Abstract

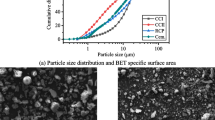

Limestone calcined clay cement (LC3), consisting of ordinary Portland cement (OPC) clinker, calcined clay, limestone powder, and gypsum, has been considered a promising solution to current challenges in the cement and concrete industry, such as high carbon emissions, high energy consumption, and resource shortages. This study carries out a series of experimental investigations of LC3-based paste, mortar, and concrete, including microstructural analyses (e.g. hydration product characterization and pore structure analysis) and macro-scale testing (e.g. workability and mechanical properties), using raw materials from south China. The results show that, in LC3 paste, the replacement of clinker by calcined clay and limestone leads to an increased volume of small pores but decreased total volume of pores. The workability of LC3 mortar and concrete can be readily tailored using conventional superplasticizers. When designed for comparable 28-d compressive strength, the LC3 mortar and concrete tend to have lower early-age compressive strength, but comparable compressive strength and higher flexural strength than those of the OPC counterparts at late ages. This study also examines the bond-slip behavior between LC3 concrete and steel bars and finds that the bond strength is comparable to that of OPC concrete with the same 28-d compressive strength, but that the LC3 concrete-rebar interface exhibits higher bond-slip stiffness. These findings on LC3 concrete provide fundamental information and guidance for furthering the application of LC3 binder in structural concrete in the near future.

概要

目的

采用华南地区的原材料研发一种 LC3 水泥胶凝材料, 并研究其水化反应、 微观结构的发展、 工作性能、 强度性能的发展以及混凝土和钢筋之间的粘结-滑移行为, 为推广 LC3 水泥胶凝材料应用于滨海结构混凝土提供基础信息和参考.

创新点

1. 鉴于目前对 LC3 水泥胶凝材料在混凝土技术和结构混凝土中的应用研究较少, 本文对采用华南地区原材料制备的 LC3 混凝土进行了技术研究和应用分析; 2. 试验结果发现, LC3 混凝土的抗折和劈裂性能优于相同抗压强度的普通混凝土; 3. 采用拔出试验研究 LC3 混凝土与钢筋之间的界面粘结滑移行为, 证明了新型 LC3 水泥胶凝材料在钢筋混凝土结构中的适用性.

方法

1. 开展一系列基于 LC3 水泥的净浆、砂浆和混凝土的实验研究, 并使用原始材料进行微观结构分析(水化产物表征和孔结构分析)和宏观测试 (工作性能和力学性能测试). 2. 研究 LC3 混凝土与钢筋之间的粘结-滑移行为.

结论

1. 与普通混凝土 (OPC) 相比, 钙矾石、 单碳铝酸盐 (MC) 和半碳铝酸盐 (HC) 是 LC3 样品中的主要晶体水合产物: 由于熟料减少 50%, 且 LC3 中发生的二次水化反应消耗了大量 OPC 熟料水化生成的氢氧化钙 (CH), 因此在 LC3 的水合产物中几乎没有残留六角形薄片 CH. 2. 与 OPC 砂浆和混凝土相比, LC3 砂浆和混凝土的早期强度较低: 由于在煅烧粘土中无定形二氧化硅和氧化铝 (与石灰石结合) 二次反应形成了更多的水化硅酸钙和碳铝酸钙水合物, LC3 砂浆和混凝土的后期强度 (7 天后) 迅速增加至与 OPC 砂浆和混凝土相当的强度水平.3. 在与 OPC 同类材料具有相同抗压强度的情况下, LC3 水泥胶凝材料具有更高的抗折和劈裂强度, 因此更有韧性. 4. 对于 LC3 水泥胶凝材料, 颗粒更细的石灰石不一定会带来更好的力学性能. 5. 对于混凝土与钢筋之间的界面粘结-滑移行为, LC3 的破坏模式与 OPC 大致相同, 且通常有两种破坏模式, 即钢筋从混凝土中拔出和混凝土劈裂破坏: 在具有相同等级的抗压强度时, LC3 混凝土的粘结强度与 OPC 混凝土相当, 但其粘结滑移刚度更大.

Similar content being viewed by others

References

Alujas A, Fernández R, Quintana R, et al., 2015. Pozzolanic reactivity of low grade kaolinitic clays: influence of calcination temperature and impact of calcination products on OPC hydration. Applied Clay Science, 108:94–101. https://doi.org/10.1016/j.clay.2015.01.028

Antoni M, Rossen J, Martirena F, et al., 2012. Cement substitution by a combination of metakaolin and limestone. Cement and Concrete Research, 42(12):1579–1589. https://doi.org/10.1016/j.cemconres.2012.09.006

ASTM (American Society of Testing and Materials), 2009. Standard Test Method for Flow of Freshly Mixed Hydraulic Cement Concrete, C1362-09. National Standards of USA.

ASTM (American Society of Testing and Materials), 2010. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-point Loading), C293-2010. National Standards of USA.

Avet F, Scrivener K, 2018. Investigation of the calcined kaolinite content on the hydration of limestone calcined clay cement (LC3). Cement and Concrete Research, 107:124–135. https://doi.org/10.1016/j.cemconres.2018.02.016

Avet F, Snellings R, Alujas Diaz A, et al., 2016. Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cement and Concrete Research, 85:1–11. https://doi.org/10.1016/j.cemconres.2016.02.015

Avet F, Li XR, Scrivener K, 2018. Determination of the amount of reacted metakaolin in calcined clay blends. Cement and Concrete Research, 106:40–48. https://doi.org/10.1016/j.cemconres.2018.01.009

Berriel SS, Favier A, Rosa Domínguez ER, et al., 2016. Assessing the environmental and economic potential of limestone calcined clay cement in Cuba. Journal of Cleaner Production, 124:361–369. https://doi.org/10.1016/j.jclepro.2016.02.125

CEMBUREAU (The European Cement Association), 2015. Activity Report 2015. CEMBUREAU, Brussels, Belgium.

Damidot D, Lothenbach B, Herfort D, et al., 2011. Thermodynamics and cement science. Cement and Concrete Research, 41(7):679–695. https://doi.org/10.1016/j.cemconres.2011.03.018

Damtoft JS, Lukasik J, Herfort D, et al., 2008. Sustainable development and climate change initiatives. Cement and Concrete Research, 38(2):115–127. https://doi.org/10.1016/j.cemconres.2007.09.008

Dhandapani Y, Sakthivel T, Santhanam M, et al., 2018. Mechanical properties and durability performance of concretes with limestone calcined clay cement (LC3). Cement and Concrete Research, 107:136–151. https://doi.org/10.1016/j.cemconres.2018.02.005

Diaz YC, Berriel SS, Heierli U, et al., 2017. Limestone calcined clay cement as a low-carbon solution to meet expanding cement demand in emerging economies. Development Engineering, 2:82–91. https://doi.org/10.1016/j.deveng.2017.06.001

Edenhofer O, Pichs-Madruga R, Sokona Y, et al., 2014. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge, UK.

GAQSIQ (General Administration of Quality Supervision and Quarantine), SA (Standardization Administration), 2005. Test Method for Fluidity of Cement Mortar, GB/T 2419–2005. National Standards of the People’s Republic of China (in Chinese).

GAQSIQ (General Administration of Quality Supervision and Quarantine), SA (Standardization Administration), 2007. Common Portland Cement, GB 175–2007. National Standards of the People’s Republic of China (in Chinese).

Gmür R, Thienel KC, Beuntner N, 2016. Influence of aging conditions upon the properties of calcined clay and its performance as supplementary cementitious material. Cement and Concrete Composites, 72:114–124. https://doi.org/10.1016/j.cemconcomp.2016.05.020

Hou LJ, Zhou BX, Guo S, et al., 2018. Bond-slip behavior between pre-corroded rebar and steel fiber reinforced concrete. Construction and Building Materials, 182:637–645. https://doi.org/10.1016/j.conbuildmat.2018.06.116

Kelly TD, Matos GR, 2015. Historical Statistics for Mineral and Material Commodities in the United States. U.S. Geological Survey, USA. http://minerals.usgs.gov/minerals/pubs/historical-statistics

Liao WY, Kumar A, Khayat K, et al., 2019. Multifunctional lightweight aggregate containing phase change material and water for damage mitigation of concrete. ES Materials & Manufacturing, 6:49–61. https://doi.org/10.30919/esmm5f606

Lothenbach B, Le Saout G, Gallucci E, et al., 2008. Influence of limestone on the hydration of Portland cements. Cement and Concrete Research, 38(6):848–860. https://doi.org/10.1016/j.cemconres.2008.01.002

Lothenbach B, Scrivener K, Hooton RD, 2011. Supplementary cementitious materials. Cement and Concrete Research, 41(12):1244–1256. https://doi.org/10.1016/j.cemconres.2010.12.001

Ma HY, 2014. Mercury intrusion porosimetry in concrete technology: tips in measurement, pore structure parameter acquisition and application. Journal of Porous Materials, 21(2):207–215. https://doi.org/10.1007/s10934-013-9765-4

Ma HY, Li ZJ, 2013a. Realistic pore structure of Portland cement paste: experimental study and numerical simulation. Computers and Concrete, 11(4):317–336. https://doi.org/10.12989/cac.2013.1L4.317

Ma HY, Li ZJ, 2013b. Microstructures and mechanical properties of polymer modified mortars under distinct mechanisms. Construction and Building Materials, 47:579–587. https://doi.org/10.1016/j.conbuildmat.2013.05.048

Ma HY, Hou DS, Li ZJ, 2015. Two-scale modeling of transport properties of cement paste: formation factor, electrical conductivity and chloride diffusivity. Computational Materials Science, 110:270–280. https://doi.org/10.1016/j.commatsci.2015.08.048

Martirena F, Favier A, Scrivener K, 2018. Calcined Clays for Sustainable Concrete. Springer, Dordrecht, the Netherlands. https://doi.org/10.1007/978-94-024-1207-9

Matschei T, Lothenbach B, Glasser FP, 2007. The role of calcium carbonate in cement hydration. Cement and Concrete Research, 37(4):551–558. https://doi.org/10.1016/j.cemconres.2006.10.013

MHURC (Ministry of Housing and Urban-Rural Construction), 2011. Specification for Mix Proportion Design of Ordinary Concrete, JGJ 55-2011. National Standards of the People’s Republic of China (in Chinese).

Muzenda TR, Hou PK, Kawashima S, et al., 2020. The role of limestone and calcined clay on the rheological properties of LC3. Cement and Concrete Composites, 107:103516. https://doi.org/10.1016/j.cemconcomp.2020.103516

Nidheesh PV, Kumar MS, 2019. An overview of environmental sustainability in cement and steel production. Journal of Cleaner Production, 231:856–871. https://doi.org/10.1016/j.jclepro.2019.05.251

SBQTS (State Bureau of Quality and Technical Supervision), 1999. Method of Testing Cements-Determination of Strength, GB/T 17671-1999. National Standards of the People’s Republic of China (in Chinese).

Schneider M, Romer M, Tschudin M, et al., 2011. Sustainable cement production—present and future. Cement and Concrete Research, 41(7):642–650. https://doi.org/10.1016/j.cemconres.2011.03.019

Scrivener K, Favier A, 2015. Calcined Clays for Sustainable Concrete. Springer, Dordrecht, the Netherlands. https://doi.org/10.1007/978-94-017-9939-3

Scrivener K, John V, Gartner E, 2018a. Eco-efficient cements: potential economically viable solutions for a low-CO2 cement-based materials industry. Cement and Concrete Research, 114:2–26. https://doi.org/10.1016/j.cemconres.2018.03.015

Scrivener K, Martirena F, Bishnoi S, et al., 2018b. Calcined clay limestone cements (LC3). Cement and Concrete Research, 114:49–56. https://doi.org/10.1016/j.cemconres.2017.08.017

Ston J, Scrivener K, 2019. Basic creep of limestone-calcined clay cements: an experimental and numerical approach. Theoretical and Applied Fracture Mechanics, 103:102270. https://doi.org/10.1016/j.tafmec.2019.102270

Tironi A, Trezza MA, Scian AN, et al., 2012a. Incorporation of calcined clays in mortars: porous structure and compressive strength. Procedia Materials Science, 1:366–373. https://doi.org/10.1016/j.mspro.2012.06.049

Tironi A, Trezza MA, Scian AN, et al., 2012b. Kaolinitic calcined clays: factors affecting its performance as pozzolans. Construction and Building Materials, 28(1):276–281. https://doi.org/10.1016/j.conbuildmat.2011.08.064

Wang L, Shen N, Zhang MM, et al., 2020. Bond performance of steel-CFRP bar reinforced coral concrete beams. Construction and Building Materials, 245:118456. https://doi.org/10.1016/j.conbuildmat.2020.118456

Zhou YW, Fu HK, Li PD, et al., 2019. Bond behavior between steel bar and engineered cementitious composite (ECC) considering lateral FRP confinement: test and modeling. Composite Structures, 226:111206. https://doi.org/10.1016/j.compstruct.2019.111206

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Natural Science Foundation of China (Nos. 51708360 and 51978407), the Shenzhen Basic Research Project of China (No. JCYJ20180305124106675), the Key Projects for International Cooperation in Science, Technology and Innovation of China (No. 2018YFE0125000), the Taipei University of Technology-Shenzhen University Joint Research Program of China (No. 2020008), the National Science Foundation of the USA (No. 1661609), and the Advanced Materials for Sustainable Infrastructure Seed Funding Program at Missouri University of Science and Technology, USA

Contributors

Zhen-yu HUANG designed the research plan and drafted the manuscript. You-shuo HUANG conducted the tests. Wen-yu LIAO processed the test data and edited the final version. Ning-xu HAN, Ying-wu ZHOU, and Feng XING contributed to methodology and organized the manuscript. Tong-bo SUI and Bin WANG provided the raw material data and helped to draft the test program. Hong-yan MA conceptualized and supervised the research, and finalized the manuscript.

Conflict of interest

Zhen-yu HUANG, You-shuo HUANG, Wen-yu LIAO, Ning-xu HAN, Ying-wu ZHOU, Feng XING, Tong-bo SUI, Bin WANG, and Hong-yan MA declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Huang, Zy., Huang, Ys., Liao, Wy. et al. Development of limestone calcined clay cement concrete in South China and its bond behavior with steel reinforcement. J. Zhejiang Univ. Sci. A 21, 892–907 (2020). https://doi.org/10.1631/jzus.A2000163

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A2000163

Key words

- Limestone calcined clay cement (LC3)

- Hydration

- Bond-slip

- Mercury intrusion porosimetry (MIP)

- Scanning electron microscope (SEM)

- Bond strength