Abstract

A review of the mechanical property development of concrete containing calcined clay was performed. A comparison of compressive and tensile strength results showed that concrete can be made to have equivalent or higher strength as an ordinary portland cement (OPC) system with up to 30% calcined clay or 50% blend of calcined clay and limestone fines in a limestone calcined clay cement (LC3) system, as long as the kaolinite content in the clay used is above 40%. Most of the strength development in these systems occurs during the first 7 days, making extended wet curing not necessary in these systems. Calcined clay systems are subject to the cross-over effect because of the high solubility of ettringite and lower cement degree of hydration at elevated temperatures. Concrete creep and shrinkage were found to be a function of the clay kaolinite content and replacement level. Bond strength was improved by the use of up to 20% metakaolin.

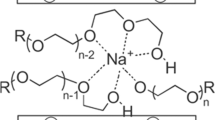

Adapted from (Coutinho 1958) [106]

Similar content being viewed by others

Availability of data and material

All data cited in this review paper is available in the referenced sources.

Abbreviations

- PC:

-

Portland cement

- MK:

-

Metakaolin

- LC3 :

-

Cement with limestone and calcined clay

- LC2 :

-

Limestone calcined clay admixture

- w/cm:

-

Water–cementitious material ratio

- w/b:

-

Water–binder ratio

- OPC:

-

Ordinary portland cement

- SCM:

-

Supplementary cementitious material

- ITZ:

-

Interfacial transition zone

- PCL:

-

Portland cement: calcined clay: limestone fines

- HTS-SHCC:

-

High-tensile strength strain-hardening cementitious composites

References

Le Sar D (1964) The production of sulphate-resisting and marine cements from local raw materials. University of Cape Town

Mehta PK, Monteiro PJM (2006) Concrete: microstructure, properties, and materials, 3rd edn. McGraw-Hill, New York

Kumar R, Bhattacharjee B (2003) Porosity, pore size distribution and in situ strength of concrete. Cem Concr Res 33:155–164. https://doi.org/10.1016/S0008-8846(02)00942-0

Ollivier JP, Maso JC, Bourdette B (1995) Interfacial transition zone in concrete. Adv Cem Based Mater 2:30–38. https://doi.org/10.1016/1065-7355(95)90037-3

Termkhajornkit P, Vu QH, Barbarulo R et al (2014) Dependence of compressive strength on phase assemblage in cement pastes: beyond gel-space ratio—experimental evidence and micromechanical modeling. Cem Concr Res 56:1–11. https://doi.org/10.1016/j.cemconres.2013.10.007

Pelisser F, Gleize PJP, Mikowski A (2012) Effect of the Ca/Si molar ratio on the micro/nanomechanical properties of synthetic C-S-H measured by nanoindentation. J Phys Chem C 116:17219–17227. https://doi.org/10.1021/jp302240c

Kim JJ, Foley EM, Reda Taha MM (2013) Nano-mechanical characterization of synthetic calcium-silicate-hydrate (C-S-H) with varying CaO/SiO2 mixture ratios. Cem Concr Compos 36:65–70. https://doi.org/10.1016/j.cemconcomp.2012.10.001

Gutteridge WA, Dalziel AJ (1990) Filler cement: the effect of the secondary component on the hydration of Portland cement. Cem Concr Res 20:778–782

Cyr M, Lawrence P, Ringot E (2005) Mineral admixtures in mortars: quantification of the physical effects of inert materials on short-term hydration. Cem Concr Res 35:719–730. https://doi.org/10.1016/j.cemconres.2004.05.030

Joseph S, Bishnoi S, Van Balen K, Cizer Ö (2017) Modeling the effect of fineness and filler in early-age hydration of tricalcium silicate. J Am Ceram Soc 100:1178–1194. https://doi.org/10.1111/jace.14676

Kunther W, Dai Z, Skibsted J (2016) Thermodynamic modeling of hydrated white Portland cement-metakaolin-limestone blends utilizing hydration kinetics from 29Si MAS NMR spectroscopy. Cem Concr Res 86:29–41. https://doi.org/10.1016/j.cemconres.2016.04.012

Avet F, Scrivener K (2018) Investigation of the calcined kaolinite content on the hydration of Limestone Calcined Clay Cement (LC3). Cem Concr Res 107:124–135

Mishra G, Emmanuel AC, Bishnoi S (2019) Influence of temperature on hydration and microstructure properties of limestone-calcined clay blended cement. Mater Struct 52:91. https://doi.org/10.1617/s11527-019-1390-5

Khatib JM, Wild S (1996) Pore size distribution of metakaolin paste. Cem Concr Res 26:1545–1553. https://doi.org/10.1016/0008-8846(96)00147-0

Frías M, Cabrera J (2000) Pore size distribution and degree of hydration of metakaolin-cement pastes. Cem Concr Res 30:561–569. https://doi.org/10.1016/S0008-8846(00)00203-9

Avet F, Boehm-Courjault E, Scrivener K (2019) Investigation of C-A-S-H composition, morphology and density in Limestone Calcined Clay Cement (LC3). Cem Concr Res 115:70–79. https://doi.org/10.1016/j.cemconres.2018.10.011

Zunino Sommariva FA (2020) Limestone calcined clay cements (LC3): raw material processing, sulfate balance and hydration kinetics. Swiss Federal Institute of Technology Lausanne

Meissner H (1950) Pozzolans used in mass concrete. In: Stanton T, Blanks R (eds) Symposium on use of pozzolanic materials in mortars and concretes. ASTM International, West Conshohocken, pp 16–30

Cyr M, Trinh M, Husson B, Casaux-Ginestet G (2014) Effect of cement type on metakaolin efficiency. Cem Concr Res 64:63–72. https://doi.org/10.1016/j.cemconres.2014.06.007

Krishnan S, Bishnoi S (2020) A numerical approach for designing composite cements with calcined clay and limestone. Cem Concr Res 138:106232. https://doi.org/10.1016/j.cemconres.2020.106232

Said-Mansour M, Kadri EH, Kenai S et al (2011) Influence of calcined kaolin on mortar properties. Constr Build Mater 25:2275–2282. https://doi.org/10.1016/j.conbuildmat.2010.11.017

Tang J, Wei S, Li W et al (2019) Synergistic effect of metakaolin and limestone on the hydration properties of Portland cement. Constr Build Mater 223:177–184. https://doi.org/10.1016/j.conbuildmat.2019.06.059

Parashar A (2020) Characterisation of hydration of supplementary cementitious materials with calcium hydroxide for use in binary and ternary cements. Indian Institute of Technology Delhi

Dhandapani Y (2020) Composite cements with limestone additions: microstructure and transport properties. Indian Institute of Technology, Madras

Vance K, Aguayo M, Oey T et al (2013) Hydration and strength development in ternary portland cement blends containing limestone and fly ash or metakaolin. Cem Concr Compos 39:93–103. https://doi.org/10.1016/j.cemconcomp.2013.03.028

Vizcaíno LM, Andrés A, Georges M et al (2015) Effect of fineness in clinker-calcined clays-limestone cements. Adv Cem Res 27:546–556. https://doi.org/10.1680/adcr.14.00095

Machner A, Zajac M, Ben Haha M et al (2017) Portland metakaolin cement containing dolomite or limestone—similarities and differences in phase assemblage and compressive strength. Constr Build Mater 157:214–225. https://doi.org/10.1016/j.conbuildmat.2017.09.056

Krishnan S, Bishnoi S (2018) Understanding the hydration of dolomite in cementitious systems with reactive aluminosilicates such as calcined clay. Cem Concr Res 108:116–128. https://doi.org/10.1016/j.cemconres.2018.03.010

Zajac M, Durdzinski P, Stabler C et al (2018) Influence of calcium and magnesium carbonates on hydration kinetics, hydrate assemblage and microstructural development of metakaolin containing composite cements. Cem Concr Res 106:91–102. https://doi.org/10.1016/j.cemconres.2018.01.008

Krishnan S, Kanaujia SK, Mithia S, Bishnoi S (2018) Hydration kinetics and mechanisms of carbonates from stone wastes in ternary blends with calcined clay. Constr Build Mater 164:265–274. https://doi.org/10.1016/j.conbuildmat.2017.12.240

Badogiannis E, Kakali G, Dimopoulou G et al (2005) Metakaolin as a main cement constituent. Exploitation of poor Greek kaolins. Cem Concr Compos 27:197–203. https://doi.org/10.1016/j.cemconcomp.2004.02.007

Arikan M, Sobolev K, Ertün T et al (2009) Properties of blended cements with thermally activated kaolin. Constr Build Mater 23:62–70. https://doi.org/10.1016/j.conbuildmat.2008.02.008

Mermerdaş K, Gesoǧlu M, Güneyisi E, Özturan T (2012) Strength development of concretes incorporated with metakaolin and different types of calcined kaolins. Constr Build Mater 37:766–774. https://doi.org/10.1016/j.conbuildmat.2012.07.077

Tironi A, Trezza MA, Scian AN, Irassar EF (2013) Assessment of pozzolanic activity of different calcined clays. Cem Concr Compos 37:319–327. https://doi.org/10.1016/j.cemconcomp.2013.01.002

Avet F, Snellings R, Alujas Diaz A et al (2016) Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cem Concr Res 85:1–11. https://doi.org/10.1016/j.cemconres.2016.02.015

Avet F, Li X, Scrivener K (2018) Determination of the amount of reacted metakaolin in calcined clay blends. Cem Concr Res 106:40–48. https://doi.org/10.1016/j.cemconres.2018.01.009

Avet F, Scrivener K (2018) Hydration Study of Limestone Calcined Clay Cement (LC3) using various grades of calcined kaolinitic clays. In: Martirena F, Favier A, Scrivener K (eds) Calcined clays for sustainable concrete. Springer, Netherlands, Dordrecht, pp 35–40

Krishnan S, Rao DG, Bishnoi S (2020) Why low-grade calcined clays are the ideal for the production of limestone calcined clay cement (LC3). In: Bishnoi S (ed) Calcined Clays for Sustainable Concrete. RILEM Bookseries, vol 25, Springer, Singapore, pp 125–130

Saleh Ahari R, Erdem TK, Ramyar K (2015) Permeability properties of self-consolidating concrete containing various supplementary cementitious materials. Constr Build Mater 79:326–336. https://doi.org/10.1016/j.conbuildmat.2015.01.053

Antoni M, Rossen J, Martirena F, Scrivener K (2012) Cement substitution by a combination of metakaolin and limestone. Cem Concr Res 42:1579–1589

Arslan F, Benli A, Karatas M (2020) Effect of high temperature on the performance of self-compacting mortars produced with calcined kaolin and metakaolin. Constr Build Mater 256:119497. https://doi.org/10.1016/j.conbuildmat.2020.119497

Batis G, Pantazopoulou P, Tsivilis S, Badogiannis E (2005) The effect of metakaolin on the corrosion behavior of cement mortars. Cem Concr Compos 27:125–130. https://doi.org/10.1016/j.cemconcomp.2004.02.041

Courard L, Darimont A, Schouterden M et al (2003) Durability of mortars modified with metakaolin. Cem Concr Res 33:1473–1479. https://doi.org/10.1016/S0008-8846(03)00090-5

Cruz JM, Fita IC, Soriano L et al (2013) The use of electrical impedance spectroscopy for monitoring the hydration products of Portland cement mortars with high percentage of pozzolans. Cem Concr Res 50:51–61. https://doi.org/10.1016/j.cemconres.2013.03.019

Du H, Pang SD (2020) High-performance concrete incorporating calcined kaolin clay and limestone as cement substitute. Constr Build Mater 264:120152. https://doi.org/10.1016/j.conbuildmat.2020.120152

Fernandez R, Martirena F, Scrivener KL (2011) The origin of the pozzolanic activity of calcined clay minerals: a comparison between kaolinite, illite and montmorillonite. Cem Concr Res 41:113–122. https://doi.org/10.1016/j.cemconres.2010.09.013

Güneyisi E, Gesolu M, Özbay E (2010) Strength and drying shrinkage properties of self-compacting concretes incorporating multi-system blended mineral admixtures. Constr Build Mater 24:1878–1887. https://doi.org/10.1016/j.conbuildmat.2010.04.015

Güneyisi E, Gesoǧlu M, Karaoǧlu S, Mermerdaş K (2012) Strength, permeability and shrinkage cracking of silica fume and metakaolin concretes. Constr Build Mater 34:120–130. https://doi.org/10.1016/j.conbuildmat.2012.02.017

Güneyisi E, Mermerdaş K (2007) Comparative study on strength, sorptivity, and chloride ingress characteristics of air-cured and water-cured concretes modified with metakaolin. Mater Struct 40:1161–1171. https://doi.org/10.1617/s11527-007-9258-5

Güneyisi E, Gesoğlu M, Gu E et al (2008) Properties of self-compacting mortars with binary and ternary cementitious blends of fly ash and metakaolin. Mater Struct 41:1519–1531. https://doi.org/10.1617/s11527-007-9345-7

Hassan AAA, Lachemi M, Hossain KMA (2012) Effect of metakaolin and silica fume on the durability of self-consolidating concrete. Cem Concr Compos 34:801–807. https://doi.org/10.1016/j.cemconcomp.2012.02.013

Ilić B, Radonjanin V, Malešev M et al (2017) Study on the addition effect of metakaolin and mechanically activated kaolin on cement strength and microstructure under different curing conditions. Constr Build Mater 133:243–252. https://doi.org/10.1016/j.conbuildmat.2016.12.068

Janotka I, Puertas F, Palacios M et al (2010) Metakaolin sand-blended-cement pastes: rheology, hydration process and mechanical properties. Constr Build Mater 24:791–802. https://doi.org/10.1016/j.conbuildmat.2009.10.028

Megat Johari MA, Brooks JJ, Kabir S, Rivard P (2011) Influence of supplementary cementitious materials on engineering properties of high strength concrete. Constr Build Mater 25:2639–2648. https://doi.org/10.1016/j.conbuildmat.2010.12.013

Kadri EH, Kenai S, Ezziane K et al (2011) Influence of metakaolin and silica fume on the heat of hydration and compressive strength development of mortar. Appl Clay Sci 53:704–708. https://doi.org/10.1016/j.clay.2011.06.008

Khatib JM, Hibbert JJ (2005) Selected engineering properties of concrete incorporating slag and metakaolin. Constr Build Mater 19:460–472. https://doi.org/10.1016/j.conbuildmat.2004.07.017

Khatib JM (2008) Metakaolin concrete at a low water to binder ratio. Constr Build Mater 22:1691–1700. https://doi.org/10.1016/j.conbuildmat.2007.06.003

Khatib JM (2009) Low temperature curing of metakaolin concrete. J Mater Civ Eng 21:362–367. https://doi.org/10.1061/(asce)0899-1561(2009)21:8(362)

Madandoust R, Mousavi SY (2012) Fresh and hardened properties of self-compacting concrete containing metakaolin. Constr Build Mater 35:752–760. https://doi.org/10.1016/j.conbuildmat.2012.04.109

Meddah MS, Ismail MA, El-Gamal S, Fitriani H (2018) Performances evaluation of binary concrete designed with silica fume and metakaolin. Constr Build Mater 166:400–412. https://doi.org/10.1016/j.conbuildmat.2018.01.138

Parande AK, Ramesh Babu B, Aswin Karthik M et al (2008) Study on strength and corrosion performance for steel embedded in metakaolin blended concrete/mortar. Constr Build Mater 22:127–134. https://doi.org/10.1016/j.conbuildmat.2006.10.003

Poon CS, Kou SC, Lam L (2006) Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr Build Mater 20:858–865. https://doi.org/10.1016/j.conbuildmat.2005.07.001

Poon CS, Lam L, Kou SC et al (2001) Rate of pozzolanic reaction of metakaolin in high-performance cement pastes. Cem Concr Res 31:1301–1306. https://doi.org/10.1016/S0008-8846(01)00581-6

Ramezanianpour AA, Bahrami Jovein H (2012) Influence of metakaolin as supplementary cementing material on strength and durability of concretes. Constr Build Mater 30:470–479. https://doi.org/10.1016/j.conbuildmat.2011.12.050

Schulze SE, Rickert J (2019) Suitability of natural calcined clays as supplementary cementitious material. Cem Concr Compos 95:92–97. https://doi.org/10.1016/j.cemconcomp.2018.07.006

Shah V, Parashar A, Mishra G et al (2020) Influence of cement replacement by limestone calcined clay pozzolan on the engineering properties of mortar and concrete. Adv Cem Res 32:101–111. https://doi.org/10.1680/jadcr.18.00073

Tironi A, Castellano CC, Bonavetti VL et al (2014) Kaolinitic calcined clays—Portland cement system: hydration and properties. Constr Build Mater 64:215–221. https://doi.org/10.1016/j.conbuildmat.2014.04.065

Wild S, Khatib JM, Jones A (1996) Relative strength, pozzolanic activity and cement hydration in superplasticised metakaolin concrete. Cem Concr Res 26:1537–1544

Wild S, Khatib JM (1997) Portlandite consumption in metakaolin cement pastes and mortars. Cem Concr Res 27:137–146

Yu J, Wu HL, Mishra DK, et al (2021) Compressive strength and environmental impact of sustainable blended cement with high-dosage Limestone and Calcined Clay (LC2). J Clean Prod 278:123616. https://doi.org/10.1016/j.jclepro.2020.123616

Zhao D, Khoshnazar R (2020) Microstructure of cement paste incorporating high volume of low-grade metakaolin. Cem Concr Compos 106:103453. https://doi.org/10.1016/j.cemconcomp.2019.103453

Krishnan S (2019) Hydration and microstructure development in limestone calcined clay cement, Thesis, Indian Institute of Technology Delhi, 260 pp

Hanpongpun W (2019) Investigation of the use of Limestone Calcined Clay Cement (LC3) applied to Thailand, Thesis, Swiss Federal Institute of Technology Lausanne, 140 pp

Martirena F, Díaz E (2016) Preliminary assessment of durability of a low carbon concrete made with limestone calcined clay Portland Cement. Proceedings of the 2nd International Conference on Concrete Sustainability (ICCS), Madrid, Spain, pp 780-798

Martirena-Hernandez F (2020) Introduction of a calcined clay-limestone based cement in concrete manufacture in Latin America. Indian Concr J 94:26–30

Li X, Snellings R, Antoni M et al (2018) Reactivity tests for supplementary cementitious materials: RILEM TC 267-TRM phase 1. Mater Struct 51:151. https://doi.org/10.1617/s11527-018-1269-x

Parashar A, Bishnoi S (2020) A comparison of test methods to assess the strength potential of plain and blended supplementary cementitious materials. Constr Build Mater 256:119292. https://doi.org/10.1016/j.conbuildmat.2020.119292

Briki Y, Avet F, Zajac M, et al (2021) Cement and concrete research understanding of the factors slowing down metakaolin reaction in limestone calcined clay cement (LC3) at late ages. Cem Concr Res 146:106477. https://doi.org/10.1016/j.cemconres.2021.106477

Zunino F, Scrivener K (2022) Microstructural developments of limestone calcined clay cement (LC3) pastes after long-term (3 years) hydration. Cem Concr Res 153:106693. https://doi.org/10.1016/j.cemconres.2021.106693

Shafiq N, Nuruddin MF, Khan SU, Ayub T (2015) Calcined kaolin as cement replacing material and its use in high strength concrete. Constr Build Mater 81:313–323. https://doi.org/10.1016/j.conbuildmat.2015.02.050

Busari A, Dahunsi B, Akinmusuru J (2019) Sustainable concrete for rigid pavement construction using de-hydroxylated Kaolinitic clay: mechanical and microstructural properties. Constr Build Mater 211:408–415. https://doi.org/10.1016/j.conbuildmat.2019.03.170

Cordoba GP, Zito SV, Sposito R et al (2020) Concretes with calcined clay and calcined shale: workability, mechanical, and transport properties. J Mater Civ Eng 32:1–11. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003296

Güneyisi E, Gesoǧlu M, Mermerdaş KK, et al Improving strength, drying shrinkage, and pore structure of concrete using metakaolin. Mater Struct 41:937–949. https://doi.org/10.1617/s11527-007-9296-z

Brooks JJ, Megat Johari MA (2001) Effect of metakaolin on creep and shrinkage of concrete. Cem Concr Compos 23:495–502. https://doi.org/10.1016/S0958-9465(00)00095-0

Dadsetan S, Bai J (2017) Mechanical and microstructural properties of self-compacting concrete blended with metakaolin, ground granulated blast-furnace slag and fly ash. Constr Build Mater 146:658–667. https://doi.org/10.1016/j.conbuildmat.2017.04.158

Dhandapani Y, Sakthivel T, Santhanam M et al (2018) Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3). Cem Concr Res 107:136–151. https://doi.org/10.1016/j.cemconres.2018.02.005

Irassar EF, Bonavetti VL, Castellano CC, et al (2019) Calcined illite-chlorite shale as supplementary cementing material: thermal treatment, grinding, color and pozzolanic activity. Appl Clay Sci 179:105143. https://doi.org/10.1016/j.clay.2019.105143

Cassagnabère F, Escadeillas G, Mouret M (2009) Study of the reactivity of cement/metakaolin binders at early age for specific use in steam cured precast concrete. Constr Build Mater 23:775–784. https://doi.org/10.1016/j.conbuildmat.2008.02.022

Cassagnabère F, Mouret M, Escadeillas G et al (2010) Metakaolin, a solution for the precast industry to limit the clinker content in concrete: mechanical aspects. Constr Build Mater 24:1109–1118. https://doi.org/10.1016/j.conbuildmat.2009.12.032

Gesoğlu M (2010) Influence of steam curing on the properties of concretes incorporating metakaolin and silica fume. Mater Struct 43:1123–1134

Shen P, Lu L, Chen W et al (2017) Efficiency of metakaolin in steam cured high strength concrete. Constr Build Mater 152:357–366. https://doi.org/10.1016/j.conbuildmat.2017.07.006

Avet F, Scrivener K (2020) Effect of temperature on the water content of C-A-S-H in plain Portland and blended cements. Cem Concr Res 136:106124. https://doi.org/10.1016/j.cemconres.2020.106124

Hanpongpun W, Scrivener K (2020) The effect of curing temperature on the properties of limestone calcined clay cement (LC3). In: Bishnoi S (ed) Calcined Clays for Sustainable Concrete. Springer Singapore, Singapore, pp 293–298

Emmanuel AC, Mishra G, Bishnoi S (2020) The Influence of temperature regime on performance of low clinker blended cements. In: Proceedings of the 3rd International Conference on Calcined Clays for Sustainable Concrete. pp 299–307

Khatib JM, Kayali O, Kenai S, Haque MN (2010) Effect of curing temperature on relative strength of metakaolin concrete. In: 2nd Int Conf Sustain Constr Mater Technol, pp 247–254

Williams A, Markandeya A, Stetsko Y et al (2016) Cracking potential and temperature sensitivity of metakaolin concrete. Constr Build Mater 120:172–180. https://doi.org/10.1016/j.conbuildmat.2016.05.087

Zunino F, Scrivener K (2018) Reactivity and Performance of Limestone Calcined-Clay Cement (LC3) cured at low temperature. In: Martirena F, Favier A, Scrivener K (eds) Calcined Clays for Sustainable Concrete. Springer, Netherlands, Dordrecht, pp 514–520

Dayanidhy S, Balasundaram N (2017) Study on effects of curing techniques on durability properties of self-compacting concrete with metakaolin. Int J Civ Eng Technol 8:790–797

Dhandapani Y, Santhanam M, Gettu R, Pillai RG (2020) Perspectives on blended cementitious systems with calcined clay-limestone combination for sustainable low carbon cement transition. Indian Concr J 94:25–38

Bai J, Wild S (2002) Investigation of the temperature change and heat evolution of mortar incorporating PFA and metakaolin. Cem Concr Compos 24:201–209. https://doi.org/10.1016/S0958-9465(01)00042-7

Markandeya A (2018) Improving early-age cracking resilience and durability of concrete elements. University of South Florida, Thesis

Emmanuel AC, Haldar P, Maity S et al (2016) Second pilot production of Limestone Calcined Clay Cement (LC3) in India: the experience. Indian Concr J 90:57–64

Emmanuel AC (2020) Influence of curing temperature on hydration kinetics, phase assemblage and strength development of blended cements. Thesis, Indian Institute of Technology Delhi

Scrivener K, Martirena F, Bishnoi S, Maity S (2018) Calcined clay limestone cements (LC3). Cem Concr Res 114:49–56. https://doi.org/10.1016/j.cemconres.2017.08.017

Neville A (2011) Properties of concrete, 5th edn. Pearson Education Limited, Harlow, England

Coutinho A de S (1958) Pozzolans, concrete with pozzolans and pozzolanic cements, Memory nr. 136, LNEC National Laboratory for Civil Engineering (in Portuguese), Lisbon.

Siddique R, Klaus J (2009) Influence of metakaolin on the properties of mortar and concrete: a review. Appl Clay Sci 43:392–400. https://doi.org/10.1016/j.clay.2008.11.007

Scrivener K, Avet F, Maraghechi H et al (2019) Impacting factors and properties of limestone calcined clay cements (LC3). Green Mater 7:3–14. https://doi.org/10.1680/jgrma.18.00029

DosSantos SB, Da Silva Filho LCP, Calmon JL (2012) Early-age creep of mass concrete: Effects of chemical and mineral admixtures. ACI Mater J 109:537–544. https://doi.org/10.14359/51684085

Ston J, Scrivener K (2019) Basic creep of limestone–calcined clay cements: An experimental and numerical approach. Theor Appl Fract Mech 103:102270. https://doi.org/10.1016/j.tafmec.2019.102270

Dhandapani Y, Joseph S, Geddes DA, et al (2020) Fresh properties of concrete containing calcined clays: a review by RILEM TC-282 CCL. Mater Struct 55:151

Mermerdaş K, Güneyisi E, Gesoǧlu M, Özturan T (2013) Experimental evaluation and modeling of drying shrinkage behavior of metakaolin and calcined kaolin blended concretes. Constr Build Mater 43:337–347. https://doi.org/10.1016/j.conbuildmat.2013.02.047

WIld S, Khatib JM, Roose LJ (1998) Chemical shrinkage and autogenous shrinkage of Portland cement—metakaolin pastes. Adv Cem Res 10:109–119. https://doi.org/10.1680/adcr.1998.10.3.109

Kinuthia JM, Wild S, Sabir BB, Bai J (2000) Self-compensating autogenous shrinkage in Portland cement—metakaolin—fly ash pastes. Adv Cem Res 12:35–43. https://doi.org/10.1680/adcr.2000.12.1.35

ASTM C1581 Standard Test Method for Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete under Restrained Shrinkage

Salimi J, Mohammad A, Javad M (2020) Studying the effect of low reactivity metakaolin on free and restrained shrinkage of high performance concrete. J Build Eng 28:101053. https://doi.org/10.1016/j.jobe.2019.101053

Ston J, Hilaire A, Scrivener K (2018) Autogenous shrinkage and creep of limestone and calcined clay based binders. In: Martirena F, Favier A, Scrivener K (eds) Calcined Clays for Sustainable Concrete. Springer, Netherlands, pp 447–454

Nguyen Q, Afroz S, Zhang Y et al (2022) Autogenous and total shrinkage of limestone calcined clay cement (LC3) concretes. Constr Build Mater 314:125720. https://doi.org/10.1016/j.conbuildmat.2021.125720

Güneyisi E, Gesoǧlu M, Akoi AOM, Mermerdaş K (2014) Combined effect of steel fiber and metakaolin incorporation on mechanical properties of concrete. Compos Part B Eng 56:83–91. https://doi.org/10.1016/j.compositesb.2013.08.002

Akinyele JO, Odunfa SO, Famoye AA, Kuye SI (2017) Structural behaviour of metakaolin infused concrete structure. Niger J Technol 36:331. https://doi.org/10.4314/njt.v36i2.2

Huang Z, Huang Y, Sui L et al (2020) Bond behavior between limestone calcined clay cement (LC3) concrete and steel rebar. In: Proceedings of the 3rd international conference on calcined clays for sustainable concrete, pp 563–570

Huang Z, Huang Y, Liao W et al (2020) Development of limestone calcined clay cement (LC3) concrete in South China and its bond behavior with steel reinforcement. J Zhejiang Univ A (Applied Phys Eng) 21:892-907. https://doi.org/10.1631/jzus.A2000163

Banthia N, Yan C (1996) Bond-slip characteristics of steel fibers in high reactivity metakaolin (HRM) modified cement-based matrices. Cem Concr Res 26:657–662

Yalçınkaya Ç, Beglarigale A, Yazıcı H (2014) The effect of metakaolin and end type of steel fiber on fiber-SIFCON matrix bond characteristics. Usak Univ J Mater Sci 1:97–105. https://doi.org/10.12748/uujms.201416504

Yu J, Leung CKY (2020) Using Limestone calcined clay to improve tensile performance and greenness of high-tensile strength strain-hardening cementitious composites (SHCC). In: Proceedings of the 3rd International Conference on Calcined Clays for Sustainable Concrete. pp 513–522

Chen Y, Chaves Figueiredo S, Li Z et al (2020) Improving printability of limestone-calcined clay-based cementitious materials by using viscosity-modifying admixture. Cem Concr Res 132:106040. https://doi.org/10.1016/j.cemconres.2020.106040

Mirmoghtadaei R, Mohammadi M, Ashraf Samani N, Mousavi S (2015) The impact of surface preparation on the bond strength of repaired concrete by metakaolin containing concrete. Constr Build Mater 80:76–83. https://doi.org/10.1016/j.conbuildmat.2015.01.018

Du Y, Yang W, Ge Y, et al (2021) Thermal conductivity of cement paste containing waste glass powder, metakaolin and limestone filler as supplementary cementitious material. J Clean Prod 287:125018. https://doi.org/10.1016/j.jclepro.2020.125018

Thitikavanont Y, Sahamitmongkol R (2020) Heat generation and thermal properties of limestone calcined clay cement paste. In: Bishnoi S (ed) Calcined clays for sustainable concrete. RILEM Bookseries, vol 25, Springer, Singapore, pp 455–467

Lin R, Han Y, Wang X (2021) Macro–meso–micro experimental studies of calcined clay limestone cement (LC3) paste subjected to elevated temperature. Cem Concr Compos 116:103871. https://doi.org/10.1016/j.cemconcomp.2020.103871

Funding

No funding was provided for this work. This work was performed by a volunteer working subgroup on RILEM committee 282-CCL.

Author information

Authors and Affiliations

Contributions

All authors contributed to the review paper conception and design. The first draft of the manuscript was written by SJ, YD, DAG, ZZ, SB,MV, FM,AC, FK and KAR and was edited by YD, SB, FM, TB and KAR. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

None. This paper was prepared by a working subgroup on RILEM committee 282-CCL.

Ethical Approval

This paper has been prepared by RILEM TC 282-CCL. The paper has been reviewed and approved by all members of the TC.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

TC Membership: Chair: Fernando Martirena-Hernandez, Cuba; Deputy Chair: Manu Santhanam, India.

Regular Members: Eduardo Irassar, Argentina; Arnaud Castel, David Law, Sumaiya Afroz, Taehwin Kim, Vinh Dao, Australia; Jan Elsen, Ruben Snellings, Belgium; Silvia Vieira, Brazil; Arezki Tagnit-Hamou, William Wilson, Canada; Kequan Yu, Tongbo Sui, Zengfeng Zhao, China; Oscar Oswaldo Vásquez, Colombia; Adrian Alujas, Roger Samuel Roger, Cuba; Joergen Skibsted, Mariana Canut, Sergio Ferreiro Garzón, Wolfgang Kunther, Denmark; Fabrizio Moro, François Avet, Gabriel Pham, Gilles Escadeillas, Pascal Dion, Pascal Boustingorry, Victor Poussardin, France; Alisa Machner, Elsa Qoku, Frank Dehn, Karl-Christian Theinel, Matthias Maier, Mohsen Ben Haha, Germany; Luis Velasquez, Guatemala; Anuj Parashar, Sri Kalyana Rama Jyosyula, Ravindra Gettu, Shashank Bishnoi, Talakokula Visalakshi, Tushar Bansal, Yuvaraj Dhandapani, India; Laith Al-Jaberi, Iraq; Luca Valentini, Italy; Joseph Mwiti Marangu, Kenya; Sol Moi Park, Korea; J Ivan Escalante-Garcia, Mexico; Hassan Ez-Zaki, Morroco; Roman Jaskulski, Poland; Angela Maria Nunes, Karyne Ferreira do Santos, Manuel Vieira, Portugal; Guoqing Geng, Singapore; Franco Zunino, Karen Scrivener, Switzerland; Alastair Marsh, Daniel Geddes, Hoda Beltagui, Wenzhong Zhu, Fragkoulis Kanavaris, John Provis, Shiju Joseph, Susan Bernal Lopez, Theodore Hanein, UK; Claire White, Katelyn O’Quinn, Kyle Riding, Maria C.G. Juenger, USA.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Joseph, S., Dhandapani, Y., Geddes, D.A. et al. Mechanical properties of concrete made with calcined clay: a review by RILEM TC-282 CCL. Mater Struct 56, 84 (2023). https://doi.org/10.1617/s11527-023-02118-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02118-8