Abstract

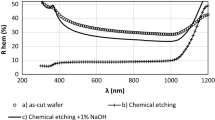

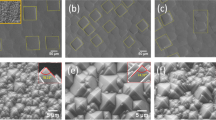

Investigations of the influence of the optimized process of wet chemical treatment on the optical characteristics of the silicon monocrystalline wafers surface have been carried out. It was found that chemical treatment of a silicon wafer surface with a KOH solution with a concentration of 45% in deionized water at a temperature of 75°C for 4 min leads to etching of the damaged surface layer, thereby reducing the number of surface recombination centers of charge carriers. The use of ozone for cleaning from organic and other contaminants and the replacement of isopropyl alcohol in a solution with KOH replaced by ALKATEX surfactant allows the plates to be textured at higher temperatures in a relatively short time and to reduce material costs. The use of an optimized wet chemical treatment process makes it possible to texture monocrystalline silicon wafers and obtain a pyramid on the surface with a base width from 1 to 4 μm and a height of ~1.5–3 μm, which will make it possible to reduce the reflection coefficient of electromagnetic radiation by more than 3 times in relation to plates with a smooth surface, in the spectral range of 600–800 nm, the reflection coefficient decreased to a value of 8.7%. A decrease in the reflection coefficient from the silicon wafer surface should lead to an increase in the transmittance of the supplying electromagnetic radiation of the silicon wafer, which will increase the number of the solar cell quanta penetrating the photoactive region, as a result of which the magnitude of the short-circuit current and the open-circuit voltage should increase. Investigation of the load current–voltage characteristic of a heterojunction with an intrinsic thin-layer (HIT) solar cell based on a textured monocrystalline silicon wafer showed an efficiency value of 22.92% under standard test conditions.

Similar content being viewed by others

REFERENCES

Kobulov, R.R., Matchanov, N.A., and Umarov, B.R., Features of load current–voltage characteristics of a monocrystalline silicon solar cell at various levels of solar illuminations, Appl. Sol. Energy, 2017, vol. 53, no. 4, pp. 297–298. https://doi.org/10.3103/S0003701X17040089

Edwards, M., Bowden, S., Das, U., and Burrows, M., Effect of texturing and surface preparation on lifetime and cell performance in heterojunction silicon solar cells, Sol. Energy Mater. Sol. Cells, 2008, vol. 92, pp. 1373–1377. https://doi.org/10.1016/j.solmat.2008.05.011

Nikitin, S.E., Verbitskiy, V.N., Nashchekin, A.V., Trapeznikova, I.N., Bobyl, A.V., and Terukova, E.E., Surface texture of single-crystal silicon oxidized under a thin V2O5 layer, Semiconductors, 2017, vol. 51, pp. 104–109. https://doi.org/10.1134/S106378261701016X

Chuchvaga, N.A., Kislyakova, N.M., Tokmoldin, N.S., Rakymetov, B.A., and Serikkanov, A.S., Problems arising from using KOH-IPA etchant to texture silicon wafers, Tech. Phys., 2020, vol. 65, pp. 1685–1689. https://doi.org/10.1134/S1063784220100047

Moreno, M., Murias, D., Martinez, J., Reyes-Betanzo, C., Torres, A., Ambrosio, R., Rosales, P., Roca i Cabarrocas, P., and Escobar, M., A comparative study of wet and dry texturing processes of c-Si wafers for the fabrication of solar cells, Sol. Energy, 2014, vol. 101, pp. 182–191. https://doi.org/10.1016/j.solener.2014.01.004

Kern, W., Overview and evolution of silicon wafer cleaning technology, in Handbook of Silicon Wafer Cleaning Technology, Reinhardt, K.A., Ed., Amsterdam: Elsevier, 2018, ch. 1, p. 85. https://doi.org/10.1016/B978-0-51084-4.00001-0

Fang, Zh., Xu, Zh., Wang, D., Huang, Sh., and Li, H., The influence of the pyramidal texture uniformity and process optimization on monocrystalline silicon solar cells, J. Mater. Sci.: Mater. Electron., 2020, vol. 31, pp. 6295–6303. https://doi.org/10.1007/s10854-020-03185-1

Mrazkova, Z., Sobkowicz, I.P., Foldyna, M., Postava, K., Florea, I., Pistora, J., and Roca i Cabarrocas, P., Optical properties and performance of pyramidal texture silicon heterojunction solar cells: Key role of vertex angles, Prog. Photovoltaics, 2018, vol. 26, no. 16, pp. 369–376. https://doi.org/10.1002/pip.2994

Munoz, D., Carreras, P., Escarre, J., Ibarz, D., Martin de Nicolas, S., Voz, C., Asensi, J.M., and Bertomeu, J., Optimization of KOH etching process to obtain textured substrates suitable for heterojunction solar cells fabricated by HWCVD, Thin Solid Films, 2009, vol. 517, pp. 3578–3580. https://doi.org/10.1016/j.tsf.2009.01.024

Kalinkin, I.P., Kukushkin, S.A., and Osipov, A.V., Effect of chemical preparation of a silicon surface on quality and structure of epitaxial silicon-carbide films synthesized by the atoms substitution method, Semiconductors, 2018, vol. 52, pp. 802–808. https://doi.org/10.1134/S1063782618060118

Strinitz, F., El Jaouhari, A., Schoerg, F., Fuerst, M., Plettig, M., and Kuehnlein, H., Advanced alkaline texturing and cleaning for PERC and SHJ solar cells, Energy Procedia, 2017, vol. 130, pp. 23-30. https://doi.org/10.1016/j.egypro.2017.09.409

Dekkers, H., Duerinckx, F., Szlufcik, J., and Nijs, J., Silicon surface texturing by reactive ion etching, Opto-Electron. Rev., 2000, vol. 8, no. 4, pp. 311–316.

Shpeiman, V.V., Nikolaev, V.I., Pozdnyakov, A.O., Bobyl, A.V., Timashov, R.B., and Averkin, A.I., Strength of silicon single-crystal wafers for solar cells, Tech. Phys., 2020, vol. 65, pp. 73–77. https://doi.org/10.1134/S1063784220010259

Suvorov, A.L., Bogdanovich, B.Yu., Zaluzhnyi, A.G., Grafutin, V.I., Kalugin, V.V., Nesterovich, A.V., Prokop’ev, E.P., Timoshenkov, S.P., and Chaplygin, Yu.A., Production technologies and methods for studying silicon-on-insulator (SOI) structures. http://www.ntsr.info/science/library/3073.htm. Accessed December 25, 2010.

Aleksandrov, O.V. and Dusj, A.I., Effect of silicon surface orientation in the bulk model of thermal oxidation, Semiconductors, 2009, vol. 43, no. 10, pp. 1373–1378. https://doi.org/10.1134/S1063782609100212

Angermann, H., Laades, A., Sturzebecher, U., Conrad, E., Klimm, C., Schulze, T.F., Jacob, K., Lawerenz, A., and Korte, I., Wet-chemical preparation of textured silicon solar cell substrates: Surface conditioning and electronic interface properties, Solid State Phenom., 2012, vol. 187, pp. 349–352. doi 10.4028/www.scientific.net/SSP.187.349

Llopis, F. and Tobias, I., Influence of texture feature size on the optical performance of silicon solar cells, Prog. Photovoltaics: Res. Appl., 2005, vol. 13, pp. 27–36. https://doi.org/10.1002/pip.571

King, D.L. and Buck, M.E., Experimental optimization of an anisotropic etching process for random texturization of silicon solar cell, The Conference Record of the Twenty-Second IEEE Photovoltaic Specialists Conference, Las Vegas, USA, 1991, pp. 303–308. https://doi.org/10.1109/PVSC.1991.169228

Kosarev, A., Cosme, I., Mansurova, S., Andronikov, D., Abramov, A., Shakhray, I., and Terukov, E., Plasma enhanced chemical vapor deposited materials and organic semiconductors in photovoltaic devices, J. Russ. Univ. Radioelectron., 2020, vol. 23, no. 4, pp. 38–47. https://doi.org/10.32603/1993-8985-2020-23-4-38-47

Terukov, E., Kosarev, A., Abramov, A., and Malchukova, E., From 11% thin film to 23% heterojunction technology (HJT) PV cell: research, development and implementation related 1600 × 1000 mm 2 PV modules in industrial production, Solar Panels Photovoltaic Mater., 2018, pp. 61–76. https://doi.org/10.5772/intechopen.75013

Abolmasov, S., Abramov, A., Andronikov, D., Emtsev, K., Ivanov, G., Nyapshaev, I., Orekhov, D., Semenov, A., Shelopin, G., and Terukov, E., Influence of DC-sputtered ITO layers on performance of silicon heterojunction solar cells, 33rd European Photovoltaic Solar Energy Conference and Exhibition, 2017, pp. 787–790. https://doi.org/10.4229/EUPVSEC20172017-2AV.3.39

Egorov, F.S., Kukin, A.V., Terukov, E.I., and Titov, A.S., Improved laser scribing of transparent con-ductive oxide for fabrication of thin-film solar module, Tech. Phys., 2018, vol. 63, no. 4, pp. 557–562. https://doi.org/10.1134/S1063784218040102

Bassi, N., Clerc, Ch., Pelet, Y., Hiller, J., Fakhfouri, V., Droz, C., Despeisse, M., Levrat, J., Faes, A., Batzner, D., and Papet, P., GRIDTOUCH: innovative solution for accurate IV measurement of busbarless cells in production and laboratory environments, 29th European Photovoltaic Solar Energy Conference and Exhibition, 2014, pp. 1180–1185. https://doi.org/10.4229/EUPVSEC20142014-2BV.8.24

IEC 61853-1:2011. Photovoltaic (PV) module performance testing and energy rating - part 1: Irradiance and temperature performance measurements and power rating, International Electrotechnical Commission, 2011.

Ataboev, O.K., Kabulov, R.R., Matchanov, N.A., and Egamov, S.R., Influence of temperature on the output parameters of a photovoltaic module based on amorphous hydrogenated silicon, Appl. Sol. Energy, 2019, vol. 55, no. 3, pp. 159–167. https://doi.org/10.3103/S0003701X19030022

ACKNOWLEDGMENTS

The authors are grateful to the staff of the R&D Center Thin-Film Technologies in Energy for valuable assistance in the process of creating and studying HIT structural solar cells, as well as to the staff of the International Solar Energy Institute for valuable advice when discussing the research results.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Ataboev, O.K., Terukov, E.I., Shelopin, G.G. et al. Wet Chemical Treatment of Monocrytalline Silicon Wafer Surfaces. Appl. Sol. Energy 57, 363–369 (2021). https://doi.org/10.3103/S0003701X21050042

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0003701X21050042