Abstract

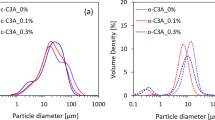

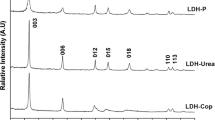

Alumina-zirconia composite materials were produced with different acid ratios by the sol-gel method using aluminum isopropoxide and zirconium chloride. The composites were produced by changing acid/alkoxside ratio in alumina. The composite materials were calcinated at 600°C, 900°C and 1300°C. The effects of acid concentration and calcination temperature on the surface area and pore radius were determined from the nitrogen adsorption isotherm at 77 K. The density of the composites was also measured. The minimum density of produced material was recorded as 1.35 g cm−3 at an acid/alkoxside ratio of 0.2. The highest specific surface area and pore diameter of the lightest material are 191.86 m2 g−1 and 18.4 Ǻ, respectively. Although pore diameter and specific surface area are not changed at any of the experimental temperatures which were tested by decreasing acid/alkoxside ratio, the density is slightly increased. However, it was observed that the calcination temperature significantly affects the surface area and density of the material.

Similar content being viewed by others

References

M. Schwartz, “Composite Material Handbook” (Mc Graw Hill, New York, 1984) 1–7

D. Hull, “An Introduction to Composite Materials” (Cambridge University Press, UK, 1981)

K. Wefers, C. Misra, “Oxides and hydroxides of aluminium”, Alcoa Technical Paper No.19 (Alcoa Laboratories, Pittsburgh, PA, 1987)

D. Sarkar, D. Mohapatra, S. Ray, S. Bhattacharyya, S. Adak, and N. Mitra, “Synthesis and characterization of sol-gel derived ZrO2-doped Al203 nanopowder”, Ceramics International, (2006)

M. Balasubramanian, S.K. Malhotra, C.V. Gokularathnam, Materials Processing Technology 67, 67 (1997)

D. Jayaseelan, T. Nishikawa, H. Awaji, F.D. Gnanam, Materials Science and Engineering A 256, 265 (1998)

B. Kerkwijk, A.J.A. Winnubst, H. Verweij, E. J. Mulder, H.S.C. Metsalaar, D. J. Schipper, Wear 225-229, 1293 (1999)

H.Y. Lee, W. Rieheman, B.L. Mordike, J Eur Ceram Soc 10, 245 (1992)

X. W. Huang, S. W. Wang, X. X. Huang, Ceram Int 29, 765 (2003)

H. Cheong, W. Cho, J. Ha, C. Kim, D. Choi, D. Cheong, J Alloys and Com 290, 304 (1999)

D.D. Jayaseelan, D.A. Rani, T. Nishikawa, H. Awaji, F.D. Gnanam, J Europ Ceram Society 20, 267 (2000)

Y. Hao, J. Li, X. Yang, X. Wang, L. Lu, Materials Science and Engineering A 367, 243 (2004)

D. Sarkar, S. Adak, N.K. Mitra, Composites: Part A. 38, 124 (2007)

B. B. Roger, G. L. Messing, J Am Ceram Soc, 82, 825 (1999)

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Ergu, O.B., Gürü, M. & Cabbar, C. Preparation and characterization of alumina-zirconia composite material with different acid ratios by the sol-gel method. cent.eur.j.chem. 6, 482–487 (2008). https://doi.org/10.2478/s11532-008-0047-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.2478/s11532-008-0047-y