Abstract

A type of azobenzene-containing block copolymer polymethyl methacrylate-b-poly (n-butylmethacrylate-co-6-(4-(phenylazo) benzoate) hexyl methacrylate) (PMMA-b-(PnBMA-co-PAzoMA)) was synthesized by the atom transfer radical polymerization (ATRP). Macroinitiator polymethyl methacrylate (PMMA) was prepared by ATRP and used to initiate the copolymerization of monomern-butyl methacrylate (nBMA) and azobenzene-based methacrylate monomer (AzoMA). Herein, three block copolymers with different molecular weights and block volume fractions were obtained and spin-coated on a silicon substrate or quartz plate before annealing at 180 °C for 14 h. The surface morphologies in these annealed copolymer films were observed by atomic force microscopy (AFM). Bicontinuous stripe or island patterns with different sizes were formed dependent on the film thickness. These ordered patterns are considered to be formed arising from the dewetting process of the surface layer in the copolymer film. Photoisomerization of azobenzene units in the copolymer films changed the dewetting behaviors of the surface layer of the thin film. Therefore, some copolymer annealed films showed a reversible morphology conversion between bicontinuous stripe and island structure when exposed to UV light and upon being stored in the dark. It was found that the composition of the block copolymer had obvious influences on the photoinduced morphology conversion behaviors in these copolymer thin films. When the volumes of PnBMA and PAzoMA phases in the block copolymer were large enough, the surface morphology could be modulated by UV light irradiation and storage in the dark. This work proposes a new possibility for photoinduced control and design of the dewetting processes of thin films using a linear block copolymer.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The fabrication of a well-defined pattern on film surfaces attracts considerable attention because of the numerous potential applications in electronic devices, sensors, information storage materials, and other functional surface materials (Reiter et al., 1996;Sehgal et al., 2002;Tokarczyk et al., 2011). Conventional means of constructing order pattern in the film is photolithography; however, photolithography requires a specific instrument and precise operation. Recently, self-organizational processes, as alternative means to producing surfaces with highly controlled and ordered structures, are attractive due to their convenience and broad tunability. Meanwhile, microphase separation and dewetting are two important self-organizational processes and are usually used to fabricate some well-defined structures on the microscale in the polymer films (Limary and Green, 1999;Thompson, 2012). Some typical highly ordered periodic geometries, such as spherical, lamellar, cylindrical, or bicontinuous nanostructures, have been formed based on microphase separation in the block copolymers (Ruzette et al., 2006;Kim and Han, 2010;Wang et al., 2012). Conversely, polymer dewetting is associated with interfacial tensions in solid/liquid, liquid/air, and solid/air phases (Limary and Green, 1999;Green and Limary, 2001). Usually, bicontinuous or island morphology can be formed based on the dewetting process.

Modulating these well-defined structures controllably is very important for some applications such as information storage materials, biomaterials, and anti-forgery materials (Lu et al., 2011). Generally, the tuning of morphology can be achieved by virtue of external stimuli, such as a solvent or temperature annealing, casting, light, and so on (Segalman and Green, 1999;Zhao and He, 2009;Sriprom et al., 2010;Zhang et al., 2010;Ma et al., 2011;Okano et al., 2011). Light provides a flexible means to handle materials in a non-contact manner. To manipulate the surface morphology of a polymer film by light, photoresponsive chromophores usually are incorporated into polymers (Zhao and He, 2009). Azobenzene is a well-known photoresponsive molecule. In azobenzene-containing block copolymers, the reversible photoiso-merization of azobenzene can serve as a means of modulating the surface morphology in polymer thin films (Zhao and He, 2009). Considerable work has been reported on the photoalignment and photopatterning of block copolymer films containing azobenzene moiety (Kadota et al., 2006).

Seki et al. (1999) andMorikawa et al. (2007) studied controlling phase separated morphology by light in the block copolymers. They synthesized the block copolymer of azobenzene-containing acrylate monomer and vinyl alcohol or styrene. These two kinds of copolymer films showed reversible morphology changes with the assistance of other mixed components, high humidity, or temperature. They also used the polydimethylsiloxane or poly(ethylene oxide) as a macroinitiator to initiate the polymerization of azobenzene-containing methacrylate monomer. The resultant block copolymers exhibited morphological conversions between rod-liked structures and dotted structures upon UV or visible irradiation under high humidity (Kadota et al., 2005;Seki, 2006;Aoki et al., 2010).Okano et al. (2011) synthesized a group of liquid crystalline polymers containing azobenzene moieties as a side group. The microphase separated fiber-like structures in the annealed polymer films can be erased by linear polarized light or UV light irradiation.Han et al. (2010) prepared azobenzene-containing poly(3-hexylthiophene) based copolymer and macroscopic domain orientation controlled by linear polarized light. A block copolymer bearing double liquid crystalline mesogens as a side chain was also prepared byZhao et al. (2010), where the smooth surface showed a photoinduced microphase separated pattern.

In most of these studies, microphase separated morphology modulation were proceeded by the virtue of polarized-light induced alignment of azobenzene units. Sometimes these morphology modulations were achieved with the assistance of other components, temperature, or humidity. Less attention has been paid to modulating patterns by controlling dewetting processes in the polymer film (Yan et al., 2011). To date, onlyLi et al. (2012) have reported on the photoinduced surface pattern modulation in an azobenzene-containing poly(propyleneimine) dendrimer film. There is few work reporting on the morphologies modulation in linear block copolymer films through controlling dewetting behaviors by light (Limary and Green, 1999;Yan et al., 2011). Herein, we synthesized a novel azobenzene-containing photoresponsive block copolymers by atom transfer radical polymerization (ATRP). The annealed thin film of these copolymers exhibited some morphologies induced by the dewetting process, and the surface pattern in the copolymer films could transform reversibly between bicontinuous and island structure by UV irradiation and upon storage in the dark. This work proposes a new method of photoinduced controlling and designing the dewetting processes of thin films using linear block copolymer.

2 Experimental

2.1 Materials and methods

Methyl methacrylate (MMA) andn-butyl methacrylate (nBMA) were obtained from the Sinopharm Chemical Reagent Co., Ltd., and were distilled under vacuum before polymerization to remove the radical inhibitor. Ethyl 2-bromoisobutyrate (EBiB) (98%), cuprous bromide (CuBr), cuprous chloride (CuCl), and pentamethyl-diethylene triamine (PMDETA, 98%) were purchased from the J&K Chemical Ltd. (Shanghai). CuBr and CuCl are purified according toXue et al. (2002), 4-nitroaniline (98%) was bought from the Alfa Aesar (Tianji). Monomer 6-(4-(phenylazo) benzoate) hexyl methacrylate) (AzoMA) was synthesized according to Yu X. et al. (2006), Yu H. et al. (2008), andLi et al. (2009). All solvents and other regents were purchased from the Sinopharm Chemical Reagent Co., Ltd., and were used as received.

1H NMR (nuclear magnetic resonance) spectra were measured on an Bruker ADVANCE DMX spectrometer (Germany) operating at 400 MHz. Spectra were run in deuterated chloroform or dimethyl sulfoxide using tetramethylsilane as a reference. Gel permeation chromatograghy (GPC) was performed on the Agilent Technologies PL-GPC-220 (USA) equipped with three mixed Agilent PL gel MIXED-B column (10 μm particle size). Tetrahydrofuran (THF) was used as eluent at a flow of 1.0 ml/min at 30 °C. The thermostability of the polymer films were performed using the PerkinElmer Pyris 1 thermogravimetric analysis (TGA, Shanghai). UV/Vis spectroscopy was recorded using the UNICO UV-3802 UV/Vis spectrophotometer (Shanghai). The film thickness was determined by spectroscopic ellipsometry (ESM-300, J. A. Woollam Co., Inc.). The UV light (365 nm, 5 mW/cm2) was emitted by FC-100 UV lamp produced by the USA SP Industries, Inc.

2.2 Synthesis of macroinitiator (PMMA-Br) for ATRP

Anisole and MMA were bubbled with argon for 30 min to remove oxygen before polymerization. CuCl (90 mg, 0.90 mmol) and copper chloride (CuCl2) (18.4 mg, 0.14 mmol) were added into a dried Schlenk flask. The flask was sealed, degassed, and filled with nitrogen three times. PMDETA (0.22 ml, 1.05 mmol), EBiB (0.13 ml, 1.04 mmol), MMA (14 ml, 0.13 mol), and 14 ml anisole were added into that dried Schlenk flask via syringes that had been purged with nitrogen. The flask was degassed and charged with dried nitrogen by three freeze-pump-thaw cycles. After being stirred for 5 min at room temperature, the solution in the Schlenk flask was heated to 60 °C for a suitable time. When the reaction finished, the mixing solution was quenched by cooling in liquid nitrogen and opened to the air before diluting with THF. The products were isolated by passage through a column of neutral alumina following precipitation in cold methanol. Lastly, the polymer was dried at 45 °C in a vacuum oven for 24 h (You et al., 2010).

2.3 Synthesis of copolymer PMMA-b-(PnBMA-co-PAzoMA)

The macroinitiator PMMA-Br (0.25 g, 0.019 mmol), methacrylate monomer containing azobenzene (47 mg, 0.13 mmol), and CuBr (3.0 mg, 0.021 mmol) were added into a dried Schlenk flask. The flask was sealed, degassed, and filled with nitrogen three times. Then PMDETA (5 μl, 0.024 mmol),nBMA (0.7 ml, 4.4 mmol), and 0.8 ml anisole were added into that dried Schlenk flask via syringes that had been purged with nitrogen. The resultant solution was degassed and charged with nitrogen by three freeze-pump-thaw cycles. After stirred for 5 min at room temperature, that solution was stirred at 70 °C for 10 h. When the reaction finished, the mixing solution was cooled down in the liquid nitrogen and open to the air before diluting with THF. The crude products in the flask were isolated by passage through a column of neutral alumina following precipitation in cold methanol. Finally, the polymer was dried at 45 °C in vacuum oven for 24 h (Shipp et al., 1998;Roos and Muller, 1999;Davis and Matyjaszewski, 2000).

2.4 Preparation of copolymer thin film

The silicon wafers were treated with ultrasonication in ethanol and acetone for a few minutes each before being dried in the oven. The block copolymers were dissolved in toluene and produced 4–7 mg/ml solutions. The solutions of the copolymer were spin-coated on cleaned silicon wafers and then the substrates coated with block polymers were dried at room temperature overnight to remove residual solvent. The polymer film was annealed in an oven at 180 °C for 14 h prior to observation by the atomic force microscope (AFM) (Sriprom et al., 2009).

2.5 Observation of the microphase separation structure by AFM

The surface morphologies of the block copolymer films were characterized with multi-mode scanning probe microscope under tapping mode at ambient atmospheric conditions. The used probes were bought from the Veeco Instruments, Inc.

3 Results and discussion

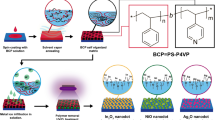

The diblock copolymers PMMA-b-(PnBMA-co- PAzoMA) containing azo-benzene were synthesized via ATRP. Macroinitiator PMMA were prepared by ATRP and used to initiate co-polymerization of monomernBMA and AzoMA, as shown inScheme 1. The molecular weight and polydispersity of macroinitiator PMMA and copolymer PMMA-b-(PnBMA-co-PAzoMA) were characterized by GPC and the results are shown inFig. 1. Two types of PMMA macroinitiators were prepared with different molecular weights. Compared with the peak of each PMMA block, the shift of the peak of the block copolymers to higher molecular weights indicates successful block copolymerization, as shown inFig. 1.

In addition, the characteristic shoulders on the peak of copolymers MBAzo-2 and MBAzo-3 indicated the presence of PMMA “dead” chains in the block copolymers. The structures of these three block copolymers were characterized by1H NMR spectra, and the related results are shown respectively in the supporting materials. In the1H NMR spectrum of the copolymer MBAzo-1, the characteristic peaks at 6.9–9.0 ppm were attributed to the hydrogen atoms in the phenyl rings in azobenzene units, which indicated the suc-cessful introduction of azobenzene into the copolymers. In addition, the characteristic peaks at 3.5 and 3.9 were from PMMA (-OCH3) and PnBMA (-OCH2). The results from1H NMR and GPC indicated that the desired copolymers were successfully synthesized.

The results of GPC and1H NMR, the number-average molecular weight (M n), polydispersity index (PDI), and block compositions of the synthesized copolymers PMMA-b-(PnBMA-co-PAzoMA) are presented inTable 1.

The thermal annealing process above the glass transition temperature of two blocks allows for the mobility of the polymer chains. Prior to the annealing, the thermostabilities of these copolymers were investigated by TGA and the results are shown inFig. 2. It was found that these block copolymers started to decompose above 230 °C, which confirmed that the block copolymer films maintained its integrity during annealing at 180 °C.Fig. 3 shows the AFM topography phase images of the annealed MBAzo-3 thin film with a thickness of 48.8 nm. The morphology was characterized by a mixture of randomly distributed stripes and dot shaped structures. The diameter of the dot shaped structures and the width of those stripe like structures were about 700–800 nm. The corresponding 3D morphology image of the annealed film is shown inFig. 3b. Judging by the shapes and sizes of these surface structures, it can be inferred that these structures arose from the dewetting process of the surface copolymer layer. When the film thickness is thinner than the characteristic thickness, the film becomes unstable; holes/islands pattern are formed spontaneously and randomly distributed on the surface of the unstable film. Sometimes, bicontinuous spinodal-like patterns are also formed (Segalman and Green, 1999;Green and Limary, 2001).

The annealed MBAzo-3 copolymer films with different thicknesses were prepared and observed by AFM (Fig. 4). Different morphologies appeared on the surface of the thin film, which were dependent on the film thickness. When film thickness decreased from 48.8 nm to 28.0 nm, bicontinuous topography transferred to the island pattern before these clear morphologies disappeared completely.

Fig. 5 shows the cross-section of the MBAzo-3 films with thicknesses of 48.8 nm, 45.1 nm, and 36.2 nm, respectively. The height differences from the top to the bottom of the surface structures such as rod shaped or dotted structures were 28.8 nm, 35.1 nm, and 34.3 nm, respectively. The film thinness is larger than the height difference of these surface structures. It was inferred that there was an underlying layer under the surface layer with particular pattern. The film on the substrate displayed lamellar structures. If the film with thicknessh 0 is stable and the surface is smooth, the surface layer becomes unstable in the film with thicknessh>h 0. The surface layer of thicknessh−h 0 will dewet on the underlying layer ofh 0 and the surface pattern will evolve into a pattern consisting of holes or bicontinuous spinodal like structures (Green and Limary, 2001). Thus, it was found that these surface patterns were formed by the dewetting processes of the surface copolymer layer occurring on the underlying layer.

AFM height images (10 μm ×10 μm) and corresponding cross-sectional profiles of MBAzo-3 thin films with thicknesses of 48.8 nm (a), 45.1 nm (b), and 36.2 nm (c), respectively. The height differences of the surface structures marked in the height images were 28.8 nm (a), 35.1 nm (b), and 34.3 nm (c), respectively

The light induced photoisomerization of azobenzene in the polymer can be used to modulate the surface morphology of the polymer film. Thus, the photoresponsive behaviors of the annealed film of these block copolymer films at ambient atmosphere were studied.Fig. 6 shows the UV/Vis absorption spectra of block copolymer MBAzo-3 annealed thin film before and after 365 nm UV light irradiation for 90 s. After irradiated with 365 nm UV light, thetrans-isomer of azobenzene units in the copolymer film transferred to thecis-isomer, and the characteristic absorption peak at 347 nm ascribed to the π-π* transition oftrans-isomer azobenzene decreased after UV light irradiation. Additionally, another weak absorption peak at 450 nm ascribed to n-π* transition ofcis-isomer azobenzene increased slightly (Jin et al., 2010). Therefore, the photoisomerization of azobenzene units in the copolymer films proceeded normally by UV or visible light irradiation (or storage in the dark).

The surface pattern before and after UV light irradiation were also observed by AFM.Fig. 7 shows the AFM topographical images of block copolymer MBAzo-3 film with a 28.3% PMMA segment before and after UV irradiation. The surface pattern in the copolymer film wherein azobenzene units were in thetrans state before exposure to the UV light shows a bicontinuous topography, as shown inFig. 7a. After UV irradiation (365 nm, 0.9 J/cm2), the initial bicontinuous morphology was converted to a mixed pattern consisting of dotted and short rod shaped structures accompanied with photoisomerization of azobenzene units from atrans tocis state, as shown inFig. 7b. The corresponding 3D topographical images are shown inFigs. 7c and 7d. The feature sizes of the surface structures were clearly reduced. Subsequently, this MBAzo-3 film exposed to UV light inFig. 7b was kept in the dark room at room temperature for a week. While being left in the dark, the azobenzene units in the film transferred from acis totrans state induced by thermal effect. Moreover, the mixed morphology consisting of dotted and short rod shaped domains reverted to the initial bicontinuous structures. Thus, the morphological conversion was reversible under UV irradiation and storage in the dark room at ambient atmospheric conditions. The height differences along the black line marked inFig. 7 were also analyzed. The height difference of these surface structures increased slightly from 34.1 nm to 37.7 nm, which indicated the mass migration induced by light irradiation.

Fig. 8 shows the AFM height images of MBAzo-1 annealed thin films upon UV light irradiation. The volume fraction of PMMA block in the copolymer was 68.2%. Before exposure to the UV light, the surface of the annealed MBAzo-1 film displayed bicontinuous topography as shown inFig. 8a. After 100 s of UV irradiation at 365 nm, there were no obvious changes in the surface patterns (Fig. 8b). When exposed to the UV light for 220 s, the length of the rod shaped structures marked with yellow (in the web version) became shorter, as shown inFig. 8c. Moreover, the relatively high domains marked with yellow dispersed in the film surface instead of remaining in the initial bicontinuous phase. The photoresponsive behaviors of the surface morphology of copolymer MBAzo-2 film were also investigated by AFM and the height images are shown inFig. 9. The volume fraction of PMMA block in the copolymer MBAzo-2 was 57.2%. Compared with MBAzo-1 with a higher volume of PMMA block, the surface pattern of MBAzo-2 annealed film exhibited photo-responsive conversion when exposed to the UV light and kept in the dark room. Upon UV light irradiation, the initial bicontinuous topography transferred to the mixed pattern consisting of short rod shaped and dotted structures. However, compared with MBAzo-3 which contained the smallest volume fraction of PMMA block (28.3%), there were more rod shaped structures, and the lengths of some rod shaped structures were larger in the MBAzo-2 film than the case of MBAzo-3.

Based on different photoresponsive behaviors in these three copolymer films, the UV light induced mor-phology conversion had a close relationship with the volume fraction of PMMA or PnBMA block in the copolymer. When the volume fraction of PnBMA blocks in the copolymer was limited within a reasonable range, the block copolymer film exhibited photoresponsive morphology conversion. The photoi-somerization of azobenzene units in the copolymer films may have changed the interaction between the two blocks or interfacial tensions in air/polymer film/substrate. Furthermore, the film equilibrium thickness for stabilizing the film was changed in the isomerization of azobenzene units betweentrans andcis states. As such, the surface layer in the copolymer film would rupture and form different patterns (Green and Limary, 2001).

4 Conclusions

Three types of azobenzene-containing block copolymers with different block volume fractions were prepared by ATRP. These block copolymers were spin-coated on silicon substrates or a quartz plate before annealing at 180 °C for 14 h. After annealing, surface patterns in the copolymers films were observed by AFM. The morphologies of these annealed copolymer films displayed bicontinuous stripe or island patterns dependent on the film’s thickness.

The height differences from the top to the bottom of the surface structures were almost the same in every kind of surface morphology. It was thought that these surface patterns arose from the dewetting process of surface polymer layer in the films. When the film is thinner than the characteristic film thickness, the film will become unstable. Moreover, bicontinuous spinodal-like or holes/islands pattern are formed spontaneously and randomly distributed on the surface of the unstable film.

Additionally, the reversible morphological conversion between bicontinuous and island structures was observed when irradiated with UV light and stored in the dark. Based on different photoresponsive behaviors shown by the films of these three block copolymer samples, it was found that the composition of block copolymer had important influences on the photoinduced morphology conversion behaviors in these thin films. When the volume fractions of PnBMA and PAzoMA phases in the block copolymer were limited within a reasonable range, the interactions between two blocks or interfacial tensions in air/polymer film/substrate were obviously changed by the photoisomerization of azobenzene units in the copolymer. This work supplied a method to modulate surface morphologies of linear block copolymer thin films based on controlling dewetting behaviors by light.

References

Aoki, K., Iwata, T., Nagano, S., Seki, T., 2010. Light-directed anisotropic reorientation of mesopatterns in block copolymer monolayers.Macromolecular Chemistry and Physics,211(23):2484–2489. [doi:10.1002/macp.201000474]

Davis, K.A., Matyjaszewski, K., 2000. Atom transfer radical polymerization of tert-butyl acrylate and preparation of block copolymers.Macromolecules,33(11):4039–4047. [doi:10.1021/ma991826s]

Green, P.F., Limary, R., 2001. Block copolymer thin films: pattern formation and phase behavior.Advances in Colloid and Interface Science,94(1-3):53–81. [doi:10.1016/S0001-8686(01)00055-0]

Han, D., Tong, X., Zhao, Y., Zhao, Y., 2010. Block copolymers comprising π-conjugated and liquid crystalline subunits: induction of macroscopic nanodomain orientation.Angewandte Chemie International Edition,49(48):9162–9165. [doi:10.1002/anie.201004445]

Jin, Q., Liu, G., Liu, X., Ji, J., 2010. Photo-responsive supramolecular self-assembly and disassembly of an azobenzene-containing block copolymer.Soft Matter,6(21):5589–5595. [doi:10.1039/C0SM00428F]

Kadota, S., Aoki, K., Nagano, S., Seki, T., 2005. Photocontrolled microphase separation of block copolymers in two dimensions.Journal of the American Chemical Society,127(23):8266–8267. [doi:10.1021/ja051200j]

Kadota, S., Aoki, K., Nagano, S., Seki, T., 2006. Morphological conversions of nanostructures in monolayers of an ABA triblock copolymer having azobenzene moiety.Colloids and Surfaces A: Physicochemical and Engineering Aspects,284-285(1):535–541. [doi:10.1016/j.colsurfa.2005.10.081]

Kim, J.K., Han, C.D., 2010. Phase behavior and phase transitions in AB- and ABA-type microphase-separated block copolymers.Advances in Polymer Science,231(15):77–145. [doi:10.1007/12_2009_20]

Li, C., Lo, C., Zhu, D., Li, C., Liu, Y., Jiang, H., 2009. Synthesis of a photoresponsive liquid crystalline polymer containing azobenzene.Macromolecular Rapid Communications,30(22):1928–1935. [doi:10.1002/marc.200900421]

Li, W., Dohi, T., Hara, M., Nagano, S., Haba, O., Yonetake, K., Seki, T., 2012. Phototriggered mass migration consorted with surface dewetting in thin films of a liquid crystalline azobenzene-containing dendrimer.Macromolecules,45(16):6618–6627. [doi:10.1021/ma301170x]

Limary, R., Green, P.F., 1999. Dewetting instabilities in thin block copolymer films: nucleation and growth.Langmuir,15(17):5617–5622. [doi:10.1021/la981693o]

Lu, Z., Liu, Y., Hu, W., Lou, X., Li, C., 2011. Rewritable multicolor fluorescent patterns for multistate memory devices with high data storage capacity.Chemical Communications,47(34):9609–9611. [doi:10.1039/c1cc13448e]

Ma, M., He, Z., Yang, J., Wang, Q., Chen, F., Wang, K., Zhang, Q., Deng, H., Fu, Q., 2011. Vertical phase separation and liquid-liquid dewetting of thin PS/PCL blend films during spin coating.Langmuir,27(3):1056–1063. [doi:10.1021/la104003p]

Morikawa, Y., Kondo, T., Nagano, S., Seki, T., 2007. Photoinduced 3D ordering and patterning of microphase-separated nanostructure in polystyrene-based block copolymer.Chemistry of Materials,19(7):1540–1542. [doi:10.1021/cm0630845]

Okano, K., Mikami, Y., Hidaka, M., Yamashita, T., 2011. Photoresponsive liquid-crystalline polymers containing a block mesogenic side chain: systematic studies on structural parameters for nanophase-separated structures.Macromolecules,44(14):5605–5611. [doi:10.1021/ma200558t]

Reiter, G., Auroy, P., Auvray, L., 1996. Instabilities of thin polymer films on layers of chemically identical grafted molecules.Macromolecules,29(6):2150–2157. [doi:10.1021/ma950297z]

Roos, S.G., Muller, A.H.E., 1999. Copolymerization ofn-butyl acrylate with methyl methacrylate and PMMA macromonomers: comparison of reactivity ratios in conventional and atom transfer radical copolymerization.Macromolecules,32(25):8331–8335. [doi:10.1021/ma9819337]

Ruzette, A.V., Girault, S.T., Leibler, L., 2006. Molecular disorder and mesoscopic order in polydisperse acrylic block copolymers prepared by controlled radical polymerization.Macromolecules,39(17):5804–5814. [doi:10.1021/ma060541u]

Segalman, R.A., Green, P.F., 1999. Dynamics of rims and the onset of spinodal dewetting at liquid/liquid interfaces.Macromolecules,32(3):801–807. [doi:10.1021/ma981208w]

Sehgal, A., Ferreiro, V., Douglas, J.F., Amis, E.J., Karim, A., 2002. Pattern-directed dewetting of ultrathin polymer films.Langmuir,18(18):7041–7048. [doi:10.1021/la020180l]

Seki, T., 2006. Photoresponsive self-assembly motions in polymer thin films.Current Opinion in Solid State and Materials Science,10(5–6):241–248. [doi:10.1016/j.cossms.2007.08.002]

Seki, T., Kojima, J., Ichimura, K., 1999. Light-driven dot films consisting of single polymer chain.The Journal of Physical Chemistry B,103(47):10338–10340. [doi:10.1021/jp992062l]

Shipp, D.A., Wang, J.L., Matyjaszewski, K., 1998. Synthesis of acrylate and methacrylate block copolymers using atom transfer radical polymerization.Macromolecules,31(23): 8005–8008. [doi:10.1021/ma981033q]

Sriprom, W., James, M., Perrier, S., Neto, C., 2009. Ordered microphase separation in thin films of PMMA-PBA synthesized by RAFT: effect of block polydispersity.Macromolecules,42(8):3138–3146. [doi:10.1021/ma9004428]

Sriprom, W., Neto, C., Perrier, S., 2010. Rapid photochromic nanopatterns from block copolymers.Soft Matter,6(5): 909–914. [doi:10.1039/B920133E]

Thompson, C.V., 2012. Solid state dewetting of thin films.Annual Review of Materials Research,42:399–434. [doi:10.1146/annurev-matsci-070511-155048]

Tokarczyk, K.K., Junginger, M., Belegrinou, S., Taubert, A., 2011. Amphiphilic polymers at interfaces.Advances in Polymer Science,242(5):151–201. [doi:10.1007/12_2010_58]

Wang, X., Goswami, M., Kumar, R., Sumpter, B.G., Mays, J., 2012. Morphologies of block copolymers composed of charged and neutral blocks.Soft Matter,8(11):3036–3052. [doi:10.1039/C2SM07223H]

Xue, L., Agarwal, U., Lemstra, P., 2002. High molecular weight PMMA by ATRP.Macromolecules,35(22):8650–8652. [doi:10.1021/ma020905s]

Yan, D., Huang, H., Tian, H., Zhang, F., 2011. Coupling of microphase separation and dewetting in weakly segregated diblock co-polymer ultrathin films.Langmuir,27(19):11973–11980. [doi:10.1021/la202379b]

You, J., Yoon, J.A., Kim, J., Huang, C., Matyjaszewski, K., Kim, E., 2010. Excimer emission from self-assembly of fluorescent diblock copolymer prepared by atom transfer radical polymerization.Chemistry of Materials,22(15): 4426–4434. [doi:10.1021/cm1011026]

Yu, H., Iyoda, T., Ikeda, T., 2006. Photoinduced alignment of nanocylinders by supramolecular cooperative motions.Journal of the American Chemical Society,128(34): 11010–11011. [doi:10.1021/ja064148f]

Yu, X., Luo, Y., Deng, Y., Yan, Q., Zou, G., Zhang, Q., 2008. Synthesis and properties of thermally cross-linkable main-chain azobenzene polymers containing diacetylene moieties.European Polymer Journal,44(3):881–888. [doi:10.1016/j.eurpolymj.2007.12.003]

Zhang, J., Yu, X., Yang, P., Peng, J., Luo, C., Huang, W., Han, Y., 2010. Microphase separation of block copolymer thin films.Macromolecular Rapid Communications,31(7): 591–608. [doi:10.1002/marc.200900541]

Zhao, Y., He, J., 2009. Azobenzene-containing block copolymers: the interplay of light and morphology enables new functions.Soft Matter,5(14):2686–2693. [doi:10.1039/B821589H]

Zhao, Y., Tong, X., Zhao, Y., 2010. Photoinduced microphase separation in block copolymers: exploring shape incompatibility of mesogenic side groups.Macromolecular Rapid Communications,31(11):986–990. [doi:10.1002/marc.200900892]

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the Natural Science Foundation of Zhejiang Province (No. Y4110187), the State Key Laboratory of Chemical Engineering (No. SKL-ChE-11D04), and the Fundamental Research Funds for the Central Universities (No. 2013FZA4019), China

Rights and permissions

About this article

Cite this article

Zhang, L., Wang, L. & Yu, Hj. Surface pattern based on an azobenzene-containing copolymer thin film and its light-driven morphology modulation. J. Zhejiang Univ. Sci. A 14, 504–513 (2013). https://doi.org/10.1631/jzus.A1300119

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A1300119

Key words

- Dewetting behavior

- Photoinduced morphology modulation

- Atom transfer radical polymerization (ATRP)

- Block copolymer