Abstract

Spacers are important devices used in all concrete structures to support reinforcing steel and achieve the required cover. However, spacers induce a weak, porous and microcracked interface that facilitates ingress of aggressive agents. This paper aims to address the problem by developing a method to produce cementitious spacers with a range of small-scale surface textures including grooves, squares, rectangles, hemispheres and pyramids. The textured spacers were cast in Portland cement mortar or concrete, cured up to 28 days, and tested for tensile bond strength, accessible porosity and mass transport properties. The properties were correlated to surface characteristics to establish the effects of texture on spacer-concrete interface. Results show that textured spacers promote mechanical interlocking with concrete, thereby increasing bond strength, resistance against microcracking and pressure-induced flow. The use of certain textures can compensate for the negative effects of spacers, achieving similar bond strength and permeability to monolithic concrete without the interface.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

All concrete structures contain spacers to hold and support steel reinforcement prior to concreting. Spacers are used to provide the required concrete cover to protect steel reinforcement to achieve adequate durability against corrosion and fire resistance. Structural design codes of practice require a spacer to be located at every meter (or less) to ensure that the steel reinforcements remain in place during concreting, and the spacers are then left permanently in the structure [1,2,3,4,5]. Therefore, a typical concrete structure will contain many spacers.

Spacers are made from cementitious materials, plastics or steel wire. Regardless of the material, shape or size, they inevitably form an interface between the reinforcing steel and concrete surface through the cover. Spacers can potentially compromise the integrity of the concrete cover and its effectiveness to protect embedded reinforcement. Indeed, some field studies have reported correlations between the location of spacers and reinforcement corrosion [6,7,8,9,10], suggesting that spacers contribute to premature deterioration. Yet very little fundamental research has been carried out on this issue.

Available studies have shown that spacers disrupt the microstructure of the concrete cover and produce an interface that is particularly weak and porous. Differential movements and volumetric changes caused by moisture and/or thermal gradients induce microcracking along the spacer-concrete interface. This facilitates mass transport, thereby accelerating local carbonation and chloride penetration [11,12,13,14]. However, a potentially important factor that has not been studied is the strength of the spacer-concrete bond. This ‘bond strength’ [15] should influence the ease with which microcracks initiate and propagate through the spacer-concrete interface. Therefore, improving the bond between spacer and concrete should lead to greater resistance to microcracking and mass transport.

Generally, the bond between two materials depends on the interfacial adhesion, friction, aggregate interlock, and other time-dependent factors [16,17,18,19,20]. The effect of surface texture has been widely investigated in the field of tribology [21,22,23]. In the field of structural repair, studies have been carried out to understand factors that influence the bond between the concrete substrate and repair material [24,25,26,27,28,29,30]. Among these, surface roughness is thought to be a major factor contributing to bond strength via mechanical interlocking. As such, several surface treatment methods have been proposed for concrete repair, including sandblasting, grinding, jackhammering, wire brushing, milling, and hydro-jetting. However, some of these methods are particularly aggressive and can cause damage to the near-surface layer [27].

Most commercially available spacers have surfaces that are flat and smooth. Spacers with simple grooved surfaces are also available, but uncommon. Therefore, a potentially viable method to enhance the spacer-concrete interface is to optimise surface texture so that spacers bond better with concrete. However, no studies on this have been published to date and the potential benefits are unknown. Therefore, the aim of this research was to develop a method to produce a range of textured spacers and carry out a systematic experimental study to understand their effects on interfacial bond strength and mass transport properties. Cementitious spacers with eight different surface textures were prepared with two different mixes and cast against concrete to produce spacer-concrete composite samples. These were then tested for bond strength, accessible porosity and mass transport properties including diffusivity, permeability, sorptivity, and epoxy impregnation. Finally, the measured properties were correlated to characteristics of the surface texture.

2 Experimental

2.1 Materials and mix proportions

Samples were produced using mortar or concrete at a water/cement ratio of 0.4. The mix proportions (Table 1) were calculated using the absolute volume method. These were chosen after several trials to ensure that the mixes achieve satisfactory workability and that the cast spacers meet the 28-day compressive strength requirement of 50 MPa in accordance with BS 7973-1 [1]. Portland cement CEM 1 52.5 N complying with BS EN 197-1:2011 [31] with specific gravity of 3.15, and fineness of 291 m2/kg was used. The oxide composition was 63.4% CaO, 20.8% SiO2, 5.4% Al2O3, 2.4% Fe2O3, 1.5% MgO, 0.3% Na2O, 0.7% K2O, 2.9% SO3 and < 0.01% Cl−, with 2.1% loss on ignition. Its Bogue composition was 53.1% C3S, 19.1% C2S, 10.8% C3A and 7.2% C4AF.

Thames Valley gravel (< 10 mm) and sand (< 5 mm) complying with BS EN 12,620:2002 + A1:2008 [32] medium grading were used as coarse and fine aggregates respectively. The specific gravity, moisture content (BS 812–109:1990 [33]) and 24 h absorption from 105 °C oven dry to saturated surface dry condition (BS 812–2: 1995 [34]) of the gravel were 2.75, 0.71% and 0.62% respectively. The corresponding values for the sand were 2.51, 2.45% and 0.60% respectively. The total aggregate volume fraction in the mortar and concrete were 50% and 70% respectively. A superplasticiser (Master Glenium SKY 920) was used at 0.75% wt. binder to improve workability. Finally, tap water was used as batching water.

2.2 Spacers with surface texture

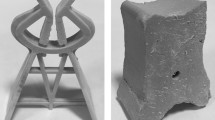

Several approaches to produce cementitious spacers with surface texture were trialled. The most successful was the method using silicone rubber moulds made from low shrinkage platinum cured silicone. These come in a variety of small-scale texture shapes, orientations, profile depths, surface roughness and densities. Eight textures representing a range of surface characteristics were selected for detailed testing. These are summarised in Table 2. Three have regular convex protruding features (i.e. squares, rectangle-small and rectangle-large). The others are concave with indented features (i.e. pyramids, hemisphere, grooves-vertical and grooves-horizontal). A flat interface was used to represent conventional spacers as control reference.

The maximum profile h, defined as the distance between highest and lowest points of the profile, ranged from 0 (flat) to 9 mm (pyramid). Surface roughness ranged from 1 (flat) to 2.0 (rectangle), while texture density ranged from 0% (flat) to 55% (rectangle). Surface roughness (r) is defined according to BS 1134:2010 [35] as r = AT/A0, where AT (mm2) is the total surface area and A0 (= L × W mm2) is the projected surface area (see Table 2). Texture density (Td) is calculated as Td = At/A0 × 100%, where At (= l × w × N mm2) is the area covered by the convex or concave features, l and w are the length and width of each feature and N is the total number of features. Figure 1 shows the spacers cast with various surface textures.

2.3 Sample preparation

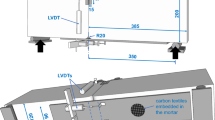

Figure 2 shows the preparation of cylindrical samples (100∅ × 50 mm) that consist of half spacer-concrete composites, cast in steel moulds and cured in two stages. The spacers were first produced by casting against textured silicone rubber sheets attached to wooden blocks in the 100∅ mm steel mould (Fig. 2a). Each wooden block is custom made such that its dimension fits the steel ring and its volume (including the silicon rubber) occupies exactly half of the sample volume. This is an important aspect of the mould assembly because it ensures that the resulting spacer-concrete interface passes through the cylindrical axis and is aligned to the load direction during strength testing. The blocks were tightly clamped from the top of the mould assembly to prevent movements during concrete placement and compaction.

Batching was done by weight. Cement and aggregates were firstly dry mixed for 30 s in a 30-L capacity pan mixer. Batch water premixed with superplasticiser was then added, and wet mixing was carried out for a further 3 min. A vibrating table with adjustable intensity was used for compaction. Samples were compacted in two equal-depth layers until no significant entrapped air escaped. During compaction, the fresh mix fills the crevices of the silicone mould to produce the desired texture as shown in Fig. 1.

The cast spacers were covered with a polyethylene sheet and wet hessian at room temperature for the first 24 h, then demoulded and transferred to a fog room at 100% RH, 21 °C where curing continued for 28 days. Subsequently, the spacers were returned to the steel mould assembly (Fig. 2b) and fresh concrete was cast against the spacers (Fig. 2c) following the procedures described above. The spacer-concrete composite samples (Fig. 2d) were then cured in the fog room (100% RH, 21 °C) for either 1, 7 or 28 days. In total, 224 composite cylindrical samples were tested. In addition, 100 mm monolithic cube samples (no interface) were prepared for density and compressive strength measurements in three replicates.

2.4 Splitting tensile strength

Bond strength of the spacer-concrete interface was determined by splitting tensile testing in accordance with BS EN 12,390-6:2009 [36]. This is based on applying a compressive load perpendicularly to the cylindrical axis to induce a uniform tensile stress over the spacer-concrete interface. The sample was positioned using a centering device (Fig. 3) to ensure alignment between the spacer-concrete interface and applied load. Plywood strips were inserted between the sample and loading platen to reduce local compressive stress concentrations and to ensure that the sample remains aligned during testing [37]. Loading was then applied at a constant rate of 0.03 MPa/s until failure. The splitting tensile strength ft was calculated as 2F/πLd, where F (N) is the maximum applied load, L (mm) and d (mm) are the length and diameter of the sample respectively. Two replicates were tested and averaged. In addition, tests were carried out on monolithic samples (no interface) of the mortar and concrete for comparison.

2.5 Oxygen diffusion and oxygen permeation

Samples for mass transport testing were prepared with concrete spacers and conditioned at 50 °C, 10% RH to constant weight to ensure that the measurements are not influenced by moisture content. The samples were monitored using an electronic balance accurate to 0.01 g for about 3.5 months when the mass loss was less than 0.01% per day. The conditioned samples were cooled to room temperature in a vacuum desiccator for 24 h, and then tested in three replicates following the sequence of oxygen diffusivity, oxygen permeability, water absorption and accessible porosity.

Oxygen diffusivity was measured by placing the sample in a transport cell sealed with silicone rubber ring. Load was applied to the rubber ring and the sample confined at 0.57 MPa to ensure that the gasses flowed through the sample only without causing further cracking or closure of existing cracks [38]. Opposite faces were subjected to oxygen and nitrogen gasses at equal pressure, which counter diffused through the sample. The oxygen concentration in the outflow stream was measured at steady-state condition with a zirconia analyser (0.25 ppm to 25%) and the average diffusion coefficient D (m2/s) was calculated according to Fick’s first law.

Oxygen permeability was determined in a similar transport cell by subjecting the sample to three inflow pressures of approximately 0.5, 1.5 and 2.5 bar above atmospheric pressure, and measuring the steady-state outflow rates. Each applied inflow pressure takes approximately 1 h to reach steady-state. The outflow rate was determined using a series of bubble flowmeters, by measuring the time required for the bubble to move through a fixed volume using a digital stopwatch. Permeability at each pressure was then calculated by following Darcy's law for compressible fluids and the intrinsic permeability kint (m2) was determined by applying Klinkenberg's correction for gas slippage.

2.6 Water absorption and accessible porosity

Water sorptivity was measured by immersing the sample in a tray containing water to a depth of about 3 mm above the bottom surface and then measuring the mass gain with time using an electronic balance accurate to 0.01 g until saturation was achieved. The tray was kept covered with a loosely fitting lid all the times to prevent the sample from drying and to avoid condensation. The sorptivity coefficient S (g/m2min0.5) was determined from the slope of the regression line (R2 > 0.99) of cumulative absorption per unit flow area against square root of time t according to the classical unsaturated flow theory.

Immediately after water absorption, the samples were fully immersed in water and vacuum saturated for approximately 4 h. The samples were left immersed in water for 24 h, then surface dried and weighed. The sample accessible porosity ϕ (%) was determined from the mass difference between the vacuum saturated-surface dry condition and preconditioned state (50 °C oven) and divided by the sample volume. Full details of the transport tests are given in [39].

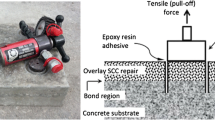

2.7 Fluorescent epoxy impregnation

Samples were impregnated with a fluorescein-dyed epoxy as another method to characterise microstructure and transport resistance. The resin was prepared by mixing low-viscosity epoxy with fluorescein dye at 0.05 wt% using a magnetic stirrer for 24 h and then heated to 40 °C. The fluorescein-dyed resin was then mixed with hardener at 25:3 mass ratio and 5% wt. toluene to reduce viscosity further [40]. The sample was sealed in a pressure cell similar to the one used for permeability testing. Its flat surface was covered with the epoxy mix and 10-bar compressed air was applied overnight to force the epoxy into the sample. After 2 days of curing at room temperature, the impregnated samples were sectioned with a slow speed diamond abrasive cutter to expose the spacer-concrete interface. The cross-section was ground with silicon carbide at 120-grit and then imaged with a digital camera under UV illumination to induce fluorescence. The depth and amount of epoxy impregnation were then measured using image analysis. Further details are provided in [41, 42].

3 Results

3.1 Properties of mortar and concrete

The average density, compressive strength and splitting tensile strength of the hardened mortar and concrete are listed in Table 3. The measured densities were slightly higher than the theoretical values obtained from mix design, which were 2356 kg/m3 and 2409 kg/m3 for the mortar and concrete respectively. This suggests that the mixes were well compacted. It can be seen that both mixes achieved similar 28-day compressive strength and that they exceeded the 50 MPa strength requirement for spacers specified in BS 7973–1 [1]. The results show that splitting tensile strength increased with curing age, however most of the strength gain occurred at early ages. The difference in tensile strength between the mortar and concrete was initially significant, but this decreased with curing. At 28 days, both mixes achieved the same tensile splitting strength of 5.3 MPa, which was approximately 8% of the compressive strength and in line with expectation.

3.2 Spacer-concrete interface bond strength

Figure 4 shows the development of bond strength with curing age for composite samples with mortar or concrete spacers. The results show that bond strength increased with curing age as expected, with the greatest increase occurring between 1 and 7 days for all spacer types. This is consistent with the strength development seen on the monolithic samples in Table 3, but the overall bond strength of the composite samples is significantly lower. Samples with flat interface consistently achieved the lowest bond strength. The data for monolithic mortar have been included as a reference in Fig. 4. It is notable that bond strength decreased by more than a factor of two when compared to the tensile splitting strength of the monolithic samples.

Development of spacer-concrete bond strength with age for various interface textures. Note that data for monolithic mortar (Table 3) have been included as a reference

The use of textured spacers increased bond strength in all cases. The magnitude of increase depends on the texture type and this ranged from a modest 10% to a substantial 140% improvement. Furthermore, samples with textured spacers showed greater increase in bond strength with curing age compared to the control. The pyramid (PY) texture consistently achieved the highest bond strength, which improved by more than a factor of 2 relative to the control (flat interface). It is also worth noting that by 7d, the PY texture achieved > 93% of the tensile splitting strength of the monolithic samples. This shows that the use of a suitable texture can recover nearly all of the strength loss that occurred as a result of the spacer-concrete interface.

The worst performing texture was the horizontal groove (GH). This is probably because the grooves in this texture are aligned with the loading direction as shown in Fig. 3 and they are prone to entrap air during casting (see Sect. 3.4 and Sect. 4), which weakens the interface bond. It is worth noting here that some commercially available spacers have horizontal grooves on their surface. The vertical groove (GV) texture performed slightly better despite having the same profile depth, surface roughness and texture density as the GH texture. This again shows that the orientation of the texture with respect to loading and casting direction has an important effect.

Figure 5 presents the interface bond strength plotted against profile depth, surface roughness and texture density for all spacer types and curing ages. The data show strong positive correlations between bond strength and surface texture, in particular profile depth and surface roughness. The results also show that samples with mortar spacers achieved similar strength levels compared to those with concrete spacers of the same texture. This is likely because both mixes have similar strength properties (Table 3). The presence of coarse aggregate in concrete did not induce a significantly negative or positive effect on the formed texture and interfacial bond strength.

3.3 Failure mode at the spacer-concrete interface

Several types of failure modes were observed during tensile splitting e.g. debonding of the interface, fracturing of the spacer or the concrete, or a combination. These are illustrated schematically in Fig. 6 and representative images of the actual split spacer-concrete interface are shown in Fig. 7. It can be observed that samples with flat interface consistently failed by debonding, which showed a clean separation without significant damages to the spacer or the concrete (Fig. 7a). In contrast, samples with textured spacers always failed through a combination of interface debonding and fracturing. Convex spacers tended to show debonding and fracturing of the spacer, while concave spacers tended to experience debonding and fracturing of the concrete. It is also interesting to note that the amount of fracturing (relative to debonding) increased with increasing curing age and bond strength. For example, the proportion of fracturing for samples with SQ texture measured via image analysis increased from 16% at 1d to 31% at 7d, and 51% at 28d. This shows that textures that promote fracturing lead to a higher interface bond strength.

3.4 Entrapped air at the spacer-concrete interface

Some textures were prone to entrap air at the spacer-concrete interface. Examples of these air voids are highlighted in Fig. 7. They tended to occur beneath indents or protruding features, where air bubbles rising along the interface are most likely to become trapped during concrete placement and compaction. The size of these voids ranged from 0.3 to 5.5 mm, they varied depending on the texture size and have an elongated shape consistent with the formation mechanism described above. The fraction of air voids measured using image analysis ranged from 0.1% (flat spacer) to 2.48% as shown in Fig. 7. This was calculated by dividing the area of segmented air voids to the total cross-sectional area of the fractured interface. It can be seen that the flat spacer (CO) entrapped the least amount of air, followed by spacers with pyramid (PY) and square (SQ) textures. In contrast, the rectangle-small texture (RS) and groove-horizontal texture (GH) caused the highest amount of entrapped air. It should be noted that additional samples were prepared with longer compaction time to establish if this would remove the interfacial voids. However, no significant improvements were observed. This shows that the excess air was a result of the interface texture rather than lack of compaction.

3.5 Mass transport properties

The measured oxygen permeability, oxygen diffusivity, water sorptivity, epoxy impregnation depth and accessible porosity of the composite samples are presented in Table 4. To further illustrate the effect of surface texture, the data are normalised to the control (flat spacer) and plotted in Fig. 8a-c. The results show that textured spacers increased accessible porosity by about 0.3% to 0.7% (absolute). This is due to the additional air trapped at the interface as discussed in Sect. 3.4, rather than due to increase in capillary porosity since all samples were made with the same concrete. Nevertheless, the greater accessible porosity did not lead to much higher diffusivity or absorption.

In contrast, all samples containing textured spacers (except GV) showed substantial reduction in permeability and depth of epoxy impregnation relative to the control. The magnitude of reduction was up to 69% and 37% respectively. Samples with pyramid (PY) texture showed much lower transport properties relative to the control (by a factor of 3), and this is consistent with the low entrapped air content and high bond strength achieved by this surface texture. However, samples with vertical grooves (GV) texture consistently produced the highest transport properties, especially for permeability and epoxy penetration. This is most likely caused by the direction of the grooves being parallel to flow during transport testing and low bond strength for this particular texture.

3.6 Correlations between transport properties and bond strength

Figure 8d shows the correlations between transport properties and interface bond strength. The data are normalised by dividing the values for textured spacers to the corresponding values for the control (flat spacer) to facilitate comparison. The data show that overall diffusivity, sorptivity and accessible porosity were not substantially influenced by interface bond strength. However, an inverse correlation can be observed between bond strength and permeability or epoxy penetration depth. The only exception to this was for samples with vertical grooves (GV) texture that showed uncharacteristically high permeability and epoxy penetration depth, as discussed previously. Since pressure induced flow is highly sensitive to presence of microcracking, the data suggests that the improved bond between textured spacers and concrete leads to less microcracking at the interface than would have otherwise impacted the samples with flat spacers.

4 Discussion

When cast against textured spacers, fresh concrete flows into and fills the crevices of the surface texture. The hardened concrete then forms a mechanical interlock with the spacer that enhances bond. In addition, textured spacers have greater surface area to form adhesion to concrete. The effectiveness of the mechanical interlocking increases with curing as the spacer and concrete gain strength. Therefore, the failure mode changes from debonding to predominantly fracturing at later ages, accompanied by substantial gains in bond strength. Such mechanical interlocking does not occur with flat spacers. Instead, the bond is transferred mainly through friction or surface adhesion between spacer and concrete. This is relatively weak and therefore failure occurs through debonding resulting in lower strength.

The observed beneficial effect of surface texture on spacer-concrete bond strength is consistent with findings from other applications. In structural repair for example, studies have shown that surface treatments such as wire-brushing, grinding, milling and sandblasting to create surface roughness can improve the bond between the substrate layer and patch repair [25, 26, 28, 43, 44]. Garbacz et al. [44] reported that certain treatments in particular shot blasting and milling produced voids and microcracks at the interface layer. Other studies have suggested that mechanical interlocking is the dominant factor affecting bond between substrate and repair layer [24]. The observed correlations between bond strength and surface texture are also consistent with the understanding that parameters such as surface area, shape and orientation affect tribological performance [21,22,23].

It is interesting to note that the improved spacer-concrete bond does not necessarily translate to greater resistance to mass transport. This is because transport mechanisms such as diffusion and absorption are controlled by open pores (mainly capillary and gel) that are interconnected and accessible to transport. The amount and distribution of these pores do not change by simply altering the physical (surface) characteristics of the spacer alone. In fact, the presence of macroscopic air bubbles trapped at the interface may counteract the benefits of textured spacers and decrease bond strength. Air voids also induce microstructural heterogeneity at the interface and provide another path for transport [45]. Therefore, it is expected that the full advantages of textured spacers can only be achieved if the surface characteristics, concrete rheology and placement are optimised. This will require further research, for example by developing surface characteristics such as the pyramid texture (PY) that reduces air entrapment or reactive surfaces that will help densify the microstructure of the spacer-concrete interface.

Nevertheless, the results clearly highlight the benefits of textured spacers in reducing mass transport driven by pressure gradients. This is related to findings from previous experimental and numerical studies that have shown that pressure-induced flow is far more sensitive to microcracking compared to diffusion or absorption [41, 46,47,48,49]. This is because permeation scales to crack width, while diffusion and absorption are more dependent on total porosity, which is not significantly increased by the microcracks. For example, it is well known that the permeability of a crack of smooth parallel surfaces is proportional to the cube of the crack width according to the cubic law, while diffusivity is considered proportional to the crack width. Other related studies have shown that the spacer-concrete interface is weak, porous and prone to microcracking, allowing preferential flow to occur [11, 13, 14]. The use of textured spacers increases bond strength and therefore the resistance against de-bonding microcracks that would otherwise occur due to differential shrinkage or thermal gradients. This leads to substantial reductions in permeability.

5 Conclusions

This paper presented a method to produce reinforcement spacers with a range of surface texture characteristics. An experimental programme was then completed to establish the effects of surface texture on bond strength and mass transport properties of the spacer-concrete interface. 224 cylindrical (100∅ × 50 mm) spacer-concrete composite samples were tested. The main parameters were surface texture (eight varieties), mix composition (mortar or concrete), curing age (1, 3, and 28 days) and transport mechanism (diffusion, permeation, absorption and epoxy impregnation). The key findings are:

-

(a)

Samples that contained textured spacers achieved substantially higher bond strength and lower permeability compared to samples with non-textured (i.e. flat) spacers. The magnitude of improvement is dependent on the profile depth, roughness, density and orientation of the surface texture.

-

(b)

The pyramid (PY) texture consistently achieved the highest bond strength and lowest transport properties. Bond strength improved by more than a factor of 2 and permeability by a factor 3 relative to the control (flat interface). This texture was able to recover most of the strength loss that occurred as a result of the spacer-concrete interface and compensated for the negative effects on pressure-induced flow.

-

(c)

Textured spacers increase bond strength with age by promoting mechanical interlocking and physical adhesion to the surrounding concrete. Therefore, textured interfaces are more resistant to microcracking induced by shrinkage or thermal gradients. In contrast, flat interfaces have greater tendency to fail by debonding, and this led to a significantly lower bond strength and higher permeability.

-

(d)

Some textures are prone to trapping air at the spacer-concrete interface. The presence of these macroscopic air voids at the interface may reduce the benefits of textured spacers on bond strength. The air voids also induce additional microstructural heterogeneity and provide another path for transport.

-

(e)

The orientation of surface texture with respect to the direction of loading or mass transport has important effects. Grooves (horizontal or vertical) were the overall worst performing texture, producing uncharacteristically lower bond strength and higher transport properties compared to other textures.

-

(f)

Textured spacers are a promising method for improving the quality of the concrete cover. The full advantage of this approach can be achieved if the surface characteristics, concrete rheology and placement are optimised to densify the microstructure and reduce air entrapment at the spacer-concrete interface.

References

BS EN 7973–1: 2001 Spacers and chairs for steel reinforcement and their specification. Part 1: Product performance requirements (2001). BSI Standards Publication, London

BS EN 7973–2: 2001 Spacers and chairs for steel reinforcement and their specification. Part 2: Fixing and application of spacers and chairs and tying of reinforcement (2001). BSI Standards Publication, London

BS En 13670 2009 Execution of concrete structures (2009) BSI Standards Publications London

ACI SP-66 (04): ACI Detailing Manual (2004). American Concrete Institute

ACI 315–99 (1999): Details and detailing of concrete reinforcement (1999). American Concrete Institute

Kawahigashi T, Kuzume K, Miyagawa T (1999) Deterioration process and estimation of durability of reinforced concrete beams in long-term exposure to marine environment. Proc Jpn Soc Civ Eng 1999:71–84

Kenai S, Bahar R (2003) Evaluation and repair of Algiers new airport building. Cement Concr Compos 25(6):633–641. https://doi.org/10.1016/s0958-9465(02)00077-x

Tang L, Utgenannt P (2009) A field study of critical chloride content in reinforced concrete with blended binder. Mater Corros 60(8):617–622. https://doi.org/10.1002/maco.200905282

Vik OTK (2002) The role of bar supports in combating corrosion in reinforced concrete. Paper presented at the The Sixth International Conference on Short and Medium Span Bridges, Vancouver, Canada

Shaw P, Materialrontgen A, Kutti T (2003) Field measurement and experience of chloride induced of reinforcement in submerged structures. AB Fardig Betong, Goteborg, Sweden

Alzyoud S, Wong HS, Buenfeld NR (2016) Influence of reinforcement spacers on mass transport properties and durability of concrete structures. Cem Concr Res 87:31–44. https://doi.org/10.1016/j.cemconres.2016.05.006

Muslim F (2018) Improving the spacer-concrete interface for durable structures. Imperial College London

Muslim F, Wong HS, Cheng G, Alexandrou C, Liu B, Buenfeld NR (2020) Combined effects of vertical spacers and segregation on mass transport properties of reinforced concrete. Mater Struct. https://doi.org/10.1617/s11527-020-01591-9

Muslim F, Wong HS, Choo TH, Buenfeld NR (2021) Influence of supplementary cementitious materials on microstructure and transport properties of spacer-concrete interface. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2021.106561

Neville AM (2011) Properties of Concrete, 5th edn. Pearson, Harlow, England

Momayez A, Ehsani MR, Ramezanianpour AA, Rajaie H (2005) Comparison of methods for evaluating bond strength between concrete substrate and repair materials. Cem Concr Res 35(4):748–757. https://doi.org/10.1016/j.cemconres.2004.05.027

Zhang D, Ueda T, Furuuchi H (2013) Fracture mechanisms of polymer cement mortar: concrete interfaces. J Eng Mech 139(2):167–176. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000486

Stolz CM, Masuero AB, Pagnussat DT, Kirchheim AP (2016) Influence of substrate texture on the tensile and shear bond strength of rendering mortars. Constr Build Mater 128:298–307. https://doi.org/10.1016/j.conbuildmat.2016.10.097

Mohamad ME, Ibrahim IS, AbdullahAbd. Rahman AB, Kueh ABH, Usman J R (2015) Friction and cohesion coefficients of composite concrete-to-concrete bond. Cement Concr Compos 56:1–14. https://doi.org/10.1016/j.cemconcomp.2014.10.003

Beushausen H, Höhlig B, Talotti M (2017) The influence of substrate moisture preparation on bond strength of concrete overlays and the microstructure of the OTZ. Cem Concr Res 92:84–91. https://doi.org/10.1016/j.cemconres.2016.11.017

Yu H, Wang X, Zhou F (2010) Geometric shape effects of surface texture on the generation of hydrodynamic pressure between conformal contacting surfaces. Tribol Lett 37(2):123–130. https://doi.org/10.1007/s11249-009-9497-4

Yan D, Qu N, Li H, Wang X (2010) Significance of dimple parameters on the friction of sliding surfaces investigated by orthogonal experiments. Tribol Trans 53(5):703–712. https://doi.org/10.1080/10402001003728889

Hsu SM, Jing Y, Hua D, Zhang H (2014) Friction reduction using discrete surface textures: principle and design. J Phys D Appl Phys 47(33):335307. https://doi.org/10.1088/0022-3727/47/33/335307

Courard L (2000) Parametric study for the creation of the interface between concrete and repair products. Mater Struct 33(1):65. https://doi.org/10.1007/BF02481698

Beushausen H, Alexander MG (2008) Bond strength development between concretes of different ages. Mag Concr Res 60(1):65–74. https://doi.org/10.1680/macr.2007.00108

Santos PMD, Julio ENBS (2011) Factors Affecting Bond between New and Old Concrete. ACI Mater J 108(4):449–456. https://doi.org/10.14359/51683118

Courard L, Piotrowski T, Garbacz A (2014) Near-to-surface properties affecting bond strength in concrete repair. Cement Concr Compos 46:73–80. https://doi.org/10.1016/j.cemconcomp.2013.11.005

Bentz DP, De la Varga I, Muñoz JF, Spragg RP, Graybeal BA, Hussey DS, Jacobson DL, Jones SZ, LaManna JM (2018) Influence of substrate moisture state and roughness on interface microstructure and bond strength: slant shear vs. pull-off testing. Cement Concr Compos 87:63–72. https://doi.org/10.1016/j.cemconcomp.2017.12.005

Feng S, Xiao H, Geng J (2020) Bond strength between concrete substrate and repair mortar: effect of fibre stiffness and substrate surface roughness. Cement Concr Compos 114:103746. https://doi.org/10.1016/j.cemconcomp.2020.103746

He Y, Zhang X, Hooton RD, Zhang X (2017) Effects of interface roughness and interface adhesion on new-to-old concrete bonding. Constr Build Mater 151:582–590. https://doi.org/10.1016/j.conbuildmat.2017.05.049

BS EN 197–1:2011 Cement. Composition, specifications and conformity criteria for common cements (2011). BSI Standards Publication, London

BS EN 12620:2002+A1:2008 Aggregates for concrete (2002). BSI Standards Publication, London

BS 812–109: 1990 Testing aggregates. Part 109: Methods for determination of moisture content (1990). BSI Publications, London

BS 812–2: 1995 Testing aggregates. Part 2: Methods for determination of density (1995). BSI Publications, London

BS 1134: 2010 Assessment of surface texture. Guidance and general information (2010). BSI Standards Publications, London

BS EN 12390–6: 2009 Testing hardened concrete. Tensile splitting strength of test specimens (2009). BSI Standards Publications, London

Raphael JM (1984) Tensile Strength of Concrete. ACI J Proc 81(2):158–165. https://doi.org/10.14359/10653

Wu Z, Wong HS, Buenfeld NR (2014) Effect of confining pressure and microcracks on mass transport properties of concrete. Adv Appl Ceram 113(8):485–495. https://doi.org/10.1179/1743676114y.0000000197

Wong HS, Buenfeld NR, Hill J, Harris AW (2007) Mass transport properties of mature wasteform grouts. Adv Cem Res 19(1):35–46. https://doi.org/10.1680/adcr.2007.19.1.35

Wong HS, Buenfeld NR (2006) Patch microstructure in cement-based materials: fact or artefact? Cem Concr Res 36(5):990–997. https://doi.org/10.1016/j.cemconres.2006.02.008

Wu Z, Wong HS, Buenfeld NR (2015) Influence of drying-induced microcracking and related size effects on mass transport properties of concrete. Cem Concr Res 68:35–48. https://doi.org/10.1016/j.cemconres.2014.10.018

Wu Z, Wong HS, Buenfeld NR (2017) Transport properties of concrete after drying-wetting regimes to elucidate the effects of moisture content, hysteresis and microcracking. Cem Concr Res 98:136–154. https://doi.org/10.1016/j.cemconres.2017.04.006

Júlio ENBS, Branco FAB, VtD S (2004) Concrete-to-concrete bond strength Influence of the roughness of the substrate surface. Constr Build Mater 18(9):675–681. https://doi.org/10.1016/j.conbuildmat.2004.04.023

Garbacz A, Górka M, Courard L (2005) Effect of concrete surface treatment on adhesion in repair systems. Mag Concr Res 57(1):49–60. https://doi.org/10.1680/macr.2005.57.1.49

Wong HS, Pappas AM, Zimmerman RW, Buenfeld NR (2011) Effect of entrained air voids on the microstructure and mass transport properties of concrete. Cem Concr Res 41(10):1067–1077. https://doi.org/10.1016/j.cemconres.2011.06.013

Aldea CM, Shah SP, Karr A (1999) Effect of cracking on water and chloride permeability of concrete. J Mater Civ Eng 11(3):181–187. https://doi.org/10.1061/(ASCE)0899-1561(1999)11:3(181)

Wong HS, Zobel M, Buenfeld NR, Zimmerman RW (2009) Influence of the interfacial transition zone and microcracking on the diffusivity, permeability and sorptivity of cement-based materials after drying. Mag Concr Res 61(8):571–589. https://doi.org/10.1680/macr.2008.61.8.571

Grassl P, Wong HS, Buenfeld NR (2010) Influence of aggregate size and volume fraction on shrinkage induced micro-cracking of concrete and mortar. Cem Concr Res 40(1):85–93. https://doi.org/10.1016/j.cemconres.2009.09.012

Abyaneh SD, Wong HS, Buenfeld NR (2016) Simulating the effect of microcracks on the diffusivity and permeability of concrete using a three-dimensional model. Comput Mater Sci 119:130–143. https://doi.org/10.1016/j.commatsci.2016.03.047

Acknowledgements

F. Muslim gratefully acknowledges the financial support for her PhD study provided by the Indonesian Endowment for Education (LPDP). We thank Mr. Richard Man and Mr. Andrew Morris for their help with the laboratory work including sample preparation and splitting tensile strength testing. The research leading to this publication benefitted from EPSRC funding under grant No. EP/R010161/1 and from support from the UKCRIC Coordination Node, EPSRC grant number EP/R017727/1, which funds UKCRIC’s ongoing coordination.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Muslim, F., Wong, H.S., Chiu, T.K.Q. et al. Improving bond strength and mass transport properties of spacer-concrete interface with textured spacers. Mater Struct 54, 191 (2021). https://doi.org/10.1617/s11527-021-01782-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01782-y