Abstract

This recommendation is devoted to testing the resistance of natural stone and fired-clay brick units against salt crystallization. The procedure was developed by the RILEM TC 271-ASC to evaluate the durability of porous building materials against salt crystallization through a laboratory method that allows for accelerated testing without compromising the reliability of the results. The new procedure is designed to replicate salt damage caused by crystallization near the surface of materials as a result of capillary transport and evaporation. A new approach is proposed that considers the presence of two stages in the salt crystallization test. In the first, the accumulation stage, salts gradually accumulate on or near the surface of the material due to evaporation. In the second, the propagation stage, damage initiates and develops due to changes in moisture content and relative humidity that trigger salt dissolution and crystallization cycles. To achieve this, two types of salt were tested, namely sodium chloride and sodium sulphate, with each salt tested separately. A methodology for assessing the salt-induced damage is proposed, which includes visual and photographical observations and measurement of material loss. The procedure has been preliminarily validated in round robin tests.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Scope of this recommendation

This procedure is aimed at evaluating the durability of porous building materials against salt crystallization through a laboratory method that allows for accelerated testing without compromising the reliability of the results.

The procedure is designed to replicate salt damage caused by crystallization near the surface of materials as a result of capillary transport and evaporation.

Damage by sodium sulfate or sodium chloride can be considered. Both salts are tested individually, at two possible concentrations.

The procedure has been validated on single materials with open porosity values between 13 vol% and 50 vol % and Water Absorption Coefficient (WAC) values between 50 and 1070 g/m2s0.5 [1].

The reasons for the choice of the details of the procedure can be found in [2].

The procedure and the proposed damage assessment methods aim to be as simple as possible (i.e., not requiring sophisticated equipment or specialized expertise) and to provide reliable results in a relatively short period of time, in order to be applicable in support of the building renovation and construction sector.

The procedure involves a novel approach [3], that draws from literature on reinforced concrete durability [4]. It operates under the assumption that sufficient salt needs to accumulate in the pores (pore filling) to initiate damage. As a consequence, salt damage is regarded as a two-stage process: (i) in the accumulation stage, salts accumulate in the pores of the material (but the degree of pore filling is not yet sufficient to initiate damage); (ii) in the propagation stage, repeated salt dissolution/crystallization cycles cause damage to initiate and propagate (Fig. 1).

This recommendation addresses the preparation of the specimens, the apparatus, the testing method, the damage assessment methodology and the information to be mentioned in the test report.

2 Specimens

2.1 Size, shape and number

The specimens consist of stone or brick cores of 50 ± 0.5 mm diameter and 50 ± 0.5 mm height.

At least 3 specimens should be used for each salt type and solution concentration.

2.2 Preparation of the specimens

Cores should be drilled in such a way that minimum damage is inflicted to the material. Wet drilling or jet water cutting are recommended. In the case of brick, it is preferable that the test face is the stretcher or the header face of the brick. In the case of natural stone, it is preferable that the direction of the bedding is parallel to the test surface. In any case, the core drilling direction should be indicated in the report.

After drilling, the loose brick or stone powder should be removed from the surface of the drilled cores, e.g., by the use of compressed air or careful washing with water. The core specimens should be dried to constant mass in a ventilated oven at 40 ± 2 °C/15 ± 5% RH. Constant mass is reached when the difference between two successive weighings at an interval of at least 24 h is ≤ 0.1%. Then, the specimen mass should be stabilized for 4 h at room conditions (22 ± 2 °C; 45 ± 15% RH). The mass of the specimen at the end of this period (initial mass, mi), should be registered in the test report, together with the corresponding values of room temperature and relative humidity.

The lateral surface of the specimens should be sealed with paraffin film, after pre-heating them in an oven at 50 °C for 10 min, to achieve better adherence. The paraffin film should extend 0.5 cm above the top surface of the specimens. A rubber O-ring should be used to secure good adhesion between the paraffin film and the uppermost area of the lateral surface of the specimen. Textile tape (water resistant and water vapour tight) can be used to secure the ends of the paraffin film and ensure sealing tightness during the entire test (Fig. 2).

2.3 Apparatus

The following apparatus is necessary for the execution of the test:

-

A climatic cabinet (or climatic room) able to reach and maintain the temperature and relative humidity conditions required by the test procedure. The cabinet is strictly necessary only in the case of the NaCl test procedure.

-

A laboratory oven able to reach and maintain a temperature of 40 ± 2 °C / 15 ± 5% RH.

-

A precision balance (minimum resolution 10−3 g and accurate to 10−2 g)

-

A digital camera

-

Glass or plastic containers for the contamination of the specimens, such as small crystallizing dishes or petri dishes (one container for each specimen; it is advised to use a container with a base dimension only slightly larger than the size of the specimen in order to reduce evaporation of the solution)

-

Boxes for storing the specimens during the accumulation and propagation stages

-

Temperature and relative humidity sensors for monitoring the conditions in the boxes containing the specimens (NB: the conditions in the boxes may deviate from those in the climatic cabinet/oven)

-

Japanese paper with grammage 10–25 g/m2

-

Rubber O-rings

-

Paraffin film

-

NaCl and/or Na2SO4 (thenardite): ACS reagents 99.0%

-

Demineralized water

-

A soft brush (toothbrush hardness “soft”)

-

Qualitative filter paper for separating the debris from the salts

3 Procedure

3.1 Accumulation stage procedure

The specimens are contaminated by capillary absorption of a salt solution from their bottom surface. Salt solutions are prepared using demineralized water and NaCl or Na2SO4 (thenardite) salts. The following salt solution concentrations are used:

-

Na2SO4: 5% and 10% by weight (expressed as salt weight / solution weight)

-

NaCl: 5% and 10% by weight (expressed as salt weight / solution weight)

Contamination takes place at room conditions (T = 22 ± 2 °C at 45 ± 15% RH).

The weight of salt solution used to contaminate a material should be equal to the capillary moisture content of the material, and determined as reported in Appendix 1. The evaporation of the solution can be minimized during absorption by covering the solution reservoir. This is particularly relevant in the case of materials with slow water absorption rate.

Immediately after the full absorption of the salt solution, the bottom surface of the specimens is sealed by covering it with a first layer of paraffin film and a second layer of tape, as shown in Fig. 3. Afterwards, the specimens are weighed again, and their mass is recorded (ms).

The specimens are set to dry at 40 ± 2 °C/15 ± 5% RH. In order to limit the influence of the ventilation rate, the specimens should be placed in a box. This is covered with a layer of Japanese paper to have nil air flow inside, while allowing for air exchange to keep the desired temperature and relative humidity conditions during the test (Fig. 4). The distance between specimens and between these and the box walls should be at least 2 cm. The temperature and relative humidity in the box should be monitored with a sensor. The weight of each specimen should be recorded over time.

The accumulation stage ends when 80% or more of the introduced water is evaporated. For example, if 100 g of salt solution at 10% concentration has been used to contaminate the specimen, the drying ends when at least 72 g of water (0.8 * 90 g = 72 g) has evaporated.

At the end of the drying period, the presence of efflorescence and/or damage is photographically recorded and described according to the methodology reported in Sect. 4.1.

3.2 Propagation stage procedure

The propagation stage differs depending on the salt type.

3.2.1 Sodium chloride

The propagation stage consists of four 3-week cycles. Each of these cycles consists of 3 sub-cycles of temperature and relative humidity, plus one rewetting of the specimens with demineralized water through their bottom surface. More specifically, each 3-week cycle consists of (Fig. 5):

-

24 h hygroscopic adsorption at 20 °C/95% RH

-

12 h drying at 20 °C 50% RH

-

44 h drying at 40 °C 15% RH

-

24 h hygroscopic adsorption at 20 °C/95% RH

-

12 h drying at 20 °C 50% RH

-

44 h drying at 40 °C 15% RH

-

24 h hygroscopic adsorption at 20 °C/95% RH

-

12 h drying at 20 °C 50% RH

-

44 h drying at 40 °C 15% RH

After this period of 240 h, the specimens are removed from the climatic cabinet and the following steps are followed:

-

The specimens are stored for 2 h at room conditions (22 ± 2 °C / 45 ± 15% RH) to cool down. After this cooling period, the sealing is removed from the bottom of the specimens and the mass of the specimens is recorded (mrew n—before, where n is the number of the rewetting)

-

The specimens are rewetted at 22 ± 2 °C / > 95% RH via their bottom surface with 30% of the water amount used for the initial contamination. After rewetting, the weight of the specimen is recorded (mrew n—after, where n is the number of the rewetting) and the bottom of the specimen is sealed again. Rewetting takes place at room temperature.

-

The specimens are stored at 22 ± 2 °C / > 95%RH for a total of 4 h (rewetting + storing time = 4 h) to allow for salt dissolution.

-

The specimens are then dried at 40 °C /15% RH for 258 h.

At the end of each 3-week cycle, the presence of damage and/or efflorescence on the surface of the specimens is photographically documented and described according to the methodology reported in Sect. 4.1. The specimens are not brushed. A new 3-week cycle can then start.

After four complete 3-week cycles, the condition of the specimens (presence of damage and/or efflorescence) is photographically documented and described according to the methodology reported in Sect. 4.1. The paraffin film is removed and the mass of the specimen is recorded (mfinal). The surface of the specimen is brushed using the toothbrush, and the material loss is assessed according to the procedure reported in Sect. 4.2.

3.3 Sodium sulfate

The propagation stage consists of four 3-week cycles. Each 3-week cycle consists of rewetting of the specimens with demineralized water through their bottom surface, followed by drying. More specifically, each 3-week cycle consists of (Fig. 6):

-

4 h cooling of the specimens at room conditions (T = 22 ± 2 °C at 45 ± 15% RH). The sealing is removed from the bottom and the mass of the specimens is recorded (mrew n-before, where n is the number of the re-wetting).

-

Rewetting with 80% of the water amount used for the initial contamination, by capillarity from the bottom at room conditions (T = 22 ± 2 °C at 45 ± 15% RH). After rewetting, the weight of the specimen is recorded (mrew n-after, where n is the number of the re-wetting), and the bottom of the specimen is sealed.

-

Drying at room conditions (T = 22 ± 2 °C at 45 ± 15% RH) up to 24 h from the start of the re-wetting.

-

476 h drying at 40 ± 2 °C/ 15 ± 5% RH

At the end of each cycle, the state of the specimens (presence of damage and/or efflorescence) is photographically documented and described according to the methodology reported in Sect. 4.1. The specimens are not brushed.

A new 3-week cycle can then start.

After 4 complete 3-week cycles, the state of the specimens (presence of damage and/or efflorescence) is photographically documented and described according to the methodology reported in Sect. 4.1. The sealing is removed from the bottom and the mass of the specimen is recorded (mcycle 4- after). The paraffin film is removed, and the mass of the specimen is recorded (mfinal). The surface of the specimen is brushed, and the material loss is assessed according to the procedure reported in Sect. 4.2.

4 Test results

The assessment of damage consists of 3 steps (see Table 1).

The results of this assessment are summarized in a report (see Appendix 2).

4.1 Damage assessment

4.1.1 Observation and documentation

The damage evolution is monitored by visual observation of the specimens and the conditions are photographically recorded. Three types of photos are taken at specific moments:

-

from above, angle of 90 degrees in relation to the horizontal plane; photos taken before the test (as a reference), after accumulation and after each propagation cycle to monitor the damage evolution;

-

under an angle of 45 degrees in relation to the horizontal plane; photos taken before the test (as a reference) and after the end of the test;

-

under an angle of 0 degrees in relation to the horizontal plane; photos taken only after the end of the test.

An example of these photographs is provided in Appendix 2.

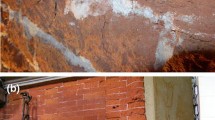

4.1.2 Description of the alterations and damage

For the description of the damage and/or any alteration resulting from the test, two existing atlases of damage types can be used:

-

ICOMOS illustrated glossary on stone deterioration patterns [5]

-

MDCS atlases for stone, brick, mortar, and plaster [6]

To support the identification of damage types, Appendix 3 reports the most common ones due to salt crystallization, with links to the aforementioned atlases. The list illustrates the main types of damage, grouped into categories, and provides detailed descriptions of each one of them.

4.1.3 Determination of the damage extent

Several types of damage may come into existence during the test, sometimes developing at the same time. Therefore, the assessment of the severity of the damage is an overall evaluation of the specimen’s condition at the end of the test, considering all types of damage. The damage extent is assessed according to three categories: none, initial, and extensive. It is assumed that this qualitative judgment is mainly useful for comparative evaluation. (e.g., when test specimens of the same or different materials are to be compared within the same lab, possibly by the same operator).

For more in-depth and quantitative description, additional methods can be used.

4.2 Material loss

The loss of material for each specimen is measured at the end of the propagation stage (i.e., after the drying phase of the last cycle) according to the procedure described hereafter.

-

The surface of the specimen is brushed with a soft toothbrush, after removing the paraffin film wrapping) and the debris is collected (including salt efflorescence and salt crust).

-

The debris is dried at 40 ± 2 °C and 15 ± 5% RH until constant weight and cooled down in a desiccator for at least 2 h prior to weighing. The weight of the debris is recorded (d1).

-

A filter paper for medium/fast filtration is used. The filter is dried at 40 ± 2 °C and 15 ± 5% RH until constant weight and cooled down in a desiccator for at least 2 h prior to weighing. The weight of the dry filter paper is recorded (mpaper).

-

The debris is put in a glass beaker with demineralized water, manually stirred and left for 24 h at room conditions to dissolve the salt efflorescence. The amount of demineralized water used for dissolution should be at least 10 times the weight of the debris, in order to ensure full dissolution of the salts.

-

After 24 h, the solution is filtered using the filter paper. The filter paper and the material left in it are then dried at 40 ± 2 °C and 15 ± 5% RH until constant mass, cooled down in a desiccator for at least 2 h, and the cumulative mass (filter paper + material) is recorded (mloss cum).

The material loss (d2) is calculated as follows:

The weight of the salt efflorescence and salt crust (meffl) is calculated as follows:

The simplified procedure for assessing the material loss, described above, is intended for the comparative evaluation of the results from the same laboratory.

References

Lubelli B, Aguilar AM, Beck K et al (2022) A new accelerated salt weathering test by RILEM TC 271-ASC: preliminary round robin validation. Mater Struct. https://doi.org/10.1617/s11527-022-02067-8

Lubelli B and RILEM TC 271-ASC members (2021) New accelerated laboratory test for the assessment of the durability of materials with respect to salt crystallization. In: Lubelli B, Kamat A, Quist W (eds) SWBSS2021 - Fifth International Conference on Salt Weathering og Buildings and Stone Sculptures. TU Delft Open, pp 55–67

Flatt RJ, Mohamed NA, Caruso F, et al (2017) Predicting salt damage in practice: a theoretical insight into laboratory tests. RILEM Tech Lett 2:108–118. https://doi.org/10.21809/rilemtechlett.2017.41

Tuutti K (1982) Corrosion of steel in concrete. Stockholm

ICOMOS ISCS (2008) Illustrated glossary on stone deterioration patterns. https://openarchive.icomos.org/id/eprint/434/. Accessed 7 April, 2023

MDCS Damage Atlas. https://mdcs.monumentenkennis.nl/damageatlas. Accessed 28 Oct 2022

CEN (1999) NEN-EN 1925 - Natural stone test methods - Determination of water absorption coefficient by capillarity

Acknowledgements

The procedure presented in this paper is the final version developed by the RILEM TC 271-ASC. The TC has previously published draft versions of (part of) the procedure [1, 2]. H. Derluyn acknowledges support from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme (grant agreement No 850853)”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This recommendation has been prepared, reviewed and approved by all members of the RILEM TC 271-ASC.

Chair: Barbara Lubelli.

Deputy chair: Inge Rörig-Dalgaard.

TC Members: A.M. Aguilar, M. Aškrabić, K. Beck, C. Bläuer, V. Cnudde, A.M. D'Altri, H. Derluyn, J. Desarnaud, T. Diaz Gonçalves, R. Flatt, E. Franzoni, S. Godts, D. Gulotta, R. van Hees, I. Ioannou, A. Kamat, T. De Kock, B. Lubelli, B. Menendez, S. de Miranda, C. Nunes, I. Rörig-Dalgaard, E. Sassoni, N. Shahidzadeh, H. Siedel, Z. Slížková, M. Stefanidou, M. Theodoridou, R. Veiga, V. Vergès-Belmin.

Appendices

Appendix 1: Determination of capillary moisture content (CMC)

The capillary moisture content of the material must be determined first by performing the water absorption test according to EN 1925:1999 (“Determination of water absorption coefficient by capillarity” [7]). The capillary moisture content of the material is the mean water content at the end of the first stage of water absorption. It is determined as the point of intersection of straight lines drawn through the first and second stages of water absorption on a t1/2 plot (Fig.

7).

The test must be carried out on a minimum of 3 specimens. In the case of a non-homogenous material, a larger number of specimens is recommended. The highest value among all tested specimens will then be used to calculate the amount of solution for the initial contamination (accumulation stage of the specimens).

Appendix 2: Reference scheme for the description of damage or alteration

Appendix 3: Types of damage and alterations

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lubelli, B., Rörig-Daalgard, I., Aguilar, A.M. et al. Recommendation of RILEM TC 271-ASC: New accelerated test procedure for the assessment of resistance of natural stone and fired-clay brick units against salt crystallization. Mater Struct 56, 101 (2023). https://doi.org/10.1617/s11527-023-02158-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02158-0