Abstract

This study aims to investigate the crack-filling effect of gel generated by the alkali–silica reaction (ASR) on the mechanical behavior of concrete and propose an analytical model to predict the compression behavior of ASR-damaged concrete. To identify the mechanical contribution of the gel-filling cracks, the distribution of the chemical compositions and elastic moduli of the crack-filling gels were observed using SEM–EDS analysis and nano-indentation tests. The experimental results showed that the elastic modulus of the gel with a high-calcium composition ranged from 30 to 40 GPa, which is comparable to the elastic modulus of concrete. In addition, through literature reviews of the time-dependent compression behaviors of ASR-affected concrete, it was hypothesized that crack-filling gels can contribute to the recovery of ASR damage, and that the mechanical contribution of gels depends on the ASR crack patterns and changes with time. Based on these assumptions, the resistance of the gels filling the cracks in the compression, shear, and recontact behaviors of ASR-damaged concrete was reflected in the proposed model, in which the gel resistance increased with time and became larger as the ratio of microcracks to total cracks increased. The proposed model was verified through a comprehensive comparison of analysis and test results of compression behavior of ASR-damaged specimens, and it appeared that the change in mechanical properties of concrete according to the degree of damage (ASR expansion) and time was well simulated by the proposed model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Alkali silica reaction (ASR) degrades mechanical properties of concrete by causing the concrete expansion; however, the mechanical properties have time-dependency and large variance even at the same expansion. This suggests that there are other factors determining the degradation of mechanical properties in addition to the expansion. When ASR occurs, gel is formed at the aggregate and causes expansive pressure, resulting in micro- and macrocracks in the concrete. The presence of macrocracks can be easily checked with the naked eye, whereas in the case of a microcrack, the width is so small that it is difficult to observe [1,2,3,4,5]. The microcrack pattern is likely to show no directionality, short in length, and have low connectivity, while macrocracks are localized with high connectivity. According to previous studies, in ASR-damaged concrete, microcracks were observed around the aggregate and in the cement paste under a microscope, and many researchers have reported that part of the microcracks can be filled by ASR gel [6,7,8,9,10,11].

The effect of gel crack-filling on the mechanical properties of concrete was experimentally investigated in a few studies [11,12,13,14]. In an experiment by Ji et al. [12], ASR damage was accelerated for cylinder specimens under 3% NaClaq and 40 °C. When the ASR expansion reached target expansions (0.2% and 0.4%), the specimens were sealed with plastic wrap and stored at room temperature (i.e., the acceleration stopped, and thus the expansion rate was significantly reduced). While the specimens were stored at room temperature, the elastic modulus of ASR-damaged concrete recovered to a level comparable to that of normal concrete without ASR damage. Their experiment result demonstrates that the crack-filling effect of gel exists, and it becomes more dominant than the effect of ASR damage as the expansion rate becomes slower, eventually recovering the ASR damage. The rate of recovery varies depending on the reaction rate of ASR.

The mechanical properties of the gel should be similar to those of concrete for the damage caused by the ASR to be recovered by the crack filling of the gel. According to previous studies [11, 15,16,17,18], the elastic modulus of the gel ranges from 20 to 40 GPa and increases as the Ca/Si ratio of the gel increases. In general, more gels with high Ca/Si ratios were observed around cement with higher calcium content than around aggregates [7, 9, 11, 19,20,21,22,23]. This is because the gels generated around the aggregate move through cracks and react with the calcium hydroxide (Ca(OH)2) in the cement. In other words, ASR gel with a high alkali content reacts with Ca(OH)2 in the cement paste and turns into a calcium silicate hydrate (C–S–H) gel. Therefore, to model the recovery from ASR damage over time, the crack-filling effect of the gel according to its chemo-physical properties should be considered comprehensively. In a previous study [24], SEM–EDS tests were performed on samples taken from ASR-damaged concrete to observe the chemical composition changes in the gel filling the cracks. The test results confirmed that the gel in contact with the cement paste had a higher calcium content than that in the middle of the crack. In addition, it was suggested that the alkali-rich gel transformed into a high-calcium composition gel over time by reacting with the Ca(OH)2 in the cement paste. However, it is still necessary to identify how the mechanical properties of gels change with time owing to changes in the chemical composition of the ASR gel. Moreover, no analytical model that can reflect the effect of crack filling by gels on the mechanical properties of concrete is currently available.

Therefore, this study aimed to develop a mechanical model capable of reflecting the ASR damage and the recovery of damage with time owing to crack filling by gels. The mechanical properties of the gels were measured using SEM–EDS and nano-indentation tests. In addition, based on the ASR test results of Ji et al. [12] and Giaccio et al. [5], the effects of the ASR cracking pattern (i.e., micro- and macrocracks) and crack-filling gel on the mechanical behaviors of concrete over time were discussed comprehensively, and they were considered in the mechanical model. The proposed model was verified by comparison with existing test results, and the change in mechanical behavior of ASR-damaged concrete according to crack patterns and the mechanical contribution of gel was investigated in detail.

2 Experiment to identify the mechanical contribution by chemical composition change of gel

2.1 Test program

In this section, SEM–EDS analysis and nano-indentation tests were conducted to observe the change in chemical composition and elastic modulus of the gel filling the cracks, and the mechanical contribution of the ASR gel was quantitatively investigated. To prepare the samples for SEM–EDS analysis and nano-indentation tests, a mortar bar specimen (40 mm × 40 mm × 160 mm) was cast using 322 kg/m3 of water, 643 kg/m3 of cement, 611 kg/m3 of non-reactive aggregate, and 613 kg/m3 of reactive sand. The water-to-cement ratio (W/C) was 0.5, and an andesite aggregate with a maximum size of 5 mm was used as the reactive sand. After curing for 7 d, the mortar bar was kept in 1 mol/L NaOH at 80 °C, and its expansion was measured using a dial gauge on the contact chips attached to the surface at intervals of 100 mm, as shown in Fig. 1a. The expansion was recorded as the average value measured on both sides.

When the expansion reached 0.35%, the acceleration of ASR was terminated, and the specimen was stored at room temperature. Subsequently, the specimen was sliced into small pieces for SEM–EDS and nano-indentation tests. The sliced sample with a thickness of 1 cm was dried at 50 °C oven for 1 d, impregnated with low viscosity epoxy under a vacuumed condition and cured for 1 d. The impregnated sample was polished using silicon carbide papers with grits of 220–1000 and oil-based diamond paste of 15 μm, 9 μm, 3 μm and 1 μm with oil-based lubricant. After cleaning in an ultrasonic bath with ethanol, the polished sample was observed under a microscope and the locations of the ASR gel filling the cracks were marked. The sample was cut to have a smaller size of 1.0 cm × 1.0 cm at the location of ASR gel, and it was used for SEM–EDS analysis and nano-indentation tests. SEM–EDS analysis was conducted using backscattering electron (BSE) detection in JSM-7900F, in which an accelerating voltage of 15 kV and a working distance of 10 mm were used. Nano-indentation tests were performed at multiple points around the location of the ASR gel using ENT-NEXUS nano-indentation tester. The maximum load was 10 mN, and the stiffness was calculated with setting 0.18 of Poisson’s ratio [25] from the load-depth curve using data analysis on ENT-NEXUS software.

2.2 Test results

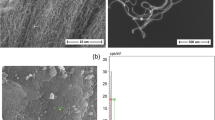

Figure 1b shows the expansion of the mortar bar specimen in 1 mol/L NaOH solution at 80 °C. The nano-indentation test and SEM–EDS analysis were performed when the expansion reached 3500 \(\mu \varepsilon\) at 2 months. Figure 2 shows the location of the ASR gel used for the test. Figure 2a, b are the ASR gel observed by a microscope and SEM with a backscattered electron (BSE) detector. The ASR gel filled the cracks that occurred along the perimeter of the reactive aggregate. The observation view in SEM and microscopy images did not perfectly match; therefore, aggregates A and B are marked in Fig. 2a, b. The color of the ASR gel observed in the SEM image differed according to the location. The gel located around the aggregate (location A) had a darker color than the cement paste (location B) because of the different chemical compositions of the gel. The stiffness and chemical composition of the gels were measured at location A around the aggregate and location B within the cement paste. Figure 2c, d are the measuring points used for the nano-indentation test in locations A and B. To measure the stiffness, multiple points were designated in the form of a matrix with an interval of 10 μm.

The analysis results from nano-indentation and SEM–EDS at location A are presented in Fig. 3. Figure 3b shows the elastic modulus measured by nano-indentation at the area marked as a yellow box in Fig. 3a. The elastic modulus is plotted in a color map for easy comparison with the EDS results. In the color map, yellow indicates a higher elastic modulus and green indicates a lower elastic modulus. At location A, the elastic modulus decreased as the gel approached the reactive aggregates. Figure 3c–f show the chemical composition distribution at location A measured from the EDS mapping, where the 7 × 5 grid indicates the areas of nano-indentation measurements. However, it was difficult to observe a small difference in the chemical composition by mapping analysis; therefore, line analysis was performed, as shown in Fig. 4, in which three lines were selected to avoid vacant regions. The changes in calcium (Ca), sodium (Na), and silica (Si) were examined along lines a, b, and c. The changes in the chemical composition measured along the blue lines in Fig. 4 are compared with the elastic modulus shown in Fig. 3b. The graph at bottom left compares the average values of calcium (Ca) calculated at intervals of 0.015 mm in the area indicated by the blue line with the measured elastic modulus, showing that the change in Ca was significantly correlated with the elastic modulus. The elastic modulus increased with Ca, and the gel near the cement showed a higher amount of calcium and elastic modulus.

At location B, the relationship between the elastic modulus and chemical composition of the gel was identified more clearly. As shown in Fig. 5, the elastic modulus of the gel in the upper left part was lower than that in other parts, and the higher calcium and less sodium existed in the region in which high elastic modulus was measured. Based on the analysis results at locations A and B, the ASR gel with high calcium and low alkali content showed an elastic modulus ranging from 30 to 40 GPa, whereas the ASR gel with low calcium and high alkali content had an elastic modulus of approximately 10 GPa. The elastic modulus of 30–40 GPa is comparable to that of normal concrete, suggesting that the crack-filling gel and solidification of the gel can play important roles in the recovery of ASR damage.

3 Modelling mechanical contribution of gel in constitutive laws of concrete

3.1 Framework for simulation of ASR-damaged concrete

It is estimated that the ASR gel filled the cracks over time and became a calcium-rich gel with a high elastic modulus based on the experiment. To reflect the time-dependent contribution of the ASR gel to the mechanical behavior of concrete, in this study, a model for ASR-damaged concrete was proposed based on a finite element analysis model (i.e., known as COM3), which was developed by the authors’ research team [26,27,28,29,30,31,32]. In previous studies conducted by Takahashi et al. [30, 31, 33, 34], pore-skeleton model was proposed to simulate concrete expansion induced by ASR, considering the fluid material (i.e., ASR gel) filling the pores and cracks in concrete.

As shown in Fig. 6, the stress in concrete (\(\sigma_{ij}\)) is calculated by summing up the effective stress in the skeleton (\(\sigma_{ij}^{*}\)) and pressure in pore (\(p\)), as follows:

where \(\delta_{ij}\) is the Kronecker delta and \(l_{i}\) is the unit directional vector normal to the crack plane. Because the ASR gel is assumed to be a semi-fluid material, it is assumed that the pore pressure (\(p\)) does not cause shear stress. Considering the forces in the pores and skeleton in x-direction, the equilibrium equation can be expressed as follows:

where \(\rho\) is the total density of concrete, \(\rho_{f}\) is the density of the ASR gel, \(g_{x}\) is the acceleration of gravity, \(u_{x}\) is the displacement of concrete skeleton, and \(w_{x}\) is the displacement of the ASR gel. In addition, the subscript x represents the first derivative in terms of direction, whereas the subscript tt denotes the second derivative in terms of time. If the above equation is generalized in all directions, Eq. (3) is derived as follows:

When the ASR gel flows through the pores, viscous stress occurs owing to the contact with the skeleton, as shown in the bottom part of Fig. 6, and it should be equilibrated with the pressure gradient. Based on this, the dynamic equilibrium can be derived as follows:

To solve the above governing equations, the generalized strain, stress, and stiffness matrix are defined, where the pore strain (\(\zeta\)) and isotropic pressure (pio) are added to the last of the original concrete strain and stress tensors, and the pore pressure in each direction is added to the skeleton stress (see Fig. 7a). The pore pressure was calculated using the poro-mechanical model proposed by Takahashi et al. [30, 32], as shown in Fig. 7b. This model [30, 32] has an advantage in that the gel pressure is estimated by reflecting the physical properties of the gel between the liquid and solid phases. While the pressure caused by the solid-phase gel is affected by the crack direction and volume, because the gel has low flowability, the pressure caused by the liquid gel is not significantly affected by crack direction. Therefore, it is assumed that the liquid gel causes isotropic pressure (pio), and the solid gel generates anisotropic pressure (pai) as follows:

Here, the generated ASR gel volume (Vasr) [\({\text{cm}}^{3} /{\text{cm}}^{3}\)] was assumed to increase linearly to its maximum during the gel generation period. The maximum gel volume was determined based on the target expansion of the simulated specimens. The solid gel volume ratio (\(\beta_{t}\)) at an arbitrary time (ti) can be obtained as follows [30, 32]:

where Δti is the increment of time at i-step and \(\Delta V_{{{\text{solid}},t_{i} }}\) is the solidified gel volume generated during Δti. Meanwhile, the stress–strain relationship in the skeleton concrete follows the constitutive laws of concrete proposed in Maekawa et al. [27], as summarized in Fig. 8 [27]. For the concrete element subjected to uniaxial force, the stress–strain relation in compression and tension are defined by Eqs. (9) and (10), respectively:

where \(\omega\) is the compressive strength reduction factor and decreases as the transverse tensile strain increases (refer to the uniaxial compression model in Fig. 8a and Eq. (12)). \(K_{0}\) is the fracture parameter proposed by Maekawa et al. [35] \(E_{{{\text{c0}}}}\) is the initial stiffness \(\left( { = 2.0\left( {f_{{\text{c}}} /\varepsilon_{{\text{c}}} } \right)} \right)\), \(\varepsilon_{{\text{p}}}\) is the plastic strain which is a function of \(\varepsilon /\varepsilon_{{\text{c}}}\), \(\varepsilon_{{{\text{tu}}}}\) is the cracking strain, and c is the softening parameter. Note that c is assumed to be 0.4 for ASR-affected concrete considering the crack-filling effect of ASR gel and 1.0 for plain concrete. The details of each parameter are provided in Ref. [27]. In addition, the stress transferred in the transition phase between tension and compression was calculated using the recontact model [27], as shown in the gray areas in Fig. 8a, b. According to this model, the compression stress can be transferred through a rough crack surface even before complete crack closure. For the shear transfer model, the equation in Fig. 8c was applied for the cracked normal concrete, where \(\beta_{{\text{s}}}\) is the normalized shear strain calculated by dividing the shear strain \(\left( {\gamma_{{{\text{cr}}}} } \right)\) by the tensile strain \(\left( {\varepsilon_{{\text{t}}} } \right)\), and \(\tau_{{{\text{st}}}}\) is the shear stress. The shear stiffness of normal concrete after cracking (G) can be calculated based on the shear stiffnesses of uncracked (Gc) and cracked (Gcr) concrete as follows:

Constitutive laws in the previous model [27]

Among the constitutive laws of concrete proposed in the previous model, compression, recontact, and shear models were developed in this study by reflecting the crack-filling effect of the ASR gel.

3.2 Discussion on crack-filling effect of gel

Based on the experimental results reported in Sect. 2, it can be concluded that if the gel fills the cracks, it can resist external forces because of its high stiffness. The crack-filling effect of the gel on the mechanical behavior of concrete was clearly observed in the compression test reported by Ji et al. [12], as shown in Fig. 9a. The specimens were classified into no expansion (N: normal concrete), medium expansion (M: 0.2% expansion), and high expansion (H: 0.4% expansion) series. All the specimens used andesite reactive coarse aggregate produced in Japan. In the specimen’s name, the number followed by the expansion level indicates the weeks elapsed since start of ASR acceleration to the compression test. Figure 9a summarizes the time at which compression test was conducted. Each test series included three specimens, labeled as − 1, − 2, and − 3. M- and H-specimens expanded by 0.2% and 0.4% in 14 weeks and in 26 weeks, respectively. It was observed that M14w and H26w specimens showed a lower elastic modulus than the normal concrete with no ASR damage (N-series). After the ASR-damaged specimens were stored at room temperature for several months (indicated by the blue line in the upper left graph of Fig. 9a), a gradual recovery in the elastic modulus was observed. For M-specimens, as represented by the red line in compression test results, the elastic moduli gradually increase from 14 to 52 weeks, eventually becoming almost the same as those of the N specimen (N52w). A similar tendency was observed in H- specimens from 26 to 52 weeks.

In addition, the compressive strength of concrete was not degraded by ASR expansion, even though the specimen was expanded by 0.4%. The compressive strength of the ASR-damaged concrete gradually increased slightly with time owing to the hydration effect. Regarding this, Ji et al. [12] suggested that the recovery of the elastic modulus of ASR-damaged concrete can be explained by gel solidification, in which the ASR gel reacts with calcium in the cement paste and hardens. Previous experimental data [16, 17, 36] also showed that the calcium-rich ASR gel (i.e., solidified gel) has high stiffness, and the experiment conducted in this study supports this phenomenon. In the experiment conducted by Ji et al. [12], because solidification occurred predominantly while the ASR expansion stopped, the elastic modulus recovered more effectively.

The hydration of the cement paste could be one possible reason why the compressive strength was not reduced by ASR damage. However, considering that even the concrete with 0.4% expansion (i.e., a large tensile strain) did not show reduction in compressive strength, other factors may have contributed to enhancing the compressive strength. In general, the pattern of cracks induced by ASR showed no directionality, and the micro- and macro-cracks were randomly distributed throughout the specimen. Microcracks are attributed to the internal gel pressure within the reactive aggregate, while macrocracks are mainly caused by the gradient of localized expansion owing to the aggregate nature and size, reactive sites, and environmental conditions. Thus, the microcracks generated close to the reactive aggregate can be easily filled by gel migration. Although Micro- and macrocracks coexisted in the ASR-damaged concrete, distributed microcrack patterns were predominantly observed. The compressive strength of concrete strongly depends on the cracking patterns because the stress transfer through the cracks is significantly affected by the crack width. In cases in which the distributed microcrack pattern is dominant, the transferred stress would be larger compared with the case in which a localized macrocrack pattern appears. In particular, if the gel fills the microcracks, the stress-transfer capacity can be improved.

In the experiment of Giaccio et al. [5], the compression behaviors of ASR-affected concretes (i.e., R2, R3, and R4) were different even under almost the same expansion ranging from 0.135 to 0.145%, as presented in the upper graphs in Fig. 9b. For the initial strength of R-specimens, since the mix proportions of the specimens were the same, except for the presence of reactive aggregates, the compressive strength of undamaged concrete was estimated based on the strength development curve of C1, as shown in the graph at the lower left of Fig. 9b. Here, it was assumed that the effect of aggregate nature is marginal compared to the effect of ASR damage on the compressive strength. In specimens R3 and R4 with high reactive and low reactive coarse aggregates, respectively, distinct crack patterns were observed. The R3 specimen exhibited more oriented and wider cracks, whereas the R4 specimen demonstrated a pattern of distributed microcracks. Consequently, despite similar expansions, the difference in crack patterns made the R4 specimen have a higher compressive strength and elastic modulus compared to the R3 specimen.

This result is attributed to the crack-filling effect of the gel and the microcrack pattern. As the ASR gel changes into a calcium-rich gel and the stiffness increases with time, the mechanical contribution of gel-filling cracks could be larger in the R4-specimen than in the R3-specimen. Moreover, the stress could be transmitted more effectively in the R4-specimen with small crack widths owing to the microcracking patterns. Based on the experimental observations and evidence, the mechanisms related to the mechanical properties of ASR-affected concrete can be hypothesized as follows:

-

1.

The mechanical contribution of the ASR gel gradually increased with time because the ASR gel solidified by reacting with calcium in the cement paste.

-

2.

Unlike macrocracks with wide widths, distributed microcracks do not have a critical impact on the reduction in compressive strength because stress can be transmitted effectively through microcracks.

-

3.

When the microcrack pattern is dominant, the mechanical contribution of the gel increases because the solidified gel fills the cracks more easily, leading to the recovery of ASR damage.

3.3 Model development considering mechanical contribution of ASR gel

Based on the aforementioned assumptions, the constitutive laws of concrete shown in Fig. 8 were modified to reflect the crack-filling effect of the ASR gel. The mechanical contribution of the ASR gel that results in the recovery of ASR damage was reflected in the uniaxial and shear models considering the effect of microcracks, which do not cause compressive strength reduction. Note that it is difficult to define a clear criterion to distinguish micro-and macro-crack patterns because crack sizes are widely distributed. Therefore, in this study, it was assumed that ASR cracks that affect the macroscopic compression behavior of concrete were macrocracks, while those that did not affect the compression behavior were microcracks.

In the compression behavior of normal concrete, as the tensile strain increased after cracking, the compressive strength in the direction parallel to the crack decreased owing to compression softening [27, 37]. To model this, the compressive strength reduction factor (ω) was adopted (refer to Fig. 8a), which is calculated as follows:

where εt,max is the transverse tensile strain causing compressive strength reduction. In the experimental results explained in Sect. 3.2, however, the compressive strength of ASR-affected concrete did not decrease despite the ASR expansion up to 0.4%, and a possible reason is the distributed microcrack pattern. Hence, it was hypothesized that the microcracks generated by the ASR do not cause compression softening, as shown in Fig. 10a. Based on this hypothesis, when calculating the compressive strength reduction factor (ω), the reduced tensile strain (ξεt,total) was applied considering the contribution of microcracks, as follows:

where ξ represents the ratio of macro-cracks that lead to a reduction in the compressive strength to the total cracks, and \(\varepsilon_{{\text{t,total}}}\) is the transverse tensile strain induced by ASR. According to the proposed model, when ξ is zero, compression softening does not occur because all the cracks are microcracks, whereas when ξ is 1.0, all strain due to ASR causes compression softening.

In the recontact behavior, if ASR gels with high stiffness fill the cracks, a larger compressive stress can be transferred through the cracks compared with the case of normal concrete with empty cracks. Therefore, in this study, it was assumed that the recontact stress increased as the gel filled the cracks, as shown in Fig. 10b. The recontact stress–strain curve was determined by the maximum recontact stress (\(\sigma_{{\text{ct,max}}}\)) and the strain \(\left( {\varepsilon_{{{\text{tl}}}} } \right)\) at which the recontact stress begins to increase, as represented in Sect. 3.1 (refer to Fig. 8b). The total maximum recontact stress (\(\sigma_{{\text{ct,max2}}}\)) reflecting the gel contribution \(\left( {\sigma_{{\text{ct,asr}}} } \right)\) is calculated as follows:

where \(\sigma_{{{\text{ct}},max1}}\) is the maximum recontact stress of normal concrete represented in Fig. 8b. To estimate the gel contribution (\(\sigma_{{\text{ct,asr}}}\)) to recontact stress, time-dependent physical properties of gels should be known. As the alkali-rich gel (i.e., liquid gel) changed into a calcium-rich gel (i.e., solid gel) by reacting with calcium in the cement paste, the elastic modulus of the gel increased with time, which was confirmed in this study. The solid gel volume (\(V_{{{\text{solid}},t_{i} }}\)) was calculated using Eq. (7) with respect to time, and the average elastic modulus of the gel was calculated as follows:

where \(E_{{\text{c,asrsolid}}}\) and \(E_{{\text{asr,liquid}}}\) are the elastic moduli of the solidified and liquid gels, respectively. \(R_{{{\text{asr}}}}\) and \(R_{{\text{asr,solid}}}\) are the crack-filling ratios of the total and solidified gels, respectively, and are calculated by dividing each gel volume by the crack volume (i.e., volumetric strain of concrete). Based on the nano-indentation test results of this study and the literature [25], \(E_{{\text{c,asrsolid}}}\) and \(E_{{\text{asr,liquid}}}\) were set to 20–40 GPa and 5 GPa, respectively. The recontact stress enhanced by gel contribution (\(\sigma_{{\text{ct,asr}}}\)) can be estimated considering the maximum capacity of the gel (= \(\varepsilon_{{\text{tl,asr}}} E_{{\text{c,asr}}}\)), as follows:

where \(\varepsilon_{{\text{tl,asr}}}\) is the strain from which the recontact stress increases, and \(\chi\) is a coefficient depending on the maximum tensile strain (\(\Delta \varepsilon_{{{\text{tmax}}}}\)) [27]. Through Eqs. (7), (15), and (16), the change in the physical properties of the gels with respect to time is reflected by the maximum recontact stress. According to Maekawa et al. [27], the recontact stress starts to develop at \(0.4\Delta \varepsilon_{{{\text{tmax}}}}\) (i.e., \(\varepsilon_{{{\text{tl}}}} = 0.4\Delta \varepsilon_{{{\text{t}}\max }}\)) in normal concrete, which is modified considering the gel contribution, as follows:

where η is newly introduced to reflect the local recontact behaviors (see “Appendix 1”) and is taken to be 0.8 based on the sensitivity analysis.

The mechanical contribution of the ASR gel filling the cracks is also reflected in the shear behavior of the cracked concrete, which is based on the shear transfer model of the previous model (refer to Fig. 8). In ASR-affected concrete, the shear resistance can be improved because of the bearing capacity of the gels filling the cracks. Hence, the shear stiffness of the ASR gel (Gasr) is added to the shear stiffness of the crack, as shown in Fig. 10c, and is calculated as follows:

The shear stiffness of the ASR gel (Gcr) was calculated as \(E_{{\text{c,asr}}} /2\left( {1 + v} \right)\), where v is Poisson’s ratio of the ASR gel (0.18) [16, 17]. In addition, as shown in Fig. 10c, reduced tensile strain \(\left( {\varepsilon_{{\text{t}}} } \right)\) is applied considering the crack-filling ratio of solidified gels (\(R_{{\text{asr,solid}}}\)).

4 Simulations on time-dependent behavior of ASR-affected concrete

4.1 Effect of mechanical contribution of gel on compression behavior of concrete

In the previous section, modified constitutive laws were proposed for ASR-affected concrete, considering that microcracks do not have a critical impact on the reduction in compressive strength (i.e., reflected by ξ) and recontact and shear behaviors can be improved as the solidified gel filling the cracks contributes to transferring stress. The newly introduced parameters reflect the effects of the crack pattern and crack-filling gel on the compression behavior of ASR-damaged concrete. Figure 11 shows the change in the compression behavior of concrete according to the ratio of macrocracks to total cracks and the gel contribution (i.e., gel stiffness and solidified gel ratio to crack volume). The analysis shown in Fig. 11a was performed on concrete cylinders with a diameter of 10 cm and height of 20 cm, in which the compression load was applied after the concrete expanded by 0.2% owing to ASR. As the macro-crack ratio (ξ) increased, compression softening affected the mechanical behavior more significantly under the same expansion level (see Fig. 11a), leading to decrease in compressive strength of concrete. Figure 11b shows a comparison of the compression behaviors of the ASR-affected concrete according to the stiffness of the gel and the solidified gel ratio to the crack volume. In this analysis, it was assumed that the concrete cylinder was subjected to ASR expansion of 0.15%. In the legend of Fig. 11b, the value followed by “E” indicates the stiffness of the solidified gel (Ec,asrsolid, GPa), and S1.5 means that the solidified gel ratio to crack volume was 1.5 times that in the case of S1.0 (Rasr,solid in Eq. 15). As mentioned in Sect. 3, it was hypothesized that the solid gel could fill cracks with small widths more easily than wide cracks; accordingly, a larger crack-filling ratio of the solid gel was also considered when the microcrack pattern was dominant. The analysis results indicated that as the Ec,asrsolid and crack-filling ratio of the solid gel increased, the compression performance of the concrete improved. Through these parametric analyses, it was confirmed that the effect of the cracking pattern on the compression behavior and mechanical contribution owing to crack filling by gels can be simulated reasonably.

4.2 Comparison of test and analysis

The compression test results reported by Ji et al. [12] and Giaccio et al. [5] were used for model verification because their test results clearly showed the effects of the time-dependent properties of the gel and crack patterns on the mechanical behavior of ASR-damaged concrete. Table 1 summarizes the collected test specimens, and the test details are explained in Sect. 3.2. In an experiment by Ji et al. [12], 100 mm × 200 mm cylinders were fabricated with andesite coarse aggregates. The target ASR expansions of M- and H- specimen series were 0.2% and 0.4%, respectively. The compression tests of the M14w and H26w specimens were conducted when the specimens reached their target expansions. In addition, the M26w and H52w specimens were planned to investigate how the mechanical behavior of concrete changes with time after the ASR expansion stops; thus, compression tests of M26w and H52w were also performed at 12 and 26 weeks later than the experiments on the M14w and H26w specimens, respectively. The test results showed that the M26w and H52w specimens had better mechanical properties (i.e., stiffness and strength) than the M14w and H26w specimens, which were comparable to those of normal concrete without ASR damage (Fig. 9a).

Giaccio et al. [5] compared the compression behaviors of concrete at different reaction rates (Fig. 9b). In their tests, different types of reactive aggregates were used (Table 1). Nonreactive coarse aggregate and natural reactive sand were applied to the R2 specimen, highly reactive coarse aggregate and nonreactive sand were used for the R3 specimen, and low reactive coarse aggregate and nonreactive sand were used for the R4 specimen. Specimens R3 and R4 had the fastest and slowest expansion rates, respectively; consequently, they clearly exhibited different cracking patterns. While oriented cracks with large widths were observed in the R3 specimen, a random microcracking pattern was observed in the R4 specimen. Based on the experimental observations, the parameters representing the effects of crack pattern and gel contribution were determined.

Before simulating the compression behavior of ASR-damaged concrete, a compression analysis was conducted on normal concrete specimens to validate the rationality of the model. “Appendix 2” compares the analysis and test results for the normal concrete specimens reported by Ji et al. [12], and the compression behavior of normal concrete was accurately evaluated. For ASR-damaged specimens of Ji et al. [12], there was no reduction in the compressive strength in the experiment, which was presumably attributed to the distributed microcrack pattern; thus, \(\xi\) = 0.7 (i.e., 70% of cracks contribute to compression softening) and \(E_{{\text{c,asrsolid}}}\) = 20 GPa were assumed in the analysis (see Table 2). As shown in Fig. 12a, in the M-specimen series with an expansion of 0.2%, the analysis results obtained using the proposed model indicated that the mechanical properties (i.e., stiffness and compressive strength) were recovered with time, which are well matched with the actual compression behaviors of test specimens. The recovery of mechanical properties can be properly reproduced through the solidified gel filling ratio to the crack volume (\(R_{{\text{asr,solid}}}\)), which increases over time. As shown in Fig. 12c, the solidified gel volume increases with time (see Eq. (7)), which contributes to the mechanical resistance and eventually leads to recovery. Figure 12b shows a comparison of the analysis and test results of H-specimen series, where 0.4% expansion was introduced through accelerated ASR. The same value of \({\upxi }\) was applied as in the analysis of the M-specimen series, and the proposed model was also found to reasonably simulate the phenomenon in which the mechanical properties of ASR-damaged concrete recovered with time. However, the stiffnesses of the H-specimen series were underestimated by the proposed model, which is probably because of the variance of mechanical contribution of ASR gel. In the analysis, the elastic modulus of solid gel was assumed as a constant (= 20 GPa) and the amount of solid gel was estimated by Eq. (7), but they may vary depending on chemical reaction. The parameters used in this analysis are appropriate for the concrete with medium expansion, and it would be necessary to investigate gel contributions for the concrete with high expansion.

Comparison of analysis and test results [12]

As mentioned above, Giaccio et al. [5] reported the ASR crack patterns of specimens observed through a microscope; the R4 specimen with a slow reaction rate showed a remarkable microcrack pattern, whereas the R2 and R3 specimens had relatively larger cracks. The measured maximum crack widths in the cement pastes are summarized in Table 2. The R4 specimen had crack widths ranging from 0.009 to 0.025 mm, whereas the R2 and R3 specimens showed maximum widths of 0.1 mm and 0.2 mm, respectively. Based on the crack patterns of test specimens, \(\xi\) was set to be 0.7 (i.e., 30% of cracks were assumed to be microcracks) for the R4 specimen and 1.0 (i.e., all the cracks are macro-cracks) for the R2 and R3 specimens. The microcrack ratio used in this analysis must be validated in the future by evaluating the crack patterns of ASR-damaged concrete according to the reaction kinetics and investigating the relationship between the crack patterns and mechanical properties.

As shown in Table 2, considering that solid gels fill small cracks more easily than larger cracks, the crack-filling ratio of the solidified gels in the R4 specimen was assumed to be twice the Rasr,solid calculated using Eqs. (7) and (8), and 1.0–1.5 times the Rasr,solid was applied in the simulations of the R2 and R3 specimens. In addition, because the elastic modulus of the solid gel (Ec,asrsolid) ranged from 20 to 40 GPa, both the minimum and maximum values of Ec,asrsolid (i.e., 20 GPa and 40 GPa) were considered in the simulation of R2 specimen to investigate the sensitivity of the parameter. The compressive strength and elastic modulus of the R2 specimen for each parameter are compared in Fig. 13a–c. The analysis results showed that as the crack-filling ratio of the solidified gels and/or the elastic modulus of the solid gel increased, the mechanical contribution of the gel increased, leading to an increase in the compressive strength and elastic modulus of the concrete. The reduction in the mechanical properties of concrete owing to ASR was accurately traced when 1.0Rasr,solid and Ec,asrsolid of 20 GPa were used in the simulation.

Comparison of test and analysis results for specimens in [5]

Because coarse reactive aggregates were applied to specimens R3 and R4 (see Table 1), the analysis results for R3 and R4 are presented in the same graph in Fig. 13d, e. The test results showed that changes in the compressive strength and elastic modulus owing to ASR were highly dependent on the crack pattern and rate of expansion. In the R3 specimen with macro-cracks, the reduction in mechanical properties occurred more significantly than in R4 specimen with microcracks. In the analysis, as a larger \(\xi\) was used for the R3 specimen than that for the R4 specimen, a greater decrease in compressive strength under similar expansion was simulated, which is consistent with the test results. In addition, because the solidified gel ratio applied to the R4 specimen was larger than that of the R3 specimen due to the longer ASR period and microcrack patterns, the elastic modulus of the R4 specimen decreased less than that of the R3 specimen. Overall, the mechanical properties of ASR-damaged concrete were reasonably evaluated using the proposed model by considering the effects of ASR crack patterns and the resistance of the solidified gel filling the cracks.

By comparing the analysis and test results, the proposed model was found to be applicable for predicting the compression behavior of ASR-affected concrete with respect to time and expansion. The proposed model not only reflects the phenomenon in which the compressive strength is not significantly affected by microcracks, but also simulates the recovery of the elastic modulus with time owing to the resistance of the crack-filling gel. However, the parameters of macro-crack ratio (\(\xi\)) and crack-filling ratio of solidified gels (\(R_{{\text{asr,solid}}}\)) used for the simulation in this study were determined qualitatively based on the experimental observations (e.g., maximum crack width and directionality). Therefore, the distribution of ASR crack size should be evaluated quantitatively under various experimental conditions to determine a criterion distinguishing micro-and macro-cracks. In addition to crack size distribution, investigating the effect of crack direction on mechanical properties is highly recommended for a future study, because cracks occur in a specific direction under confined conditions, causing anisotropic mechanical behaviors in the damaged concrete. Also, the tensile behavior of ASR-damaged concrete can significantly affect the structural performance as well. Therefore, it is required to investigate the mutual effect of ASR damage and the crack-filling of gel on the tensile behavior of ASR-affected concrete.

Regarding the recovery of ASR damage suggested in this study, it is possible that the crack-filling effect of the gel may not appear in actual structures, especially in those with localized cracks. ASR causes both dispersed microcracks and localized macrocracks; however, there is still no research that can identify the reason why certain crack patterns (i.e., micro- or macro-cracks) become dominant in specific ASR environments. Therefore, it is recommended to conduct structural safety inspection to detect ASR damage as early as possible, so that development of localized cracks can be prevented. In the safety inspection, it is believed that the proposed model can be used to predict the performance of the structure based on the observed crack patterns and suggest appropriate repair and reinforcement time.

5 Conclusions

In this study, the mechanical behavior of concrete damaged by ASR was comprehensively examined by not only considering ASR damage but also reflecting the effect of a crack-filling gel. The mechanical properties of ASR-induced concrete can be changed with time owing to ASR damage and mechanical contribution of gel under various crack patterns. Based on the experimental observations, the constitutive laws of concrete for the compression, shear, and recontact behaviors were modified, and the proposed model was validated by comparing it with the test results of the mechanical properties of ASR-damaged concrete with various expansions and crack patterns. Based on this, the following conclusions were drawn:

-

1.

The mechanical contribution of the crack-filling gel was confirmed by microscopic observations using SEM–EDS analysis and nano-indentation tests, in which the distributions of the chemical compositions and elastic moduli of the gels filling the cracks were measured. In the experiments, the alkali-rich gel changed to a calcium-rich gel in the cement paste, and the elastic moduli of the alkali-rich and calcium-rich gels were approximately 10 and 30–40 GPa, respectively.

-

2.

The elastic modulus of 30–40 GPa is comparable to that of normal concrete, which suggests that the crack-filling gel and solidification of the gel play an important role in recovering from ASR damage.

-

3.

The effects of cracking pattern and crack-filling gels on the mechanical properties of ASR-affected concrete have been reviewed in detail in previous compression tests. Distributed microcracks did not have a critical impact on the reduction in compressive strength because stress can be transmitted effectively through microcracks. In addition, when the microcrack pattern was dominant, the mechanical contribution of the gel increased because the solidified gel filled the cracks more easily, leading to the recovery of ASR damage. By contrast, macrocracks with large widths reduced the mechanical properties because the damage can progress more easily and the gels are difficult to fill the cracks.

-

4.

Based on the experimental observations, a mechanical model for ASR-damaged concrete was proposed, in which the increase in gel stiffness with time due to solidification (Ec,asrsolid), crack-filling ratio of solidified gels (\({R}_{{\text{asr}},{\text{solid}}}\)), and macro-crack ratio (\(\xi\)) were introduced. The analysis results showed that the higher Ec,asrsolid and/or the smaller \(\xi\) led to improvement of mechanical properties of ASR-affected concrete, which is consistent with the tendency observed in the experiment.

-

5.

The ASR crack patterns and amounts of solidified gel may vary depending on the reaction kinetics and anisotropic confinement conditions. In addition, the proposed model underestimated the elastic modulus of concrete with high expansion. Therefore, further quantitative investigations on the crack distribution and solidified gel volume under various ASR conditions are required to determine the key parameters introduced in the proposed model (e.g., \(\xi\) and \({R}_{{\text{asr}},{\text{solid}}}\)) more precisely, by which the applicability of the proposed model to the engineering field can be improved.

References

Miura T, Multon S, Kawabata Y (2021) Influence of the distribution of expansive sites in aggregates on microscopic damage caused by alkali–silica reaction: insights into the mechanical origin of expansion. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2021.106355

Kawabata Y, Dunant C, Yamada K, Scrivener K (2019) Impact of temperature on expansive behavior of concrete with a highly reactive andesite due to the alkali–silica reaction. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2019.105888

Sanchez LFM, Drimalas T, Fournier B (2020) Assessing condition of concrete affected by internal swelling reactions (ISR) through the Damage Rating Index (DRI). Cement 1–2:100001. https://doi.org/10.1016/j.cement.2020.100001

Fiset M, Sanchez LFM, Bilodeau S et al (2021) Influence of Alkali–Silica reaction (ASR) on aggregate interlock and shear-friction behavior of reinforced concrete members. Eng Struct 233:111890. https://doi.org/10.1016/j.engstruct.2021.111890

Giaccio G, Zerbino R, Ponce JM, Batic OR (2008) Mechanical behavior of concretes damaged by alkali–silica reaction. Cem Concr Res 38:993–1004. https://doi.org/10.1016/j.cemconres.2008.02.009

Leemann A, Shi Z, Lindgård J (2020) Characterization of amorphous and crystalline ASR products formed in concrete aggregates. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2020.106190

Shi Z, Park S, Lothenbach B, Leemann A (2020) Formation of shlykovite and ASR-P1 in concrete under accelerated alkali–silica reaction at 60 and 80 °C. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2020.106213

Shi Z, Geng G, Leemann A, Lothenbach B (2019) Synthesis, characterization, and water uptake property of alkali–silica reaction products. Cem Concr Res 121:58–71. https://doi.org/10.1016/j.cemconres.2019.04.009

Katayama T (2010) The so-called alkali-carbonate reaction (ACR)—its mineralogical and geochemical details, with special reference to ASR. Cem Concr Res 40:643–675. https://doi.org/10.1016/j.cemconres.2009.09.020

Balachandran C, Muñoz JF, Peethamparan S, Arnold TS (2023) Alkali–silica reaction and its dynamic relationship with cement pore solution in highly reactive systems. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2022.129702

Okano Y, Takahashi Y (2021) Macroscale and microscale studies on time-dependent mechanical properties of concrete with alkali silica reactions. In: Lecture notes in civil engineering, pp 1881–1890

Ji X, Joo HE, Yang Z, Takahashi Y (2021) Time-dependent effect of expansion due to alkali–silica reaction on mechanical properties of concrete. J Adv Concr Technol 19:714–729. https://doi.org/10.3151/jact.19.714

Miura T, Sato K, Fujishima M et al (2022) Mechanism for reduction in compressive properties of cementitious materials in relation to internal crack patterns due to ASR and DEF expansion. Cem Concr Compos 128:104441. https://doi.org/10.1016/j.cemconcomp.2022.104441

Inoue S (2022) Residual load carrying capacity of ASR damaged reinforced concrete beam after 12 years exposure. In: 16th international conference on alkali-aggregate reaction in concrete volume I. Lisboa, pp 985–994

Zheng K (2016) Pozzolanic reaction of glass powder and its role in controlling alkali–silica reaction. Cem Concr Compos 67:30–38. https://doi.org/10.1016/j.cemconcomp.2015.12.008

Hu C, Gautam BP, Panesar DK (2018) Nano-mechanical properties of alkali–silica reaction (ASR) products in concrete measured by nano-indentation. Constr Build Mater 158:75–83. https://doi.org/10.1016/j.conbuildmat.2017.10.006

Leemann A, Lura P (2013) E-modulus of the alkali–silica-reaction product determined by micro-indentation. Constr Build Mater 44:221–227. https://doi.org/10.1016/j.conbuildmat.2013.03.018

Moon J, Speziale S, Meral C et al (2013) Determination of the elastic properties of amorphous materials: case study of alkali–silica reaction gel. Cem Concr Res 54:55–60. https://doi.org/10.1016/j.cemconres.2013.08.012

Rajabipour F, Maraghechi H, Fischer G (2010) Investigating the alkali–silica reaction of recycled glass aggregates in concrete materials. J Mater Civ Eng 22:1201–1208. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000126

Boehm-Courjault E, Barbotin S, Leemann A, Scrivener K (2020) Microstructure, crystallinity and composition of alkali–silica reaction products in concrete determined by transmission electron microscopy. Cem Concr Res 130:105988. https://doi.org/10.1016/j.cemconres.2020.105988

Thomas M (2001) The role of calcium hydroxide in alkali recycling in concrete. In: Materials science of concrete: special volume: calcium hydroxide in concrete, pp 225–236

Rajabipour F, Giannini E, Dunant C et al (2015) Alkali–silica reaction: current understanding of the reaction mechanisms and the knowledge gaps. Cem Concr Res 76:130–146. https://doi.org/10.1016/j.cemconres.2015.05.024

Katayama T (2012) ASR gels and their crystalline phases in concrete-universal products in alkali–silica, alkali–silicate and alkali–carbonate reactions. In: 14th international conference of alkali-aggregate reaction. Austin, pp 1–12

Joo HE, Takahashi Y (2023) Analytical and experimental studies on alkali–silica reaction mechanism: aggregate cracking and chemical composition change of gel. Cem Concr Compos. https://doi.org/10.1016/j.cemconcomp.2023.105003

Takahashi Y (2019) A review of measurements and modellings of mechanical properties of products by alkali–silica-reaction in concrete. Concr J 57:454–460

Maekawa K, Fujiyama C (2013) Rate-dependent model of structural concrete incorporating kinematics of ambient water subjected to high-cycle loads. In: Engineering computations (Swansea, Wales), pp 825–841

Maekawa K, Okamura H, Pimanmas A (2003) Non-linear mechanics of reinforced concrete. CRC Press

Maekawa K, Ishida T, Kishi T (2008) Multi-scale modeling of structural concrete. Taylor & Francis, Oxford

Takahashi Y, Tanaka Y, Maekawa K (2018) Computational Life assessment of ASR-damaged RC decks by site-inspection data assimilation. J Adv Concr Technol 16:46–60. https://doi.org/10.3151/jact.16.46

Takahashi Y, Ogawa S, Tanaka Y, Maekawa K (2016) Scale-dependent ASR expansion of concrete and its prediction coupled with silica gel generation and migration. J Adv Concr Technol 14:444–464. https://doi.org/10.3151/jact.14.444

Ji X, Takahashi Y, Maeshima T et al (2022) Simulation of concrete structures deformation affected by alkali–silica reaction considering environmental conditions and multiaxial stress state. Struct Infrastruct Eng. https://doi.org/10.1080/15732479.2022.2063905

Joo HE, Takahashi Y (2021) Development of alkali–silica reaction model considering the effect of aggregate size. Cem Concr Compos 122:104149. https://doi.org/10.1016/j.cemconcomp.2021.104149

Takahashi Y, Tanaka Y, Maekawa K (2015) Chemo-hygral model for ASR expansion and its effects on fatigue lives of bridge slabs. In: XIII international conference on computational plasticity, fundamentals and applications, pp 944–955

Takahashi Y, Shibata K, Maekawa K (2014) Chemo-hygral modeling and structural behaviors of reinforced concrete damaged by alkali silica reaction. In: Asian concrete federation, pp 1274–1281

Maekawa K, Takemura J, Irawan P, Irie M (1993) Continuum fracture in concrete nonlinearity under triaxial confinement. Proc Japan Soc Civ Eng. https://doi.org/10.2208/jscej.1993.460_113

Zheng K, Lukovic M, De Schutter G et al (2016) Elastic modulus of the alkali–silica reaction rim in a simplified calcium–alkali–silicate system determined by nano-indentation. Materials 9:787. https://doi.org/10.3390/ma9090787

Vecchio FJ, Collins MP (1993) Compression response of cracked reinforced concrete. J Struct Eng 119:3590–3610. https://doi.org/10.1061/(ASCE)0733-9445(1993)119:12(3590)

Acknowledgements

This study was financially supported by JSPS KAKENHI Grant No. 21H01416 and 22K18825. We are greatly thankful to Prof. Junichiro Shiomi and Dr. A. Alperen Gunay from The University of Tokyo for their help with the nano-indentation experiments.

Funding

Open Access funding provided by The University of Tokyo.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Parameters regarding local recontact behaviors

The proposed mechanical model represents the global behavior of ASR-affected concrete. However, in concrete damaged by ASR, the local strains vary depending on the crack location and distribution; thus, it is necessary to propose a parameter that reflects the local recontact behaviors in the global response. Figure 14a shows the recontact behavior in local regions with different damages. In the uniaxial compression behavior of concrete, the orthogonal tensile strain can increase when the crack is closed. Therefore, it can be assumed that the time at which the local tensile strain began to increase corresponds to the time of crack closure. In Fig. 14a, \(\Delta \varepsilon_{{{\text{t}},\max 1}}\) and \(\Delta \varepsilon_{{{\text{t}},\max 2}}\) are the tensile strain induced by ASR in each local region. As shown in Fig. 14b, in the case where the crack is empty (i.e., Rasr is zero), the recontact stress starts to develop at strains of \(0.4\Delta \varepsilon_{{{\text{t}},\max 1}}\) and \(0.4\Delta \varepsilon_{{{\text{t}},\max 2}}\) in the regions with small and large damages, respectively [27], and \(\sigma_{{{\text{ct}},\max }}\) in the severely damaged region is larger than that in the less damaged area. In addition, when the crack is empty, compressive stress cannot be exerted during the initial stages of global compression behavior.

However, when the crack was fully filled with ASR gel, as shown in Fig. 14c, the recontact stress can develop from the crack strains (i.e., \(\Delta \varepsilon_{{{\text{t}},\max 1}}\) and \(\Delta \varepsilon_{{{\text{t}},\max 2}}\)), and \(\sigma_{{{\text{ct}},\max }}\) is larger than that in the case of empty cracks because of the mechanical contribution of ASR gel. Thus, in ASR-affected concrete in which the gel fills the cracks, compressive stress can be exerted immediately after loading. However, in a real situation, Cases 1–4, shown in Fig. 14b, c, appear simultaneously in the same local area, and thus, it is difficult to quantitatively estimate a representative value of \(\varepsilon_{{\text{tl,asr}}}\). Therefore, this study introduced a parameter, η, to reflect the local recontact behaviors in the global response and conducted sensitivity analysis, and the results are shown in Fig. 15a, b. When η = 0.8, the compression behavior of ASR-damaged concrete was most closely simulated, based on which η was set to be 0.8 in this study.

Appendix 2: Comparison of analysis and test results on compression behaviors of normal concrete

Figure 16 compares the analysis and test results for normal concrete specimens without ASR damage reported in Ji et al. [12], where N14w, N26w, and N52w are the compression behaviors of concrete cured at room temperature for 14, 26, and 52 weeks, respectively. It was confirmed that the compression behaviors of normal concrete specimens were accurately simulated using the proposed model.

Analysis results for normal concrete [12]

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Joo, H.E., Takahashi, Y. Crack-filling effect of gel on time-dependent mechanical behavior of concrete damaged by alkali–silica reaction. Mater Struct 57, 45 (2024). https://doi.org/10.1617/s11527-024-02308-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-024-02308-y