Abstract

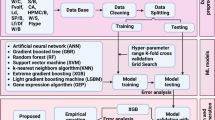

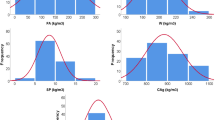

Glass fiber reinforced polymer (GFRP) rebars reinforced in concrete are susceptible to degradation in harsh alkaline environments such as moist reinforced concrete and seawater and sea sand concrete. The residual tensile strength of GFRP rebar is essential in designing guidelines for GFRP reinforced concrete in different codes. The residual tensile strength is reflected as an environment reduction factor (CE) to incorporate long-term environmental exposure effects. For this purpose, an extensive database comprising 715 tested specimens were collected from literature to develop GEP tree-based model. Aging tests of GFRP rebars were carried out in the laboratory to test the trained model. Initially, nine gene expression programming (GEP) tree-based models were initially developed using RMSE, MAE, and RSE as fitness functions while varying the numbers of genes. The models were developed employing a random selection of 70% of the conditioned specimens for the training purpose in accordance with the literature. The trained models were validated using the remaining 30% data. A model was chosen to create a prediction formula evaluated from the GEP-expression trees (ETs) and derived MATLAB model based on a broader range of statistical errors and correlations. The chosen model was tested using 36 experimental accelerated aging results, which yielded a comparable statistical evaluation to training and validation data. Two types of GFRP rebars, Type-I (volume fraction of 0.50) and Type-II (volume fraction of 0.60) of three different rebar sizes, i.e., 9.5 mm, 12.7 mm, and 15.9 mm were investigated for determining tensile strength retention (TSR) and CE. The results concluded that smaller Type-I rebars are more susceptible to degradation as compared to Type-II rebars of larger size. A value of 0.76 is recommended for a uniform CE based on the upper bound of 95% confidence interval for design life of 100 years.

Similar content being viewed by others

References

Angst UM (2018) Challenges and opportunities in corrosion of steel in concrete. Mater Struct 51(1):4

Miller SA, Monteiro PJM, Ostertag CP, Horvath A (2016) Concrete mixture proportioning for desired strength and reduced global warming potential. Constr Build Mater 128:410–421. https://doi.org/10.1016/j.conbuildmat.2016.10.081

Cooke SJ, Bergman JN, Nyboer EA, Reid AJ, Gallagher AJ, Hammerschlag N, Van de Riet K, Vermaire JC (2020) Overcoming the concrete conquest of aquatic ecosystems. Biol Conserv 247:108589. https://doi.org/10.1016/j.biocon.2020.108589

Uomoto T, Mutsuyoshi H, Katsuki F, Misra S (2002) Use of fiber reinforced polymer composites as reinforcing material for concrete. J Mater Civ Eng 14(3):191–209

440 ACIC Guide for the Design and Construction of Concrete Reinforced with FRP Bars: ACI 440.1 R-03. In: 2003. American Concrete Institute, Indianapolis

Hosseini S-A, Nematzadeh M, Chastre C (2021) Prediction of shear behavior of steel fiber-reinforced rubberized concrete beams reinforced with glass fiber-reinforced polymer (GFRP) bars. Compos Struct 256:113010. https://doi.org/10.1016/j.compstruct.2020.113010

Nanni A, De Luca A, Zadeh HJ (2014) Reinforced concrete with FRP bars: mechanics and design. CRC Press, Boca Raton

Yang S, Yang C, Huang M, Liu Y, Jiang J, Fan G (2018) Study on bond performance between FRP bars and seawater coral aggregate concrete. Constr Build Mater 173:272–288

Jun Y, Kim JH, Han SH, Kim T (2021) Influence of seawater on alkali-activated slag concrete. Mater Struct 54(3):1–16

Wang Z, Zhao X-L, Xian G, Wu G, Raman RS, Al-Saadi S, Haque A (2017) Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr Build Mater 139:467–489

Chen Y, Davalos JF, Ray I, Kim H-Y (2007) Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures. Compos Struct 78(1):101–111

Robert M, Cousin P, Benmokrane B (2009) Durability of GFRP reinforcing bars embedded in moist concrete. J Compos Constr 13(2):66–73

Fergani H, Di Benedetti M, Oller CM, Lynsdale C, Guadagnini M (2018) Durability and degradation mechanisms of GFRP reinforcement subjected to severe environments and sustained stress. Constr Build Mater 170:637–648

Mufti A, Onofrei M, Benmokrane B, Banthia N, Boulfiza M, Newhook J, Bakht B, Tadros G, Brett P (2005) Durability of GFRP reinforced concrete in field structures. In: Proceedings of the 7th international symposium on fiber-reinforced polymer reinforcement for reinforced concrete structures (FRPRCS-7), Kansas City, pp 6–9

Wang Z, Zhao X-L, Xian G, Wu G, Raman RS, Al-Saadi S (2017) Durability study on interlaminar shear behaviour of basalt-, glass- and carbon-fibre reinforced polymer (B/G/CFRP) bars in seawater sea sand concrete environment. Constr Build Mater 156:985–1004

Kim H-Y, Park Y-H, You Y-J, Moon C-K (2008) Short-term durability test for GFRP rods under various environmental conditions. Compos Struct 83(1):37–47

Benmokrane B, Manalo A, Bouhet J-C, Mohamed K, Robert M (2017) Effects of diameter on the durability of glass-fiber-reinforced-polymer (GFRP) bars conditioned in alkaline solution. J Compos Constr 21(5):1–12

Al-Salloum YA, El-Gamal S, Almusallam TH, Alsayed SH, Aqel M (2013) Effect of harsh environmental conditions on the tensile properties of GFRP bars. Compos B Eng 45(1):835–844

Gaona FA (2004) Characterization of design parameters for fiber reinforced polymer composite reinforced concrete systems. Texas A&M University, College Station

Sawpan MA, Mamun AA, Holdsworth PG (2014) Long term durability of pultruded polymer composite rebar in concrete environment. Mater Des 57:616–624

Micelli F, Nanni A (2004) Durability of FRP rods for concrete structures. Constr Build Mater 18(7):491–503

Manalo A, Maranan G, Benmokrane B, Cousin P, Alajarmeh O, Ferdous W, Liang R, Hota G (2020) Comparative durability of GFRP composite reinforcing bars in concrete and in simulated concrete environments. Cem Concr Compos 109:103564

Debaiky AS, Nkurunziza G, Benmokrane B, Cousin P (2006) Residual tensile properties of GFRP reinforcing bars after loading in severe environments. J Compos Constr 10(5):370–380

Robert M, Benmokrane B (2013) Combined effects of saline solution and moist concrete on long-term durability of GFRP reinforcing bars. Constr Build Mater 38:274–284

Huang J, Aboutaha R (2010) Environmental reduction factors for GFRP bars used as concrete reinforcement: new scientific approach. J Compos Constr 14(5):479–486

Tu J, Xie H, Gao K, Li Z, Zhang J (2019) Durability prediction of GFRP rebar based on elastic modulus degradation. Front Mater 6:258

Bazli M, Ashrafi H, Oskouei AV (2017) Experiments and probabilistic models of bond strength between GFRP bar and different types of concrete under aggressive environments. Constr Build Mater 148:429–443

D’Antino T, Pisani M, Poggi C (2018) Effect of the environment on the performance of GFRP reinforcing bars. Compos B Eng 141:123–136

Benmokrane B, Elgabbas F, Ahmed EA, Cousin P (2015) Characterization and comparative durability study of glass/vinylester, basalt/vinylester, and basalt/epoxy FRP bars. J Compos Constr 19(6):04015008

Benmokrane B, Ali AH, Mohamed HM, ElSafty A, Manalo A (2017) Laboratory assessment and durability performance of vinyl-ester, polyester, and epoxy glass-FRP bars for concrete structures. Compos B Eng 114:163–174

Kamal A, Boulfiza M (2011) Durability of GFRP rebars in simulated concrete solutions under accelerated aging conditions. J Compos Constr 15(4):473–481

Chen Y, Davalos JF, Ray I (2006) Durability prediction for GFRP reinforcing bars using short-term data of accelerated aging tests. J Compos Constr 10(4):279–286

Council INR (2006) Guide for the design and construction of concrete structures reinforced with fiber-reinforced polymer bars. CNR-DT 203/2006

ACI Guide for the design and construction of structural concrete reinforced with FRP bars (ACI 440.1 R-15). In: 2015. American Concrete Institute, Indianapolis

Dejke V, Tepfers R (2001) Durability and service life prediction of GFRP for concrete reinforcement. In: Proceedings of 5th international conference on fiber-reinforced plastics for reinforced concrete structures (FRPRCS-5). Citeseer, pp 505–516

Benmokrane B, Brown VL, Ali AH, Mohamed K, Shield C (2020) Reconsideration of the environmental reduction factor CE for GFRP reinforcing bars in concrete structures. J Compos Constr 24(4):06020001

ASTM Standard specification for solid round glass fiber reinforced polymer bars for concrete reinforcement. In: 2017. ASTM, West Conshohocken

Iqbal M, Zhang D, Jalal FE, Faisal Javed M (2021) Computational AI prediction models for residual tensile strength of GFRP bars aged in the alkaline concrete environment. Ocean Eng 232:109134. https://doi.org/10.1016/j.oceaneng.2021.109134

Bradshaw R, Brinson L (1997) Physical aging in polymers and polymer composites: an analysis and method for time-aging time superposition. Polym Eng Sci 37(1):31–44

Bank LC, Gentry TR, Thompson BP, Russell JS (2003) A model specification for FRP composites for civil engineering structures. Constr Build Mater 17(6–7):405–437

Micelli F, Aiello MA (2019) Residual tensile strength of dry and impregnated reinforcement fibres after exposure to alkaline environments. Compos B Eng 159:490–501

Micelli F, Corradi M, Aiello MA, Borri A (2017) Properties of aged GFRP reinforcement grids related to fatigue life and alkaline environment. Appl Sci 7(9):897

Phani KK, Bose NR (1987) Temperature dependence of hydrothermal ageing of CSM-laminate during water immersion. Compos Sci Technol 29(2):79–87

Davalos JF, Chen Y, Ray I (2012) Long-term durability prediction models for GFRP bars in concrete environment. J Compos Mater 46(16):1899–1914

Wang Z, Zhao X-L, Xian G, Wu G, Raman RS, Al-Saadi S (2018) Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars. Corros Sci 138:200–218

Huang Y, He X, Wang Q, Sun Y (2018) Mechanical properties of sea sand recycled aggregate concrete under axial compression. Constr Build Mater 175:55–63

Ali A, Benmokrane B, Mohamed H, Manalo A, El-Safty A (2018) Statistical analysis and theoretical predictions of the tensile strength retention of GFRP bars based on resin degradation. J Compos Mater 52(21):1–20

Ferreira C (2001) Gene expression programming: a new adaptive algorithm for solving problems. arXiv preprint arXiv:cs/0102027

Al-Zahrani MM, Al-Dulaijan SU, Sharif A, Maslehuddin M (2002) Durability performance of glass fiber reinforced plastic reinforcement in harsh environments. In: 6th Saudi engineering conference

Abbasi A, Hogg PJ (2005) Temperature and environmental effects on glass fibre rebar: modulus, strength and interfacial bond strength with concrete. Compos B Eng 36(5):394–404

Won J-P, Lee S-J, Kim Y-J, Jang C-I, Lee S-W (2008) The effect of exposure to alkaline solution and water on the strength–porosity relationship of GFRP rebar. Compos B Eng 39(5):764–772

Faradonbeh RS, Hasanipanah M, Amnieh HB, Armaghani DJ, Monjezi M (2018) Development of GP and GEP models to estimate an environmental issue induced by blasting operation. Environ Monit Assess 190(6):351

Gandomi AH, Alavi AH (2012) A new multi-gene genetic programming approach to nonlinear system modelling. Part I: materials and structural engineering problems. Neural Comput Appl 21(1):171–187

Gandomi AH, Roke DA (2015) Assessment of artificial neural network and genetic programming as predictive tools. Adv Eng Softw 88:63–72

Jalal FE, Xu Y, Iqbal M, Javed MF, Jamhiri B (2021) Predictive modeling of swell-strength of expansive soils using artificial intelligence approaches: ANN, ANFIS and GEP. J Environ Manag 289:112420

Babanajad SK, Gandomi AH, Alavi AH (2017) New prediction models for concrete ultimate strength under true-triaxial stress states: an evolutionary approach. Adv Eng Softw 110:55–68

Taylor R (1990) Interpretation of the correlation coefficient: a basic review. J Diagn Med Sonogr 6(1):35–39

Onyelowe KC, Iqbal M, Jalal FE, Onyia ME, Onuoha IC (2021) Application of 3-algorithm ANN programming to predict the strength performance of hydrated-lime activated rice husk ash treated soil. Multiscale Multidiscip Model Exp Des. https://doi.org/10.1007/s41939-021-00093-7

Iqbal M, Onyelowe KC, Jalal FE (2021) Smart computing models of California bearing ratio, unconfined compressive strength, and resistance value of activated ash-modified soft clay soil with adaptive neuro-fuzzy inference system and ensemble random forest regression techniques. Multiscale Multidiscip Model Exp Des. https://doi.org/10.1007/s41939-021-00092-8

Jalal FE, Xu Y, Li X, Jamhiri B, Iqbal M (2021) Fractal approach in expansive clay-based materials with special focus on compacted GMZ bentonite in nuclear waste disposal: a systematic review. Environ Sci Pollut Res 28:43287–43314. https://doi.org/10.1007/s11356-021-14707-7

Jalal FE, Xu Y, Iqbal M, Jamhiri B, Javed MF (2021) Predicting the compaction characteristics of expansive soils using two genetic programming-based algorithms. Transp Geotech 30:100608. https://doi.org/10.1016/j.trgeo.2021.100608

Azim I, Yang J, Javed MF, Iqbal MF, Mahmood Z, Wang F, Liu Q-f (2020) Prediction model for compressive arch action capacity of RC frame structures under column removal scenario using gene expression programming. Structures 25:212–228. https://doi.org/10.1016/j.istruc.2020.02.028

Khandelwal M, Faradonbeh RS, Monjezi M, Armaghani DJ, Abd Majid MZB, Yagiz S (2017) Function development for appraising brittleness of intact rocks using genetic programming and non-linear multiple regression models. Eng Comput 33(1):13–21

Ferreira C (2006) Gene expression programming: mathematical modeling by an artificial intelligence, vol 21. Springer, Berlin

Brownlee J (2011) Clever algorithms: nature-inspired programming recipes. Jason Brownlee, Austin

Giakoumelis G, Lam D (2004) Axial capacity of circular concrete-filled tube columns. J Constr Steel Res 60(7):1049–1068

Sakino K, Nakahara H, Morino S, Nishiyama I (2004) Behavior of centrally loaded concrete-filled steel-tube short columns. J Struct Eng 130(2):180–188

Acknowledgements

The authors gratefully acknowledge the resources of Shanghai Jiao Tong University that help in the data collection and literature review. Thanks to the financial supports from the National Natural Science Foundation of China (12072192, U1831105), the Natural Science Foundation of Shanghai (20ZR1429500), and the State Key Laboratory of Ocean Engineering (GKZD010077).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Iqbal, M., Zhao, Q., Zhang, D. et al. Evaluation of tensile strength degradation of GFRP rebars in harsh alkaline conditions using non-linear genetic-based models. Mater Struct 54, 190 (2021). https://doi.org/10.1617/s11527-021-01783-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01783-x