Abstract

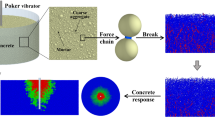

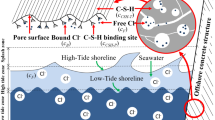

High-frequency vibration helps to improve the compactness of concrete, but also causes the settlement of coarse aggregates (CAs) and then affects the durability of hardened concrete. In this paper, a numerical study combining multi-phase CA settlement model and multi-component ionic transport model is performed to understand the influence of vibration-induced settlement on long-term chloride transport in concrete. Through parametric analysis, the influence mechanism of relevant factors on both chloride profile distribution and reinforcement corrosion initiation is discussed in detail. The results indicate that with the increase of vibration time, a decrease of chloride concentration appears in the bottom part of concrete specimen and a significant increase in the top part, because more CAs deposit in the bottom layer. Due to sedimentation, a more obvious fluctuation of chloride concentration along the height direction can be observed in the concrete mixed with a larger density and particle size of CAs. According to the model prediction, the corrosion of the top steel bar initiates 1.03–1.80 years earlier than that of the bottom steel bar under the same parameters. In practical engineering, special attention should be paid on the stability of fresh concrete and vibrating procedures to avoid obvious CA settlement.

Similar content being viewed by others

References

Aïssoun BM, Hwang SD, Khayat KH (2016) Influence of aggregate characteristics on workability of superworkable concrete. Mater Struct 49:597–609

Jang KP, Kwon SH, Choi MS, Kim YJ, Park CK, Shah SP (2018) Experimental observation on variation of rheological properties during concrete pumping. Int J Concr Struct Mater 12:79

Koch JA, Castaneda DI, Ewoldt RH, Lange DA (2019) Vibration of fresh concrete understood through the paradigm of granular physics. Cem Concr Res 115:31–42

Safayenikoo H, Khajehzadeh M, Nehdi ML (2022) Novel evolutionary-optimized neural network for predicting fresh concrete slump. Sustainability 14(9):4934

Roussel N (2006) A theoretical frame to study stability of fresh concrete. Mater Struct 39(1):81–91

Pan J, He J, Zhu J, Gao X (2022) Theoretical and experimental study on the electrical resistivity method for evaluating fresh concrete segregation. J Build Eng 48:103943

Muslim F, Wong HS, Cheng G, Alexandrou C, Liu B, Buenfeld NR (2020) Combined effects of vertical spacers and segregation on mass transport properties of reinforced concrete. Mater Struct 53:151

Khayat KH, Manai K, Trudel A (1997) In situ mechanical properties of wall elements cast using self-consolidating concrete. ACI Mater J 94(6):491–500

Megid WA, Khayat KH (2018) Effect of concrete rheological properties on quality of formed surfaces cast with self-consolidating concrete and superworkable concrete. Cem Concr Compos 93:75–84

Gao X, Zhang J, Su Y (2019) Influence of vibration-induced segregation on mechanical property and chloride ion permeability of concrete with variable rheological performance. Constr Build Mater 194:32–41

Panesar DK, Shindman B (2012) The effect of segregation on transport and durability properties of self consolidating concrete. Cem Concr Res 42:252–264

Cai Y, Zhang W, Yu L, Chen M, Yang C, François R, Yang K (2020) Characteristics of the steel-concrete interface and their effect on the corrosion of steel bars in concrete. Constr Build Mater 253:119162

Cai Y, Zhang W, Yang C, François R, Yu L, Chen M, Chen H, Yang H (2021) Evaluating the chloride permeability of steel–concrete interface based on concretes of different stability. Struct Concr 22(5):2636–2649

Zhang W, François R, Wang R, Cai Y, Yu L (2020) Corrosion behavior of stirrups in corroded concrete beams exposed to chloride environment under sustained loading. Constr Build Mater 274:121987

Liu QF, Iqbal MF, Yang J, Lu XY, Zhang P, Rauf M (2021) Prediction of chloride diffusivity in concrete using artificial neural network: modelling and performance evaluation. Constr Build Mater 268:121082

Ashraf M, Iqbal MF, Rauf M, Ashraf MU, Ulhaq A, Liu QF (2022) Developing a sustainable concrete incorporating bentonite clay and silica fume: mechanical and durability performance. J Cleaner Prod 337:130315

Chen M, Wei Y, Zheng H, Yu L, Liu Q, Wang Y, Yuan H, Wang C, Li W (2022) Ca-LDH-modified cementitious coating to enhance corrosion resistance of steel bars. J Build Eng 51:104301

Liu QF, Hu Z, Wang XE, Zhao H, Qian K, Li LJ, Meng Z (2022) Numerical study on cracking and its effect on chloride transport in concrete subjected to external load. Constr Build Mater 325:126797

Li LJ, Liu QF (2022) Freezing rate and chloride transport in concrete subjected to freeze-thaw cycles: a numerical study. J Chin Ceram Soc 50(8):2245–2256

Tong L, Liu QF (2023) Multi-scale prediction model of chloride diffusivity of fiber reinforced concrete. Acta Mater Compositae Sin 40:1–12 https://doi.org/10.13801/j.cnki.fhclxb.20220422.003

Angst U, Elsener B, Larsen CK, Vennesland Ø (2009) Critical chloride content in reinforced concrete—a review. Cem Concr Res 39(12):1122–1138

Mundra S, Criado M, Bernal SA, Provis JL (2017) Chloride-induced corrosion of steel rebars in simulated pore solutions of alkali-activated concretes. Cem Concr Res 100:385–397

Zhang W, François R, Cai Y, Charron JP, Yu L (2020) Influence of artificial cracks and interfacial defects on the corrosion behavior of steel in concrete during corrosion initiation under a chloride environment. Constr Build Mater 253:119165

Meng Z, Liu QF, She W, Cai Y, Yang J, Iqbal MF (2021) Electrochemical deposition method for load-induced crack repair of reinforced concrete structures: a numerical study. Eng Struct 246:112903

Chen M, Cai Y, Zhang M, Yu L, Wu F, Jiang J, Yang H, Bi R, Yu Y (2021) Novel Ca-SLS-LDH nanocomposites obtained via lignosulfonate modification for corrosion protection of steel bars in simulated concrete pore solution. Appl Clay Sci 211:106195

Petrou MF, Harries KA, Gadala-Maria F, Kolli VG (2000) A unique experimental method for monitoring aggregate settlement in concrete. Cem Concr Res 30(5):809–816

Navarrete I, Lopez M (2017) Understanding the relationship between the segregation of concrete and coarse aggregate density and size. Constr Build Mater 149:741–748

Khayat KH, Pavate TV, Assaad J, Jolicoeur C (2003) Analysis of variations in electrical conductivity to assess stability of cement-based materials. ACI Mater J 100(4):302–310

Benaicha M, Jalbaud O, Roguiez X, Alaoui AH, Burtschell Y (2015) Prediction of self-compacting concrete homogeneity by ultrasonic velocity. Alex Eng J 54(4):1181–1191

Gokce HS, Ozturk BC, Çam NF, Andiç-Çakir O (2018) Gamma-ray attenuation coefficients and transmission thickness of high consistency heavyweight concrete containing mineral admixture. Cem Concr Compos 92:56–69

Cai Y, Liu QF, Yu L, Meng Z, Hu Z, Yuan Q, Savija B (2021) An experimental and numerical investigation of coarse aggregate settlement in fresh concrete under vibration. Cem Concr Compos 122:104153

Petrou MF, Wan BL, Gadala-Maria F, Kolli VG, Harries KA (2000) Influence of mortar rheology on aggregate settlement. ACI Mater J 97(4):479–485

Tattersall GH, Baker PH (1989) An investigation into the effect of vibration on the workability of fresh concrete using a vertical pipe apparatus. Mag Concr Res 41(146):3–9

Banfill PFG, Xu Y, Domone PLJ (1999) Relationship between the rheology of unvibrated fresh concrete and its flow under vibration in a vertical pipe apparatus. Mag Concr Res 51(3):181–190

Li Z, Cao G (2019) Rheological behaviors and model of fresh concrete in vibrated state. Cem Concr Res 120:217–226

Petit JY, Wirquin E, Vanhove Y, Khayat KH (2007) Yield stress and viscosity equations for mortars and self-consolidating concrete. Cem Concr Res 37(5):655–670

Leemann A, Winnefeld F (2007) The effect of viscosity modifying agents on mortar and concrete. Cem Concr Compos 29(5):341–349

Tong LY et al (2023) Modelling the chloride transport in concrete: from microstructure generation to chloride diffusivity prediction. Comput Struct

Hansen TC (1986) Physical structure of hardened cement paste: a classical approach. Mater Struct 19:423–436

Bentz DP, Garboczi EJ, Lagergren ES (1998) Multi-scale microstructural modelling of concrete diffusivity: identification of significant variables. Cem Concr Aggreg 20:129–139

Xiong QX et al (2023) A new analytical method to predict permeability properties of cementitious mortars: the impacts of pore structure evolutions and relative humidity variations. Cem Concr Compos

Zheng J, Zhou X (2008) Analytical solution for the chloride diffusivity of hardened cement paste. J Mater Civ Eng 20(5):384–391

Yu H, Da B, Ma H, Zhu H, Yu Q, Ye H, Jing X (2017) Durability of concrete structures in tropical atoll environment. Ocean Eng 135:1–10

Tang L, Nilsson LO (1993) Chloride binding capacity and binding isotherms of OPC pastes and mortars. Cem Concr Res 23(2):247–253

Li LJ, Liu QF, Tang L, Hu Z, Wen Y, Zhang P (2021) Chloride penetration in freeze–thaw induced cracking concrete: a numerical study. Constr Build Mater 302:124291

Liu QF (2018) Multi-phase modelling of concrete at meso-micro scale based on multi-species transport. J Chin Ceram Soc 46(08):1074–1080

Chen WK, Liu QF (2021) Moisture and multi-ions transport in concrete under drying-wetting cycles: a numerical study. J Hydraul Eng 52(5):622–632

Liu QF, Shen XH, Šavija B, Meng Z, Tsang DCW, Sepasgozar S, Schlangen E (2023) Numerical study of interactive ingress of calcium leaching, chloride transport and multi-ions coupling in concrete. Cem Concr Res

Liu QF, Meng Z, Hou D, Zhou Y, Cai Y, Zhang M, Tam VWY (2022) Numerical modelling on electrochemical deposition technique for healing alkali silica reaction induced damaged concrete. Eng Fract Mech. https://doi.org/10.1016/j.engfracmech

Tong LY et al (2023) Modelling of chloride transport in concrete by considering the heterogeneous characteristics from micro- to macro-scale. Constr Build Mater

Elakneswaran Y, Iwasa A, Nawa T, Sato T, Kurumisawa K (2010) Ion-cement hydrate interactions govern multi-ionic transport model for cementitious materials. Cem Concr Res 40(12):1756–1765

Liu Y, Shi X (2012) Ionic transport in cementitious materials under an externally applied electric field: Finite element modelling. Constr Build Mater 27:450–460

Hu Z, Liu QF (2023) Numerical study of multi-species transport in cracked concrete under external load. Mater Rep 37(9):21120077

Johannesson B (2010) Comparison between the Gauss’ law method and the zero current method to calculate multi-species ionic diffusion in saturated uncharged porous materials. Comput Geotech 37:667–677

Meng Z, Liu QF, Xia J, Cai Y, Zhu X, Zhou Y, Pel L (2022) Mechanical–transport–chemical modeling of electrochemical repair methods for corrosion-induced cracking in marine concrete. Comput Aided Civ Inf 37:1854–1874

Diamond S, Huang JD (2001) The ITZ in concrete—a different view based on image analysis and SEM observations. Cem Concr Compos 23(2–3):179–188

Liu QF, Feng GL, Xia J, Yang J, Li LY (2018) Ionic transport features in concrete composites containing various shaped aggregates: a numerical study. Compos Struct 183:371–380

Yu Y, Gao W, Feng Y, Castel A, Chen X, Liu A (2021) On the competitive antagonism effect in combined chloride-sulfate attack: a numerical exploration. Cem Concr Res 144:106406

Shane JD, Mason TO, Jennings HM, Garboczi EJ, Bentz DP (2000) Effect of the interfacial transition zone on the conductivity of portland cement mortars. J Am Ceram Soc 83(5):1137–1144

Wu L, Ju X, Liu M, Guan L, Ma Y, Li M (2020) Influences of multiple factors on the chloride diffusivity of the interfacial transition zone in concrete composites. Compos B Eng 199:108236

Abyaneh SD, Wong HS, Buenfeld NR (2013) Modelling the diffusivity of mortar and concrete using a three-dimensional mesostructure with several aggregate shapes. Comput Mater Sci 78:63–73

Gao Y, De Schutter G, Ye G, Tan Z, Wu K (2014) The ITZ microstructure, thickness and porosity in blended cementitious composite: effects of curing age, water to binder ratio and aggregate content. Compos B Eng 60:1–13

Niknezhad D, Raghavan B, Bernard F, Kamali-Bernard S (2015) Towards a realistic morphological model for the meso-scale mechanical and transport behavior of cementitious composites. Compos B Eng 81:72–83

ASTM C1202–19 (2019) Standard test method for electrical indication of Concrete’s Ability to Resist Chloride Ion Penetration, Annual Book of ASTM Standards

NT Build 492 (1999) Concrete, mortar and cement-based repair materials: chloride migration coefficient from non-steady-state migration experiments, Nordtest Method.

ASTM C1556–11a (2011) Standard test method for determining the apparent chloride diffusion coefficient of cementitious mixtures by bulk diffusion, Annual Book of ASTM Standards

Navarrete I, Lopez M (2016) Estimating the segregation of concrete based on mixture design and vibratory energy. Constr Build Mater 122:384–390

Safawi MI, Iwaki I, Miura T (2004) The segregation tendency in the vibration of high fluidity concrete. Cem Concr Res 34(2):219–226

Shen L, Jovein HB, Wang Q (2016) Correlating aggregate properties and concrete rheology to dynamic segregation of self-consolidating concrete. J Mater Civ Eng 28(1):04015067

Angst UM, Geiker MR, Alonso MC, Polder R, Isgor OB, Elsener B, Wong H, Michel A, Hornbostel K, Gehlen C, François R, Sanchez M, Criado M, Sørensen H, Hansson C, Pillai R, Mundra S, Gulikers J, Raupach M, Pacheco J, Sagüés A (2019) The effect of the steel–concrete interface on chloride-induced corrosion initiation in concrete: a critical review by RILEM TC 262-SCI. Mater Struct 52:88

Rossi E, Polder R, Copuroglu O, Nijland T, Šavija B (2020) The influence of defects at the steel/concrete interface for chloride-induced pitting corrosion of naturally-deteriorated 20-years-old specimens studied through X-ray computed tomography. Constr Build Mater 235:117474

Rossi E, Zhang H, Garcia SJ, Bijleveld J, Nijland TG, Copuroglu O, Polder RB, Šavija B (2021) Analysis of naturally-generated corrosion products due to chlorides in 20-year old reinforced concrete: an elastic modulus-mineralogy characterization. Corros Sci 184:109356

Yu L, François R, Gagné R (2016) Influence of steel-concrete interface defects induced by top-casting on development of chloride-induced corrosion in RC beams under sustained loading. Mater Struct 49:5169–5181

Acknowledgements

This work was funded by the National Natural Science Foundation of China (51978396, 52222805), the Natural Science Foundation of Shanghai, China (22ZR1431400), and the Oceanic Interdisciplinary Program of Shanghai Jiao Tong University, China (SL2021MS016).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

The acceleration of CA movement (a) is expressed as:

Assumptions:

Equation (20) can be further expressed as:

The expression of v can be obtained by solving Eq. (23):

Through integral calculation, the CA settlement height is expressed as:

Bring Eqs. (21) and (22) into Eq. (25), that is:

Appendix 2

See Fig.

13.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cai, Y., Liu, Qf., Meng, Z. et al. Influence of coarse aggregate settlement induced by vibration on long-term chloride transport in concrete: a numerical study. Mater Struct 55, 235 (2022). https://doi.org/10.1617/s11527-022-02038-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-022-02038-z