Abstract

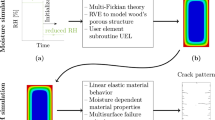

Recent rapid improvements in laminated timber technology have led to the increased use of wood in both mid- and high-rise construction, generally posed as a more carbon-friendly alternative to concrete. However, wood is significantly more sensitive to changes in relative humidity than concrete, which may impact the sustainability and durability of mass timber buildings. Moisture cycling in particular affects not only shrinkage and swelling but also strongly influences wood creep. This sensitivity is of high concern for engineered wood used in mass timber buildings. At the same time, wood, considered as an orthotropic material, exhibits varying diffusivity in all three directions, complicating efforts to characterize its behavior. In this work, an orthotropic hygroscopic model was developed for use in laminated timber. A species database for wood sorption isotherm was created and an existing model was used to fit species-based parameters. Diffusion behavior which considers the sorption isotherm was modeled through numerical simulations, and species-dependent orthotropic diffusion parameters were identified. A database of permeability in all directions for various species was created. The resulting model is able to predict diffusion behavior in glulam and cross-laminated timber (CLT) for multiple species of the lab tests. The model also predicts the moisture ranges for a CLT panel under environmental change with parameters from these sorption isotherm and diffusion databases.

Similar content being viewed by others

References

Lehne J, Preston F (2018) Making concrete change: innovation in low-carbon cement and concrete. Technical report, Chatham House

Sun X, He M, Li Z (2020) Novel engineered wood and bamboo composites for structural applications: State-of-art of manufacturing technology and mechanical performance evaluation. Constr Build Mater 249:118751. https://doi.org/10.1016/j.conbuildmat.2020.118751

Osborne L, Dagenais C, Bénichou N (2012) Preliminary clt fire resistance testing report. Advanced Building Systems-Serviceability and Fire Group, Point-Claire, Canada

Kremer P, Symmons M (2015) Mass timber construction as an alternative to concrete and steel in the Australia building industry: a pestel evaluation of the potential. Int Wood Prod J 6(3):138–147. https://doi.org/10.1179/2042645315Y.0000000010

Abrahamsen R (2017) Mjøstårnet-construction of an 81 m tall timber building. Int House Forum

Fernandez A, Komp J, Peronto J (2020) Ascent-challenges and advances of tall mass timber construction. Int J High-Rise Build 9(3), 235–244. https://doi.org/10.21022/IJHRB.2020.9.3.235

Žlahtič-Zupanc M, Lesar B, Humar M (2018) Changes in moisture performance of wood after weathering. Constr Build Mater 193:529–538. https://doi.org/10.1016/j.conbuildmat.2018.10.196

Usta I (2005) A review of the configuration of bordered pits to stimulate the fluid flow. Maderas. Ciencia y tecnología 7(2):121–132. https://doi.org/10.4067/S0718-221X2005000200006

Baker WJ (1956) How wood dries. Forest Product Laboratory

Silva C, Branco JM, Camões A, Lourenço PB (2014) Dimensional variation of three softwood due to hygroscopic behavior. Constr Build Mater 59:25–31. https://doi.org/10.1016/j.conbuildmat.2014.02.037

Ross RJ (2010) Wood handbook: wood as an engineering material. USDA Forest Service, Forest Products Laboratory

Holzer SM, Loferski JR, Dillard DA (1989) A review of creep in wood: concepts relevant to develop long-term behavior predictions for wood structures. Wood and Fiber Science, 376–392

Tong D, Brown SA, Corr D, Cusatis G (2020) Wood creep data collection and unbiased parameter identification of compliance functions. Holzforschung 74(11):1011–1020. https://doi.org/10.1515/hf-2019-0268

Hunt DG (1999) A unified approach to creep of wood. Proc R Soc Lond Ser A Math Phys Eng Sci 455(1991):4077–4095. https://doi.org/10.1098/rspa.1999.0491

Ranta-Maunus A (1975) The viscoelasticity of wood at varying moisture content. Wood Sci Technol 9(3):189–205. https://doi.org/10.1007/BF00364637

Mukudai J, Yata S (1986) Modeling and simulation of viscoelastic behavior (tensile strain) of wood under moisture change. Wood Sci Technol 20(4):335–348. https://doi.org/10.1007/BF00351586

Hoffmeyer P, Davidson R (1989) Mechano-sorptive creep mechanism of wood in compression and bending. Wood Sci Technol 23(3):215–227. https://doi.org/10.1007/BF00367735

Autengruber M, Lukacevic M, Füssl J (2020) Finite-element-based moisture transport model for wood including free water above the fiber saturation point. Int J Heat Mass Transf 161:120228. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120228

Pang S-J, Jeong GY (2020) Swelling and shrinkage behaviors of cross-laminated timber made of different species with various lamina thickness and combinations. Constr Build Mater 240:117924. https://doi.org/10.1016/j.conbuildmat.2019.117924

Chiniforush A, Akbarnezhad A, Valipour H, Malekmohammadi S (2019) Moisture and temperature induced swelling/shrinkage of softwood and hardwood glulam and lvl: An experimental study. Constr Build Mater 207:70–83. https://doi.org/10.1016/j.conbuildmat.2019.02.114

Skaar C (1988) Electrical properties of wood. In: Wood-water relations, pp. 207–262. Springer, Berlin. https://doi.org/10.1007/978-3-642-73683-4_6

Kaymak-Ertekin F, Sultanoğlu M (2001) Moisture sorption isotherm characteristics of peppers. J Food Eng 47(3):225–231. https://doi.org/10.1016/S0260-8774(00)00120-5

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60(2):309–319

Dent R (1977) A multilayer theory for gas sorption: Part i: sorption of a single gas. Text Res J 47(2):145–152. https://doi.org/10.1177/00405175770470021

Thémelin A (1998) Comportement en sorption de produits ligno-cellulosiques. Bois Forets des Tropiques 256: 55–67. https://doi.org/10.19182/bft1998.256.a19960

Oswin C (1946) The kinetics of package life iii the isotherm. J Soc Chem Ind 65(12), 419–421. https://doi.org/10.1002/jctb.5000651216

Merakeb S (2006) Modélisation des structures en bois en environnement variable. Université de Limoges 46

Hozjan T, Svensson S (2011) Theoretical analysis of moisture transport in wood as an open porous hygroscopic material. Holzforschung 65(1):97–102. https://doi.org/10.1515/hf.2010.122

Abbasion S, Carmeliet J, Gilani MS, Vontobel P, Derome D (2015) A hygrothermo-mechanical model for wood: part a poroelastic formulation and validation with neutron imaging. Holzforschung 69(7):825–837. https://doi.org/10.1515/hf-2014-0189

Gezici-Koç Ö, Erich SJ, Huinink HP, Van der Ven LG, Adan OC (2017) Bound and free water distribution in wood during water uptake and drying as measured by 1d magnetic resonance imaging. Cellulose 24(2):535–553. https://doi.org/10.1007/s10570-016-1173-x

Borrega M, Kärenlampi PP (2011) Cell wall porosity in norway spruce wood as affected by high-temperature drying. Wood Fiber Sci 43(2):206–214

Afshari Z, Malek S (2022) Moisture transport in laminated wood and bamboo composites bonded with thin adhesive layers-a numerical study. Constr Build Mater 340:127597. https://doi.org/10.1016/j.conbuildmat.2022.127597

Wood D, Vailati C, Menges A, Rüggeberg M (2018) Hygroscopically actuated wood elements for weather responsive and self-forming building parts-facilitating upscaling and complex shape changes. Constr Build Mater 165:782–791. https://doi.org/10.1016/j.conbuildmat.2017.12.134

Nakajima S, Sakabe Y, Kimoto S, Ohashi Y (2020) Deterioration of clt under humid and dry cyclic climate. In: XV international conference on durability of building materials and components (DBMC 2020). https://doi.org/10.23967/dbmc.2020.030

Bažant Z, Najjar L (1972) Nonlinear water diffusion in nonsaturated concrete. Matériaux et Construct 5(1):3–20. https://doi.org/10.1007/BF02479073

Di Luzio G, Cusatis G (2009) Hygro-thermo-chemical modeling of high performance concrete. i: Theory. Cement Concrete Comp 31(5):301–308. https://doi.org/10.1016/j.cemconcomp.2009.02.015

Krupińska B, Strømmen I, Pakowski Z, Eikevik T (2007) Modeling of sorption isotherms of various kinds of wood at different temperature conditions. Drying Technol 25(9):1463–1470. https://doi.org/10.1080/07373930701537062

Vishwakarma R, Shivhare U, Nanda S (2011) Moisture adsorption isotherms of guar (cyamposis tetragonoloba) grain and guar gum splits. LWT-Food Sci Technol 44(4):969–975. https://doi.org/10.1016/j.lwt.2010.09.002

Bažant ZP, Li G-H (2008) Unbiased statistical comparison of creep and shrinkage prediction models. ACI Mater J 105(6), 610–621. https://doi.org/10.14359/20203

Weichert L (1963) Investigations on sorption and swelling of spruce, beech and compressed beech wood at temperatures between 20 c and 100 c. Holz Roh Werkst 21(8):290–300

Fredriksson M, Thybring EE (2018) Scanning or desorption isotherms? characterising sorption hysteresis of wood. Cellulose 25(8):4477–4485. https://doi.org/10.1007/s10570-018-1898-9

Zhang X, Zillig W, Künzel HM, Zhang X, Mitterer C (2015) Evaluation of moisture sorption models and modified mualem model for prediction of desorption isotherm for wood materials. Build Environ 92:387–395. https://doi.org/10.1016/j.buildenv.2015.05.021

Pittet V (1996) Etude expérimentale des couplages mécanosorptifs dans le bois soumis à variations hygrométriques contrôlées sous chargements de longue durée. Technical report, EPFL. https://doi.org/10.5075/epfl-thesis-1526

Hill CA, Ramsay J, Keating B, Laine K, Rautkari L, Hughes M, Constant B (2012) The water vapour sorption properties of thermally modified and densified wood. J Mater Sci 47(7):3191–3197. https://doi.org/10.1007/s10853-011-6154-8

Papadopoulos A, Hill C (2003) The sorption of water vapour by anhydride modified softwood. Wood Sci Technol 37(3):221–231. https://doi.org/10.1007/s00226-003-0192-6

Zelinka SL, Glass SV (2010) Water vapor sorption isotherms for southern pine treated with several waterborne preservatives. J Test Eval 38(4), 1-5. Paper ID JTE102696. 38(4), 1–5. https://doi.org/10.1520/jte102696

Jalaludin Z, Hill CAS, Samsi HW, Husain H, Xie Y (2010) Analysis of water vapour sorption of oleo-thermal modified wood of acacia mangium and endospermum malaccense by a parallel exponential kinetics model and according to the hailwood-horrobin model. De Gruyter 64(6):763–770. https://doi.org/10.1515/hf.2010.100

Jakieła S, Bratasz Ł, Kozłowski R (2008) Numerical modelling of moisture movement and related stress field in lime wood subjected to changing climate conditions. Wood Sci Technol 42(1):21–37. https://doi.org/10.1007/s00226-007-0138-5

Okoh KI, Skaar C (1980) Moisture sorption isotherms of the wood and inner bark of ten southern us hardwoods. Wood and Fiber Sci 98–111

Choong ET, Achmadi SS (1991) Effect of extractives on moisture sorption and shrinkage in tropical woods. Wood and Fiber Sci 185–196

Perkowski Z, Świrska-Perkowska J, Gajda M (2017) Comparison of moisture diffusion coefficients for pine, oak and linden wood. J Building Phys 41(2):135–161. https://doi.org/10.1177/1744259116673967

Hukka A (1999) The effective diffusion coefficient and mass transfer coefficient of nordic softwoods as calculated from direct drying experiments. De Gruyter 53(5):534–540. https://doi.org/10.1515/HF.1999.088

Angst V, Malo KA (2012) The effect of climate variations on glulam–an experimental study. Eur J Wood Wood Prod 70(5):603–613. https://doi.org/10.1007/s00107-012-0594-y

Hawley LF (1931) Wood-liquid Relations vol. 248. US Department of Agriculture

Eitelberger J, Hofstetter K, Dvinskikh SV (2011) A multi-scale approach for simulation of transient moisture transport processes in wood below the fiber saturation point. Compos Sci Technol 71(15):1727–1738. https://doi.org/10.1016/j.compscitech.2011.08.004

Droin A, Taverdet J, Vergnaud J (1988) Modeling the kinetics of moisture adsorption by wood. Wood Sci Technol 22(1):11–20. https://doi.org/10.1007/BF00353224

Amer M, Kabouchi B, Rahouti M, Famiri A, Fidah A, El Alami S, Ziani M (2020) Experimental study of the linear diffusion of water in clonal eucalyptus wood. Int J Thermophys 41(10):1–17. https://doi.org/10.1007/s10765-020-02723-7

Simpson WT (1993) Determination and use of moisture diffusion coefficient to characterize drying of northern red oak (quercus rubra). Wood Sci Technol 27(6):409–420. https://doi.org/10.1007/BF00193863

Jönsson J (2004) Internal stresses in the cross-grain direction in glulam induced by climate variations. De Gruyter 58(2), 154–159. https://doi.org/10.1515/HF.2004.023

Chiniforush A, Ataei A, Valipour H, Ngo T, Malek S (2022) Dimensional stability and moisture-induced strains in spruce cross-laminated timber (clt) under sorption/desorption isotherms. Constr Build Mater 356:129252

Mannes D, Sanabria S, Funk M, Wimmer R, Kránitz K, Niemz P (2014) Water vapour diffusion through historically relevant glutin-based wood adhesives with sorption measurements and neutron radiography. Wood Sci Technol 48:591–609

Hayashi S, Ishikawa N, Giordano C (1993) High moisture permeability polyurethane for textile applications. J Coated Fabrics 23(1):74–83. https://doi.org/10.1177/152808379302300110

Franke B, Franke S, Schiere M, Müller A (2016) Moisture diffusion in wood–experimental and numerical investigations. In: World conference on timber engineering. https://doi.org/10.24451/arbor.7304

Tripathi J, Rice RW (2019) Finite element modelling of heat and moisture transfer through cross laminated timber panels. BioResources 14(3):6278–6293. https://doi.org/10.1007/s10570-018-1898-9

Kordziel S, Pei S, Glass SV, Zelinka S, Tabares-Velasco PC (2019) Structure moisture monitoring of an 8-story mass timber building in the pacific northwest. J Archit Eng 25(4). 14. https://doi.org/10.1061/(ASCE)AE.1943-5568.0000367

Kordziel S, Glass SV, Boardman CR, Munson RA, Zelinka SL, Pei S, Tabares-Velasco PC (2020) Hygrothermal characterization and modeling of cross-laminated timber in the building envelope. Build Environ 177:106866. https://doi.org/10.1016/j.buildenv.2020.106866

Belytschko T, Liu WK, Moran B (2000) Nonlinear finite elements for continua and structures. Wiley, New York

Acknowledgements

Financial support from the U.S. National Science Foundation (NSF) under Grant No. CMMI-20 1762757 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests:

The authors declare that they have no confict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Weighted least square method

In the isotherm database, data points are not necessarily distributed evenly along the x-axis (relative humidity). Thus, the data for each curve was divided by intervals of equal size. Noted that if the data points are almost equally spaced, it is not necessary to divide into intervals or add the weight. The number of intervals, n, was defined such that each interval has a similar number of data points, \(m_i\), where i = 1, 2,...n. To eliminate human bias, the same weight was assigned to each interval. This is achieved by considering the statistical weights \(w_i\) of the individual data points in each interval to be inversely proportional to the number \(m_i\) of data points in that interval and \(\sum _{i=1}^{n} w_{i}=1\). Then \({\bar{w}} = \sum _{i=1}^n\frac{1}{m_i}\) and \(w_i = \frac{1}{m_i{\bar{w}}}\) where the \(w_i\) is the \(i^{th}\) interval weight

Once the equal-weighted interval was obtained, the standard error s of the prediction model is defined as follows:

where \(y_{ij}\) are the measured isotherm data; \(Y_{ij}\) are the corresponding GAB predictions; N is the number of all data points in the database; p is the number of input parameters of the model (\(p =3\) for GAB model). \(\epsilon _{ij} = y_{ij}-Y_{ij}\) computes the arithmetic difference between the measured points and predictions.

Next, the least square estimation of unknown parameters is found by minimizing Eq. A1 for each individual data curve and the whole database, respectively. Once parameters are identified, it is possible to evaluate the fit and prediction quality. Two statistical indicators are introduced. The first is the coefficient of variation of the regression errors \(\omega\) (%) which characterizes the ratio of the scatter band width to the data mean \(\omega =\frac{s}{{\bar{y}}}\) and \({\bar{y}}=\frac{{\bar{w}}}{n} \sum _{i=1}^{n} w_{i} \sum _{j=1}^{m_{i}} y_{i j}\) where \({\bar{y}}\) represents the weighted mean value of measured points in the database. The smaller the \(\omega\) is, the more accurate the fitting results.

The second term is the coefficient of determination \(r^2\), which specifies the ratio of the scatter band width to the overall spread of data and designates what percentage of data variation is accounted for by the model response as \(r^2 = 1-\frac{s^2}{\bar{s}^2}\).

A value of \(r^2=1\) indicates the prediction is closer to measured points.

Appendix 2: Expanded derivation of the finite element implementation

The primary field, relative humidity h, in an infinitesimal control volume \(\Omega\) with the boundary subjected to the inflow/outflow of mass \(\Gamma _h\), the moisture mass balance equation reads

where the rate term (or capacity term) \(\partial u/\partial t=(\partial u/\partial h)(\partial h/\partial t)\), the diffusion flux density of water mass per unit time \(q_{h}=- {\textbf{J}}\cdot {\textbf{n}}\), \({\textbf{J}}\) is the mass flux density vector per unit time, \({\textbf{n}}\) is the normal vector of the boundary where the flux passes through. The flux density vector per unit time \({\textbf{J}}\) can be associated with the relative humidity gradient \(\varvec{ \nabla } h\) by an equivalent Darcy’s law \({\textbf{J}} = - \mathbf {D_u} ~ \varvec{ \nabla }h\) where \(\mathbf {D_u}\) is the orthotropic moisture permeability matrix.

To derive the finite element formulation, we need to find the weak form of the governing balance equations mentioned above. For boundary flux term, by using the divergence theorem:

Substituting Eq. 21 into Eq. 20 yields

By multiplying arbitrary test functions \(\delta h\) to Eq. 22, one obtains

After integral by parts, Eq. 23 becomes

The temporal discretization of rate terms uses the Backward Euler scheme:

where the subscript t denotes for the values in the current time step, \(t+\Delta t\) denotes for the values in the next time step.

The spatial discretization of the primary field is selected to be consistent with classical Galerkin FEM, which reads:

where \(n_{node}\) is number of nodes for the element, \(h_i\), and \(\delta h_i\) are nodal relative humidity and associated nodal testing function at the \(i^{th}\) node, respectively, \(N_i\) is the shape function at the \(i^{th}\) node, \(\partial N_i/\partial x_j\) is the first derivative of the shape function at the \(i^{th}\) node with respect to \(j^{th}\) dimension. The element-wise Eq. 24 can be discretized as

where \(\Omega ^e\) denotes the element domain, \(D_{ul}\) denotes the diffusivity in \(l^{th}\) dimension. By using the Einstein notation, the summations \(\sum _{i=1}^{n_{node}}\), \(\sum _{i=j}^{n_{node}}\), \(\sum _{k=1}^{3}\), \(\sum _{l=1}^{3}\) will be simplified in equations below. Since the variational field \(\delta h\) can be arbitrarily chosen, the term in the biggest braces of Eq. 27 should equal to 0, which makes:

Denotes Eq. 28 as function f, for the situation \(f = 0\), use Newton–Raphson method to linearize the equation with the form: \(f\left( x_{n+1}\right) =f\left( x_{n}\right) +\frac{\partial f\left( {x}_{n}\right) }{\partial x} \Delta x+ H.O.T\) (high order terms, neglected)

rearranging the equations yields

where the subscript n and \(n+1\) denotes the current and the next Newton step, respectively. The matrix on the left hand side is the Jacobian (or tangent stiffness) matrix (AMATRX in user subroutines). The vector on the right hand side is called residual (RHS in user subroutines).

Substituting the discritized rate term in Eq. (28) yields

For the variables that depend on humidity, since \(h_{t+\Delta t} = N_j h_{j,t+\Delta t}\), the variation with respect to the nodal humidity values can be written:

For the partial derivative of f with respect to h, the rate/capacity term reads:

the gradient term:

Combining Eq. 33 and 34, one gets:

Gauss quadrature is a prevalent approach for numerical integration in most finite element methods, it required the space mapping from the parent domain \(\varvec{\xi }\) to the physical domain \({\textbf{x}}\), however, this falls in conventional finite element scope and will not be derived here; for details, one may refer to [67].

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tong, D., Brown, SA., Yin, H. et al. Orthotropic hygroscopic behavior of mass timber: theory, computation, and experimental validation. Mater Struct 56, 109 (2023). https://doi.org/10.1617/s11527-023-02196-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02196-8