Abstract

The purpose of the study is to evaluate strain-dependent behaviour of Cold Recycled Material (CRM) mixtures using three frameworks typically applied for Hot Mix Asphalt (HMA): linear viscoelastic (LVE) limits; non-linearity directions; changes in rheological model parameters. To this aim, the complex modulus of three CRM mixtures with different bitumen-to-cement ratio (0.2, 0.6 and 1.8) was measured in cyclic compression mode, at increasing level of axial deformation (from 35 to 195 μstrain) and at three temperatures (4, 20 and 40 °C). CRM mixtures showed strong strain dependent behaviour, which does not fully comply with the LVE hypothesis. LVE limit framework is applicable, but strain limits for CRM are different from HMA. Linearity direction framework does not give unique trend, hence it is not applicable in the same way as it was developed for HMA. The most promising framework for further analysis is the change in rheological model parameters, but it requires high number of performed tests.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Background

Cold recycling is currently one of the most environmental friendly and cost-effective techniques for reconstruction of old and heavily deteriorated bituminous pavements [1,2,3]. Cold recycled material (CRM) mixtures consist mostly of: reclaimed asphalt pavement (RAP) (usually from 60 up to 100%); additional virgin aggregate, used to improve the grading curve, and water, used to improve workability and compactability. CRM mixtures are bound by two differently working binding agents: bituminous emulsion (or foamed bitumen) and Portland cement (or other hydraulic binder).

Due to different environmental issues, specifications for CRM mixtures differ among different countries, especially in terms of amount of binding agents. In countries with warmer climate conditions and mild winters (like Italy [4], Spain [5], Greece [6], South Africa [7] or Brazil [8]), bituminous emulsion is the dominating binding agent. In such cases, Portland cement is used either to enhance the breaking of the emulsion (dosages up to 1.0%) or to improve structural performance (dosages up to 2.0%). In other countries such as Poland [1] or Germany [9] the dosage of Portland cement is higher (up to 4.0%), due to higher mechanical performance required by local specifications. Differences in the composition and mechanical performance of CRM mixtures can be highlighted by using different names (Fig. 1) [4]: bitumen stabilized material (BSM), cement-bitumen treated material (CBTM) or cold recycled asphalt (CRA). Figure 1 also shows the dosages of binding agents required by Polish specifications; the corresponding CRM mixture is normally identified as mineral-cement-emulsion (MCE) mixture.

Composition of the mixtures tested in this study and its location among the cold recycled mixtures families, on the basis of Mignini et al. [4]

The presence of two binding agents makes the behaviour of CRM mixture very complex. The bituminous binder leads to time–temperature dependence and to a certain flexibility, while the cementitious binder leads to high strength and stiffness, but also to higher risk of premature brittle failure [10, 11].

Due to their thermo-viscoelastic behaviour, the stiffness of CRM mixtures is often measured using methods and protocols originally developed for hot mix asphalt (HMA) mixtures, such as indirect tensile stiffness modulus [12,13,14,15,16,17,18], or complex modulus [19,20,21,22] in compression or tension/compression schemes. Usually, it is assumed that the limitations of the methods are similar for both HMA mixtures and CRM mixtures, and therefore the applied protocols are exactly the same. However, recent research showed that this assumption may not be correct if the strain- or stress-dependency of the stiffness is of concern [23,24,25]. Specifically, the effect of strain level on CRM mixtures may be different from that of HMA mixtures and, therefore, testing at the same strain level may lead to stiffness values that are not directly comparable. In addition, recent studies performed using the indirect tensile scheme, showed that changes of stiffness due to increasing or decreasing strain levels are not reversible [24, 26]. This implies that, even at low strain levels (less than 100 μstrain), some damage is induced in the specimen during testing.

1.2 Methods for evaluating the strain dependant behaviour of HMA mixtures

In the last 20 years, several original approaches were proposed to investigate the strain-dependent behaviour of bitumen, mastic and HMA mixtures ([27,28,29,30,31,32,33,34,35]).

Normally it is assumed that, when stress/strain is gradually increased, the linearity limit is defined by a 5% reduction in stiffness modulus [27, 36, 37]. While this is relatively easy to verify for both bitumen and mastic (e.g. using the DSR), it is more difficult for mixtures because testing at very low strain levels is challenging. This framework was applied to other materials with trial of using it also for phase angles by Jaczewski et al. [23].

Next common framework used to describe the strain dependent behaviour of bitumen and HMA mixtures is the concept of non-linearity paths in the Black diagram presented by Gauthier et al. [30]. This approach was further developed by Nguyen et al. [31] and Mangiafico et al. [32] that linked the non-linearity directions in the Black and Cole–Cole diagrams to the slopes of stiffness modulus and phase angles variation with increasing strain amplitude.

An additional approach for evaluating the strain dependant behaviour of HMA mixtures is the analysis of changes of the parameters of selected complex modulus rheological models with the change (increase) of applied strain. It is known that complex modulus is strictly defined only in the LVE range. However, its measure at larger strain amplitudes can provide meaningful information and is well documented in the literature [38]. Until now this framework was used to describe the rheological properties of HMA mixtures in the small-strain domain (from 15 to 60 µstrain) [39, 40] and to characterize fatigue related changes of the viscoelastic behaviour of asphalt binders [41].

1.3 Objective

The objective of this study is to evaluate the strain-dependent behaviour of CRM mixtures using the three frameworks described in Sect. 1.2: (a) linear viscoelastic limits; (b) non-linearity directions; (c) changes in the parameters of the linear viscoelastic Huet-Sayegh model. To this aim, the complex modulus of three CRM mixtures with different bitumen-to-cement ratio was measured in cyclic compression mode, at increasing level of axial deformation. Cyclic compression test mode was chosen due to its widespread usage, linked to the relative simplicity of specimen preparation. It is highlighted that using a different loading mode, such as tension–compression, indirect tension or flexure, may lead to different results.

2 Materials and methods

2.1 Materials and mixtures

The laboratory experiments were conducted on three CRM mixtures produced with combinations of binding agents: a) 2% of cement and 6% of emulsion (C2E6), b) 6% of cement and 2% of emulsion (C6E2) and c) 6% of cement and 6% of emulsion (C6E6). The used binders were Portland cement CEM I 32.5R (EN 197) and slow-setting cationic bituminous emulsion C 60 B10 ZM/R (EN 13808) with neat 70/100 residual bitumen. Mixture C2E6 complies with the Polish requirements for MCE mixtures for base course (Fig. 1) [42]. The two additional mixtures were tested to highlight the impact of cement and emulsion dosages on the stiffness properties. All tested mixtures had the same fixed grading curve, with small differences only on the finest parts, which were exchanged with cement. The base mixture gradation was designed for C2E6 and adjusted for other cement contents. Moreover, similar combinations of binder agents for MCE mixtures were employed in Poland in previous years [1].

Mixtures were prepared in laboratory and compacted in a gyratory compactor (EN 12697–31). The compacted specimens had height of 170 mm and diameter of 150 mm and were cured at 20 °C and 70% RH. Average mass of the specimens was around 3100 g. After 14 days specimens were cut to the target height of 150 mm and diameter of 100 mm. Before the complex modulus tests specimens were cured for total 28 days in laboratory conditions after compaction. Their basic properties are presented in Table 1.

2.2 Cyclic compression test

The complex modulus was determined in the cyclic compression configuration, according to the AASHTO TP79 standard [43] (Fig. 2). The tests were conducted at multiple strain levels (peak-to-peak values from 35 to 195 µstrain), multiple frequencies (from 0.01 to 25 Hz) and at three temperatures (4, 20 and 40 °C). The tests were performed in the Simple Performance Tester equipment (IPC Global) using haversine loading. The tests were performed without lateral confinement. The results were measured by three LVDT sensors with gauge length of 70 mm. In each test frequency the equipment first perform 10 conditioning loads and next it performs additional 10 loads from which the complex modulus and phase angle are determined.

2.3 Experimental plan

While it is assumed that the cyclic compression tests within small strain level are non-destructive test, testing a wide range of target strain levels and three different temperatures required to prepare strict experimental plan. Additionally, previously performed tests [23] suggested to start from the conditions where the material is stiffer (lowest temperature, highest frequency). The experimental plan is presented in Fig. 3 and was performed as follows:

-

Prior to testing at each temperature, the specimens (two replicates for each mixture) were conditioned for more than 12 h at that temperature.

-

Frequency sweeps (from 25 to 1 Hz) were carried out at each strain level (starting from 35 µstrain), without rest time between consecutive frequencies.

-

A rest time of 10 min was allowed between frequency sweeps carried out at different strain levels (e.g. between 35 and 55 µstrain, between 55 and 75 µstrain, and so on).

-

At selected strain levels of 45 and 95 µstrain the frequency sweep was extended to lower frequencies (from 25 to 0.01 Hz), those extended tests are shown in grey in Fig. 3.

Selected extended test for 45 and 95 µstrain were performed after the base frequencies sweeps (from 35 up to 195 µstrains) to confirm that there is no damage induced to the specimen. Comparison of the results for 95 µstrain for base and extended sweeps showed almost no differences in the measured moduli (the difference was similar to the consecutive tests performed on the same specimen).

2.4 Rheological modelling

During the analysis of the test data, it was verified that for each strain level the material complied with the time–temperature superposition principle (TTSP). First step for rheological modelling was the development of the master curve for the reference temperature Tref = 20 °C. Shifting of the stiffness modulus data for temperatures of 4 °C and 40 °C was performed using an extended version of the closed-form shifting (CFS) algorithm which is based on the minimisation of the overlapping area between two successive isothermal curves of stiffness modulus [44]. Those shift factors were also applied to the phase angle data. The shift factors were then modelled using the WLF equation [45]:

where \({\alpha }_{{\text{Tref}}}\left(T\right)\) is the shift factor for data measured at temperature T with respect to the reference temperature, Tref and C1, C2 are empirical constants determined using least-squares fitting. Rheological modelling of the complex modulus was performed using an approach developed for CRM mixtures by Graziani et al. [46]. The model describes the complex modulus (\({E}_{{\text{HY}}}^{*}\left(\omega \right)\)) using the following equation:

where \({E}_{{\text{LVE}}}^{*}\) is a LVE complex modulus model and \({\text{exp}}\left({{\text{j}}\varphi }_{{\text{HY}}}\right)\) is a correction (also known as hysteretic dissipation term) that adds a time- and temperature-independent phase angle \({\varphi }_{{\text{HY}}}\) to the LVE phase angle \({\varphi }_{{\text{LVE}}}\). In CRM mixtures the hysteretic dissipation may be linked to the presence of cementitious bonds and internal friction caused by an incomplete coating of the aggregate [47, 48]. In the present research the Huet-Sayegh (HS) model [49] was used to simulate the LVE behaviour. The HS model is described by the following equation:

where \(\omega =2\pi {f}_{r}\) is the angular frequency, \({f}_{r}=f {\alpha }_{{\text{Tref}}}\left(T\right)\) is the reduced frequency, \(f\) is the testing frequency, \({E}_{g}\) and \({E}_{e}\) are the glassy and equilibrium moduli, h, k, and δ are dimensionless shape parameters and τ is the characteristic time parameter.

For each tested strain level, the following model fitting procedure was used:

-

a.

The CSF algorithm was used to determine the shift factors, for the reference temperature Tref = 20 °C. Afterwards, the C1 and C2 parameters were estimated using non-linear least square fitting.

-

b.

The initial values of Ee and Eg were estimated from the trends of the experimental data of the Cole–Cole and Black diagrams, respectively.

-

c.

The parameters k, h, δ, log τ, were estimated using non-linear least square fitting. The error function considered only the residuals of the logarithm of the stiffness modulus.

-

d.

The parameter \({\varphi }_{{\text{HY}}}\) was estimated using non-linear least square fitting. The error function considered only the residuals of the phase angle.

-

e.

The final optimization of all the parameters was achieved by minimizing the distance between the experimental data and the model on the Cole–Cole diagram.

The examples of the rheological modelling of different analysed mixtures and strain levels are presented in Fig. 4.

3 Results and discussion

3.1 Test results

Selected results of stiffness modulus and phase angle are presented to highlight the behaviour of the three tested mixtures. The full dataset of test results is available as supplementary material [50].

Figure 5 shows the stiffness modulus and phase angle values determined for all six tested specimens using the target strain of 45 µstrain. Only one strain level is presented to highlight the differences between the three mixtures and the typical variability between two replicate specimens of each mixture. All results show a low scatter between the two replicates and follow typical trends presented in literature [4, 8, 19, 51, 52]. It is interesting to note that the C6E6 specimens showed intermediate values of stiffness modulus and phase angle at all temperatures. This confirms that the time and temperature dependency of CRM mixtures is affected by the relative dosage of the two binders (i.e., the residual bitumen to cement ratio) and, ultimately, by the relative volume of cementitious and bituminous bonds that develop during the curing phase. In the case of the C6E2 (b/c = 0.2) CRM mixture the cementitious bonds dominate the viscoelastic behaviour of the mixture resulting in higher values of complex modulus and lower values (< 10°) of phase angles, while in the case of C2E6 (b/c = 1.8) the bituminous bonds dominates the viscoelastic behaviour of the mixture which results in lower values of complex modulus and higher values (up to 20°) of phase angles. It is also important to note that in the present research several strain levels were applied in sequence at the same temperature, before moving to the next temperature (Fig. 6). Therefore, the data measured at 20 and 40 °C, had been subjected to higher strain levels at the previous testing temperature (5 and 20 °C, respectively).

Figure 6 shows the strain dependency of complex modulus values determined for all six tested specimens at the frequency of 10 Hz. Similar trends can be observed at other frequencies [50]. The experimental data show that the stiffness modulus decreases with the increase in strain level. The decreasing rate is higher until around 100 µstrain and then it apparently stabilizes. As for phase angle, the behaviour slightly differs for various temperatures. For the temperatures of 4 and 20 °C the increase of phase angle with increasing strain level is with almost constant rate. In the case of 40 °C the behaviour is more similar to that observed for the stiffness modulus (i.e. higher increase rate up to about 100 µstrain). In single cases a decrease of phase angle was also observed, which can indicate damage developing in the specimen. The obtained results are in compliance with previously obtained [23, 25].

3.2 Frameworks for characterizing the strain-dependant behaviour

3.2.1 The linear viscoelastic limit

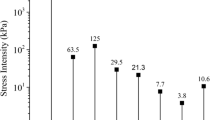

The LVE strain limits for three tested mixtures were determined separately, considering a 5% reduction in stiffness modulus, and a 5% increase in phase angle, with respect to the values measured at the lowest strain level (from Fig. 6). The LVE limits are summarized in Fig. 7. The strain limits for the stiffness modulus showed a strong positive linear correlation with the stiffness modulus. In fact, values of the Pearson correlation coefficient varied from 0.86 to 0.96. From a practical point view this also implies a correlation to the mixture type, with the stiffest mixture (C6E2) showing the highest limits. It is highlighted that 40% of the calculated limits were equal to (or greater than) the maximum strain applied in this investigation (195 µstrain). The strain limits for the phase angle were generally lower than those determined for the stiffness modulus, at same testing temperature and frequency. In fact, 92% of the calculated limits were lower than 120 µstrain. Moreover, the correlation with the phase angle values was not so strong, except for the mixture C2E6 that showed a quite strong negative correlation (r = − 0.81).

Overall, the determined LVE strain limits confirmed the results of a preliminary study obtained for specimen subjected to very long curing period [23]. In addition, it is possible to state that in cyclic compression tests, a limiting value of applied strain for which the CRM mixtures are expected to exhibit a linear behaviour is lower than about 50 µstrain (peak-to- peak), as the changes of the measured stiffness moduli and phase angles fits into 5% limit for all tested frequencies and test temperatures. It should be noted that this is trial to applicate the framework determined for HMA, and the behaviour of the CRM mixtures is much more complicated and not always present clear constant value of measured parameters.

3.2.2 Non-linearity direction

The non-linearity directions were determined in the Black diagram considering experimental data for fixed temperature and frequency conditions and using the whole applied strain range – from 35 µstrain up to 195 µstrain. The directions are visually presented as red arrows in Fig. 8 for selected frequencies. Those arrows were obtained using an exponential regression on the data measured at same temperature and frequency.

The direction of change is more or less constant for middle and lower part of the plots which represents results at 4 °C and 20 °C. The direction starts to change with the increase of the temperature to 40 °C and lowering the test frequency. Also, some deviations from the trend are visible in the case of high frequencies for the temperature of 4 °C. The direction of those cases is shifted towards left what is the results of faster decrease of the values of stiffness modulus with the same rate of change of the phase angles. The probable case of such behaviour could be damage induced to the specimen (in the temperature of 4 °C when the specimen is brittle and in 40 °C when the behaviour of CRM mixture is probably more related to the presence of cement.

Figure 9 shows the slopes of stiffness modulus decrease (pE) and phase angle increase (pϕ). The slopes were calculated until 100 µstrain, as outlined in Fig. 6. The black solid line represents the unique linear trend obtained by Mangiafico et al. [32] on HMA. For the tested CRM mixtures, the linear trend does not appear. In particular, the data obtained at 40 °C (lowest pE values and highest pϕ values) deviate from the linear trend – while the changes of the slopes of stiffness moduli are visible the changes of slope of phase angles start to diminish (as presented in Fig. 9). Slopes of phase angles obtained for higher applied strains started to reach value of 0. Results obtained for other set of data with longer curing times [25] also presented diminishing of the slope of the phase angles. It is probably due to cement hydration in the mixture.

3.2.3 Rheological model parameters analysis

Analysis of changes of the parameters of rheological model is the last framework used to evaluate the strain-dependant behaviour of CRM mixtures. For this purpose modified Huet-Sayegh model was used (Eqs. 2 and 3). The analysis was based on two sets of parameters: (a) WLF shift factor model parameters C1 and C2 and (b) 7 rheological model parameters: Ee, Eg, k, h, δ, log τ, and \({\varphi }_{{\text{HY}}}\). The results for determined rheological model parameters and linear trend for strain dependant behaviour are presented respectively in Figs. 10 (WLF model parameters) and Fig. 11 (HS model parameters). All basic data presented in the figures are given in the supplementary materials [50]. The parameters “a” (slope) and “b” (intercept) of the trend lines are given in the Table 2.

The C1 and C2 parameters can be considered constant in selected strain range and are not related to the composition of the mixture (Fig. 10). Only for specimen (C6E2) the value of both parameters decreased with increasing of applied strain.

In the case of HS rheological model parameters, the tested specimen showed evident trends of strain dependence:

-

a.

The values of Eg (which describes the glassy modulus) decreased with the increase of applied strain. The decrease had similar slope of change for all tested mixtures regardless of combination of binding agents.

-

b.

The values of Ee (which describes the equilibrium modulus) were in the case of this research constant and did not show strain dependence. It was expected, that Ee would behave similar to Eg, therefore it should decrease with increasing applied strain [41]. The observed trend could be related to the accumulation of permanent strain due to the selected testing scheme (cyclic compression).

-

c.

The values of k and h (which describe the slope of the Cole–Cole curve at low and high reduced frequencies, respectively) increased with increased applied strain level. From an analytical point of view, k and h are a fractional order of derivation, ranging from 0 for elastic response to 1 for viscous response [53]. What is interesting, the increase of k and h suggests that the material response is becoming more viscous and less elastic. A similar change was observed by Mignini et al. [6] when comparing CRM mixtures to HMA mixtures. The possible explanation for this behaviour could be the damage of cementitious bonds in the tested specimen, what should be verified in further research – if this behaviour is reversible and if it depends on the curing time of analysed material.

-

d.

The logτ parameter also showed evident trends that are strongly depended on the mixture composition. For high bitumen-to-cement ratio (C2E6) it showed increase of analysed values with increasing strain. This can be related to a decrease of the crossover frequency and thus to lower the relaxation ability of the mixture. On the other hand, for low bitumen-to-cement ratio (C6E2) it showed decrease of analysed values with increasing strain. This can be related to an increase of the crossover frequency and thus to a higher relaxation ability of the mixture. The explanation of such behaviour requires further analysis.

-

e.

The value of φHY showed high dependency on applied strain level and b/c ratio. For all tested mixtures φHY increased with increasing strain. This confirms that φHY can be used to represent a dissipation mechanism linked to internal friction (the higher the strain, the higher the dissipation, the higher the hysteretic phase angle). Similarly, lower slope and initial value characterize the mixtures with lower b/c ratios, confirming a more pronounced cement-like behaviour,

As seen in the analysis the determined trends are generally in compliance with previous results [40] which were obtained from very limited amount of data (3 strain levels lower than 100µstrain). The strain dependent behaviour of CRM mixtures shows clear trends, which can be mathematically modelled. But it should be noted that the study was performed on limited set of materials and test methods to formulate general conclusions about the strain dependent behaviour of CRM mixtures. (Test were performed as compression test for limited amount of frequencies (from 1 to 25 Hz). As analysis shows it could be important especially in higher temperatures. It should be also noted, that while the study was performed for fully cured specimen, the presence of cement changes the properties of the CRM mixtures even for very long times after compaction. Therefore this behaviour should be further validated, especially whether it is a non-linear reversible one or it is related to the microdamage accumulated developed in the specimen during tests. Nevertheless rheological model framework shows the most promising results for further analysis of strain dependent behaviour of CRM mixtures.

3.2.4 Comparison of the frameworks for evaluating strain dependence

The comparison of potential and limitations of the used frameworks are presented in the Table 3. It should be noted that all of them can be utilized in different aspects of modelling of CRM mixtures. Additionally, it should be noted that those models were used for analysis of linear visco-elastic materials. Recent studies performed in different research groups proved, that CRM mixtures do not show clear linear or non-linear behaviour as it is visible in the case of asphalt mixtures.

4 Conclusions

Study aimed to determine the framework which shows the best performance for analysis and modelling of cold recycled material (CRM) mixtures. Three different frameworks used in literature were used and compared. The following conclusions can be stated on the basis of preformed research:

-

1.

CRM mixtures showed strain dependent behaviour, which does not fully comply with LVE hypothesis most often assumed for such mixtures. Due to small reduction in the value of stiffness modulus, behaviour presented by CRM mixture is approximated as linear. This behaviour is similar as present in HMA mixtures.

-

2.

All presented frameworks can be used with limitations to describe the behaviour of CRM mixtures, but for different applications.

-

3.

LVE limit approach is applicable, but LVE limits for CRM are different from HMA. The approach can be applied to stiffness modulus, but not to phase angle. Moreover, this approach cannot be used to characterize "non-linearity"

-

4.

Linearity direction (pE/pϕ), does not give unique trend, hence it is not applicable in the same way as it was developed for HMA. Moreover, it is applicable only until 100 µstrain, because above this value the trend is not linear anymore.

-

5.

The most promising framework for further analysis is rheological model parameters framework, but it requires high number of performed tests. Rheological model parameters framework showed following strain dependant trends:

-

o

The values of Eg decrease with the increase of applied strain. The decrease has similar slope of change for all tested mixtures regardless of combination of binding agents.

-

o

The values of Ee are in case of this research constant and do not show strain dependence.

-

o

The values of k and h increased with increased applied strain level.

-

o

The logτ parameter did not show evident trends, but it is evident that it is strain-dependent, but the direction of trend strongly depended on the mixture composition

-

o

The value of φHY showed high dependency on applied strain level and b/c ratio. For all tested mixtures φHY increased with increasing strain.

-

o

General recommendation is such that regardless of its limitations the rheological model parameters analysis framework shows the most promising results and should be used in further research and verified on bigger database.

References

Dołżycki B, Jaskuła P (2019) Review and evaluation of cold recycling with bitumen emulsion and cement for rehabilitation of old pavements. J Traffic Transp Eng. https://doi.org/10.1016/j.jtte.2019.02.002

Kukiełka J, Sybilski D (2018) Durability of base courses with mineral-cement-emulsion mixes (MCEM). IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/356/1/012006

Lin J, Hong J, Xiao Y (2017) Dynamic characteristics of 100% cold recycled asphalt mixture using asphalt emulsion and cement. J Clean Prod 156:337–344. https://doi.org/10.1016/j.jclepro.2017.04.065

Mignini C, Cardone F, Graziani A (2022) Complex modulus of cement-bitumen treated materials produced with different reclaimed asphalt gradations. Mater Struct 55:169. https://doi.org/10.1617/s11527-022-02009-4

Recasens RM, Pérez Jiménez FE, Aguilar SC (2000) Mixed recycling with emulsion and cement of asphalt pavements. Design procedure and improvements achieved. Mater Struct 33:324–330. https://doi.org/10.1007/BF02479703

Loizos A, Papavasiliou V (2006) Evaluation of foamed asphalt cold in-place pavement recycling using nondestructive techniques. J Transp Eng 132:970–978. https://doi.org/10.1061/(ASCE)0733-947X(2006)132:12(970)

Dal Ben M, Jenkins KJ (2014) Performance of cold recycling materials with foamed bitumen and increasing percentage of reclaimed asphalt pavement. Road Mater Pavement Des 15:348–371. https://doi.org/10.1080/14680629.2013.872051

Kuchiishi AK, Vasconcelos K, Bariani Bernucci LL (2021) Effect of mixture composition on the mechanical behaviour of cold recycled asphalt mixtures. Int J Pavement Eng 22:984–994. https://doi.org/10.1080/10298436.2019.1655564

Wacker B, Kalantari M, Diekmann M (2020) Cold recycling in Germany—current experiences and future projects, Proceedings of the 9th International Conference on Maintenance and Rehabilitation of Pavements—Mairepav9, pp 813–823 https://doi.org/10.1007/978-3-030-48679-2_76

Dołżycki B, Jaczewski M, Szydłowski C, Wojciech B, Gajewski M (2023) Analysis of selected mechanical properties of mineral-cement-emulsion mixtures (MCE). Roads Bridg.—Drog. i Most 22:41–61. https://doi.org/10.7409/rabdim.023.003

Meknaci L, Graziani A, Mignini C, Henni AD, Miljković M (2022) Influence of bitumen emulsion on the curing behaviour of standardised cold bitumen emulsion mortars. Road Mater Pavement Des 23:99–115. https://doi.org/10.1080/14680629.2021.2017329

Valentin J, Čížková Z, Suda J, Batista F, Mollenhauer K, Simnofske D (2016) Stiffness characterization of cold recycled mixtures. Transp Res Procedia 14:758–767. https://doi.org/10.1016/j.trpro.2016.05.065

Buczyński P, Iwański M, Mazurek G, Krasowski J, Krasowski M (2020) Effects of portland cement and polymer powder on the properties of cement-bound road base mixtures. Materials (Basel) 13:4253. https://doi.org/10.3390/ma13194253

Pettinari M, Simone A (2015) Effect of crumb rubber gradation on a rubberized cold recycled mixture for road pavements. Mater Des 85:598–606. https://doi.org/10.1016/j.matdes.2015.06.139

Sangiorgi C, Tataranni P, Simone A, Vignali V, Lantieri C, Dondi G (2017) A laboratory and filed evaluation of cold recycled mixture for base layer entirely made with reclaimed asphalt pavement. Constr Build Mater 138:232–239. https://doi.org/10.1016/j.conbuildmat.2017.02.004

Graziani A, Godenzoni C, Cardone F, Bocci M (2016) Effect of curing on the physical and mechanical properties of cold-recycled bituminous mixtures. Mater Des 95:358–369. https://doi.org/10.1016/j.matdes.2016.01.094

Miljković M, Dołżycki B, Jaczewski M, Szydłowski C (2022) Comparative study of the mechanical behaviour of bitumen- and cement-dominated mixtures with reclaimed asphalt, Proceedings of the RILEM international symposium on bituminous materials, RILEM Bookseries 27, pp 413–419. https://doi.org/10.1007/978-3-030-46455-4_52

Orosa P, Orozco G, Carret JC, Carter A, Pérez I, Pasandín AR (2022) Compactability and mechanical properties of cold recycled mixes prepared with different nominal maximum sizes of RAP. Constr Build Mater 339:127689. https://doi.org/10.1016/j.conbuildmat.2022.127689

Dolzycki B, Jaczewski M, Szydlowski C (2017) The long-term properties of mineral-cement-emulsion mixtures. Constr Build Mater 156:799–808. https://doi.org/10.1016/j.conbuildmat.2017.09.032

Gandi A, Carter A, Singh D (2017) Rheological behavior of cold recycled asphalt materials with different contents of recycled asphalt pavements. Innov Infrastruct Solut 2:1–9. https://doi.org/10.1007/s41062-017-0094-3

Grilli V, Virgili A, Graziani A (2023) Evaluation of complex modulus and fatigue properties of cold recycled material mixtures using small-scale specimens. Road Mater Pavement Des. https://doi.org/10.1080/14680629.2023.2194450

Iwański M, Mazurek G, Buczyński P, Iwański MM (2022) Effects of hydraulic binder composition on the rheological characteristics of recycled mixtures with foamed bitumen for full depth reclamation. Constr Build Mater 330:127274. https://doi.org/10.1016/j.conbuildmat.2022.127274

Jaczewski M, Szydlowski C, Dolzycki B (2022) Preliminary study of linear viscoelasticity limits of cold recycled mixtures determined in Simple Performance Tester (SPT). Constr Build Mater 357:129432. https://doi.org/10.1016/j.conbuildmat.2022.129432

Jaczewski M, Szydłowski C, Dołżycki B (2023) Stiffness of cold-recycled mixtures under variable deformation conditions in the IT-CY test. Case Stud Constr Mater. https://doi.org/10.1016/j.cscm.2023.e02066

Jaczewski M, Szydłowski C, Dołżycki B (2023) The dependence of linear viscoelasticity limits of cold recycled mixtures on time of curing and compaction method, In: Mater Today Proc

Grilli V, Grilli A, Graziani A, Jaczewski M (2024) Effect of strain level on the stiffness of cold recycled bituminous mixtures, In: 8th Int. Conf. Bitum. Mix. Pavements, Thessaloniki, Greece

Airey GD, Rahimzadeh B, Collop AC (2002) Linear viscoelastic limits of bituminous binders. Assoc Asph Pavement Technol 71:160–196

Underwood BS, Kim YR (2015) Nonlinear viscoelastic analysis of asphalt cement and asphalt mastics. Int J Pavement Eng 16:510–529. https://doi.org/10.1080/10298436.2014.943133

Uzan J, Levenberg E (2007) Advanced testing and characterization of asphalt concrete materials in tension. Int J Geomech 7:158–165. https://doi.org/10.1061/(ASCE)1532-3641(2007)7:2(158)

Gauthier G, Bodin D, Chailleux E, Gallet T (2010) Non linearity in bituminous materials during cyclic tests. Road Mater Pavement Des 11:379–410. https://doi.org/10.1080/14680629.2010.9690339

Nguyen QT, Di Benedetto H, Sauzéat C (2015) Linear and nonlinear viscoelastic behaviour of bituminous mixtures. Mater Struct Constr 48:2339–2351. https://doi.org/10.1617/s11527-014-0316-5

Mangiafico S, Babadopulos LFAL, Sauzéat C, Di Benedetto H (2018) Nonlinearity of bituminous mixtures. Mech Time-Dependent Mater 22:29–49. https://doi.org/10.1007/s11043-017-9350-3

Coulon L, Koval G, Chazallon C, Roux J-N (2021) Modeling of T/C complex stiffness modulus test and non-linearity of asphalt concrete mixes, In: Proceedings of the RILEM International Symposium on Bituminous Materials pp 1343–1350 https://doi.org/10.1007/978-3-030-46455-4_171

Graziani A, Raschia S, Mignini C, Carter A, Perraton D (2020) Use of fine aggregate matrix to analyze the rheological behavior of cold recycled materials. Mater Struct Constr. https://doi.org/10.1617/s11527-020-01515-7

Zeng M, Bahia HU, Zhai H, Anderson MR, Turner P (2001) Rheological modeling of modified asphalt binders and mixtures. J Assoc Asph Paving Technol 70:403–441

Airey GD, Rahimzadeh B, Collop AC (2003) Viscoelastic linearity limits for bituminous materials. Mater Struct 36:643–647. https://doi.org/10.1007/BF02479495

Di Benedetto H, Olard F, Sauzéat C, Delaporte B (2004) Linear viscoelastic behaviour of bituminous materials: from binders to mixes. Road Mater Pavement Des 5:163–202. https://doi.org/10.1080/14680629.2004.9689992

Hyun K, Wilhelm M, Klein CO, Cho KS, Nam JG, Ahn KH, Lee SJ, Ewoldt RH, McKinley GH (2011) A review of nonlinear oscillatory shear tests: analysis and application of large amplitude oscillatory shear (LAOS). Prog Polym Sci 36:1697–1753. https://doi.org/10.1016/j.progpolymsci.2011.02.002

Graziani A, Bocci M, Canestrari F (2014) Complex Poisson’s ratio of bituminous mixtures: measurement and modeling. Mater Struct Constr 47:1131–1148. https://doi.org/10.1617/s11527-013-0117-2

Graziani A, Cardone F, Virgili A, Canestrari F (2019) Linear viscoelastic characterisation of bituminous mixtures using random stress excitations. Road Mater Pavement Des 20:S390–S408. https://doi.org/10.1080/14680629.2019.1587494

Katbeh J, Masad E, Lakshmi Roja K, Srinivasa A (2023) A framework for the analysis of damage and healing viscoelastic behaviour of asphalt binders. Constr Build Mater 374:130908. https://doi.org/10.1016/j.conbuildmat.2023.130908

Dołżycki B (2019) Instrukcja projektowania i wbudowania mieszanek mineralno-cementowo-emulsyjnych (MCE)

AASHTO ((2013)) AASHTO TP 79, Standard method of test for determining the dynamic modulus and flow number for asphalt mixtures using the asphalt mixture performance tester (AMPT)

Gergesova M, Zupančič B, Saprunov I, Emri I (2011) The closed form t-T-P shifting (CFS) algorithm. J. Rheol. (N. Y. N. Y) 55:1–16. https://doi.org/10.1122/1.3503529

Williams M, Landel RF, Ferry JD (1955) The temperature dependance of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J Am Chem Soc 77:3701–3707

Graziani A, Mignini C, Bocci E, Bocci M (2020) Complex modulus testing and rheological modeling of cold-recycled mixtures. J Test Eval 48:20180905. https://doi.org/10.1520/JTE20180905

Ashmawy A, Salgado R, Guha S, Drnevich V (1995) Soil damping and its use in dynamic analyses, In: Third Int. Conf. Recent Adv. Geotech. Earthq. Eng. Soil Dynyamics 1-Static Dyn. Eng. Soil Parameters Const. Relations Soils

Chen X, Huang Y, Chen C, Lu J, Fan X (2017) Experimental study and analytical modeling on hysteresis behavior of plain concrete in uniaxial cyclic tension. Int J Fatigue 96:261–269. https://doi.org/10.1016/j.ijfatigue.2016.12.002

Olard F, Di Benedetto H (2003) General “2S2P1D” model and relation between the linear viscoelastic behaviours of bituminous binders and mixes. Road Mater Pavement Des 4:185–224. https://doi.org/10.1080/14680629.2003.9689946

Jaczewski M, Szydłowski C, Dołżycki B (2023) Complex modulus of cement bitumen treated material mixture (28 days of curing at 20C), [dataset]. Gdańsk University of Technology, mostwiedzy.pl https://doi.org/10.34808/7zxz-vw46

Ferrotti G, Grilli A, Mignini C, Graziani A (2020) Comparing the field and laboratory curing behaviour of cold recycled asphalt mixtures for binder courses. Materials (Basel) 13:4697. https://doi.org/10.3390/ma13214697

Buczyński P, Iwański M (2018) Complex modulus change within the linear viscoelastic region of the mineral-cement mixture with foamed bitumen. Constr Build Mater 172:52–62. https://doi.org/10.1016/j.conbuildmat.2018.03.214

Pronk AC (2005) The Huet-Sayegh model: a simple and excellent rheological model for master curves of asphaltic mixes, In: Asph. Concr., American Society of Civil Engineers, Reston, VA pp 73–82. https://doi.org/10.1061/40825(185)8

Acknowledgements

Financial support for these studies from the Gdańsk University of Technology under the DEC-43/2020/IDUB/I.3.3 grant “Linear and non-linear viscoelastic behaviour of cold recycled bitumen-cement composites” – ‘Excellence Initiative – Research University’ program is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Mariusz Jaczewski (M.J.); Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Resources, Writing – original draft, Writing – review & editing. Andrea Graziani (A.G.); Conceptualization, Formal Analysis, Investigation, Methodology, Supervision, Writing – original draft, Writing – review & editing.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jaczewski, M., Graziani, A. Strain-dependent behaviour of cold recycled material mixtures in cyclic compression tests. Mater Struct 57, 92 (2024). https://doi.org/10.1617/s11527-024-02366-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-024-02366-2