Abstract

In this study, the influence of calcium formate (CF) on the hydration of a synthesized calcium sulfate hemihydrate (HH) powder was investigated. Isothermal calorimetry measurements showed that CF retards the hydration reaction of HH. This was confirmed by XRD of stored samples and pore solution analysis. Two retardation mechanisms were identified. The combination of pore solution and laser granulometric experiments revealed that firstly, the initial dissolution of hemihydrate decelerates because of high Ca2+ ion concentrations, donated by the faster dissolving CF. Secondly, the HCOO− species of CF adsorb on surfaces of the gypsum crystals, as further pore solution measurements showed. This impedes their formation kinetic. The gypsum crystals exhibited anisotropic peak narrowing in XRD measurements when CF was added. This was caused by a morphology change, which could be verified using the anisotropic domain size morphology approach during Rietveld refinement analysis and SEM images. Gypsum crystals exhibit a blockier shape with CF addition compared to the usual acicular shape in pure water.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Gypsum plaster is a widespread building material, which is predominantly used in the interior of buildings because of its solubility and thus the increased potential for damage in outside conditions. It provides major benefits for the room climate, like regulating room temperature and relative air humidity. Furthermore, it acts as sound insulator and fire protector and also protects the walls of buildings mechanically and chemically [1,2,3].

During the hydration of gypsum plaster, the raw powder which is mainly composed of hemihydrate (CaSO4∙0.5H2O) dissolves and gypsum (CaSO4∙2H2O) precipitates. This process is rapid and finishes within less than one hour and the timeframe where the paste is workable spans only a few minutes. According to the EN 13279-1 standard however, the initial setting time of gypsum plasters should be at least 20 min [4]. Thus, the hydration of gypsum plasters needs to be controlled to improve their workability and other properties. This is accomplished by adding various organic agents. They can be classified by their function, for example reaction accelerators or retarders, dispersants, density-reducing or –increasing agents, antifoam and defoaming agents, etc. [5, 6]. Because of the fast setting of gypsum plasters, retarding agents are particularly important, and their effects need to be investigated in detail. According to Hill and Plank [7], retarding agents in principle can act in three ways:

-

by adsorbing on the surfaces of the raw phases, in this case hemihydrate.

-

by forming complexes in the pore solution with the required ions of the hydrate phases.

-

by adsorbing on the surfaces of the hydrate phases, in this case gypsum.

Most commonly, retarding agents act by adsorbing on to the growing gypsum surfaces, although hindrance of the hemihydrate dissolution is reported as well [8,9,10,11]. Calcium formate (CF, Ca(HCOO)2) is a common organic additive in cementitious systems. It has been the subject of many investigations regarding its influence on the setting of cements. Generally, monocarboxylic acids (C1 to C4) and their salts are reported have accelerating effects, whereas higher carboxylic acids act as retarders [6, 12]. Early investigations in the 1960s found, that CF accelerates the setting and increases the early strength of Ordinary Portland Cement (OPC) [13]. Later, Heikal (2004) [14] discovered that the initial and final setting times are shortened in pozzolanic cements and OPC. He explains this effect with a much higher diffusion rate of HCOO− compared to Ca2+ ions. HCOO− species penetrate the hydrated layers covering C3S and C2S grains, which accelerates their dissolution and simultaneously the precipitation of portlandite (Ca(OH)2) and C–S–H. This also leads to an increase in the degree of hydration. A property that affects the effectiveness of CF is the C3A/SO3 ratio in the cement. In under sulfated cements (C3A/SO3 > 4), the potential for accelerating the early strength is higher than in cements with higher sulfate content [15]. Jin et al. [16] investigated the effect of CF on the early hydration of alkali silicate activated slag. They found that it extended the working time, although it had no influence on hydration kinetics. Thus, they linked the effect of CF to the depletion of Si concentration in the solution, which decreased the amount of C–S–H gel at the early stage of hydration.

CF is also commonly applied in gypsum plasters. It is known to improve the adhesion of the plaster on plastic and metal surfaces and to prevent sodium sulfate efflorescence caused by subsequent moisture [17]. The influence of CF on the early hydration of gypsum plasters however has not been investigated yet. This is an important issue since the hydration of gypsum plasters is affected by a number of organic agents. Their performance might however be influenced if individual organic additives affect the hydration or interact with one another. Gartner [18] investigated the effect of various calcium carboxylate salts on bulk expansion of a hydrating gypsum plaster. He found that CF modifies the morphology of gypsum crystals from acicular to blocky shapes, which is a strong indication that certain crystal faces are occupied by CF, thus reducing growth of gypsum crystals in that direction thereby altering the crystal shape.

This study systematically investigates the influence of CF on the early hydration of a calcium sulfate hemihydrate powder mainly by XRD and heat flow calorimetry. Furthermore, the potential adsorption of CF on gypsum crystals is studied by laser diffraction method in combination with pore solution analysis.

2 Materials and methods

All measurements were performed at 23 ± 0.5 °C and at a water-to-solid ratio (w/s) of 0.8. The stirring time of water with powder was one minute. Hemihydrate and various dosages of CF (0, 0.5, 1, 2.5, and 5 wt.%, in relation to the hemihydrate powder) were investigated. CF was dry mixed as a powder to the hemihydrate before mixing with water. Each measurement was reproduced twice, and results are presented as expressed mean values with error bars indicating the standard deviation.

2.1 Hemihydrate powder characterization

To model a pure gypsum plaster without minor phases or impurities, hemihydrate was synthesized from a gypsum batch from Carl Roth GmbH & Co.KG with purity ≥ 98%. The gypsum powder was stored for 24 h in a 100 °C oven, where mainly it dehydrated into hemihydrate, next to small amounts of anhydrite. The dehydrated powder was then characterized by XRD measurements in a Bruker D8 Advance device with quantification error ± 0.1 wt.%, with Bragg–Brentano geometry and a Lynx-Eye detector, using the Rietveld refinement analysis method with the software TOPAS. Cu Kα radiation was used, voltage and current were set to 40 kV and 40 mA. The step size of each measurement step was set to 0.011°2θ, the counting time for each step was 0.6 s/step and the detection range was 7–70°2θ. The used structures for hemihydrate, anhydrite and gypsum have the PDF-numbers 83–0439 [19], 72–0916 [20], and 70–0982 [21], respectively. The dehydrated powder consists of 94.6 ± 0.3 wt.% hemihydrate, 5.0 ± 0.4 wt.% anhydrite (CaSO4), and 0.4 ± 0.1 wt.% gypsum (Fig. 1).

2.2 Heat flow calorimetry

Isothermal heat flow calorimetry was performed at 23 °C in a TAM Air calorimeter from TA-Instruments, with an instrumental error of ± 8 µW. InMixEr tools were used, which are custom-made for sample equilibration, water injection and mixing inside the calorimeter [22]. After water injection, the samples were stirred for one minute by means of an electrical motor at 380 rpm. This is advantageous as the heat flow can be recorded immediately from the time when water is injected without artefacts within the first minutes. Since the main hydration of hemihydrate, that can be detected as heat flow curve, is finished within the first hour, the adopted procedure is deemed essential as it is important to capture the heat signatures from the beginning. The measurements were recorded for 180 min.

2.3 XRD measurements of hydrated samples

Sample pastes were analyzed by means of XRD using Bruker D8 Advance device after 15, 30, 45, 60 and 360 min of hydration to understand the phase development. The instrumental error is 0.1 wt.%. After mixing with water, the pastes were put into sealed sample holders with diameter of 25 mm, which is the same size as for the XRD sample holders. The samples were then stored in an Heratherm incubator from ThermoFisher Scientific at 23 °C. They were then cut parallel to the base into 3 mm thick slices using a Buehler Isomet low speed saw equipped with a diamond-coated blade. The sample and saw were rinsed with isopropanol for removing saw dust and cooling purposes, and to stop further hydration of the cut surface. The samples were then immediately prepared for subsequent XRD measurement. The same instrumental settings and crystalline structures as for the raw powder characterization were applied again. The G-factor method was applied to quantify the samples during Rietveld refinement [23]. Quartzite, identical to that described in [23] was used as external standard. The samples were sealed with a Kapton film. The humps induced by water and Kapton film in the XRD patterns were fitted with models that were created as described by Bergold et al. [24].

The addition of CF yielded anisotropic peak narrowing produced from the grown gypsum in the XRD patterns compared to the pure hemihydrate samples. This is caused by a change in the domain morphology of the mineral phase [25, 26]. The term domain morphology refers to the coherently scattering domains (CSD) measured by XRD analysis. Crystalline particles are generally clusters of CSD. This change was calculated on the basis of geometrical shapes, such as cuboid, cylinder or ellipsoid [27, 28]. Depending on the crystal system and the expected morphology, the geometrical shape was adjusted accordingly as cuboid shaped. The anisotropic peak refinement was applied to the XRD samples stored for six hours to compare the calculated CSDs of the pure sample and one with 5 wt.% CF addition (HH–CF5%).

2.4 Porewater analysis during hydration

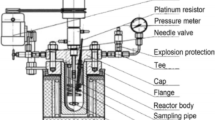

Porewater analyses during hydration were performed immediately after mixing the powder with water and after 15, 30, 45, 60, 120, and 180 min. At early stages of hydration, the pore solution was extracted by centrifuging the pastes in a Megafuge 1.0 from Heraeus Instruments at 4000 rpm for 5 min. At later stages as the pastes hardened, the pore solution was pressed out in a Stuermer Metallkraft hydraulic press of the type WPP30 at maximal pressures of 400 bar. Pressures need to be significantly higher (well above 1000 bar) to detect an influence on pore solutions [29]. For pure hemihydrate samples, the pore solution was extracted promptly after 15 min of hydration. In the sample with 5 wt.% CF addition, porewater could be extracted by centrifuging up to 45 min of hydration.

The extracted pore solution samples were then filtered through a syringe filter of 2 µm mesh size, before the pH of these samples was measured with a SevenCompact probe from Mettler Toledo. Then, 1/3 HNO3 was added to 2/3 porewater to stabilize the samples and avoid precipitation. Major cations (Na+, K+, Li+, NH4+, Ca2+, Fe2+, Mg2+) and trace elements were determined using an iCAP Qc ICP-MS from Thermo Fisher Scientific Inc. Samples were measured three times and the typical relative standard deviation (RSD) was < 1%. Operating conditions of the instrument are listed in Table 1 in the appendix. Major anions (F−, Br−, Cl−, NO3−, NO2−, SO42−, PO43−) were analyzed by ion chromatography (ICS 2000, Thermo Dionex). The typical RSD was < 5% based on the repeated analysis of two control standards in the lower and upper calibration range. Calcium and Sulphur were the only detected ions; no impurities in the samples were found.

The samples were furthermore analyzed for the carbon stable isotope ratio of dissolved inorganic carbon (δ13 CDIC) and dissolved organic carbon (δ13 CDOC) by an OI Analytical Aurora 1030W TOC-TIC analyzer (OI Analytical) coupled in continuous flow mode to a Thermo Scientific Delta V plus isotope ratio mass spectrometer (IRMS). For these measurements, samples were not acidified to prevent oxidation of the organic carbon. At first, each sample was added with 1 mL of 5% phosphoric acid (H3PO4) at 70 °C for 2 min to release the dissolved inorganic carbon (DIC) as CO2, which was then purged from the sample by helium. Secondly, 2 mL of 10% sodium persulfate (Na2S2O8) was reacted for 5 min at 98 °C to oxidize the dissolved organic carbon (DOC) to CO2. It was purged from the solution again by helium. A trap and purge (T&P) system was installed for the analysis of low concentrations. Concentration was determined from the signal of the OI Aurora 1030W internal nondispersive infrared sensor (NDIR) and a set of calibration standard with known concentrations prepared from analytical (A.C.S.) grade potassium hydrogen phthalate (KHP). The location of the sample peaks are directly proportional to the amount of CO2 generated by the reaction of the sample with acid (DIC) or sodium persulfate (DOC). Precision (i.e. reproducibility) was better than 5% RSD.

Saturation indices of the calcium sulfate minerals were calculated using the software PHREEQC [30] and the Thermoddem database of Blanc et al. [31]. Saturation indices were calculated excluding thermodynamic data of HCOO−, since they are not included in the database.

2.5 Laser granulometry

The dissolution behavior of the hemihydrate powder in water and in a CF solution was investigated using a Mastersizer 3000 laser granulometer from Malvern Panalytical with an RSD better than 1%. The CF dosage in the solution was 480 mmol/L, which is equal to the concentration of a HH–CF5% sample during hydration if CF dissolves completely. The solution volume was 600 ml and the mass of gypsum added was one gram. This is below the gypsum solubility and prevents precipitation, so only dissolution behavior is recorded. The measurement was started immediately after the powder was poured into the solution, and the particle size distribution was measured every 30 s for 5 min in total. Operating conditions during the measurements are listed in Table 2 in the appendix. The protocol followed here is based on identical dissolution experiments of Marschetzky [32].

2.6 Scanning electron microscopy (SEM)

Scanning electron microscopy (SEM) analyses were conducted on hardened gypsum pastes using secondary electrons with a TEXCAN VEGA II device to determine, whether CF addition leads to a morphology change of produced gypsum crystals. To prepare the samples, HHpure and HH–CF5% pastes were stirred with water and then stored for 24 h at 23 °C. Then the samples were dried at 40 °C for seven days. Then the samples were then carefully ground using a mortar-pestle and the powders were spread over sample carriers with conductive tape placed on a sample holder. The entire assembly (sample + foil + holder) was coated with an 8–10 nm conductive carbon layer to ensure no charge builds up on the sample during the analysis.

3 Results and discussion

3.1 Hydration of hemihydrate with CF

3.1.1 Heat flow calorimetry

The heat flow signatures of pure hemihydrate and with additions of 0.5–5 wt.% CF are displayed in Fig. 2. CF retards the hydration of hemihydrate. Increasing concentrations thereby lead to a stronger retardation. An addition of 5 wt.% delays the time of the main hydration peak from 10 to 45 min. Furthermore, a rising CF content suppresses the initial heat flow event increasingly strongly. An influence of CF can also be seen in the cumulative heat of hydration (Fig. 2, right y-axis). The pure hemihydrate sample reaches about 120 J/gsolid after 3 h, but cumulative heat drops with higher CF contents to a minimum of approximately 100 J/gsolid with 5 wt.% addition. This indicates that CF potentially lowers the degree of hydration. Further investigations were focused on the samples HHpure and HH–CF5%.

3.1.2 XRD analysis of hydrated samples

To check whether CF addition leads to a lower degree of the phase conversion, XRD measurements with G-factor analysis were performed up to 3 h from the start of hydration (Fig. 3). Calcium sulfate phases can easily be distinguished with this method because of their varying diffraction patterns. Characteristic peaks of gypsum are located at 11.6 and 20.7°2θ, for hemihydrate they are at 14.7 and 29.7°2θ, and the main reflex of anhydrite is at 25.4°2θ. For the used w/s of 0.8, the theoretical starting value of hemihydrate is 52.6 wt.% in the pure sample and 50.1 wt.% if CF is added. Whereas in the pure sample, hemihydrate is already almost completely dissolved after 15 min, with 5 wt.% calcium formate addition it can be detected up to 45 min after mixing with water. This can be seen evidently in Fig. 3 a) after 30 min hydration. Simultaneously, the gypsum precipitation is retarded in this sample. The trend of the precipitation indicates however a further slow gypsum formation, which might continue, until the gypsum contents are equal in both samples. The anhydrite content remains unaffected throughout the recorded timeframe.

3.1.3 Porewater analysis

Results of the porewater analysis are shown in Fig. 4. In the pure sample, calcium and sulfur concentrations are always equal within the measured time period. At the beginning of hydration, the concentrations lie slightly above 50 mmol/L, but drop rapidly to 20 mmol/L at the next measurement point after 15 min. After 30 min until the last measured point at 3 h, calcium and sulfur remain constant at relatively low concentrations of approx. 18 mmol/L. In the sample with CF, calcium and organic carbon concentrations remain at much higher level throughout the whole examination time. With a w/s ratio of 0.8, the concentration of CF in HH–CF5% should theoretically be 480 mmol/L if it dissolves completely. Ca2+ concentrations match this value very accurately if additional Ca2+ from the HH dissolution is taken into account. Calcium formate contains two moles of HCOO−, so concentrations should be at around 960 mmol/L. Measured values at the beginning fit this accurately, which shows that CF dissolves entirely immediately after the first contact with water.

However, the concentrations increase slightly over time. This might be caused by a reduction of liquid water in the system due to hemihydrate hydration into gypsum. Thus, organic carbon concentrations need to be corrected, which is shown in Fig. 5. The corrected concentrations show a decrease of dissolved HCOO− during hydration. The reason may be adsorption processes of HCOO− onto surfaces of gypsum crystals as discussed in a later section.

The retardation of the hydration can be understood by the development of the sulfur concentrations (Fig. 4). When CF is added, the sulfur ionic concentrations remained higher between 40 and 50 mmol/L compared to the pure hemihydrate sample. After 30 min the sulfur ion concentration began to drop, and after 60 min, concentrations remained stable at 12 mmol/L. The pH remained relatively constant throughout the hydration process in both samples. However, the measured values were around 7 in HH–CF5% and were higher by approximately 0.5 than in HHpure. Isothermal calorimetry, phase development, and changes in pore solution concentrations are in excellent kinetic agreement to one another.

The calculated saturation indices from porewater data of both gypsum and hemihydrate are reflecting one another in each sample and follow the sulfur concentrations (Fig. 6). The saturation of hemihydrate started at relative equilibrium below zero but drops to − 0.6 after 30 min without CF addition. The gypsum saturation index started at 0.7 but then drops to a relative equilibrium at 0.1 after 30 min. When CF was present, the saturation index values of hemihydrate and gypsum were initially similar to the sample without CF. However, they remained at high values (− 0.1, and 0.7, respectively) for a longer period of time. They begin to drop after 30 min, and after 60 min they reach again comparable values as in the pure hemihydrate sample.

The HCOO− species from CF can form complexes with the excessive calcium ions which are donated to the porewater by the organic agent itself, so the available Ca2+ for the growth of gypsum should not be affected by the formate addition. Retardation caused by complexation processes can therefore be excluded here with relative certainty. The longer near equilibrium conditions of the hemihydrate saturation index might indicate that its dissolution is hindered, which might be caused by adsorption of HCOO− on hemihydrate. In turn, the gypsum precipitation also would have to be slower to explain the higher sulfate values in the porewater in the first 30 min when CF is present. A retarded initial hemihydrate dissolution would also explain the decreasing initial heat flow with increasing formate content. The result can however also be interpreted the other way round. The gypsum saturation index remains at higher values for a longer period of time if CF is added. Simultaneously, XRD data show that the gypsum precipitation is slower, despite the high SI values. A probable reason may be that the gypsum growth is hindered by HCOO− adsorption on its surface planes. Since the ion concentrations then decline slower because of gypsum precipitation, the porewater composition remains in relative equilibrium with bassanite. Consequently, bassanite then dissolves slower as well. Whether calcium formate affects the hemihydrate dissolution and adsorbs on gypsum crystals will be investigated in the following part.

3.2 Hydration retarding effect of calcium formate

3.2.1 Influence on the hemihydrate dissolution

Immediately after mixing the hemihydrate powder with water, hemihydrate was still the predominant mineral phase (Fig. 3b). Porewater measurements at this point were conducted with the pure hemihydrate sample and with 1, 2.5, 5, and 10 wt.% CF additions (in regard to the hemihydrate powder, Fig. 7). The stirring time was one minute. The measured Ca2+ concentrations match the dissolved calcium formate amount, which again shows that it immediately dissolves completely after mixing with water. CF contains one mole of Ca2+ per two moles of HCOO−. The measured organic carbon concentrations were therefore plotted with halved values for better visibility. Measured and added carbon concentrations are then equal, which indicates that HCOO− initially doesn’t adsorb on surfaces of hemihydrate, but instead remains in the porewater. pH values slightly increase with rising CF content from 6.4 without CF, to approximately 7. From 5 to 10 wt.% CF addition, the measured pH remains constant.

Ca2+ concentrations are somewhat higher than the halved carbon concentrations at low CF addition. However, this difference decreases linearly with increasing formate content, and at 10 wt.% CF addition, Ca2+ and HCOO− concentrations are equal. This is unexpected, since the difference should remain consistently around 50 mmol/L, since this is the added content when the hemihydrate dissolves (Fig. 4, sulfur concentration at 0 min hydration time). The measured ion concentrations however suggest that the initial dissolution of hemihydrate lessens, the more CF is present in the solution. To investigate this phenomenon, dissolution experiments as described in part 2.5 were performed. Results are shown in Fig. 8 (a) for dissolution in water and (b) for dissolution in a CF solution of same molarity as in the HH–CF5% sample. The hemihydrate dissolution in water is evidenced by the decreasing proportion of large particle sizes (10–300 µm), accompanied by a simultaneous increasing proportion of small particle sizes (0.1–10 µm) (Fig. 8a). In the CF solution of 0.48 molarity however (Fig. 8b), minor differences in the particle size distribution only occur from zero to one minute in the range of small particles. After this initial dissolution the particle size distribution remains consistent. The results show that the dissolution of hemihydrate is impeded by the addition of calcium formate and explain the declining difference in the measured Ca2+ and HCOO− ion concentrations (Fig. 7). This is also the reason why the initial heat flow drops if CF is added (Fig. 2). There are several possible explanations why CF impedes hemihydrate dissolution. CF dissolves faster than hemihydrate and thereby donates Ca2+ ions to the porewater. The high calcium concentrations then may prevent hemihydrate from dissolving in the same rate as in pure water. Another explanation may be that CF alters the dissolution mechanism of hemihydrate. Juilland et al. [33] have observed that the dissolution of alite in pure water is rapid and dominated by the formation of etch pits. In a lime saturated solution however, the dissolution took place by step retreat formation and was much slower [33]. This might very well apply here as well. This behavior is the first mechanism that is responsible for the retarding effect of CF. Its influence on the growth of gypsum will be discussed in the following parts.

Particle size development of hemihydrate during its dissolution in a water and b CF solution of 0.48 molarity. This equals the CF concentration in the HH–CF5% sample during hydration. As has been done in [32]

3.2.2 Influence on the gypsum precipitation

To investigate the adsorption behavior of HCOO− on gypsum surfaces, a saturated gypsum solution containing excessive undissolved gypsum was prepared and continuously stirred. CF was then added stepwise every thirty minutes up to a concentration of 500 mmol/L, and ion concentrations as well as the pH of every step were analyzed. The amount of adsorbed organic carbon is the difference between the added and measured carbon concentrations (Fig. 9). Sulfur concentrations remain at the same very low level throughout the whole experiment. Ca2+ concentrations rise linearly with increasing CF amount. The measured values match the added CF, evidencing again that calcium formate dissolves completely. Interestingly, organic carbon concentrations show a different behavior. At lower concentrations up to 300 mmol/L, they rise linearly, similar to Ca2+, but with a lower slope. At higher concentrations, the increase flattens, even though CF is dissolved completely in the solution. This is a strong indication that HCOO− adsorbs on the excessive undissolved gypsum crystals in the solution. This behavior is stronger the more CF is present and might correlate to the rising pH. CF is a deprotonated formic acid with a pKa of 4.27. From pH 6 and higher, it is completely dissociated. HCOO− then protonates in water, thereby withdrawing H+ from the solution which leads to a rising pH. Protonated HCOOH is electrically neutral, so it does not adsorb on the positively charged surfaces of gypsum, which is why the measured concentrations are similar to the added amount for low formate contents. With increasing CF addition, a larger HCOO− portion remains deprotonated, which then is able to adsorb onto gypsum. The highest CF addition of 500 mmol/L resembles roughly the concentration in the HH–CF5% sample (at the given w/s ratio the CF concentration is 480 mmol/L). Here, the amount of adsorbed HCOO− is around 20% of the total added calcium formate.

This result also explains the corrected HCOO− concentrations during hydration (Fig. 5), where the rising gypsum content is accompanied by a decreasing dissolved organic carbon content in the system. Since gypsum precipitates, more crystal surfaces are then available where HCOO− can adsorb. The HCOO− adsorption onto gypsum surfaces slows its growth kinetic and is the second mechanism that is responsible for the retarding effect of CF on the hydration of gypsum plasters. This behavior is accompanied by a morphology change of the grown gypsum crystals.

3.3 Morphology change of the gypsum crystals

Comparing the XRD diagrams from HHpure and HH–CF5%, there is a small difference in the peak widths of the grown gypsum (Fig. 10). It can qualitatively be observed that the peaks belonging to the (020) lattice plane show smaller FWHM-values than the other peaks in the sample containing formate, whereas other peaks show the same width in both samples. This can be explained by a change in the morphology of gypsum crystals which leads to differences in the size of coherently scattering domains in different crystallographic directions. To check whether this is the case, an anisotropic crystallite size refinement was performed to compare HHpure and HH–CF5%.

The Scherrer equation [34] is used in TOPAS to relate the physical part of the peak broadening to the mean apparent crystallite sizes of phases. The commonly implemented calculations thereby give an isotropic mean volume to surface-weighted crystallite size for a phase, meaning that an average crystallite size is calculated for all related Bragg reflections of a corresponding crystal structure. Unless the crystal has the shape of a sphere, this model can however only be seen as an approximation [25]. In case of gypsum, a cuboid model reflects its structure much better (Fig. 11). The gypsum structure shown in Fig. 11 was created using the software VESTA 3.5.5 [35].

Usually, the isotropic domain size approach gives satisfying fitted results in the Rietveld refinement for gypsum quantification, despite the disparity to its actual structure. The anisotropic approach was used here to be able to compare possible differences in the shapes of the coherently scattering areas of the grown gypsum in the two samples. The results are shown in Fig. 12. The calculated radii of the pure gypsum are rx = 65.5, ry = 30.0, and rz = 97.4 nm. For the HH–CF5% sample, they are rx = 67.9, ry = 29.4, rz = 62.7 nm. As could be seen, the change in the peak width because of the presence of CF could be attributed smaller thickness of lattice planes in z-direction in the refined gypsum structure. Figure 13 shows that this also affects the morphology of grown gypsum crystals in the hardened paste. In HHpure, grown gypsum crystals exhibit acicular shapes, whereas the morphology in HH–CF5% appear blockier and more compact. This gives insights on the adsorption behavior of CF. Natural formed gypsum crystals exhibit acicular morphologies along the c-axis, because ions preferably attach there leading to higher stacking of lattice planes, compared to the a- and b-axis (Fig. 14). If the lattice planes which are relative perpendicular to the z-axis are occupied (here the (111) and \(\text{(11}\overline{1}\text{)}\) planes), the gypsum growth in this direction is suppressed compared to the other lattice planes, leading to a change in the crystal morphology. This agrees with Gartner [18] who observed that the morphology of grown gypsum crystals changed in a 20% CF solution into blockier forms, instead of the usual needles.

The key mechanism of retarding agents is mainly attributed to adsorption on preferred gypsum lattice planes, although hindrance of the hemihydrate dissolution is reported as well [7,8,9,10,11]. Common retarding agents are tartaric acid and citric acid. Their effectiveness is dependent on a high pH of at least 8 to 9; in acidic and neutral environments no or only little retardation is determined [7]. This probably also applies to CF, as discussed above. Another mutual characteristic is that the adsorption of tartaric and citric acid on preferred gypsum lattice planes also affects its crystal morphology. The reason is that the surfaces exhibit different energies, and therefore the agents preferably adsorb on certain surfaces over others [7]. The (020) lattice plane of a natural formed crystal is dominating (Fig. 14), however, the agents seem not to adsorb on it which leads to a preferred growth compared to the other lattice planes. The (020) lattice plane then becomes subordinate or even disappears completely [7, 36].

The results of this work show that CF acts in the same way as commonly applied retarding agents. An important difference is however the necessary dosage of the additives. In case of citric acid, concentrations of 500–1000 ppm are sufficient to delay the setting time to satisfactory times according to EN 13279-1 [11], which lesser than the CF dosage used in the current study. Nevertheless, the effectiveness of calcium formate might increase with rising pH as it is the case for citric and tartaric acid. Further research is necessary to validate this. Additionally, the possible interaction of CF with retarding agents when they are applied together might yield important insights about the optimal dosages of the various organic additives in industrial applications.

4 Conclusions

This study investigated the influence of CF on the hydration of hemihydrate. CF retards the setting of HH with two mechanisms. The first one is caused by the fact, that the formate initially dissolves faster than HH. The high calcium concentrations which are then present in the pore solution decelerate the initial HH dissolution. Pore solution analysis at the beginning of hydration showed, that HCOO− does not adsorb on hemihydrate crystals. The second retardation mechanism is the adsorption of HCOO− on crystal surfaces of the forming gypsum crystals, which inhibits their formation kinetic. Both effects intensify with increasing CF addition. In case of the adsorption, this is caused by the simultaneous rise in pH, which lowers the protonating drive of HCOO− species. Larger proportions then remain negatively charged in the pore solution and can adsorb on gypsum. Higher pH values may therefore increase the effectiveness of the retarding effect of CF.

The morphology of the gypsum crystals changes when the organic carbon adsorbs on their surfaces. The state of knowledge in present literature on this phenomenon could be confirmed with the anisotropic domain size model in Rietveld analysis. The z-axis, which is the fastest forming direction of gypsum crystals in water, shortens with CF addition. The lengths of the x- and z-axes were calculated to be even at the investigated calcium formate dosage, which leads to a blocky morphology instead of the usual acicular shape. This was confirmed by SEM images of hydrated gypsum particles.

CF acts in the same way as commonly applied retarding agents like tartaric and citric acid. Its possible interaction with these agents remains a topic for future research. This might help to identify optimal dosages of the additives to optimize workability and at the same time minimize added amounts when they are used together in industrial applications.

References

Lushnikova N, Dvorkin L (2016) 25 - Sustainability of gypsum products as a construction material. In: Khatib E 2nd (ed) J.M.B.T.-S. of C.M, Woodhead Publ Ser Civ Struct Eng, Woodhead Publishing, pp 643–681. https://doi.org/10.1016/B978-0-08-100370-1.00025-1

Durgun MY (2020) Effect of wetting-drying cycles on gypsum plasters containing ground basaltic pumice and polypropylene fibers. J Build Eng. https://doi.org/10.1016/j.jobe.2020.101801

Karni J, Karni E (1995) Gypsum in construction: origin and properties. Mater Struct 28:92–100. https://doi.org/10.1007/BF02473176

EN 13279-1:2008 (2008) Gypsum binders and gypsum plasters - Part 1: Definitions and requirements. Eur Comm Stand.

Engineer P, Chemicals OF (2015) Cement additives in petroleum. Diambil kembali dari Engineer's Guide to Oil Field Chemicals and Fluid. https://doi.org/10.1016/b978-0-12-803734-8.00010-2

American Concrete Institute Committee 212 (2010) Report on Chemical Admixtures for concrete

Hill JR, Plank J (2004) Retardation of setting of plaster of paris by organic acids: understanding the mechanism through molecular modeling. J Comput Chem 25:1438–1448. https://doi.org/10.1002/jcc.20070

Freyer D, Voigt W (2003) Crystallization and phase stability of CaSO4 and CaSO4—Based Salts. Monatshefte Fur Chemie 134:693–719. https://doi.org/10.1007/s00706-003-0590-3

Amathieu L, Boistelle R (1987) Zur Fremdstoffbeeinflussung des Wachstums von Gips: Auswirkungen auf die Kinetik der Hydratation, auf die Kristalltextur und die mechanischen Eigenschaften. Chemie Ing Tech 59:858–860. https://doi.org/10.1002/cite.330591109

Magallanes-Rivera RX, Escalante-García JI, Gorokhovsky A (2009) Hydration reactions and microstructural characteristics of hemihydrate with citric and malic acid. Constr Build Mater 23:1298–1305. https://doi.org/10.1016/j.conbuildmat.2008.07.022

Lanzón M, García-Ruiz PA (2012) Effect of citric acid on setting inhibition and mechanical properties of gypsum building plasters. Constr Build Mater 28:506–511. https://doi.org/10.1016/j.conbuildmat.2011.06.072

Myrdal R (2007) Accelerating admixtures for concrete. SINTEF Rep N SBF BK A 07025:1–35

Dodson VH (1990) Set accelerating admixtures BT—Concrete Admixtures. In: Dodson VH (ed), Springer, Boston. pp. 73–102. https://doi.org/10.1007/978-1-4757-4843-7_4

Heikal M (2004) Effect of calcium formate as an accelerator on the physicochemical and mechanical properties of pozzolanic cement pastes. Cem Concr Res 34:1051–1056. https://doi.org/10.1016/j.cemconres.2003.11.015

Gebler S (1983) Evaluation of calcium formate and sodium formate as accelerating admixtures for Portland cement concrete. ACI J Proc. https://doi.org/10.14359/10868.

Jin Y, Stephan D, Lu Z (2019) The effects of calcium formate on the early hydration of alkali silicate activated slag. Mater Struct Constr 52:1–9. https://doi.org/10.1617/s11527-019-1336-y

Aftergut JH, Kilkenny TJ (2004) Gypsum plaster compositions with improved adhesion to plastic surfaces and metal surfaces. United States Patent, 6699339B2

Gartner EM (2009) Cohesion and expansion in polycrystalline solids formed by hydration reactions—the case of gypsum plasters. Cem Concr Res 39:289–295. https://doi.org/10.1016/j.cemconres.2009.01.008

Bezou C, Nonat A, Mutin JC, Christensen AN, Lehmann MS (1995) Investigation of the crystal structure of γ-CaSO4, CaSO4, 0.5 H2O, and CaSO4, 0.6 H2O by powder diffraction methods. J. Solid State Chem. 117(1995):165–176. https://doi.org/10.1006/jssc.1995.1260

Kirfel A, Will G (1980) Charge density in anhydrite, CaSO4, from X-ray and neutron diffraction measurements, Acta Crystallogr. B Struct Crystallogr Cryst Chem 36:2881–2890. https://doi.org/10.1107/s0567740880010461

Cole WF, Lancucki CJ (1974) A refinement of the crystal structure of gypsum CaSO4.2H2O. Acta Cryst. B30: 921–929. https://doi.org/10.1107/S0567740874004055

Hertel T, Neubauer J, Goetz-Neunhoeffer F (2016) Study of hydration potential and kinetics of the ferrite phase in iron-rich CAC. Cem Concr Res 83:79–85. https://doi.org/10.1016/j.cemconres.2016.01.004

Jansen D, Goetz-Neunhoeffer F, Stabler C, Neubauer J (2011) A remastered external standard method applied to the quantification of early OPC hydration. Cem Concr Res 41:602–608. https://doi.org/10.1016/j.cemconres.2011.03.004

Bergold ST, Goetz-Neunhoeffer F, Neubauer J (2013) Quantitative analysis of C-S-H in hydrating alite pastes by in-situ XRD. Cem Concr Res 53:119–126. https://doi.org/10.1016/j.cemconres.2013.06.001

Ectors D, Goetz-Neunhoeffer F, Neubauer J (2015) A generalized geometric approach to anisotropic peak broadening due to domain morphology. J Appl Crystallogr 48:189–194. https://doi.org/10.1107/S1600576714026557

Schreiner J, Jansen D, Ectors D, Goetz-Neunhoeffer F, Neubauer J, Volkmann S (2018) New analytical possibilities for monitoring the phase development during the production of autoclaved aerated concrete. Cem Concr Res 107:247–252. https://doi.org/10.1016/j.cemconres.2018.02.028

Ectors D, Goetz-Neunhoeffer F, Neubauer J (2015) Domain size anisotropy in the double-Voigt approach: an extended model. J Appl Crystallogr 48:1998–2001. https://doi.org/10.1107/S1600576715018488

Ectors D, Goetz-Neunhoeffer F, Neubauer J (2017) Routine (an)isotropic crystallite size analysis in the double-Voigt approximation done right? Powder Diffr 32:S27–S34. https://doi.org/10.1017/S0885715617000070

Vollpracht A, Lothenbach B, Snellings R, Haufe J (2016) The pore solution of blended cements: a review. Mater Struct Constr 49:3341–3367. https://doi.org/10.1617/s11527-015-0724-1

Parkhurst DL, Appelo CA (2013) Description of input and examples for PHREEQC version 3—A computer program for speciation, batch-reaction , one-dimensional transport, and inverse geochemical calculations. U.S. Geological Survey Techniques and Methods, book 6, chapter A43, 497 p., U.S. Geol. Surv Tech Methods. B. 6, Chapter A43. 6–43A

Blanc P, Lassin A, Piantone P, Azaroual M, Jacquemet N, Fabbri A, Gaucher EC (2012) Thermoddem: a geochemical database focused on low temperature water/rock interactions and waste materials. Appl Geochem 27:2107–2116. https://doi.org/10.1016/j.apgeochem.2012.06.002

Marschetzky M (2013) Einfluss von Alkalisalzen und Fließmitteln auf die Hydratation von Calciumsulfathalbhydrat, Bauhaus-Universität Weimar

Juilland P, Gallucci E, Flatt R, Scrivener K (2010) Dissolution theory applied to the induction period in alite hydration. Cem Concr Res 40:831–844. https://doi.org/10.1016/j.cemconres.2010.01.012

Scherrer P (1918) Bestimmung der Größe und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen, Nachrichten von Der Gesellschaft Der Wissenschaften Zu Göttingen. Math Klasse 1918:98–100

Momma K, Izumi F (2011) VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J Appl Crystallogr 44:1272–1276. https://doi.org/10.1107/S0021889811038970

Schneider J (2010) Beitrag zur Wirkungsweise von Verzögerern beim Abbinden von Stuckgipsen. Technische Universität Bergakademie Freiberg

Acknowledgements

We would like to thank Christian Hanke from the department of applied geology for carrying out the porewater measurements, and also Christian Schulbert from the department of paleontology for helping with the SEM analyses.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fobbe, N., Goetz-Neunhoeffer, F. & Jansen, D. The influence of calcium formate on the hydration of calcium sulfate hemihydrate. Mater Struct 56, 92 (2023). https://doi.org/10.1617/s11527-023-02181-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02181-1