Abstract

Permanent deformation in the form of rutting is a critical mode of failure observed in flexible pavements. While several research have been conducted to develop multiple tests for the characterisation of permanent deformation, little information is obtainable from the existing literature on how the factors or the interaction of the factors from these tests affect the permanent deformation behaviour in a simulative test, such as the wheel tracker. This research focuses on statistical analysis and ruggedness testing of the factors affecting the permanent deformation behaviour of asphalt mixes tested in the Modified Wheel Tracker (MWT). The analysis involved five factors in total, each at two levels. These factors are binder type, voids in total mix (VTM %), nominal maximum aggregate size, temperature, and confining pressure. The study utilised half-fractional factorial design in accordance with ASTM E1169-20. Significant parameters were determined through statistical analysis and regression models were proposed. The contour plots provided various combinations of the most significant factors for the corresponding responses. Based on the statistical analysis of the experiments conducted without any confinement, temperature, amongst all other factors, was found to impose the greatest effect on the permanent deformation behaviour based on vertical and horizontal FN Indices. Experiments with controlled confinement show that “confining pressure” is the most significant factor for the rutting parameters. The sensitivity analysis points out that to maintain the vertical deformation at 2000 cycles to be in the range ± 25% from the model, the confining pressure and temperature should be controlled within the range ± 25% and ± 5%. The use of the MWT shows that long-term rutting development can well be predicted from rutting at 2000 cycles using linear and exponential models.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Permanent deformation in hot mix asphalt (HMA)

Permanent deformation in the form of rutting presents itself as longitudinal depressions along the wheel paths. According to Tarefder et al. [1], this critical failure in flexible pavements is mainly caused by repeated loading, which induces progressive movement of materials. Saleh [2], and Roy-Chowdhury et al. [3] indicated that the composition of asphalt mixture along with the degree of compaction, mix stiffness, temperature and loading rate are the contributory factors for rutting resistance of asphalt concrete pavements [2, 3]. Saleh [2] concluded that the combination of densification and shear deformation causes rutting, and that, the latter causes the severe form of the distress. In other words, rutting is caused by both vertical and horizontal permanent deformations. Therefore, the characterisation of rutting must consider susceptibility of the asphalt mixtures to shear deformation. As pointed out by Tarefder et al. [1], the individual effect of aggregate and asphalt binder, along with their interaction with each other in a mixture have significant contribution on the rutting characteristics of Hot Mix Asphalt (HMA). There can be occasions when the asphalt pavements with very stiff binder and adequate aggregates may still fail to exhibit low rutting, which is mainly due to other properties, such as incorrect volumetric properties. Moreover, it can also be said that the mixture properties solely may not be sufficient for the purpose of ensuring low rutting, but the external factors such as temperature should also be considered [1].

Temperature is one of the main factors that affects the rutting resistance of asphalt pavements.

The change of temperature in the pavement changes the viscoelastic properties of the asphalt mix, which in turn induces permanent deformation (rutting) in the pavement [4]. Souza and Castro [5] concluded that the deformation in asphalt concrete is the result of the individual and combined effect of temperature, and the susceptibility of the asphalt mix to temperature. Roy-Chowdhury et al. [6] statistically analysed the factors that have significant effect on rutting behaviour. It was shown that the individual effect of air voids and test temperature, and the combined effect of binder type and air voids have the greatest influence on the rutting resistance of the asphalt mixtures. It is generally well-established that stiffer binder is preferred over softer binder for increasing the rutting resistance of the asphalt pavements [6]. As pointed out by Roy et al. [7], the densification that occurs as a result of reduction of air voids after construction, is a primary cause of rutting during initial traffic loading. The mix later undergoes shear flow when the material reaches the densest state in which the materials flow with volume change.

The study by Rahmani et al. [8] indicated that the level of confinement has a significant effect on the nonlinear viscoelastic characteristics of asphaltic materials. Roy et al. [7] reported that the effect of confinement on the variation in rutting is more for the mixes with high air voids content than for the mixes with lower air voids content. It can be noted that NCHRP report 465 [9] involve the option of altering confinement only for the Simple Performance Tests (SPTs), such as the dynamic modulus test. However, no study until now addressed or analysed the effect of confinement in a simulative test such as the wheel tracker. The current research addresses this point, for which a modified setup of the wheel tracker was utilised. The details of this modified wheel tracker (MWT) are presented in the following sections. A laboratory and statistical investigation of the effect of the aforementioned factors on the rutting properties of HMA is the focus of this research. Furthermore, although there are a number of studies such as that by Garba [10], Muraya [11], and Souza and Castro [5], which investigated and analysed the effect of different factors on permanent deformation characteristics of asphalt mixtures using viscoelastic and viscoplastic models, it should be noted that these models are undeniably complex and cannot be readily implemented for routine analysis in industry. Therefore, this research focused on a statistical analysis, the results of which are expected to be readily understood and implemented by the practitioners as to the control of the factors influencing permanent deformation in laboratory, thereby, in-situ.

1.2 The modified wheel tracker (MWT)

The Wheel Tracking Test is the preferred test method for laboratory characterisation of rutting in asphalt mixtures because of its simplicity. However, Saleh [2] concluded that the fully confined assembly used in the conventional system of the wheel tracker creates unrealistic boundary conditions around the asphalt specimen, and thereby immobilises the lateral deformation. The research showed that the fully confined assembly of the device revealed no significant difference in rut depth in the samples, despite the samples being considerably different in both volumetric properties and mix composition. This fact was observed by as also discussed by Shami et al. [12], and Yildirim et al. [13]. Additionally, Saleh [2], Azari [14], and Roy-Chowdhury et al. [15] indicated that the primary phase and only a part of the secondary phase of the permanent deformation curve could be observed in the data produced by the fully confined setup of the wheel tracker. In other words, the fully confined setup of the wheel tracker is less likely to capture the shear deformation in the asphalt concrete mixes, thereby making it difficult to evaluate the true rutting behaviour of the mixes.

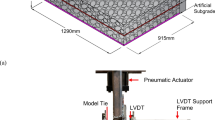

Hence, a modified setup of the wheel tracker was proposed for use and was standardised under ASTM D8292-20 [16]. In the new setup, the lateral sides along the wheel tracking direction are unconfined or can be under full lateral pressure control, while the remaining two sides are fixed. Hence, in this way, both the rut depth or the vertical deformation and the horizontal deformation can be recorded with the loading cycles, which can be utilised to fully analyse the permanent deformation behaviour of the asphalt mixes. Additionally, the option of controlled confinement on the lateral sides was incorporated in this new setup, to simulate the confining stresses that flexible pavements experience in field. Roy-Chowdhury et al. [3, 8] experimented with this new setup of the wheel tracker, and successfully concluded that it is capable of capturing the tertiary zone of the permanent deformation curve where shear deformation takes place. Moreover, the authors also concluded that the measurement of the horizontal deformation is crucial to fully analyse the permanent deformation behaviour of the asphalt mixes.

Figure 1a shows the newly modified setup of the wheel tracker; while Fig. 1b and c depict the vertical deformation of 15 mm and the development of horizontal deformation of 10 mm in the lateral sides of a sample tested in the modified setup (unconfined) of the wheel tracker.

2 Ruggedness testing and factorial design approach

Ruggedness testing is a critical part of the development of a test method by designing robust and effective experimental designs. These designs are very efficient for evaluating the effect of changes in the factors on the chosen responses. For this type of statistical design, it is inherently assumed that each factor has an independent effect on the test results. Therefore, the observed effect resulting from simultaneous variation of several factors is essentially the sum of the individual effects. Since ruggedness testing is concerned with the evaluation of the effect of changes in testing conditions and not necessarily the form of the effect, each testing condition is usually evaluated at only two levels [17].

3 Problem statement

The accurate and precise measurement of asphalt mixture properties is important for both selecting and designing appropriate mixture for the pavement projects, and Quality Assurance (QA) and Quality Control (QC) purposes. It has been discussed earlier how the MWT could be helpful in true characterisation of the asphalt mixtures by considering the lateral flow or shear deformation, thereby producing the tertiary zone in the permanent deformation curve. While several research have been conducted to develop multiple tests for the characterisation of permanent deformation, limited information is obtainable from the existing literature on how the factors or the interaction of the factors from these tests affect the permanent deformation behaviour in the field. This study deals with the ruggedness testing of the experimental factors affecting the permanent deformation behaviour of dense-graded asphalt mixtures tested in the MWT. It should be noted that the Simple Performance Test (SPT) candidates utilise a sophisticated test setup, and that, they are unlikely to be adopted for quality control or quality assurance purposes by the practitioners. In contrast to that, the wheel trackers are simple and common tool for routine testing of the asphalt mixtures. Therefore, the current study utilised the Modified Wheel Tracker (MWT) as the asphalt mixture testing device, and thereby, statistically investigate the effect of different factors on the permanent deformation characteristics on different asphalt mixtures. Finally, the objective of this research is not only to study the effect of the factors on rutting behaviour, but to find the ideal setting for these factors in the MWT.

4 Methodology

The current study focuses on the ruggedness test of the factors that affect permanent deformation to investigate the significance of each factor and their interactions when studied under the MWT. Moreover, it is also important to rank and distinguish these factors in terms of their significance on the permanent deformation behaviour of the asphalt mixes. This statistical analysis is expected to help in controlling and adjusting of the factors in the test method to evaluate the actual field response. The factors and their levels which were included in this research for each phase of the 2 k−p fractional factorial design ruggedness testing are presented in Table 1. Roy-Chowdhury et al. [3, 15] reported the precision and repeatability of the MWT, and these were found to be comparable to the Hamburg Wheel Tracking Test (HWTT) repeatability reported by Azari [14], and Cox et al. [18], and within the tolerable limits for the Dynamic Creep or unconfined Flow Number test covered in AASHTO 378 [19]. Also, it is a common practice to use two replicates for wheel tracker tests because of the large sized specimens weighing in excess of 17,000 gm, compared to other tests that utilise small sized specimens. Therefore, two replicates per mix were considered in this study.

The responses which were considered for each phase of experiments were fitted to a regression model and the factors were ranked. The statistical analysis was conducted according to ASTM E1169-20 [20], and the statistical software Minitab 19.2020.1 [21] was used to design the experiments and run the analysis.

For the selection of confining pressures, initially, unconfined (0 kPa lateral pressure), and lateral pressures of 0.9 kPa, and 1.31 kPa were applied on AC 14 mixes with PG 70–16 binder, two air voids contents (4 and 7%) and one temperature 60 °C. The vertical and horizontal permanent deformation results for these mixes were obtained and presented in Fig. 2. As can be observed from the deformation curves, the AC 14 mix with 4% air voids and with lateral pressure of 1.31 kPa behaved almost similarly to the AC 14 mix with 7% air voids and with lateral pressure of 0.9 kPa, while the mixes with zero confinement or lateral pressure behaved quite distinctly from each other and from the ones with confinement. It can be observed that the absence of confinement in the specimens resulted in higher vertical and horizontal deformations compared to others.

Hence, the confining pressures for the subsequent work of ruggedness testing included 0 kPa (unconfined–lower end of the said pressures), and 1.31 kPa (upper end of the said pressures) to statistically investigate the effect of lateral pressures along with other factors on the permanent deformation characteristics of a series of asphalt mixtures with different combinations of mix and test conditions.

Phase I will focus on the effect of test parameters on FN Index values, while Phase II will focus on different measures of rutting, i.e., permanent deformation at 2000 cycles, and creep slope.

5 Experimental setup and preparation of asphalt mixtures

The study utilised the modified wheel tracker, standardised under ASTM D8292, for the testing of 305 mm × 305 mm × 75 mm compacted HMA slab specimens. A vertical load of 0.7 kN is applied on the specimens with a wheel tracking rate of 26 cycles/min (52 passes per min). The test was conducted in dry condition, at specified temperatures. The test can be run in both unconfined and confined setups. The test is stopped at 50,000 cycles or when the total cumulative vertical permanent deformation (rut depth) reaches 15-mm, whichever occurs first.

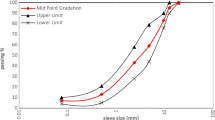

The mixing, pre-conditioning, and compaction temperatures were chosen as 150 °C, with conditioning time of 60 ± 10 min, according to AS/NZS 2891.2.1:2014 and AS/NZS 2891.2.2:2014 [22, 23]. The gradation curves for AC 14 and AC 20 are shown in Fig. 3. As can be observed, the gradations differ only in the coarse fractions while the middle and fine fractions are very similar to each other. Both AC 14 and AC 20 are used as heavy-duty mixes in New Zealand, that is why both were considered in this study.

6 Calculations

6.1 Determination of vertical and horizontal indices

As discussed earlier, the immediate result of using the modified setup of the wheel tracker (unconfined) is that, in most cases, the permanent deformation curve tends to show three distinct phases or zones similar to the results from other fundamental tests, such as the SPTs. These curves can be analysed using the Francken model, and as a result, a definite FN (vertical and horizontal) can be obtained, in contrast to only ‘rut depth’ that is produced by conventional wheel trackers.

Therefore, in this study, the flow number based on vertical deformation (FNV), and the flow number based on horizontal deformation (FNH) for each specimen were determined by fitting the experimental vertical and horizontal deformation data to the Francken model, the details of which can be found in the study by Roy-Chowdhury et al. [3]. Figure 4 illustrates the three zones of a typical permanent deformation curve resulting from the MWT test with zero confinement, and the Francken model fitted to the experimental data.

As pointed out by Zhang et al. [24] and Ali et al. [25], although the Flow Number (FN) has been widely used as a rutting parameter, the FN Index is a better indicator of rutting susceptibility than the FN approach. This is because FN Index considers both FN and the deformation at FN. Mathematically, FN index can be expressed as the ratio of the accumulated permanent deformation to the FN, presented in Eq. 1.

where \(\updelta (\mathrm{F})\) represents permanent deformation (in mm) and FN is the flow number.

7 Results and analysis

7.1 Phase—I

The vertical and the horizontal FN Indices of the asphalt concrete mixes tested under the MWT are presented in Table 2. Subsequently, the values were converted into logarithmic values to address the skewness in the data, and to reduce the wide range of values in the dataset to a more manageable size. Hence, the logarithmic values of the said parameters were considered as the responses for the statistical analysis. While Roy Chowdhury et al. [6] considered only Log (FNV) and Log (FNH) for the analysis, this research considered the vertical and horizontal FN Indices.

It can be seen that the higher FN produced lower FN Index and vice-versa (Fig. 5a and b). Additionally, prior to the main analysis, the correlation of vertical and horizontal FN Indices was obtained to investigate if there exists any linearity between the said parameters. As depicted in Fig. 5c, an excellent correlation was found between the two with an R2 value of 0.98. Moreover, these parameters showed promising correlation with each other, indicating that they are well-connected and can serve as surrogate or alternative parameters for assessing the true permanent deformation characteristics of HMA.

7.1.1 Statistical analysis

The null hypothesis for this study is that the response will not be affected by the change in test factors. The level of significance for this statistical analysis, "α", is equal to 0.05. Therefore, the acceptance or rejection of the null-hypothesis will depend on the P value, which is calculated and compared with "α". P value indicates the probability of getting a mean difference between the groups as high as what is observed by chance. Lower P value indicates higher significance between the groups. In this study, a P value lower than 0.05 indicates that a factor is significantly affecting the response. Analysis of Variance (ANOVA) method is used in order to evaluate the statistical significance among the responses [Log (Vertical FN Index) and Log (Horizontal FN Index)]. The results are presented in Table 3.

As shown in Fig. 6, all the main factors–binder type, %VTM, test temperature, and mix NMAS were found to be significant. Among the two-way interactions or joint effects, “Binder*VTM”, “Binder*Temperature” were found to be significant. The results demonstrate that the change in these factors will significantly affect the permanent deformation behaviour of the asphalt mixtures.

The reason why the combinations such as “VTM*Test Temperature” and “VTM*Mix NMAS” are absent is essentially due to the fact that a fractional factorial design such as the one utilised in this research, is in fact a subset of a full-factorial design, which confounds some of the 2-way interactions and main effects. Hence, these combinations or interactions cannot be distinguished from the effects of other higher-order interactions [21]. Hence, this research should serve as a screening study to obtain the factors which are most significant, so that a full factorial design and analysis can be conducted in future to obtain a complete set of factors and their combinations affecting the response.

As pointed out by Montgomery [26], the half-normal probability plots are another approach to find the significant factors. The probability plot shows the effect of the factors against the percent probability of that effect. In this technique, the significance of the factors is proportional to their distance from the probability line (red-dotted line in Fig. 6). The factor deviating the most is the one with highest significance (i.e., temperature, in this phase of study).

Based on the analysis, temperature was found to have the greatest influence on the permanent deformation behaviour. It is primarily attributed to the fact that the increase in test temperature reduces the binder viscosity, and the binder softens as a result, with the decrease in mix stiffness, leading to higher permanent deformation. The second most influencing factor was found to be %VTM, the reason being, increase in air voids in the asphalt mixture reduces the mix stiffness and weakens the structure, thereby making it more susceptible to permanent deformation. For the effect of bitumen binder, it is a well-established fact that softer binder generally induces more permanent deformation. The NMAS, amongst the individual factors, was found to have the least significance for both vertical and horizontal indices. This is primarily attributed to the fact that, the mix gradations of AC 14 and AC 20 in this study are quite similar to each other, as discussed earlier.

The regression models for vertical and horizontal indices can be constructed as:

7.2 Phase II

As discussed earlier, the factors utilised in this phase of experiments are binder type, VTM, temperature and confining pressure. NMAS appeared to be the least significant individual factor in Phase I testing, therefore, it was replaced with “confining pressure” as a new factor for the Phase II testing. It should be noted that with the induced confinement of 1.31 kPa, the mixes in most cases plateaued. Therefore, the rutting parameters utilised for the ruggedness analysis are the vertical and horizontal deformation at 2000 cycles, and the creep slope. The reason for choosing 2000 cycles as a parameter is that, this particular cycle number is shared by all the runs (mixes) and replicates of the matrix. The values of these parameters are presented in Table 4.

7.2.1 Determination of creep slope

Yildirim et al. [13], and Izzo and Tahmoressi [27], defined the creep slope as the linear region of the curve after post-compaction, which represents the rutting susceptibility due to plastic flow. The MWT utilised in this study, utilised the dry test condition, and the resulting creep slope was determined for the mixes.

Figure 7a shows the correlations of the vertical and hoizontal indices with the vertical and horizontal deformations at 2000 cycles of mixes/runs 1–4. As can be celarly observed, the high correlations validate the use of vertical and horiontal deformation at 2000 cycles for the statistical analysis presented in this section. Moreover, the correlations of vertical and horizontal deformations at 2000 cycles with higher cycle numbers, such as 10,000, 25,000, and 50,000 were investigated for mixes/runs 5–8, presented in Fig. 7b and c. The correlations show that long-term rutting development can well be predicted from rutting at 2000 cycles using linear and exponential models. The slightly lower linear correlation and exponential correlation for the relationship of vertical and horizontal deformation at 2000 cycles and that at 50,000 cycles could have been due to the combined effect of stress and remperature at higher loading cycles. The advantage of such models is that these can potentially minimise the time and cost of testing significantly, as also discussed by Javilla et al. [28].

7.2.2 Statistical analysis

As can be seen from Table 5 and Fig. 8, the statistical analysis of this phase of experiments showed that all the main factors except “binder” were found to be significant for the vertical and horizontal deformations at 2000 cycles. This can be further supported by the fact pointed out by Montgomery [26], that, a significant interaction can often mask the significance of main effects. It indicates that the ultimate effect of binder type is evaluated as a result of its interaction with VTM and test temperature. Another important observation is that, “confining pressure” was found to be significant for all three parameters studied in this phase, with its distinction being the greatest for the creep slope, followed by horizontal deformation, and vertical deformation. This indicates that the creep slope, followed by horizontal deformation and vertical deformation is most sensitive to any change in the confining pressure. The findings clearly demonstrate that the increase of the lateral confining pressure increasingly immobilises the lateral permanent deformation, producing lesser vertical (shear) and horizontal deformation. For obvious reason that temeprature has a tremendous effect on the viscoelastic materials such as asphalt, it is the immediate next factor that imposed significant effect on the test results, where the increase in temeprature increased the permanent deformation in the mixes. The results also indicate that VTM is more important than “binder” to be maintained at specified limits with little deviation, because even little change in design VTM can result in unwarranted results.

The regression models for vertical and corresponding horizontal deformation at 2000 cycles, and creep slope can be constructed as:

8 Model accuracy

The residual values and their trends, which were calculated and examined during the ANOVA, were assessed to validate the accuracy of the models. As pointed out by Montgomery (2017), an adequate model does not bear any obvious pattern [26]. The model adequacy can be verified by studying the normal probability plot of the residuals, which should fall upon the equality line, indicating that the normal distribution assumption of the errors is satisfied. However, moderate departures from normality are usually observed and is generally accepted. Figure 9a–d illustrate the normal probability plot of the residuals for vertical and horizontal FN Index (Phase I), and vertical and horizontal deformation at 2000 cycles (Phase II). The general impression of these figures is that the errors are normally distributed with very few points having large residual.

9 Effects and interaction contour plots

The effects and interaction plots, which show the effects of two factors interactions on the response were presented. The idea is to predict how much deviation in the factors from their design/target value produces a desired range of the corresponding response. This can help control and adjust the design values in the laboratory when conducting the test procedure. The analysis in this section covers the important findings of the experiments discussed and presented earlier. The combinations of the most significant factors for the corresponding responses were considered in the effects and interaction contour plots.

The analysis of the contour plots for vertical deformation at 2000 cycles (Fig. 10a and b) revealed that lower value of the vertical permanent deformation (< 3) was obtained at any one of the following combinations: (a) confining pressure > 1.0 kPa, temperature < 52 °C, for AC 14 mix samples with PG 70–16, with 7% VTM; (b) confining pressure > 1.2 kPa, VTM < 4.3%, for AC 14 samples with PG 70–16, at 60 °C. The analysis of the contour plots for horizontal deformation at 2000 cycles (Fig. 10c and d) revealed that low value of the horizontal deformation (< 1) was obtained at any one of the following combinations: (a) confining pressure > 1.05 kPa, temperature < 52 °C, for AC 14 samples with PG 70–16, with 7% VTM; (b) confining pressure > 1.05 kPa, VTM < 4.7%, for AC 14 samples with PG 70–16, at 60 °C.

Apart from these combinations, which were based on high values of the variables when the other two factors were varied, various other combinations based on high and low values of the variables can be determined.

10 Sensitivity analysis

The vertical deformation at 2000 cycles of the eight corresponding runs from Phase II experiments was considered as the sensitivity analysis. For the analysis, the confining pressure was changed by ± 10%, ± 20% and ± 30%, and the temperature was changed by ± 1%, ± 3% and ± 5%. The changed values were substituted into the model and the output was compared with the initial model output for the responses.

Figure 11a and b indicate that the vertical deformation at 2000 cycles to be within the range ± 25% from the model, the confining pressure and temperature should be controlled in the range ± 25% and ± 5%. This indicates that even minimal change in temperature and confinement would possibly increase the variability amongst the mix replicates and make the coefficient of variation (CV %) of the target permanent deformation parameters yield exceedingly high values, which is not ideal.

11 Conclusion

A total of 16 combinations were considered for the MWT test and the analysis was broken down into two phases. Permanent deformation parameters including the vertical and horizontal FN Indices, vertical and horizontal deformations at specific cycle number, and creep slope were determined. Two combinations of mix gradation AC 14 and AC 20, %VTM (4.0% and 7.0%), binder type (PG 64–16 and PG 70–16), test temperature, and lateral confinement were included in half-factorial design of two- level analysis. Based on the findings, the following can be concluded:

-

1.

ANOVA analysis was used to determine the factors with significant effect on permanent deformation behaviour of HMA studied in the MWT. For both Log (Vertical FN Index) and Log (Horizontal FN Index), all the main factors–binder type, %VTM, test temperature, and mix NMAS were found to be significant. As for the joint effects, the two-way interactions, i.e., “Binder*VTM”, “Binder*Temperature” were found to be significant. The results indicate that the change in any of these factors would potentially alter the rutting or permanent deformation behaviour of the asphalt mixtures studied under the MWT.

-

2.

The use of the MWT shows that long-term rutting development can well be predicted from rutting at 2000 cycles using linear and exponential models. The advantage of such models is that these can potentially minimise the time and cost of testing significantly.

-

3.

Initial results show that the AC 14 mix with 4% air voids and with lateral pressure of 1.31 kPa behaved almost similarly to the AC 14 mix with 7% air voids and with lateral pressure of 0.9 kPa, while the mixes with zero confinement or lateral pressure behaved quite distinctly from each other and from the ones with confinement. It was observed that the absence of confinement in the specimens resulted in higher vertical and horizontal deformations compared to others. Ruggedness matrix-based experiments with controlled confinement and unconfined mixes show that “confining pressure” is the most significant factor for the rutting parameters, with its influence being the greatest for the creep slope, followed by horizontal deformation, and vertical deformation.

-

4.

The contour plots provided various combinations of the most significant factors for the corresponding responses. This can help control, adjust, and optimise the design values in the field.

-

5.

The sensitivity analysis points out that even minimal change in temperature and confining pressure can possibly increase the variability among the mix replicates. The vertical deformation at 2000 cycles to be in the range ± 25% from the model, the confining pressure and temperature should be controlled within the range ± 25% and ± 5%.

References

Tarefder RA, Zaman M, Hobson K (2003) A laboratory and statistical evaluation of factors affecting rutting. Int J Pavement Eng 4(1):59–68. https://doi.org/10.1080/10298430310001593263

Saleh M (2018) Modified wheel tracker as a potential replacement for the current conventional wheel trackers. Int J Pavement Eng 21:1–9. https://doi.org/10.1080/10298436.2018.1435880

Roy-Chowdhury AB, Saleh MF, Moyers-Gonzalez M et al (2022) Empirical correlation of the modified wheel tracker (MWT) and the dynamic creep test for evaluating the permanent deformation of HMA. Can J Civ Eng 49:802–812. https://doi.org/10.1139/cjce-2020-0599

Ji J et al (2019) Effect of high temperature and heavy load on deformation resistance of DCLR modified asphalt mixture. J Tra Transp Eng 19(1):1–8

Souza FV, Castro LS (2012) Effect of temperature on the mechanical response of thermo-viscoelastic asphalt pavements. J Constr Build Mater 30:574–582

Roy-Chowdhury AB, Saleh MF, Moyers-Gonzalez M et al (2021) Ruggedness testing of the factors affecting the permanent deformation behavior studied under the modified wheel tracker (MWT). In: International airfield and highway pavements conference 2021, ASCE. https://doi.org/10.1061/9780784483510.007

Roy N, Veeraragavan A, Murali KJ (2013) Influence of air voids of hot mix asphalt on rutting within the framework of mechanistic-empirical pavement design. 2nd conference of transportation research group of India (2nd CTRG). Procedia Soc Behav Sci 104:99–108

Rahmani E et al (2013) Effect of confinement pressure on the nonlinear-viscoelastic response of asphalt concrete at high temperatures. Constr Build Mater 47:779–788. https://doi.org/10.1016/j.conbuildmat.2013.05.090

Witczack MW et al (2002) NCHRP report 465: simple performance test for superpave mix design. Transportation Research Board, Washington, DC

Garba R (2002) Permanent deformation properties of asphalt concrete mixtures. Doctoral thesis. Department of Road and Railway Engineering, Norwegian University of Science and Technology (NTNU).

Muraya PM (2007) Permanent deformation of asphalt mixtures. Doctoral thesis. TU Delft.

Shami HI et al (1997) Development of temperature-effect model for predicting rutting of asphalt mixtures using Georgia loaded wheel tester. Transp Res Record: J Transp Res Board 1590:17–22. https://doi.org/10.3141/1590-03

Yildirim Y et al (2007) Hamburg wheel-tracking database analysis. Report FHWA/TX-05/0-1707-7, Project 0-1707-7. Texas Department of Transportation.

Azari H (2014) Precision estimates of AASHTO T 324, Hamburg wheel-track testing of compacted hot mix asphalt (HMA). Washington, DC: The National Academies Press. https://doi.org/10.17226/22242

Roy-Chowdhury AB, Saleh MF, Moyers-Gonzalez M et al (2020) Precision assessment of the modified wheel tracking device based on small-scale testing of New Zealand hot mix asphalt. In: Proceedings of the 9th international conference on maintenance and rehabilitation of pavements—Mairepav9. https://doi.org/10.1007/978-3-030-48679-2_64

ASTM D8292 (2020) Standard test method for permanent deformation behavior and rutting resistance of compacted asphalt mix in the modified loaded wheel tracker test utilizing controlled confining pressure. ASTM International, 2020

National Academies of Sciences, Engineering, and Medicine (2008) Ruggedness testing of the dynamic modulus and flow number tests with the simple performance tester. Washington, DC: The National Academies Press. https://doi.org/10.17226/14200.

Cox JA, Van Frank KM, and Romero P (2013) On the variability of results from the Hamburg wheel tracker device. In: Sulbaran, T (ed), Proceedings of the 49th ASC annual international conference, San Luis Obispo, California, USA, 11 pp.

AASHTO T 378–17 (2017) Standard method of test for determining the dynamic modulus and flow number for asphalt mixtures using the asphalt mixture performance tester (AMPT). American Association of State Highway and Transportation Officials (AASHTO), Washington, DC.

ASTM E1169–20. (2020) Standard practice for conducting ruggedness tests. ASTM International, 2020.

Minitab 19 Statistical Software. (2020). [Computer software]. State College, PA: Minitab, Inc.

AS/NZS 2891.2.1 (2014) Methods of sampling and testing asphalt. Part 2.1: sample preparation–mixing, quartering and conditioning of asphalt in the laboratory, 2014

AS/NZS 2891.2.2 (2014) Methods of sampling and testing asphalt. Part 2.2: sample preparation-compaction of asphalt test specimens using a gyratory compactor, 2014

Zhang J et al (2013) Comparison of flow number, dynamic modulus, and repeated load tests for evaluation of HMA permanent deformation. Constr Build Mater 44:391–398

Ali Y et al (2017) Empirical correlation of permanent deformation tests for evaluating the rutting response of conventional asphaltic concrete mixtures. J Mater Civ Eng 29(8):04017059. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001888

Montgomery CD (2017) Design and analysis of experiments. Ninth Edition: John Wiley & Sons, Inc. ISBN 9781119299363.

Izzo RP, Tahmoressi M (1999) Use of the hamburg wheel-tracking device for evaluating moisture susceptibility of hot-mix asphalt. Transp Res Record: J Transp Res Board 99–0955:76–85

Javilla B et al (2017) Significance of initial rutting in prediction of rutting development and characterization of asphalt mixtures. Constr Build Mater 153:157–164. https://doi.org/10.1016/j.conbuildmat.2017.07.007

Acknowledgements

The authors would like to acknowledge the staff from Fulton Hogan in Christchurch for supplying the materials utilised in this study. The authors also owe considerable thanks to the colleagues at the Department of Civil and Natural Resources Engineering (CNRE), University of Canterbury (UC), Christchurch, New Zealand, especially the ones in Pavement Research. Mr. John Kooloos, the technical officer of the Pavement Research Laboratory, UC, is particularly acknowledged for his constant help in the production of the samples, and for providing useful advice. This research is an augmentation of a previous work by the same authors with overlap of methods and the description of the Modified Wheel Tracker (MWT) only, where a different parameter from the device in focus was presented and analysed. The current work includes significant addition in terms of inclusion of new factors in the test matrix and experiments, where more detailed analysis of new parameters has been presented. While the previous research investigated and analysed the Flow Number (FN) parameter from the MWT, the current research involved the parameters FN Index, permanent deformation at 2000 cycles, and creep slope. The previous research can be accessed at https://ascelibrary.org/doi/10.1061/9780784483510.007.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Missing Open Access funding information has been added in the Funding Note.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Roy-Chowdhury, A.B., Saleh, M.F. & Moyers-Gonzalez, M. A statistical analysis of the effect of confining pressure on deformation characteristics of HMA mixtures in the modified wheel track testing. Mater Struct 56, 18 (2023). https://doi.org/10.1617/s11527-023-02106-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02106-y