Abstract

Compressive strength of grouted concrete masonry is an important parameter to design reinforced/grouted concrete masonry walls. The design standards stipulate two methods to determine the compressive strength of masonry (1) using tabulated unit strength and mortar type, and (2) testing representative masonry prisms. The compressive strength prediction of grouted concrete masonry is influenced by compressive strength values of hollow blocks, mortar and grout, and their geometries. Therefore, a multi-level approach was employed in this study to improve the existing unit strength correlations of the standards for more reliable prediction of compressive strengths of grouted concrete masonry. The existing methods to determine the compressive strength of grouted masonry were critically appraised and a database of compression tests of grouted concrete masonry prisms/wallettes was developed. This database was then used to evaluate the correlations between the compressive strengths of block, mortar, grout and masonry. The applicability of existing unit strength correlations from the design standards and literature were assessed and their relevancy and limitations are highlighted. Subsequently, updated sets of unit strength correlations are proposed in this study, through statistical reliability analyses of the predictions against the experimental results included in the database. The proposed unit strength correlations were classified according to the mortar type/strengths (≤ 10 MPa and > 10 MPa). It has been shown that the new correlations are more structurally reliable than the existing unit strength correlations through comparing the 95th percentile error values.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Compressive strength is the most important parameter in designing of masonry under different effects such as axial compression, in-plane and out-of-plane shear/flexure. However, the compressive strength of masonry is dependent on many factors such as masonry unit characteristics (geometry and mechanical properties), mortar properties (thickness, bedding pattern and mechanical properties) and bonding characteristics between unit and mortar. Many studies have been conducted to correlate the compressive strengths of masonry to these influencing parameters in the past [1,2,3]. Consequently, two approaches are employed in the design standards to determine the compressive strength of masonry (1) through testing representative masonry assemblages (prisms or wallettes) under compression, and (2) using tabulated correlations, which are based on the unit strengths and mortar classes [4,5,6].

The masonry walls should be reinforced in the cyclonic and seismic regions, which is usually achieved by using hollow blocks for inserting reinforcement in the cementitious grout fill. For designing of these walls, masonry compressive strength is of primary importance. In grouted masonry, the strength and deformation properties of grout also influence the compressive strength, along with other parameters mentioned before [7,8,9]. Therefore, determination of compressive strength of grouted masonry is more complex than un-grouted masonry. Similar to un-grouted masonry, the compressive strength of grouted masonry can also be determined either from representative testing or tabulated values provided in the design standards. The tabulated values given in Canadian (CSA S304.1–14 [5]) and American (TMS 402/602–08 [6]) masonry standards to determine the compressive strengths of grouted masonry assemblages are summarised in Table 1. It can be noted that the grouted masonry strengths are correlated to the specified compressive strength/characteristic of units and mortars (Types S, M and N), regardless of grout strength used in the masonry.

Several studies have been conducted to assess the influence of grout strengths to the compressive strengths of grouted concrete masonry in the last four decades [7, 10,11,12]. Drysdale and Hamid [12], investigated the compressive strengths of grouted concrete masonry by varying block, mortar and grout properties, and a similar study was recently conducted by Martins et al. [13]. The main difference between these two studies were the type of tested masonry prisms. Three courses high prisms were tested in Drysdale and Hamid [12], whereas two courses high prisms were tested in Martins et al. [13]. Moreover, Fonseca et al. [14] stated that for grouted concrete masonry, high-strength blocks (> 40 MPa) were not efficient for improving the compressive strengths, as the grouted masonry prisms made of medium-strength blocks (> 25 MPa) also showed similar strengths. Rahman and Galal [15], tested the influence of pre-wetting of blocks and usage of non-shrink grout to the compressive strength of grouted masonry. Their results showed that grouting of wet prisms exhibited a significant increase in the compressive strength of grouted masonry. Hence, good execution of grouted masonry including pre-wetting is emphasised. Leite et al. [16], have used an extensive experimental data of grouted concrete masonry to estimate the compressive strengths. Some other studies [16,17,18] have also studied the axial compression stress–strain behaviour of grouted masonry prisms.

Although several studies have assessed the characteristics of grouted masonry under compression, limited attempts have been made to establish appropriate correlations between the block/mortar/grout types and the compressive strength of grouted masonry. The availability of such reliable strength correlations would eliminate the need for testing of grouted prisms at site, which in turn reduce to the cost and time of constructing walls. Fortes et al. [17], investigated the relationship between unit strengths and compressive strengths of grouted concrete masonry, and proposed a set of equations using statistical regression analyses to determine the compressive strength of grouted masonry from unit strengths. Ross and Korany [18], updated the correlations given in CSA S304.1–14 [5] by calibrating them through the experimental data gathered from different testing campaigns, consisting of 192 datasets of grouted concrete masonry assemblages. Thompson et al. [19], re-evaluated the correlation between unit and un-grouted masonry strengths given in CSA S304.1–14 [5] and proposed a new set of correlation between them. It is generally perceived that the existing unit strength correlations in the design standards are over-conservative [20, 21] and are based on old experimental data. Therefore, updated relations are needed to account for all influencing parameters using the data from latest studies. Moreover, the structural reliability of the available and new correlations of masonry compressive strengths should be verified, for safe and appropriate design [22].

In this study the existing correlations between the constitutive properties (i.e. unit, mortar and grout) and compressive strengths of grouted masonry have been evaluated systematically and new sets of correlations are proposed. An experimental database was developed to analyse and establish updated correlations between grouted masonry compressive strengths and block strengths. The developed database was analysed to verify the existing correlations between unit, mortar, grout and masonry strengths. Consequently, structural reliabilities of these correlations were evaluated through a statistical method, and then an updated sets of strength correlations are proposed. Section 2 explains existing methods to determine the compressive strengths of grouted masonries given in literature, and the design standards. The details of experimental database created is outlined in Sect. 3. The outcomes of the analyses of the database pertaining to the correlations between constitutive properties and compressive strength of grouted masonry are presented in Sect. 4. In Sect. 5, the approach followed to statistically analyse the correlations and the updated unit strength correlations are provided with the confirmations of their accuracies. The structural reliabilities of the proposed unit strength correlations are also reported in this section.

2 Available correlations to predict the grouted masonry strength

The existing provisions to determine the compressive strength of grouted masonry from the design standards and literature were appraised to verify their consistency. The CSA S304.1–14 [5] provides a tabulated unit strength method to predict the compressive strengths of grouted masonry, in the absence of representative experimental results. The specified compressive strengths (of blocks and grouted masonry), were determined from mean and standard deviations of the testing results as per Eq. (1). The s is the standard deviation to be taken as 10% coefficient of variation (COV) or higher, which is related to the variations of the testing results. It can be seen from Table 1, that the specified compressive strength values proposed by Ross and Korany [18] slightly differ from the CSA S304.1–14 [5], particularly higher compressive strength values are given for N type mortar, than in CSA S304.1–14 [5]. The recommended minimum grout strengths as per CSA S304.1–14 [5] range between 10 to 12 MPa, however it has to be similar to the block strength used. The volume mix ratios specified for the masonry mortar types are given in Table 2, with only certain types of mortars are specified for grouted and reinforced masonry constructions.

TMS 402/602–16 [6] also allows to use unit strength method or representative prism testing of grouted masonry assemblages with three different mortar types (S, M and N) as listed in Table 1, which are based on specified block and masonry strengths. The main difference between CSA S304.1–14 [5] and TMS 402/602–16 [6], is the way the tabulated values are given. In TMS 402/602–16 [6], the variation of block strengths with different mortar types used (M, S and N) are shown, whereas in CSA S304.1–14 [5], the variation of grouted masonry strengths corresponded to different mortar types are given. The minimum and maximum specified compressive strengths of grout that should be used in masonry are 13.8 MPa (2000 psi) and 34.5 MPa (5000 psi). The block and masonry specified strengths values given in TMS 402/602–16 [6], are for the net area, regardless of grouted, partially grouted or un-grouted masonry. This implies that the grout strengths are not explicitly considered, when determining the compressive strength of grouted masonry, as far as the grout strengths used in the masonry complies within the minimum and maximum values stipulated.

Moreover, Fortes et al. [17], conducted series of testing using different block, mortar and grout strengths combinations, specifically block strengths up to 70 MPa, which was used to construct and test grouted masonry prisms. Subsequently, a logarithmic function as given in Eq. (2) was proposed to determine the characteristic compressive strengths of grouted masonry.

The AS 3700 [4], does not provide tabulated values to determine the compressive strength of grouted masonry, instead a formulation is available to compute the compressive capacity of grouted masonry as shown in Eq. (3). In this formulation, the contributions of masonry and grout are separately included. For concrete masonry, only M3 structural mortar type is recommended in AS 3700 [4], and its volume mix ratio is given in Table 2. The formulation given in Eq. (3), was calibrated using an experimental dataset of reinforced concrete masonry walls tested under axial compression, and those details are provided in Zahra et al. [23], and Thamboo et al. [21]. AS 3700 [4] also states that the grout strength in the masonry should be at least 12 MPa.

where, fm and fcg are the characteristics compressive strengths of un-grouted masonry and grout, respectively. Kc is strength factor for grout in compression, which is recommended as 1.4 for grouted concrete masonry. It can be inferred that the unit strength correlations given in the standards slightly differ from each other, whereas AS 3700 [4] provides a completely different approach to determine the compressive strength of grouted masonry. Therefore, the applicability of existing correlations should further be verified, for development of more appropriate design correlations to determine the compressive strength of grouted masonry. The minimum grout strengths are mandated in the standard for grouted masonry to avoid early cracking of blocks under compression. It was observed in the past studies that, when grout strength lower than block strength was used, early cracking was observed in the face-shells of the blocks due to incompatible expansion of the grout [11, 24].

3 Experimental database

An experimental database of grouted masonry prisms/wallettes tested under axial compression was developed in this study to comprehend the correlations between the compressive strengths of grouted masonry and other parameters (strength and geometrical properties of block, mortar and grout). This database was then employed to update the existing correlations for improved prediction of the compressive strength of grouted masonry. Experimental results from 44 studies were collected in this research, which resulted in 291 datasets of grouted masonry tested under axial compression. The data collected in this study, consists of compressive strengths of grouted masonry, outer geometries of block, mortar thickness, masonry test sample type (prism and wallettes), and strength properties of these constitutive materials. Figure 1 shows the outlook of the information gathered in the database. The list of experimental studies considered, and number of datasets collected from those studies are given in Table 3. The complete database is provided in Online Appendix. Summary of the datasets in terms of main parameters that influence the compressive strength of grouted masonry is given in Table 4. Therefore, it must be noted that the analyses carried out in this paper are limited to the ranges of block, mortar and grout strengths, and their geometries given in Table 4.

The masonry compressive strengths determined through the experimental testing should be corrected according to their height to thickness (h/t) ratio using the correction factors specified in different testing standards such as ASTM C1314-18 [58], AS 3700 [4], and CSA S304.1–04 [5]. The h/t ratios of grouted masonry in the database varied between 2.0 to 7.1, where most of the data points fell between 2.0–4.0 range. The aspect ratios (h/l) of the masonry also affects the compressive strength of masonry assemblage tested, due to platen effect, which requires corrections in the strength values. These dimensions are marked on the schematic diagrams of grouted prisms and wallettes (Fig. 2). However, the above mentioned standards do not incorporate these correction factors, although this aspect is highlighted in the past studies [58, 59]. Subsequently, the compressive strength of grouted masonry in the database were corrected according to the h/t and h/l ratios. The h/t corrections were carried out as per the method outlined in Zahra et al. [60].

The type of masonry assemblages tested (prism or wallette) also influence the compressive strengths obtained. The prisms are made of stack bonded assemblages, whereas the wallettes have prepend joints with full and half blocks. Out of 291 datasets gathered, 222 experimental testing results corresponded to prisms and the rest were derived through testing of masonry wallettes. It is well known that the prism testing results tend to show higher compressive strengths than corresponding wallettes tested with same constitutive materials and outer geometry used [61, 62]. This phenomenon is not due to the platen effect or different h/t or h/l ratios, rather due to the presence of perpend joints in the wallette masonry assemblage. Therefore, corrections must be applied to compare these two different sets of compression test results. To apply this correction, the wallette strengths were divided by a factor of 0.9 to convert them to prism strength as suggested in Thamboo and Dhanasekar [63]. To maintain further consistency, all the compressive strength results were converted to prism testing results according to the method outlined in Thamboo and Dhanasekar [63], since most of the masonry design standards (AS3700 [4], CSA S304.1–04 [5] and TMS 402/602–08 [6]) use prism results for the site verification and design.

In the developed experimental database, the compressive strengths of mortars were determined through various testing methods such as 50 mm cubes (as per ASTM C109 / C109M–20a [64]), 70 mm cubes (as per ASTM C780–19 [65]), 160 mm × 40 mm prisms (as per BS EN 1015–11 [66], and 100 mm × 200 mm mortar cylinders by the researchers. It is obvious, that the compressive strengths determined through these different testing methods cannot be directly compared and require corrections for consistent comparison [67, 68]. The relationships provided in Lakshani et al. [69] were used to covert the mortar strength determined through different testing method to cylinder testing method. Though there is a slight deviation in the testing method followed in Lakshani et al. [69] to test 160 mm × 40 mm prism halves under axial compression, these empirical correlations between different types of mortar testing methods were employed to convert all datasets to 100 mm × 200 mm mortar cylinders. To determine the compressive strengths of grouts, 100 mm × 200 mm cylinders and 150 mm cube specimens have been used in the past. To make uniform comparisons between the grout strengths determined, all the values were converted to 100 mm × 200 mm cylindrical strength as per the EN 1992–1-1 [70], by using the correction factor of 0.92 to convert the 150 mm cube strengths into cylindrical strengths. Subsequently, these corrected compressive strength values were used to further assess the correlations between the compressive strengths of grouted masonry and its constitutive materials used.

4 Analysis of database

The database was analysed to comprehend the correlations between the compressive strengths of grouted masonry and the compressive strengths of constitutive materials (block, mortar and grout). Figure 3 shows the correlations between the compressive strengths of grouted masonry and compressive strengths of blocks (Fig. 3a), grout (Fig. 3b) and mortar (Fig. 3c). It can be noted that the grouted masonry compressive strengths increased with the increase in compressive strengths of block, mortar and grout used. Dispersions in the trends are apparent as the datasets comprised of diverse experimental results from different experimental campaigns, workmanship and execution levels. Although limited datasets are available for block strengths more than 40 MPa, the increase in block strength tended to increase the grouted masonry strength in general. This could be the reason that an upper threshold of 40 MPa for blocks given in the standards (as shown in Table 1) seem rational.

A linear trend between the compressive strengths of grouted masonry and grout strength was observed. This affirms the findings of Zahra et al. [23], where the grout strength dominated the axial capacity of grouted or reinforced masonry walls. This comparison shows that the contribution of grout strengths should be considered in determining the compressive strengths of grouted masonry. However, existing provisions in the standards, do not explicitly account for the grout strength in computing the compressive strength of masonry (as shown in Table 1, the masonry strengths have only been correlated to block and mortar types), presumably to simplify the design. Only, AS 3700 [4], separately incorporates grout strength to determine the axial capacity of grouted masonry or reinforced masonry walls.

To further verify the relevancy of existing correlations between the compressive strengths of grouted masonry and the block and mortar types, the database was divided into two categories based on the mortar types/strengths. CSA S304.1–14 [5] and TMS 402/602–16 [6] specify that the mortar classes of S and N can be used in grouted/reinforced masonry. The AS 3700 [4], specify that the mortar classes of M3 and M4 for grouted/reinforced masonry must be used. S, N, M3 and M4 mortar classes in these standards correspond to volume ratios of mixes as shown in Table 2. Although, a relation between mortar mix ratios and their compressive strengths are not explicitly given in the standards (as they can be affected by curing and water to binder ratios used), past studies revealed that these mortar classes can be associated to their compressive strengths [68, 71]. In EN 1996–1-1 [72], 1:5–6 and 1:3–4 mortar mixes correlate to compressive strengths of up to 5–10 MPa and more than 10 MPa strengths, respectively. Subsequently, the datasets were divided into mortar strength categories of less than 10 MPa and more than 10 MPa. The correlations between the compressive strengths of grouted masonry and block strengths are presented in Fig. 4a, b, and the correlations between the grouted masonry strengths and grout strengths are given in Fig. 4c, d.

a Grouted masonry vs block compressive strengths (mortar strength (≤ 10 MPa), b Grouted masonry vs block compressive strengths (mortar strength (> 10 MPa), c Grouted masonry vs grout compressive strengths (mortar strength (≤ 10 MPa), and d Grouted masonry vs grout compressive strengths (mortar strength (> 10 MPa)

It can be noted from Fig. 4, though the datasets were divided into mortar strengths (≤ 10 MPa and > MPa), these trends are similar to what observed in Fig. 3 (between compressive strengths of grouted masonry and blocks/grouts). The correlations suggested in CSA S304.1–04 [5] and TMS 402/602–08 [6] are conservative, as most of the data points are located above the trend line. The updated correlations given in Ross and Korany [18] also follow similar trend with CSA S304.1–04 [5] and TMS 402/602–08 [6] for mortar strengths less than 10 MPa category (see Fig. 4a, c), and deviate for mortar strength more than 10 MPa cases (see Fig. 4b, d)). However, the characteristics compressive strength relationship proposed in Fortes et al. [17], seemed to overestimate the compressive strengths of grouted masonry than those given in CSA S304.1–04 [5] and TMS 402/602–08 [6], where limited test results are explored. Although some of these correlations (e.g. CSA S304.1–04 [5], TMS 402/602–08 [6], and Ross and Korany [18]) have shown to conservatively predict the compressive strengths of grouted masonry, their reliability should further be verified for more precise predictions. The reliability of these correlations were verified and those details are given in the following section.

5 Reliability assessments

The reliability of existing correlations was verified to understand the effectiveness of the compressive strength predictions of grouted masonry. This analysis was also informed the improvements in the existing standards.

5.1 Predictability of existing unit strength correlations

In order to compare the experimental grouted masonry compressive strengths with the available correlations, the mean experimental strengths were converted to specified or characteristic strengths as per Eq. (1). The correlations given in CSA S304.1–14 [5], TMS 402/602–16 [6], and Ross and Korany [18]) require the specified strengths, therefore the mean experimental values were converted accordingly. Figure 5 shows the experimentally determined specified strengths (from Eq. 1) and predicted specified compressive strengths from CSA S304.1–14 [5], TMS 402/602–16 [6], and Ross and Korany [18]) of the grouted masonry cases in the database. It also shows the relation between specified compressive strength of block and specified grouted masonry strengths from the existing correlations.

Comparisons of specified experimental and predicted grouted masonry compressive strengths a CSA S304.1–04 [5] (≤ 10 MPa mortar strength), b CSA S304.1–14 [5] (> 10 MPa mortar strength), c Ross and Korany [20] (≤ 10 MPa mortar strength), d Ross and Korany [20] (> 10 MPa mortar strength), e TMS 402/602–16 [6] (≤ 10 MPa mortar strength) and f TMS 402/602–16 [6] (> 10 MPa mortar strength)

In general, the correlations in CSA S304.1–04 [5], and Ross and Korany [18]) tend to under predict the compressive strengths as shown in Fig. 5, however there are exceptions in some of the datasets, where the predicted specified compressive strengths are more than experimental specified strengths. Comparatively, the correlations given in TMS 402/602–16 [6] tend to predict the compressive strengths in either way, as data points fall above and below the median line drawn (See Fig. 5e, f). To consistently compare the predictions, the model error (ME) values of the predictions, which is the ratio between experimental and prediction were computed and their statistical values were determined. Subsequently, mean, minimum, maximum and COVs of ME values were determined and given in Table 5. Also, the distribution functions of the ME values were analysed, and the histograms of the ME values of the predictions are given in Fig. 6. It was found that the lognormal distribution functions can be logically assigned to the distribution of ME values (through Kolmogorov–Smirnov analyses of the ME values obtained fit to the acceptable 5% significance level), hence the 95th and 99th percentile values of the ME values were also computed, assuming lognormal distribution of the ME values [35].

Histograms and best fit distribution functions of the ME values computed. a CSA S304.1–14 [5] (≤ 10 MPa mortar strength), b CSA S304.1–14 [5] (> 10 MPa mortar strength), c Ross and Korany [20] (≤ 10 MPa mortar strength), d Ross and Korany [20] (> 10 MPa mortar strength), e TMS 402/602–16 [6] (≤ 10 MPa mortar strength) and f TMS 402/602–16 [6] (> 10 MPa mortar strength)

As it can be seen from Table 4, that the mean ME values for TMS 402/602–16 [6] are closer to 1.0 with minimum and maximum values of fall above and below 1.0. However the predictions using CSA S304.1–14 [5], and Ross and Korany [18]) correlations show better conservativeness as their mean ME values are in the range of 1.61–1.91 (for both categories of mortars). Conversely, in certain mortar categories the minimum ME values of strength correlations are low at 0.7 and 0.72. It could be inferred that the existing correlations are based on limited and old experimental datasets. It can be noted that the 95th and 99th percentile confidence levels of these predictions are lower than 1.0, which implied the need for improvement in the compressive strength correlations of grouted masonry.

5.2 Proposed unit strength correlations

The verifications of the existing unit strength correlations against the experimental data of different grouted masonry assemblages implied that they need modification for enhanced reliable predictions. It can be noted from Fig. 5 and Table 4, that the unit strength correlations given in CSA S304.1–14 [5] and Ross and Korany [18] conservatively predicted the compressive strengths of grouted masonry. Particularly, for mortar strength category equal and less than 10 MPa, the CSA S304.1–14 [5] values showed more reliable predictions as the minimum and 95th percentile of ME values are more than 1.0. However, for mortar strength category more than 10 MPa, Ross and Korany [18] values showed improved predictions than others, as the minimum and 95th percentile of ME values obtained are closer to 1.0. Subsequently, these two sets of unit strengths correlations were considered for further modifications.

The strength values of materials to be used in design should conventionally have confidence level of 95% in the predictions, which implies that only in 5% chance, the specified material strength could be less than the actual strength, incorporating all the inherent variations in the constitutive materials and workmanship. It can be noted from Table 5, that the 95% percentile values computed for mortar strength category more than 10 MPa using Ross and Korany [18] correlations is 0.87, and for mortar strength category equal and less than 10 MPa using CSA S304.1–14 [5] is 1.07. Subsequently, these unit strength correlations were modified to get the reliable predictions.

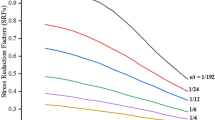

Table 6 shows the unit strength correlations proposed in this study and Fig. 7 shows the trends of predicted and experimental grouted masonry strengths using the proposed unit strength correlations. It can be noted that the existing values were scaled down, so that their 95% percentile ME values were closer to 1.0. The ME statistical parameters for the unit strength correlations proposed in this study are given in Table 7. It can be noted that the proposed unit strength correlations have improved the predictability of the compressive grouted masonry and they can rationally be used in design. However, these unit strength correlations proposed are limited to the experimental datasets considered in this study, when more datasets are made available in future, the proposed unit strength correlations can be further updated.

5.3 Reliability indices of proposed correlations

Structural reliability analysis in this study involved analysing the safety of proposed unit strength correlations against the actual values that could be attained during service life with relevant stochastic variations. The safety can be defined as the difference between the resistance, R (predicted compressive strength) and effect, E created due to load action, this is in turn defined as reliability index (β) as per Eq. (4). The probability of failure can be expressed as given in Eq. (5). An appropriate definition of β can be written as per Eq. (6), where the variation of resistance and effects are incorporated considering the statistical variations of these parameters (R and E). The derivation of this function assuming the resistance and effect parameters follow lognormal distribution can be referred in Ellingwood [73].

where CE and CR are the coefficient of variations for effects (E) and resistance (R). Then the ratio of R and E can be determined from the function given in Eq. (7), Where En and Rn are the normalised effect and resistance parameters. γ and ϕ are the partial safety and capacity reduction factors.

In order to determine the \({R \mathord{\left/ {\vphantom {R {R_{n} }}} \right. \kern-0pt} {R_{n} }}\) ratio, the resistance R, which is a random variable is related to the standard specified resistance Rn, as a deterministic value, through Eq. (8), in which, Kg, KME, Kp, and Kw are factors that contribute to the uncertainties in the computation of resistance to incorporate the variations in geometry, prediction of resistance, accuracy of design equation and workmanship. The mean and COVs of Kg, Kp, and Kw considered in this study were 1.0, 0.9 and 0.8, and 0.1, 0.15 and 0.2, respectively. The mean and COVs of the KME were taken as the ME and COVs of the proposed correlations in Table 7. The coefficient of variance of normalised resistance factor can be expressed as per Eq. (9).

Similarly, in the design, the computed effects can be subjected to stochastic variations. The normalised statistical variations.\({E \mathord{\left/ {\vphantom {E {E_{n} }}} \right. \kern-0pt} {E_{n} }}\) of permanent, imposed, wind, snow and earthquake actions are given in Table 8. These values were taken from the Australian Building Code Board handbook (ABCB) for structural reliability verification method for products and standard specifications [74]. Similar normalised effect ratios were used in other international standards such as depicted in Moosvai and Kornay [75] in Canada, and Zhai et al. [76] in China. Subsequently, the reliability indices of proposed unit strength correlation sets, (as given in Table 7) were computed.

The reliability indices achieved for the proposed set of unit strength correlations are given in Table 9. The target reliability index set for structural element that exhibit brittle failure similar to concrete/grouted masonry can be in the range of 3.7 to 4.3 as per ABCB handbook [74]. Other studies on assessing the structural reliabilities of reinforced concrete masonry or unreinforced concrete masonry reliability also suggested the target reliability index in the range of 3.7 to 4.0, [12, 24]. It can be noted from Table 9, that the reliability indices achieved for permanent, imposed, and snow actions are within or above the target reliabilities. ABCB handbook [73], recommends considering the average reliability index based on the analysis against combinations of actions; in that case, the average reliability index obtained are above the target reliability indices generally considered as a safer system. These results implied that the proposed unit strength correlations are structurally reliable, and can be applied in the design. A comparison of reliability for existing unit strength correlations to determine the axial compressive strength of grouted masonry is not presented here, since their reliability indices were found lower than the recommended indices. This proves that the proposed unit strength correlations rationally predict the compressive strength of grouted masonry and are structurally reliable for design.

6 Summary and conclusion

The compressive strength of grouted concrete masonry is influenced by different parameters such as strengths of blocks, mortar, and grout. In the absence of experimental data, the compressive strength of grouted masonry can be determined from tabulated unit strength correlations in the masonry design standards (e.g. CSA S304.1–14 [5] and TMS 402/602–16 [6]). Limited studies have been carried out to verify the accuracies of the available unit strength correlations to determine the compressive strengths of grouted masonry assemblages. In this study, the accuracies of the existing unit strengths correlations given in the design standards and literature were verified. For this purpose, an experimental database of grouted masonry assemblages tested under axial compression was developed. The database contained 291 datasets of grouted masonry assemblages with different block, mortar, and grout strength properties.

Initially, the existing unit strength correlations for compressive strength prediction of grouted masonry were critically reviewed. It was found that the compressive strengths of blocks and grout influenced the compressive strengths of grouted masonry. Although the mortar strength was also found to be influencing the compressive strength, larger scatter in the trend was observed. Subsequently, the database was divided into two mortar strength categories (1) equal and less than 10 MPa and (2) more than 10 MPa for further analyses. The evaluations of the accuracies of existing unit strength correlations revealed that the values given in CSA S304.1–14 [5] and Ross and Korany [18] were more conservative than the values stipulated in TMS 402/602–08 [6]. Therefore, the existing unit strength correlations given in CSA S304.1–14 [5] and Ross and Korany [18] were further calibrated to provide more reliable unit strength correlations. The updated unit strength correlations proposed in this study have been shown to predict the compressive strengths grouted masonry assemblages with enhanced accuracy. Furthermore, the reliabilities of the proposed unit strength correlations were also assessed. The reliability indices were found more than the target reliability indices set (3.7 to 4.3).Therefore, the proposed unit strength correlations to predict the compressive strength of grouted masonry are structurally reliable as well.

Although the updated unit strength correlations were developed based on the latest available data, when more datasets are available through various experimental campaigns, the proposed unit strength correlations can be further refined.

References

Asteris PG, Lourenço PB, Hajihassani M et al (2021) Soft computing-based models for the prediction of masonry compressive strength. Eng Struct 248:113276. https://doi.org/10.1016/j.engstruct.2021.113276

Zahra T, Thamboo J, Asad M (2021) Compressive strength and deformation characteristics of concrete block masonry made with different mortars, blocks and mortar beddings types. J Build Eng 38:102213. https://doi.org/10.1016/j.jobe.2021.102213

Ferretti D (2020) Dimensional analysis and calibration of a power model for compressive strength of solid-clay-brick masonry. Eng Struct 205:110064. https://doi.org/10.1016/j.engstruct.2019.110064

Australian standards (AS) (2018) AS3700: Australian standards for masonry structures, Sydney, Australia. Stand Aust

Canadian standards association (CSA) (2014) CSA S304–14 (R2019): Design of masonry structures, Canadian standards association, Mississauga, Canada

The Masonry Society (2016) Building code requirements for masonry structures (TMS 402/602-16), Colorado, 58

Cheema TS, Klinger RE (1986) Compressive strength of concrete masonry prisms. J Am Concr Inst 83:88–97. https://doi.org/10.14359/1752

AbdelRahman B, Galal K (2021) Experimental investigation of axial compressive behavior of square and rectangular confined concrete-masonry structural wall boundary elements. Eng Struct 243:112584. https://doi.org/10.1016/j.engstruct.2021.112584

Zahra T, Dorji J, Thamboo J et al (2023) Behaviour of reinforced mortarless concrete masonry panels under axial compression: An experimental and analytical study. Constr Build Mater 377:131097. https://doi.org/10.1016/j.conbuildmat.2023.131097

Dhanasekar M, Shrive NG (2002) Strength and deformation of confined and unconfined grouted concrete masonry. ACI Struct J 99:819–826. https://doi.org/10.14359/12347

Khalaf FM, Hendry AW, Fairbairn DR (1994) Study of the compressive strength of blockwork masonry. ACI Struct J 91:367–375. https://doi.org/10.14359/4139

Drysdale RG, Hamid AA (1979) Behavior of concrete block masonry under axial compression. J Am Concr Inst 76(6):707–721. https://doi.org/10.14359/6965

Martins ROG, Nalon GH, de Alvarenga R, CSSA et al (2018) Influence of blocks and grout on compressive strength and stiffness of concrete masonry prisms. Constr Build Mater 182:233–241. https://doi.org/10.1016/j.conbuildmat.2018.06.091

Fonseca FS, Fortes ES, Parsekian GA, Camacho JS (2019) Compressive strength of high-strength concrete masonry grouted prisms. Constr Build Mater 202:861–876. https://doi.org/10.1016/j.conbuildmat.2019.01.037

AbdelRahman B, Galal K (2020) Influence of pre-wetting, non-shrink grout, and scaling on the compressive strength of grouted concrete masonry prisms. Constr Build Mater 241:117985. https://doi.org/10.1016/j.conbuildmat.2019.117985

de Leite MLP, Liberati EAP, Parsekian GA (2023) Estimate models of compression strength of prisms from structural masonry components. Rev IBRACON Estrut e Mater. https://doi.org/10.1590/s1983-41952024000600001

Fortes ES, Parsekian GA, Fonseca FS (2015) Relationship between the compressive strength of concrete masonry and the compressive strength of concrete masonry units. J Mater Civ Eng 27:04014238. https://doi.org/10.1061/(asce)mt.1943-5533.0001204

Ross M, Korany Y (2011) Concrete masonry compressive strength using the unit strength method. Univ Alberta. https://doi.org/10.7939/R3SQ8QK31

Thompson J, Lang N, Witthuhn T (2013) Recalibration of the unit strength method for verifying compliance with the specified compressive strength of concrete masonry. In: 12th Canadian masonry symposium, Vancouver.

Sarhat SR, Sherwood EG (2014) The prediction of compressive strength of ungrouted hollow concrete block masonry. Constr Build Mater 58:111–121. https://doi.org/10.1016/j.conbuildmat.2014.01.025

Thamboo J, Zahra T, Asad M, Song M (2021) Improved design provisions for reinforced concrete block masonry walls under axial compression. Constr Build Mater 310:125226. https://doi.org/10.1016/j.conbuildmat.2021.125226

Zhai X, Stewart MG (2010) Structural reliability analysis of reinforced grouted concrete block masonry walls in compression. Eng Struct 32:106–114. https://doi.org/10.1016/j.engstruct.2009.08.020

Zahra T, Thamboo J, Asad M, Song M (2021) Experimental investigation on the effectiveness of lateral restrainers to the vertical steel in reinforced masonry walls under axial compression. Constr Build Mater 297:123790. https://doi.org/10.1016/j.conbuildmat.2021.123790

Atkinson RH, Kingsley GR (1985) A Comparison of the behavior of clay and concrete masonry in compression

Thamboo J, Zahra T, Sathurshan M (2024) Cyclic compression behaviour of reinforced concrete block masonry panels. In: 18th International Brick and Block Masonry Conference, Birmingham, United Kingdom. (submitted)

Wang R, Elwi AE, Hatzinikolas MA, Warwaruk J (1997) Tests of tall cavity walls subjected to eccentric loading. J Struct Eng 123:912–919. https://doi.org/10.1061/(asce)0733-9445(1997)123:7(912)

Xiao X, Lu X (1997) Study on Bearing Capacity of Concrete Masonry. In: 11th Int Brick/Block Mason conference Tongji University Shanghai.

Gouda O, Hassanein A, Youssef T, Galal K (2021) Stress-strain behaviour of masonry prisms constructed with glass fibre-reinforced grout. Constr Build Mater 267:120984. https://doi.org/10.1016/j.conbuildmat.2020.120984

Khalaf FM (1996) Factors influencing compressive strength of concrete masonry prisms. Mag Concr Res 48:95–101. https://doi.org/10.1680/macr.1996.48.175.95

Fahmy EH, Ghoneim TGM (1995) Behaviour of concrete block masonry prisms under axial compression. Can J Civ Eng 22:898–915. https://doi.org/10.1139/l95-107

Ouyang J, Wu F, Lü W et al (2019) Prediction of compressive stress-strain curves of grouted masonry. Constr Build Mater 229:116826. https://doi.org/10.1016/j.conbuildmat.2019.116826

Khattab MSM (1993) In-plane behaviour of grouted concrete masonry under biaxial states of stress. McMaster University

Guo P (1991) Investigation and Modeling of the Mechanical Properties of Masonry. Ph. D. thesis McMaster University

Bexten K, Tedros M, Horton R (1989) Compression strength of masonry. In: 5th Canadian masonry symposium, Vancouver, pp. 629-639

Atamturktur S, Ross BE, Thompson J, Biggs D (2017) Compressive strength of dry-stacked concrete masonry unit assemblies. J Mater Civ Eng 29:06016020. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001693

Yao C (1989) Failure mechanisms of concrete masonry. Ph. D. thesis University of British Columbia. https://doi.org/10.14288/1.0062803

Ross MD (2013) Recalibration of the unit strength method for determining the compressive strength of grouted concrete masonry. https://doi.org/10.7939/R3Z992

Sakr K, Neis V (1989) Some Studies on the stress-strain behaviour of grouted concrete masonry block units. 5th Can Mason Symp

Kingsley G, Atkinson R, Noland J, Hart G (1989) The effect of height on stress-strain measurements on grouted concrete masonry prisms. In: 5th Canadian masonry symposium, Vancouver.

Liu L, Wang Z, Zhai C, Zhai X (2009) Experimental research on biaxial compressive strength of grouted concrete block masonry. Adv Struct Eng 12:451–461. https://doi.org/10.1260/136943309789508519

Olatunji TM, Warwaruk J, Longworth J (1986) Behavior and strength of masonry wall/slab joints. Structural engineering report 139. University of Alberta. https://doi.org/10.7939/R3S46H74X

Duncan L (2008) Effect of block face shell geometry and grouting on the compressive strength of concrete block masonry. MSc thesis Univ Wind

Hou J, Liu Y (2007) Strain gradient effect on the behaviour and strength of masonry. Can J Civ Eng 34:1208–1215. https://doi.org/10.1139/L07-055

Long L, Hamid A, Drysdale R (2005) Small-scale modelling of concrete masonry using ½ scale units: a preliminary study. In: 10th Canadian masonry symposium. Banff, Alberta.

Baba A, Senbu O (1986) Influencing factors on prism strength of grouted masonry and fracture mechanism under uniaxial loading. In: The 4th Canadian masonry symposium.

Dhanasekar M (2004) Effect of grout confinement on the compressive strength of masonry. J Inst Eng India Civ Eng Div 85:26–30

Hamid AA, Abboud BE, Harris HG (1985) Direct modeling of concrete block masonry under axial compression. ASTM Spec Tech Publ. https://doi.org/10.1520/STP34553S

Wong HE, Drysdale RG (1985) Compression Characteristics of Concrete Block Masonry Prisms. ASTM Spec Tech Publ. https://doi.org/10.1520/STP34554S

Roman H, Romagna R (2002) Compressive strength of grouted and un-grouted concrete block masonry. Br Mason Soc

Priestley MJN, Elder DM (1983) Stress-Strain Curves for Unconfined and Confined Concrete Masonry. J Proc 80:192–201. https://doi.org/10.14359/10834

Thompson JJ, Walloch CT, Thomas RD (2002) Predicting grouted concrete masonry prism strength. ASTM Spec Tech Publ. https://doi.org/10.1520/STP11041S

Drysdale RG, Hamid AA (1983) Capacity of concrete block masonary prisms under eccentric compressive loading. J Proc 80:102–108. https://doi.org/10.14359/10465

Ahmadi B (2001) Performance of grouted masonry walls under severe environment. In: Banthia N (ed) Proceedings of the third international conference on concrete under severe conditions., University of British Columbia, Vancouver.

Boult BF (1979) Concrete masonry prism testing. J Proc 76:513–536. https://doi.org/10.14359/6957

Zhu YJ (2001) Experimental study of dynamic analysis of mechanical properties of high strength concrete block masonry. Ph. D. thesis, Northeast University Shenyang, China

Hawk S, McLean D, Young T (1997) Compressive Behavior of Insulated Concrete Masonry Prisms. Mason Soc J 15(2):53–60

Hamid A, Heidebrecht A, Drysdale R (1979) Shear Strength of Concrete Masonry Joints. J Struct Div 105(7):1227–1240

ASTM C1314-18 (2018) Standard test method for compressive strength of masonry prisms. ASTM Int West Conshohocken, 1–10

Abasi A, Hassanli R, Vincent T, Manalo A (2020) Influence of prism geometry on the compressive strength of concrete masonry. Constr Build Mater 264:120182. https://doi.org/10.1016/j.conbuildmat.2020.120182

Zahra T, Asad M, Thamboo J (2021) Effect of geometry on the compression characteristics of bonded brickwork. Structures 32:1408–1419. https://doi.org/10.1016/j.istruc.2021.03.040

Gumaste KS, Rao KSN, Reddy BVV, Jagadish KS (2007) Strength and elasticity of brick masonry prisms and wallettes under compression. Mater Struct Constr 40:241–253. https://doi.org/10.1617/S11527-006-9141-9/METRICS

Thamboo J, Dhanasekar M (2020) Assessment of the characteristics of lime mortar bonded brickwork wallettes under monotonic and cyclic compression. Constr Build Mater 261:120003. https://doi.org/10.1016/j.conbuildmat.2020.120003

Thamboo JA, Dhanasekar M (2019) Correlation between the performance of solid masonry prisms and wallettes under compression. J Build Eng 22:429–438. https://doi.org/10.1016/j.jobe.2019.01.007

ASTM C 109/ C109M-20a (2020) Standard test method for compressive strength of hydraulic cement mortars. ASTM Int West Conshohocken, PA

ASTM C780–19 (2019) Standard test method for preconstruction and construction evaluation of mortars for plain and reinforced unit masonry. ASTM Int West Conshohocken, PA

BSI Standards Publication (2019) BS EN 1015-Methods of test for mortar for masonry-part 11

Parsekian GA, Fonseca FS, Pinheiro GL, Camacho JS (2014) Properties of mortar using cubes, prism halves, and cylinder specimens. Mater J 111:443–454. https://doi.org/10.14359/51686726

Haach VG, Vasconcelos G, Loureno PB (2011) Influence of aggregates grading and water/cement ratio in workability and hardened properties of mortars. Constr Build Mater 25:2980–2987. https://doi.org/10.1016/j.conbuildmat.2010.11.011

Lakshani MMT, Jayathilaka TKGA, Thamboo JA (2020) Experimental investigation of the unconfined compressive strength characteristics of masonry mortars. J Build Eng 32:101558. https://doi.org/10.1016/j.jobe.2020.101558

EN:1992–1–1:2004-(E) (2004) Eurocode 2: design of concrete structures-Part 1–1: General rules and rules for buildings

Thamboo J, Jayarathne N, Bandara A (2019) Characterisation and mix specification of commonly used masonry mortars. SN Appl Sci 1:1–12. https://doi.org/10.1007/s42452-019-0312-z

BSI Standards Publication (2005) EN 1996-1-1: Eurocode 6: design of masonry structures-Part 1–1: general rules for reinforced and unreinforced masonry structures. Eurocode 6 123

Ellingwood BR, Galambos T V, MacGregor JG, Cornell CA (1982) Development of a probability based load criteria for American national institute A58. Gaithersburg, MD

ABCB (2019) Handbook: structural reliability verification method. Australian building codes board, Canberra.

Moosavi H, Korany Y (2014) Assessment of the structural reliability of loadbearing concrete masonry designed to the Canadian standard s304.1. Can J Civ Eng 41:1046–1053. https://doi.org/10.1139/cjce-2013-0498

Zhai X, Zhong Z, Stewart M (2012) Model error and structural reliability for reinforced concrete block masonry walls in shear. Adv Struct Eng 15:389–398. https://doi.org/10.1260/1369-4332.15.3.389

Acknowledgements

Authors likes to thanks the Department of Civil Engineering, South Eastern University of Sri Lanka and the School of Civil and Environmental Engineering, Queensland University of Technology for the administrative support given for this project.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Contributions

Julian Thamboo: Conceptualization Formal analysis, Data Curation, Writing—Original Draft. Mathavanayakam Sathurshan: Formal analysis, Data Curation. Tatheer Zahra: Data Curation, Writing-review and editing.

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Thamboo, J., Sathurshan, M. & Zahra, T. Reliable unit strength correlations to predict the compressive strength of grouted concrete masonry. Mater Struct 57, 151 (2024). https://doi.org/10.1617/s11527-024-02417-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-024-02417-8