Abstract

Lignin is one of major by-product from wood and paper industry. As natural biopolymer, it could be a valid alternative as bitumen replacement and/or modifier to enhance the relevant performance of asphalt mixtures, promoting concurrently environmental benefits. In this context, the study focused on the effects of two different binders containing 30% of lignin (by weight) on the mechanical properties of bio-asphalt mixtures. Specifically, two different lignins were blended with two plain bitumens having different consistencies so obtaining two bio-binders with a similar consistency to that of a reference plain bitumen. The two bio-binders and the reference bitumen were used to produce in the laboratory three dense graded asphalt mixtures for binder courses according to the Italian Technical Specifications. The binder-aggregate adhesion, Indirect Tensile Strength, Stiffness Modulus, thermal susceptibility, fatigue resistance, and low-temperature cracking of mixtures were analysed in both unaged and long-term aged conditions. Overall, this investigation demonstrates that bio-mixtures containing lignin offer comparable results to the reference asphalt mixture. Moreover, the bio-asphalt mixtures exhibit a lower thermal susceptibility, as well as lower aging susceptibility. The findings of this research highly encourage the use of lignin as partial replacement of bitumen in asphalt pavements.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, asphalt mixture is the most used material for road pavement construction and maintenance, involving 276.9 Mt in the EU countries in 2020 [1] and 500 Mt in USA [2]. Its popularity is basically related to the wide variety of mixes that can be obtained, in order to meet different technical requirements in terms of functional and structural performance (e.g. texture, regularity, permeability, noise, drainage) of the road pavement. However, ever-increasing traffic loads lead to a rapid degradation of asphalt mixture and consequent premature pavement failure with continuous need for new material in maintenance works. According to the International Renewable Energy Agency (IRENA) [3], the current challenge is a global energy transformation which provides to stop producing fossil fuels by 2050. Therefore, as crude oil distillation for fuel production is phased out, the by-products of these production processes, including components for bitumen, will also decrease significantly. Despite its wide and satisfactory use in the road materials sector, current economic and environmental reasons lead to find and develop increasingly high-performance materials deriving from renewable sources for more durable road pavements. In the last decades, using bitumen modifiers to prolong the life of asphalt mixture has been considered a practical approach in constructing asphalt pavement [4, 5]. Among various bitumen modifiers, biomass organic materials have been more noteworthy because of their abundance, cost-effectiveness, renewability, and sustainability [6].

Recently, the scientific community has turned its attention to lignin applications in road pavement sector. Lignin is one of the most abundant biopolymers on Earth and easily available since it derives from by-products of the wood and paper industry. Due to its hydrocarbon composition, it presents a certain chemical similarity with bitumen [7], in the specific with its aromatic and asphaltene fractions, since lignin contains similar unsaturated aromatics rings joined by alkyl chains as well. This similarity could result in a good compatibility and, at the same time, give the possibility of adding extra potentialities to asphalt binder without penalising its quality. As regards, an antioxidant property is attributable to lignin, deriving from the scavenging action of its phenolic structures on oxygen containing free radicals. Benzene rings of phenolic structures are able to neutralize free radicals, remaining relatively stable so relieving the bitumen ageing effect [8–10]. In particular, aging is a very complex phenomenon affected by different factors which occur during the entire service life. High temperatures lead to a significant thermos-oxidation mainly during production, storage and construction of asphalt binder and mixture. Indeed, reactive gasses, moisture, UV lights and others phenomenon to which the road pavement is exposed during the entire service life are also responsible for promoting aging [11–13]. Giving its potential antioxidant properties, lignin seems to be a very promising solution to ensure longer lifetime of pavements with reduced maintenance needs and consequent economic saving.

In this context it is believed that lignin could represent a potentially valid partial substitute of bitumen, offering an important contribution in a more sustainable development. At the same time, it is necessary to remark that lignin chemical recalcitrance and structural complexity [13] as well as the great variability of its physical and chemical properties, are extremely dependent on the original source, extraction and production method [14]. Several recent laboratory investigations focused on the evaluation of rheological properties of bitumen modified or partially replaced with lignin. In particular, some studies showed overall improved performances against rutting phenomenon [15] for unaged and aged binders, specifically the higher the lignin content, the higher the increase of rutting resistance response [16]. Contrarily, not univocal results were found regarding low temperature cracking potential of bio-binders produced with lignin. According to Fakhiri and Norouzi [16], a slight decrease in resistance to low temperature cracking and weaker capability to absorb thermal stress were evaluated, probably attributable to the stiffening effect of lignin (dosed at 5–10% by weight of bitumen). On the contrary, Norgebey [17] found no significant changes in rutting behaviour by studying the same amounts of lignin as modifier. The fatigue life appeared slightly reduced in case of bio-binder, regardless of the sources of lignin used [18], however the significant reduced ageing susceptibility recognised [9, 16, 21] could mitigate the penalized fatigue behaviour.

Despite the potential applicability of lignin as partial bitumen replacement and/or modifier is satisfactorily evaluated through rheological analysis on lignin-based binders, the performance benefits of using lignin should be validated on a wider scale by directly going into the mechanical characterization of asphalt mixtures containing lignin. To date, less research has been devoted to this goal and the performance of lignin-based asphalt mixtures has still not been exhaustively investigated, while more aspects should be deepened, even though results seem to reflect what found for bio-binders produced with lignin. Despite the various sources and lignin contents experienced, the overall results presented in literature show that lignin-based asphalt mixtures offer better results, or at least comparable performances to the conventional asphalt mixtures. Several studies showed that lignin causes a stiffening effect, leading to a better behaviour at high temperatures against permanent deformations [18, 19]. From the same study conducted by Arafat et al. [19] on asphalt mixture prepared with binder modified with 6% lignin it also emerged a lower fracture energy, but a better cracking resistance and improved flexibility index compared to the control mixture. This is also confirmed by Marshall test experienced by Xu et al. [18] on asphalt mixtures containing 5% of lignin by weight of bitumen. Zahedi et al. [20] showed that lignin, ranging between 3 and 6% by weight, does not affect the thermal sensitivity of the asphalt mixture, but the increase of its content to more than 9% improved this response. On the contrary, the same study showed that the addition of 3–6% of lignin to the asphalt mixture increased the fatigue life, but by increasing the amount of lignin to 9%, the fatigue life was reduced. Even improved resistance to moisture damage has been found by considering Tensile Strength Ratio on different types of asphalt mixture containing lignin [18, 19, 23]. Promising result were found also in terms of aging resistance by Xu et al. [18] on asphalt mixtures, confirming the lignin antioxidant potential effect evaluated on binder phase.

2 Aims and scope

Based on the previous considerations, the goal of this experimental study is to give a contribution for a better understanding of the effect of lignin on the performance of asphalt mixtures consistently with a more sustainable material production. To this end, two lignin-based asphalt mixtures were produced, tested and compared with a conventional reference asphalt mixture. Specifically, bio-based mixtures were produced with bio-binders obtained by using two different lignin sources via wet process. An exhaustive mechanical characterization including Bitumen Bond Strength tests (BBS), Indirect Tensile Strength, Indirect Tensile Stiffness Modulus, thermal sensitivity, Indirect Tensile Fatigue Test and Semi-Circular Bending Test was performed on the selected asphalt mixtures. Long-term aging effects were evaluated as well.

3 Materials

3.1 Binders

Two types of powder lignin, coming from Sweden (coded as “S”) and Baltic region (coded as “B”), both obtained from bio-refineries and derived from some kind of thermochemical and/or enzymatic treatment of wood, were selected to replace respectively 30% by weight of a plain 70/100 and 100/150 pen. grade bitumens, respectively, through a wet process. Before blending both lignins were crumbled and dried at 105 °C to allow the complete moisture evaporation. Then, lignin was slowly added to the pre-heated bitumen and blended at 180 °C with the use of a high shear mixer set at 5000 rpm for 30 min to guarantee a homogenous dispersion of lignin within bitumen, obtaining at the final stage the so-called bio-binder (i.e. bitumen-lignin blend). The two bio-binders were designed to have approximately the same consistency of a conventional 50/70 penetration grade bitumen selected as reference material. The details about the optimization of binders can be found elsewhere [22]. Table 1 lists some of basic characteristics of base bitumens and bio-binders produced. Despite lignin was dried in the oven, a considerable volumetric expansion was recorded, but it was possible to keep the bubble formation under control and at the end of the blending the lignin seemed to be well mixed with the bitumen [23].

3.2 Asphalt mixtures

Three dense-graded asphalt mixtures for binder courses (nominal maximum aggregate size 20 mm), coded as M50/70, M70/100_S and M100/150_B respectively, were produced according to the Italian Technical Specifications [24]. The solid skeleton of the mixtures was composed of 85% by weight of virgin aggregates (i.e. two fractions of limestone coarse aggregate, a limestone sand, a calcareous filler) and 15% by weight of Reclaimed Asphalt Pavement (RAP). All the selected asphalt mixtures were produced by adopting the design gradation shown in Fig. 1. A 5.4% of bitumen content was adopted for the reference M50/70 mixture, whereas 6.4% of bio-binder was adopted for the M70/100_S and M100/150_B mixtures (Fig. 2). Such a bio-binder content was optimised in a previous study in order to design bio-based mixtures having satisfying volumetric and mechanical properties while allowing a reduction of 15% of fresh bitumen [22]. After mixing by an automated mechanical mixer, the loose asphalt mixtures were aged in a forced-draft oven for 4 h at 135 °C to simulate the short-term aging of material. Afterwards, aged mixtures were compacted by means of a gyratory compactor (GC) according to EN 12697-31 [25] in order to obtain 100 mm and 150 mm diameter cylindrical specimens with a thickness of 60 and 150 mm, respectively, characterized by a residual air voids content equal to 4.5 ± 0.5% and 6 ± 0.5% [26]. In order to evaluate the long-term aging effects, a series of the GC specimens was aged in a forced-draft oven for 5 days at 85 °C according to the AASHTO R30-02 [27]. Workability and water susceptibility of the selected bio-based mixtures have been optimised and evaluated elsewhere [22].

4 Experimental plan and methods

A preliminary phase of the experimental program involved the evaluation of the bond strength of bio-binders/natural aggregate systems by performing BBS testing. A second phase was devoted to a mechanical characterization on unaged and long-term aged specimens consisting in Indirect Tensile Strength (ITS), Indirect Tensile Stiffness Modulus (ITSM), Indirect Tensile Fatigue Test (ITFT) and Semi-Circular Bending Test (SCB) in order to assess strength, stiffness and fracture properties as well as thermal and aging susceptibility of the selected bio-based mixtures. The summary of the testing program is shown in Table 2.

4.1 Bitumen bond strength (BBS)

BBS tests were carried out by using a modified pneumatic adhesion tensile testing instrument (PATTI) consisting of a metal stub, a pneumatic piston, a reaction plate and a control module according to the AASHTO T 361 designation [28]. The metal pull-off stubs employed in this study were characterized by an internal diameter (corresponding to the diameter of the binder-substrate contact area) of 12.5 mm, an external diameter of 12.7 mm and a 0.3 mm-thick edge (corresponding to the thickness of the binder specimen), which presents small cuts allowing the excess binder to flow out during the stub application [30, 31]. As for the BBS specimen preparation, a sample of hot binder (0.08 g) was placed on metal stubs surface allowing the binder to perfectly adhere to the stub. After heating, the stub with the binder sample was then pressed onto the aggregate surface, previously heated at the same application temperature of the binder (i.e. 160 °C), to produce the BBS assembly (Fig. 3). Before testing, BBS specimens were subjected to dry (at 25 °C for 24 h in a climatic chamber) or wet (at 40 °C for 24 h in a water bath + at 25 °C for 1 h in a climatic chamber) conditioning. Five BBS replicates were tested at 25 °C for each binder/aggregate system. The test allowed to quantify the tensile force needed to remove the binder sample adhering to the solid substrate. Specifically, during the test an increasing pulling force was applied to the stub with a constant loading rate through the pneumatic system. In such way, the binder specimen was subjected to a growing tensile force until reaching the failure. The failure pressure was recorded and then converted into the pull-off tensile strength (POTS) as follows:

where BP is the burst pressure in kPa, \({A}_{\mathrm{g}}\) is contact area of gasket with reaction plate (mm2), C is the piston constant and \({A}_{\mathrm{ps}}\) is the area of pull-off stub (mm2). Moreover, the type of failure was identified by visually inspecting the coating level of the contact area after the test in order to discriminate between adhesive and cohesive type failure. In this investigation, BBS tests were performed on 20 binder/aggregate systems by considering the following testing parameters: 2 aggregate substrates (limestone and basalt), 5 binders (3 plain bitumen and 2 bio-binders) and 2 types of conditioning (dry and wet).

4.2 Indirect tensile strength (ITS)

The ITS test was carried out at 25 °C according to the EN 12697-23 standard. The test consisted in applying continuously a progressive load at a constant speed of 50 mm/min along the vertical plane until the specimen reached the failure. The ITS was calculated by the following equation:

where P is the peak load applied, D and h are the specimen diameter and height, respectively. Test was performed on 100 mm diameter GC specimens having a height of 60 mm, after a conditioning in a climatic chamber at 25 °C for at least 4 h. Four replicates for each mixture and testing condition (unaged/long-term aged) were tested.

4.3 Indirect tensile stiffness modulus (ITSM)

The ITSM tests were performed through a servo-pneumatic machine according to the EN 12697-26. The test consists in applying an impulsive loading with a rise-time of 124 ms along the vertical diameter of the specimen, in order to induce a target maximum horizontal deformation of 5 ± 2 μm. The ITSM can be calculated by the following equation:

where P is the compressive load applied, \(\Delta x\) is the maximum horizontal deformation, \(t\) is the specimen height and \(\nu\) is the Poisson’s ratio related to the test temperature. Test was performed on 100 mm GC specimens having a height of 60 mm, which were preliminary conditioned in a climatic chamber for at least 4 h at test temperature (i.e. 20 °C). For each selected mixture and testing condition (unaged/long-term aged), 9 replicates were tested at 20 °C, and among them, 4 specimens were also tested at 10, 30 and 40 °C to evaluate the thermal sensitivity of the mixture.

4.4 Indirect tensile fatigue test (ITFT)

The resistance to cyclic loading of mixtures was evaluated by performing ITFT testing in accordance with the EN 12697-24 (Annex E). Similarly to ITSM configuration, the application of a compressive impulsive loading along the vertical diameter of the specimen results in an uniform tensile stress which is perpendicular to the vertical diametral plane. The system measures the cumulative horizontal deformation of the specimen throughout the test and the number of loading cycles to failure, which is established as the complete fracture of the specimen. The tests were carried out in controlled stress mode by applying repeated haversine load with 0.1 s loading time and 0.4 s rest time. The stress levels were selected in order to have initial horizontal strains ranging between 100 and 400 με. The tests were performed at 20 °C on the specimens preliminarily tested for ITSM analysis after a conditioning period of 4 h at the test temperature. At least 6 repetitions for each mixture and testing condition were tested to allow the depiction of the fatigue curve and the calculation of the strain corresponding to 106 cycles (ε6), as representative of the fatigue response of material.

4.5 Semi-circular bending (SCB) test

The SCB test was performed according to the EN 12697-44 standard to characterize the cracking resistance of mixture. The test consists in applying a load in a three-point bending configuration to a half cylindrical specimen having a central artificial notch to induce crack initiation. The tests were run at 10 °C by applying a constant vertical deformation of 5 mm/min, during the test load and vertical deformation are continuously recorded. Four replicates for each mixture and testing condition were tested. Specifically, 4 half-cylindrical specimens of thickness of 50 mm, were obtained from a single 150 mm diameter GC specimen by suitable cutting. Then, an artificial notch (with 15 mm depth) was produced in the middle of the base of each specimen. Before testing, specimens were kept in a climatic chamber at test temperature for 4 h.

The fracture response of material was evaluated in terms of fracture toughness \({k}_{\mathrm{Ic},i}\) and fracture energy G, which is determined as the whole area under the load–displacement curve normalized with respect to the ligament area of the specimen as follows, respectively:

where Wi is the height of the specimen (mm), ai is the notch depth of specimen (mm) and \({\sigma }_{{\max},i}\) is the stress at failure of specimen (N/mm2),

where \(\int F\mathrm{d}s\) is the area under the whole load–displacement curve and \({t}_{i}\) is the thickness of the specimen (mm).

5 Results and discussion

5.1 Bitumen bond strength

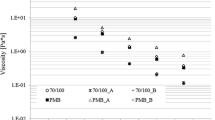

Figure 4 sums up the results of BBS tests carried out on virgin limestone and basalt aggregates, both in dry and wet conditions. For each binder-aggregate systems the results are plotted in terms of POTS value along with the related type of failure. Specifically, the failure is considered purely cohesive (coded as C) when it occurs within the binder film, denoting that the binder-aggregate adhesion is stronger than the binder cohesion. On the other side, a purely adhesive (coded as A) failure takes place at the interface between binder and aggregate and indicates that the cohesion within the binder prevails on the adhesion at the interface. Finally, when both cohesive and adhesive mechanisms occur at failure a hybrid failure (coded as C/A) can be depicted. In addition to comparing the two bio-binders B.70/100_S30 and B.100/150_B30 to reference B.50/70 bitumen, the figures report the results for the plain bitumens B.70/100 and B.100/150 from which bio-binders were obtained as well.

As far as dry conditioning is concerned, it can be noticed that all binders-aggregate combinations showed cohesive failure highlighting the good affinity and adhesion between bio-binders and selected aggregates as well. This finding means that the presence of both type of lignin does not compromise the adhesion of plain bitumen with both aggregates. In terms of POTS value, the results show a comparable response among the selected binder-aggregate systems, with the exception for the reference B.50/70 bitumen which exhibits higher POTS values, denoting its higher inner cohesion.

As far as wet conditioning is concerned, different results were gathered for the several systems depending on the type of aggregate. In the case of limestone aggregate, the systems continued to show only cohesive failure after water conditioning and only a slight reduction of POTS values was observed. As for basalt aggregates, it is evident that the two plain and the reference bitumens were significantly affected by the water showing a transition from cohesive to hybrid or adhesive failure and a significant drop in POTS value, especially for the reference B.50/70 bitumen which yielded the highest POTS reduction (up to 50%). This aspect could be attributable to the hydrophobic nature of limestone, characterised by basic chemical nature due to a low silica content. Differently, the acid composition of basalt types (imputable to the high silica content) leads to water to reach the bonding layer and reduce the adhesion at the interface which dropped below the cohesion strength of the binder [29].

On the other hand, it is worth noting that especially with the basalt substrate, the bio-binders showed the lowest POTS reduction, likely caused by an emulsification process which can weaken the cohesive bonds within the binder film, with associated failures which were exclusively cohesive type. Given the different failure types, higher or similar POTS values indicate that the adhesive bond between bio-binders and aggregate substrates is improved with respect to the plain and reference bitumens in presence of water.

From the analysis of overall results, it can be stated that the lignin replacement basically does not penalize the adhesion and cohesion of bitumen-aggregate system, on the contrary the investigated bio-binders showed an improved moisture susceptibility as compared to plain and reference bitumens, so guaranteeing a satisfactory bond strength level also with hydrophilic aggregate in presence of water.

5.2 Indirect tensile strength (ITS)

Figure 5 displays the ITS test results in unaged and long-term aged conditions for the two bio-based mixtures and the reference one. The ITS analysis shows perfectly comparable results between M70/100_S and the reference mixtures in both aging conditions, which means that lignin likely allows to compensate the lower effective bitumen content contained in the bio-based mixture that cannot contribute to the strength development. As for the bio-based mixtures, it can be observed that the M100/150_B mixture shows a lower ITS value as compared to M70/100_S mixture regardless of the aging condition despite both mixtures are characterized by the same bio-binder and lignin content. Although not significant differences are highlighted, this penalized performance can be attributable to the softer consistency of the base bitumen and different lignin source. Moreover, as expected aging results in an increase in ITS response for all mixtures, confirming the hardening effect experienced by the mixtures throughout the aging process. In particular, bio-based mixtures show a susceptibility to ageing comparable to the reference mixture, however this aptitude is dependent on the combination of base bitumen and lignin type considered, indeed softer bitumen and lignin B seem to experience a higher aging effect.

5.3 Indirect tensile stiffness modulus (ITSM)

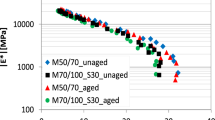

Figure 6 shows the ITSM results for all the investigated mixtures in both aging conditions. ITSM data are represented as a function of the testing temperature and fitted by a linear regression expressing the temperature dependence of stiffness modulus. From the analysis of the data shown in Fig. 6, it can be noticed that the lignin-based mixtures are stiffer than the reference one at any testing temperature, except for the M100/150_B mixture which shows a comparable stiffness as compared to the M50/70 mixture in aged condition. This experimental finding highlights that despite the similar consistency of the binder phase (Table 1) the presence of lignin results in a hardening effect of mixture. As expected, as the temperature increases the ITSM decreases for all the investigated mixtures because of the temperature dependence of bitumen. However, experimental data show that the increase in stiffness of bio-based mixtures with respect to the reference one is more marked at higher temperatures, entailing a potential better performance at high temperature of bio-mixtures especially for the M70/100_S. This means that not only the bio-based mixtures are stiffer than the reference M50/70, but at the same time they are also less prone to thermal susceptibility, as confirmed by the lower slope of the regression curves meaning that mixtures are less sensitive to temperature variation in both aging conditions.

In order to evaluate the aging effects on the stiffness properties of mixtures, the ITSM value were compared and the ITSMR parameter was calculated as the ratio between the measured aged and unaged ITSM at each temperature (Table 3). As can be noticed, ITSMR values are always higher than 1 for all the mixtures and this confirm the global hardening effect caused by aging experienced by the materials. However, both bio-based mixtures show lower ITSMR values at any temperature, so entailing a lower aging susceptibility as compared to the reference mixture consistently with the analysed ITS response. On the one hand this result can testify the effect of lignin as "antioxidant" agent [8, 18, 21, 22, 33],on the other hand it is right to point out that the reduced aging sensitivity could also attributable to the lower content of effective bitumen within the bio-based mixtures as compared to the reference one (i.e. 4.65% vs. 5.4%), or however it could be due to a combination of the two effects.

5.4 Indirect tensile fatigue test (ITFT)

Figure 7 shows the fatigue response of the lignin-based mixtures and the reference one in both aging conditions in terms of initial strain plotted as a function of the number of cycles to failure, whereas fatigue laws and ε6 parameter values are listed in Table 4. The analysis of unaged conditions (Fig. 7a) shows that both lignin-based mixtures are characterized by a penalised fatigue performance with respect to the reference mixture. This result can be likely due to the higher stiffness of bio-based mixture due to the lignin as compared to the reference one, moreover the lower content of effective bitumen results in less ductile properties making the bio-based more prone to the fracture. On the contrary, the aging conditions show comparable results between the lignin-based and conventional asphalt mixtures when considering the stress–strain levels to which the materials are commonly subjected in situ. From Fig. 7b, the bio-based mixtures look less sensitive to the applied strain level as confirmed by a lower slope of the fatigue curves, especially for the M70/100_S mixture (Table 4). The analysis of ε6 parameter confirms the shortest fatigue life of lignin-based asphalt mixtures in unaged conditions and a more comparable behaviour among mixtures in aged conditions, especially for M70/100_S which reveals the lowest aging susceptibility among the investigated mixtures. Moreover, it is worth to consider that fatigue phenomena produce long-term effects on asphalt pavements, and despite the penalised performances emerged in unaged conditions, after aging results are more promising, at least for 70/100_S, while 100/150_B seems to be the most penalised. Despite the similar consistency of the binder phase, the different resistance to aging of two bio-based mixtures could be ascribed to the different aging sensitivity of the base materials (i.e. type of bitumen and lignin source) and it is consistent with what found for ITS analysis.

5.5 Semi-circular bending test (SCB)

Figure 8a and b depict the fracture propagation behaviour evaluated at 10 °C in both aging conditions of all investigated mixtures in terms of fracture toughness and fracture energy, respectively. As for the fracture toughness, in unaged conditions the lignin-based mixtures show a lower resistance to fracture as compared to the reference one, although all the three mixtures show a comparable stiffness response at the same test condition (see Sect. 5.3). Contrarily in aged conditions, an opposite trend can be observed with both bio-mixtures showing higher k values than reference mixture. However, the high result variability (standard deviation) found in unaged condition would seem to minimize aging effects on toughness of the bio-mixtures.

On the other hand, the analysis of fracture energy shows penalized performances for the unaged mixtures containing lignin. Whereas, as regards aged condition the reference mixture experience a significant drop in fracture energy contrarily to the bio-mixtures which show comparable fracture energy values with respect to the unaged ones, so highlighting the tendency to a lower aging susceptibility. Based on the overall results, it can be seen that the lignin-based mixtures show k and G values comparable to those of the reference mixture, thus highlighting that the fracture behaviour of the mixtures is not penalized by the presence of lignin, which seems to reduce aging effects instead.

6 Conclusions

The goal of this study was to give a contribution about the feasibility of using lignin as renewable material in asphalt pavement application. In this regard, two asphalt mixtures for binder course having the same composition (i.e. gradation and binder content), but using two bio-binders obtained from the combination of different bitumen and lignin sources, were produced in laboratory and compared with a conventional asphalt mixture, whose bitumen had a similar consistency of the produced bio-binders. A laboratory mechanical characterization aimed at evaluating the bond strength of bio-binder/aggregate systems, strength and stiffness properties as well as fatigue and fracture response of selected mixtures was performed, by taking also into account aging susceptibility.

The following conclusions can be drawn based on the overall test results:

-

The presence of lignin does not compromise bond strength between bio-binder and natural aggregate, even better it seems to guarantee an reduced moisture susceptibility as compared to reference bitumens especially in the case of hydrophilic aggregate.

-

ITS results highlight that bio-based mixtures show comparable strength response to the reference mixture, whereas ITSM analysis proves that lignin-based mixtures guarantee higher stiffness properties especially at high temperature with an associated slight lower thermal susceptibility with respect to the reference one.

-

Although fatigue and SCB results show penalised fracture behaviour in unaged condition for lignin-based mixtures, comparable performances are found as aged conditions are considered; this experimental finding highlights that the lignin rather than penalizing the fracture response of bio-mixtures seems to mitigate the aging effects on it.

-

Overall results show that the aging susceptibility of bio-mixtures is strictly dependent on the combination of base materials, that is type of bitumen and lignin source; however, the slight lower content of effective bitumen within lignin-based mixtures could result in a reduced aptitude to aging of the mixtures.

Despite no generalization can be drawn, the current experimental findings found in the present study strongly encourage the use of lignin in the production of asphalt mixtures. Indeed, no mechanical penalization were found for the investigated lignin-based mixtures, but even better performances were observed especially as aged condition is concerned, instead. Moreover, it is right remark the use of lignin as replacement allowed a reduction of 15% by weight of effective bitumen with consequent both economical saving and environmental benefit, while guaranteeing satisfactory performance level of asphalt mixtures.

Further investigations aimed at analysing lignin-based mixtures from full-scale production and application are strongly recommended to provide a more comprehensive understanding of lignin use to produce bituminous materials satisfying performance and sustainability requirements for pavement applications.

Data availability

The data presented in this study are available on request from the corresponding author.

References

EAPA—European Asphalt Pavement Association (2021) Asphalt in figure 2020

Gielen D, Boshell F, Saygin D, Bazilian MD, Wagner N, Gorini R (2019) The role of renewable energy in the global energy transformation. Energy Strateg Rev 24(2018):38–50. https://doi.org/10.1016/j.esr.2019.01.006

Fatemi S, Bazaz JB, Ziaee SA (2022) Investigating the effect of calcium lignosulfonate on the durability and performance of asphalt mixtures. Adv Mater Sci Eng. https://doi.org/10.1155/2022/5260159

Zhu J, Birgisson B, Kringos N (2014) Polymer modification of bitumen: advances and challenges. Eur Polym J 54(1):18–38. https://doi.org/10.1016/j.eurpolymj.2014.02.005

Dhasmana H et al (2015) Rheological and chemical characterization of biobinders from different biomass resources. Transp Res Rec 2505:121–129. https://doi.org/10.3141/2505-16

Besamusca J, Landa P, Zoetemeyer R, Gosselink R, Lommers B. The use of lignin as bio-binder in asphalt applications. In: Abstract several investigations have shown interest in the use of durable material for road constructions, including bio-based oil. The introduction of lignin in asphal

Pan T (2012) A first-principles based chemophysical environment for studying lignins as an asphalt antioxidant. Constr Build Mater 36:654–664. https://doi.org/10.1016/j.conbuildmat.2012.06.012

Zhang RJY, Liu X, Apostolidis P, Gard W, van de Ven M, Erkens S (2019) Chemical and rheological evaluation of aged lignin-modified bitumen. Materials (Basel) 12:4176

Mirwald J, Nura D, Eberhardsteiner L, Hofko B (2022) Impact of UV–Vis light on the oxidation of bitumen in correlation to solar spectral irradiance data. Constr Build Mater 316(2021):125816. https://doi.org/10.1016/j.conbuildmat.2021.125816

Mirwald J, Maschauer D, Hofko B, Grothe H (2020) Impact of reactive oxygen species on bitumen aging—the Viennese binder aging method. Constr Build Mater 257:119495. https://doi.org/10.1016/j.conbuildmat.2020.119495

Li Y et al (2019) Aging degradation of asphalt binder by narrow-band UV radiations with a range of dominant wavelengths. Constr Build Mater 220:637–650. https://doi.org/10.1016/j.conbuildmat.2019.06.035

Constant S et al (2016) New insights into the structure and composition of technical lignins: a comparative characterisation study. Green Chem 18(9):2651–2665. https://doi.org/10.1039/c5gc03043a

Watkins D, Nuruddin M, Hosur M, Tcherbi-Narteh A, Jeelani S (2015) Extraction and characterization of lignin from different biomass resources. J Mater Res Technol 4(1):26–32. https://doi.org/10.1016/j.jmrt.2014.10.009

Pérez I, Pasandín AR, Pais JC, Pereira PAA (2020) Feasibility of using a lignin-containing waste in asphalt binders. Waste Biomass Valoriz 11(6):3021–3034. https://doi.org/10.1007/s12649-019-00590-4

Fakhri M, Norouzi MA (2021) Rheological and ageing properties of asphalt bio-binders containing lignin and waste engine oil. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2022.126364

Norgbey E et al (2020) Unravelling the efficient use of waste lignin as a bitumen modifier for sustainable roads. Constr Build Mater 230:116957. https://doi.org/10.1016/j.conbuildmat.2019.116957

Xu C et al (2021) Effect of lignin modifier on engineering performance of bituminous binder and mixture. Polymers (Basel) 13(7):1083. https://doi.org/10.3390/polym13071083

Arafat S, Kumar N, Wasiuddin NM, Owhe EO, Lynam JG (2019) Sustainable lignin to enhance asphalt binder oxidative aging properties and mix properties. J Clean Prod 217:456–468. https://doi.org/10.1016/j.jclepro.2019.01.238

Zahedi M, Zarei A, Zarei M (2020) The effect of lignin on mechanical and dynamical properties of asphalt mixtures. SN Appl Sci 2(7):1–10. https://doi.org/10.1007/s42452-020-3041-4

Gao J, Wang H, Liu C, Ge D, You Z, Yu M (2020) High-temperature rheological behavior and fatigue performance of lignin modified asphalt binder. Constr Build Mater 230:117063. https://doi.org/10.1016/j.conbuildmat.2019.117063

Gaudenzi F, Canestrari F, Lu X, Cardone F, (2022) Performance analysis of bio-based asphalt mixtures containing lignin

Pérez IP, Rodríguez Pasandín AM, Pais JC, Alves Pereira PA (2019) Use of lignin biopolymer from industrial waste as bitumen extender for asphalt mixtures. J Clean Prod 220:87–98. https://doi.org/10.1016/j.jclepro.2019.02.082

CSA_Capitolato Speciale d’Appalto. Norme Tecniche ANAS. Pavimentazioni stradali/autostradali. Allegato D

E. 12697-31 (2007) Bituminous mixtures: test methods for hot mix asphalt, part 31: specimen preparation by gyratory compactor, 2019

E. 12697-8 (2005) Test methods for hot mix asphalt. Determination of void characteristics of bituminous specimens

AASHTO R 30-02 (2019) Standard practice for mixture conditioning of hot mix asphalt. Am Assoc State Highw Transp Off 2:1–5

AASHTO TP-91 (2011) Standard method of test for determining asphalt binder strength by means of the binder bond strength (BBS) test. Am Assoc State Highw Transp Off 3:1–14

Tarrer AR, Wagh V (1991) The effect of the physical and chemical characteristics of the aggregate on bonding. SHRP-A/UIR-91-507-91-507

Ingrassia LP, Cardone F, Canestrari F, Lu X (2019) Experimental investigation on the bond strength between sustainable road bio-binders and aggregate substrates. Mater Struct Constr 52(4):1–14. https://doi.org/10.1617/s11527-019-1381-6

D’angelo S, Ferrotti G, Cardone F, Canestrari F (2022) Asphalt binder modification with plastomeric compounds containing recycled plastics and graphene. Materials (Basel) 15(2):516. https://doi.org/10.3390/ma15020516

Ren S et al (2021) Multi-scale characterization of lignin modified bitumen using experimental and molecular dynamics simulation methods. Constr Build Mater 287:123058. https://doi.org/10.1016/j.conbuildmat.2021.123058

Boeriu CG, Bravo D, Gosselink RJA, Van Dam JEG (2004) Characterisation of structure-dependent functional properties of lignin with infrared spectroscopy. Ind Crops Prod 20(2):205–218. https://doi.org/10.1016/j.indcrop.2004.04.022

Funding

Open access funding provided by Università Politecnica delle Marche within the CRUI-CARE Agreement. This research received no external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization, FC and XL; methodology, FC and FC; experimental investigation, EG; resources, XL; data analysis, FC, FC, EG, and XL; writing—original draft preparation, E.G.; writing—review and editing, FC; supervision, XL and FC. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gaudenzi, E., Cardone, F., Lu, X. et al. Performance assessment of asphalt mixtures produced with a bio-binder containing 30% of lignin. Mater Struct 55, 221 (2022). https://doi.org/10.1617/s11527-022-02057-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-022-02057-w