRS Bull. 17 (7), 28-33 (1992). https://doi.org/10.1557/S0883769400041634

S. K. Vanimisetti and R. Narasimhan, “A numerical analysis of spherical indentation response of thin hard films on soft substrates,” Int. J. Solids Sturct. 43 (20), 6180–6193 (2006). https://doi.org/10.1016/j.ijsolstr.2005.05.032

A. H. A. Hogg M. A., “XLVIII. Equilibrium of a thin plate, symmetrically loaded, resting on an elastic foundation of infinite depth,” Philos. Mag. 25 (168), 576–582 (1972). https://doi.org/10.1080/14786443808562039

H. M. Westergaard, “Stresses in concrete pavements computed by theoreticalanalysis,” Public Roads 7 (2), 25–35 (1926).

Z. Tan and J. Guo, “The unified solution of infinite plate on elastic foundation,” Chin. J. Appl. Mech., No. 2, 9 (2016).

S. Aizikovich, L. Krenev, I. Sevostianov, et al., “Evaluation of the elastic properties of a functionally-graded coating from the indentation measurements,” ZAMM 91 (6), 493–515 (2011). https://doi.org/10.1002/zamm.201000179

I. Goryacheva, N. Myshkin, E. Torskaya, et al., “Modeling friction of tribological composite coatings,” J. Frict. Wear 33, 407–414 (2012). https://doi.org/10.3103/S1068366612060037

F. Stepanov and E. Torskaya, “Modeling of indentation of hard coatings by an arbitrarily shaped indenter,” J. Frict. Wear 40, 326–331 (2019). https://doi.org/10.3103/S1068366619040147

E. Torskaya and I. Goryacheva, “The effect of interface imperfection and external loading on the axisymmetric contact with a coated solid,” Wear 254 (5–6), 538–545 (2003). https://doi.org/10.1016/S0043-1648(03)00141-8

J. L. Bucaille, E. Felder, and G. Hochstetter, “Identification of the viscoplastic behavior of a polycarbonate based on experiments and numerical modeling of the nano-indentation test,” J. Mater. Sci. 37, 3999–4011 (2002). https://doi.org/10.1023/A:1019644630927

D. Maji and S. Das, “AFM and Nanoindentation investigation of PDMS elastomeric substrate compliancy for various sputtered thin film morphologies,” J. Biomed. Mater. Res. A 106 (3), 725–737 (2017). https://doi.org/10.1002/jbm.a.36283

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Yan, J., Zhang, S. & Liu, Y. Indentation behavior of a hard film resting on a soft substrate. Mech. Solids 56, 1140–1151 (2021). https://doi.org/10.3103/S0025654421060248

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654421060248