Abstract

Superabsorbent polymers (SAP) are a new, promising class of chemical admixtures which offer new possibilities in respect of influencing the properties of cement-based materials in the fresh, hardening, and hardened states. Much research work has been done in the last two decades to set the stage for introducing this truly multipurpose agent into the practice of construction. In particular, three RILEM Technical Committees: 196-ICC, 225-SAP and 260-RSC contributed considerably to the related progress by coordinating and combining the efforts of international experts in the field. The major product of the RILEM TC 225-SAP work was the State-of-the-Art Report published in 2012. This comprehensive document covered all topics relevant to the application of SAP as a concrete admixture. Since then further important progress has been made in understanding the working mechanisms of SAP in concrete and the effects of SAP-addition on various concrete properties. The article at hand presents an update on the state-of-the-art and is the concluding document delivered by the RILEM TC 260-RSC.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In the construction practice chemicals play a major role in the development of modern concrete technologies by enabling a wide range of solutions for controlling the properties of cement-based materials at different stages of their evolution, from the fresh to the hardened state and between. These chemical admixtures, such as superplasticizers, air-entrancing agents, or accelerators, allow the purposeful shaping of various features of concrete and, in so doing, producing superior performance characteristics. The introduction of superabsorbent polymers (SAP) as a new type of concrete admixture widens the range of these possibilities even further by enabling powerful control over the key concrete ingredient, namely water, and eventually, macroporosity. Through purposeful water absorption and/or water release, SAP can affect various properties of either fresh or hardened concrete.

One of the first applications of SAP in concrete was in promotion of self-sealing, studied by Tsuji et al. [1]. Jensen and Hansen [2, 3] popularized application of SAP for the internal curing of high performance concrete. Using SAP as a possible internal curing agent had then been proposed along with other internal curing methods by the RILEM Technical Committee (TC) 196-ICC started in 2002 [4]. Answering the increasing interest of the research community and industry, particularly in SAP, RILEM TC 225-SAP was established in 2007. The main objectives of that TC were to coordinate the research efforts of different groups interested in the topic and to explore possible fields of application.

One of the major deliverables of the TC 225-SAP was a State-of-the-Art Report [5]. The report was published in 2012 summarizing the scientific knowledge and the application potential of SAP in the concrete industry. Since that time, significant progress regarding the SAP as a material itself and different aspects of its action in cement-based materials has taken place. The TC 225-SAP coordinated two large interlaboratory studies and jointly evaluated the results obtained by 13 research teams from around the world. The studies were concentrated on the mitigating effects of SAP on the autogenous shrinkage of high performance concrete [6] and to the freeze–thaw resistance of concrete [7].

The activities of the TC 225-SAP were finalized in 2014 with an international conference on the application of new additives, particularly SAP, in concrete construction [8]. The work of the TC 225-SAP has been continued by the new committee, TC 260-RSC, which started in 2014. The major goal of this new TC is to facilitate the introduction of SAP into the construction practice by preparing technical recommendations on the use of SAP in concrete. Three RILEM recommendations were published: (1) for testing sorption by SAP prior to implementation in cement-based materials [9], (2) for using SAP to mitigate autogenous shrinkage [10], and (3) for using SAP to improve the freeze–thaw resistance of cement-based materials [11]. Another RILEM recommendation is ongoing, i.e., verification of the presence of SAP in as-delivered concrete.

The TC 260-RSC also completed several literature reviews and interlaboratory studies on the characterization of SAP and their performance in concrete [12,13,14]. One of the finalizing activities of the TC 260-RSC was the organization of the third RILEM international conference in a series, after Lyngby, Denmark in 2010 [15], and Dresden, Germany in 2014 [8]. The 3rd International Conference on the Application of Superabsorbent Polymers (SAP) and Other New Admixtures Towards Smart Concrete in Skukuza, South Africa in November 2019 brought together many experts working on SAP and gave them the chance to advance their understanding and identify the pending questions surrounding the application of SAP in concrete construction [16].

Considering the numerous scientific activities following the first state-of-the-art report published in 2012 [5], the advancements in understanding, and the continuously increasing interest of the scientific community, manufacturers of construction chemicals and practitioners in the topic, the members of RILEM TC 260-RSC decided to deliver an update to the book. The article at hand is an update of the 2012 state-of-the-art report book [5]. It summarizes the progress in the research and development of superabsorbers related to application in cement-based building materials over the last nine years. It also constitutes the concluding deliverable of the RILEM TC 260-RSC.

The main body of the article is divided into six sections. Section 2 covers SAP materials, where in particular new insights regarding their chemical composition, physical properties, and absorption/desorption behavior are addressed. The following four sections are dedicated to new knowledge regarding different aspects of the action of SAP in cement-based materials, namely, in Sect. 3 the effects of SAP addition on the rheological properties/workability of fresh concrete, in Sect. 4 the microstructure of hardening concrete, in Sect. 5 the shrinkage behavior of concrete, and in Sect. 6 the mechanical properties and durability of hardened concrete. Section 7 presents recent application examples of SAP in construction practice. The article also identifies open questions and directions for future studies toward the application of SAP in the concrete industry.

2 SAP materials

In SAP chemistry numerous studies related to cement-based construction materials have been published since the respective chapter of the state-of-the-art report in 2012 [5], including four reviews [12, 17,18,19].

As with any chemical admixture to concrete, SAP have a limited shelf life. Recommendations by manufacturers and providers on storing conditions, e.g., dark, dry environment, room temperature, and expiry dates should be strictly followed. Chemical changes may affect over time sorption properties and consequently the concretes modified with such SAP material [13, 20]. One scientific article reported a shelf life of a minimum of eight years for some cross-linked, acrylate-based SAP used in a cementitious material [21].

Few studies have linked individual SAP syntheses and fundamental chemical analyses with performance-oriented tests of the polymers embedded in cement-based materials. Numerous publications have disclosed sufficient polymer-chemical details which allow for promoting structure/efficiency relations and the molecular working mechanisms of distinct polymer compositions [22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45].

Such approaches and the depth of the information provided enable us to understand the chemical and physical working mechanisms of SAP and their effects on the macroscopic properties of the building materials. Regrettably a considerable number of publications on SAP in building materials has not reported sufficient chemical information on the polymers used.

In many publications, the fundamental chemical nature of the SAP used is specified as a cross-linked, acrylate-based network, acrylic acid and acryl amide being the most important monomers along the main chains [24,25,26, 28,29,30, 33, 34, 46,47,48,49,50,51,52,53,54,55,56,57,58,59].

Common cross-linkers include bifunctional monomers that are co-polymerized along the primary chains [25, 29, 30, 33, 55, 56]. N,N′-methylenebisacrylamide (MBA) is most frequently named [20, 22, 42, 49, 60]. For the efficient self-healing of cracked concrete, pH-responsive SAP, which swell less at alkaline pH but swell more at a lower pH when water infiltrates cracks, have been found most appropriate [32]. Bacteria may be included in the SAP structure as well [61, 62] (further details on the bacteria cf. Sect. 6.4).

The synthesis procedure determines the particle shape. Inverse suspension polymerization results in spherical particles [23, 24, 49, 51, 54, 63,64,65]. A narrow particle size distribution is adjusted via synthesis parameters, emulsifiers, and attendant sieving. On the other hand, bulk solution polymerization yields a gel block. The synthesis product is later crushed or ground and sieved to obtain the most suitable size distribution. Hereby irregular SAP particles are obtained, e.g. [24, 25, 33, 39, 41, 44, 53, 66].

Post-processing steps like surface cross-linking may impose special features on the SAP particles. As an example, swelling properties can be fine-tuned to optimize the performance under specific ionic or mechanical loading conditions [67].

A concise review of instrumented analytics to characterize SAP has been provided by three members of the TC 260-RSC. Besides chemistry-oriented analytical methods, numerous experimental approaches to quantify the inherent ab- and desorption behavior of SAP upon exposure to typical saline solutions have been collected there [12]. Two of the methods evaluated in [12] have proven most effective in testing the sorption characteristics of SAP prior to implementation in cement-based materials. By name, the so-called “tea-bag method” and “the filtration method” are specifically recommended by the TC [9]. A round-robin test organized and evaluated by the TC verified the good manual functioning and the statistical meaningfulness of these two procedures [13].

The general mechanism of SAP swelling is presented in Fig. 1. Kinetics of ab- and desorption by the SAP are of utmost importance in understanding the actions of the polymers as a concrete admixture in chemical and physical terms. Time-resolved swelling experiments with SAP dispersed in a cement paste filtrate or a synthetic pore solution are widely used as pre-tests [9, 12, 13, 55, 68]. First aspects are the rate of absorption within time spans of concrete mixing and placing, e.g., 30 or 60 min, and the absorption capacity reached within the respective interval. Next, the ability to keep the liquid absorbed for a considerably longer time than this, or a release of the liquid during following several hours without any external trigger are essential distinctions. Inherent sorption characteristics of SAP dictate specific effects on short- and long-term properties of the concrete doped with the SAP.

Schematic of an SAP network in the collapsed (dry) state without water molecules taken up (left) and in the swollen state with absorbed water molecules and ions dissolved inside the network structure (right). The green bonds indicate the chemical cross-linkages which interconnect the primary polymer chains, drawn in black, to form the characteristic swellable, but non-dissolving polymer network

Particle size plays an important role in the sorption kinetics of the SAP and in their distinct effects on the properties of building materials as well. Some studies have specifically used smaller and larger fractions of one distinct SAP composition [28, 50, 53, 56, 69,70,71,72,73]. However, the vast majority of publications reported using SAP material as-obtained, with dry particle size typically below 100 µm and in the swollen state reaching a few hundred µm, for example [15, 16].

Commonly, SAP is introduced into a concrete mixture as a dry powder, in turn, to other dry ingredients and premixed to homogenize the distribution of the SAP particles. Dry SAP can as well be added to already mixed mortar or concrete [74]. On the other hand, pre-soaking the SAP and adding the swollen hydrogel to a mortar or concrete mixture has also been described. Much attention has to be paid to uniform distribution throughout the mixture’s volume, especially in the latter case [25, 27, 48, 57, 69, 75, 76].

Interestingly, only scant attention has been paid to the effects of temperature on the sorption characteristics of SAP and the resultant effects on cement-based composites [37]. Well cementing as a special field of concrete technology has recently focused on this issue [45, 77].

From these points onwards, the TC 260-RSC recommends that civil engineers form collaborative groups with polymer chemists. Pathways for upcoming research and development may include:

-

As an alternative to acrylic-based, anionic SAP, hydrogels with sulfonate groups stemming from 2-acrylamido-2-methylpropane sulfonic acid (AMPS) as a co-monomer could be very interesting to the field of concrete technology [27, 76, 77]. Their sorption characteristics may be less sensitive to ions dissolved in the cement paste, especially due to their limited intensity of complex formation with calcium.

-

Non-ionic SAP [42, 45], e.g., those based on cross-linked poly(ethylene oxide), can also be more salt-tolerant in their swelling properties, their absorption rate being, however, possibly significantly slower than the acrylic-based SAP.

-

Reaching beyond petrochemical monomers or precursors, bio-based pre-products constitute an emerging field, including, as examples, alginate, starch, or cellulose [27, 68]. However, only few such substances have yet been implemented in cement-based composites [22, 31, 32, 78].

In general, close links between chemists and civil engineers should be fostered for targeted design and synthesis of SAP in trying to achieve tailor-made effects. Besides the effects outlined, possible temperature-dependency of SAP's ab- and desorption should be borne in mind [9].

3 Effect of SAP on rheological properties and workability of fresh concrete

SAP addition considerably affects the rheology and workability of fresh cement-based materials. Due to the SAPs’ individual ab- and desorption properties, which depend on their chemical structure and grading, the amount of freely available water in the mixture is altered as compared to an SAP-free equivalent. Both yield stress and plastic viscosity are governed by the sorption kinetics of SAP. Any time-dependent rheological behavior from accelerated stiffening via steady consistency over a certain time to delayed liquefaction can be attained. The distinct effect depends on the speed and intensity of the polymer-inherent ab- and desorption properties after completion of concrete mixing. Such rheological impact can be enhanced or attenuated by a high-range, water-reducing admixture (HRWRA). These interplays offer splendid areas purposefully to fine-tune rheological properties if their fundamental mechanisms are thoroughly understood. Besides intense activities in research and development, open-minded communication strategies will be indispensable in gaining acceptance with practitioners in the field.

Most studies of SAP in concrete to date have increased the overall water content from a reference mixture to compensate for the loss of flowability. Based on the slump flow of the SAP-free reference at a distinct point in time, the amount of water is increased to readjust this spread value. In rheological terms, herewith only the yield stress at a particular concrete age is indirectly considered.

In some cases, the amount of mixing water was kept constant. A HRWRA was implemented or its dosage increased to recover the original slump flow at a specific time [6, 7, 46, 51, 70, 79, 80].

Ma et al. [56] combined the two fundamental approaches for compensating the loss of flowability. They first increased the water-to-cement ratio slightly by 0.02 in comparison the reference mixture without respecting the sorption capacity of their SAP. Then they increased the HRWRA dosage to adjust for the same slump flow as the reference mixture.

Finally, a very quick and intense absorption of water by SAP can intentionally be exploited in special application techniques that require rapid stiffening at distinct points in time during their processing. In shotcreting, addition of SAP at the spraying nozzle can reduce rebound, enhance the sticking of the material to the substrate and improve form and size stability. In 3D concrete printing, shape stability and green strength of a freshly extruded layer is essential for successful deposition of subsequent layers. The absorptivity by superabsorbers added to a 3D-printable mixture at a suitable point of the process chain can enhance these properties as well as improve the layer-to-layer bond [81].

To date genuine rheological research on cementitious composites with SAP has been rather seldom. An extensive parameter study using a Viskomat PC rheometer and flow table spread value for a comparison was presented by Senff et al. [82]. Seven SAP dosages, seven HRWRA dosages, and three water-to-binder ratios were tested. Bingham’s model was used to evaluate plastic viscosity and yield stress. Regrettably only the trade name of the sole SAP, but neither the chemical information nor the individual sorption characteristics of the specific polymer sample under consideration, was disclosed. The conclusion suggested that the yield stress depends on the distinct composition of the pastes and that it varies considerably over time.

A rotational rheometer was used to assess plastic viscosity, yield stress, and thixotropy of the cement-based mortar and, as a consequence, the sorptivity characteristics of SAP during the 80 min following preparation by Ma et al. [73]. One commercially available, covalently cross-linked acrylic acid-co-acrylamide was used in two specific gradings of 30 to 300 µm and 350 to 1400 µm in the dry state, respectively. The base water-to-binder ratio was 0.18, whereby the mixtures with SAP had systematically varied water-to-binder ratios between 0.18 and 0.24. The rheological parameters obtained resulted in the conclusion that the smaller SAP particles had faster and lower absorption than the larger ones.

Mechtcherine et al. [28] investigated the effects of SAP with distinctly different sorption properties on the rheological properties of fresh Portland cement-based mortars. The release of a portion of the initially absorbed liquid by a “self-releasing” type of SAP caused a slower increase, or even a slight decrease, in plastic viscosity over time as compared with the reference mixture. Contrarily, mortars with an intrinsically “retentive” SAP showed a steady increase in this parameter, either because of negligible desorption of liquid from the polymer or because of some additional, ongoing absorption by the SAP. The effect of SAP addition on yield stress was less straightforward since it counteracted the effect of the HRWRA on the development of this rheological parameter over time. For the same amount of internal curing water, mortars containing the finest retentive SAP particles provided the highest values of yield stress and plastic viscosity due to the greater total absorption surface of the particles and, consequently, more rapid achievement of equilibrium. However, the larger particles of the retentive SAP, while slow at the beginning, continued to absorb water over the entire time of experimentation. This led to a steady and most pronounced increase in the values of the Bingham parameters.

The same publication reported that both ab- and desorption by an SAP depend on the availability of free water in the mixture [28]. Increasing the water-to-binder ratio results in higher water absorption by SAP and, accordingly, higher relative changes in the Bingham parameters for such mixtures in comparison to the reference. Furthermore, silica fume changes the water ab- and desorption kinetics of an SAP sample in fresh mortar. It seems that the competition for absorbing and attaining water becomes more difficult for SAP in the presence of silica fume.

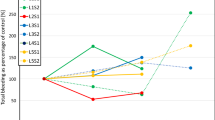

Secrieru et al. [37, 83] investigated the effect of SAP on the development of the rheological properties of a strain-hardening cement-based composite (SHCC) over time at various temperatures. Rheological and tribological tests were performed, and in addition a sliding pipe rheometer was used to estimate pumpability. The addition of SAP increased plastic viscosity and yield stress at any temperature despite SAP-inherent desorption behavior observed in the cement pore solution. Partial desorption by SAP particles could be considered negligible in this investigation with respect to rheological behavior. At 20 °C and 30 °C the SAP seemed to impair the formation of a lubricating layer in the SHCC during pumping and as well to change its properties, leading to a steeper slope in the pressure-delivery rate curve. Conversely, the SAP had almost no impact on pumpability at 10 °C.

To conclude, research on SAP-related rheology of cement-based building materials should be intensified to understand the effects observed in practice better. While rheology issues related to the use of SAP in concrete can already be empirically mastered in most instances, more research is needed to be able to predict and influence the effects of SAP addition on the rheological properties and process characteristics of fresh concrete in a comprehensive manner. It may be expected that a wider application of concretes with SAP will be facilitated when the effects of SAP addition become predictable according to objective rheological criteria.

4 Effect on transport properties, hydration, and microstructure formation

4.1 Effect of SAP on hydration

The promotion of cement hydration by internal curing with SAP has already been theoretically considered by Jensen and Hansen [2] with experimental results presented by Lura et al. [84]. More recently, Justs et al. [85] showed with isothermal calorimetry that the addition of SAP to cement pastes with low water-to-cement ratios (w/c) led to acceleration of the main hydration peak beyond those of the reference mixes with the same total w/c but without SAP; see Fig. 2a. This acceleration was explained by the more concentrated pore solution and the higher alkalinity of the mixtures, where SAP absorbed initially a part of the mixing water. Acceleration due to the addition of SAP, compared to the mix with the same total w/c, was also reported based on semi-adiabatic calorimetry in [86]. It should be mentioned that the acceleration due to absorption of part of the mixing water by SAP may be in practice masked if a higher amount of superplasticizer is used to compensate for the loss of workability caused by the addition of SAP and the resulting water intake.

a Hydration heat release rate and b cumulative heat of cement pastes with and without SAP. Reprinted by permission from Springer Nature [85]

As presented in Fig. 2b, the final degree of hydration of the mixtures with SAP was very close to that of the reference mixture with the same w/c. That the same degree of hydration was finally reached indicates that all water is released from the SAP and consumed by the cement, as originally suggested in [2]. A higher final degree of cement hydration thanks to internal curing with SAP was found also in [87]. Zhutovsky and Kovler [88] showed that the effect of SAP on cement hydration is only significant at lower w/c (below about 0.30). This is in line with the findings in [36], where no significant effect of SAP on the hydration peaks in isothermal calorimetry was found for pastes with w/c of 0.38 and 0.42.

An additional effect of internal curing with SAP on hydration can play a role with regard to the final degree of hydration in low w/b mixes. It has been reported that the reduction of internal RH, in particular below 90%, strongly inhibits the hydration process [89]. Hence, by maintaining RH at higher levels, thanks to SAP, a higher final degree of hydration can be expected.

Although most studies have focused on the effect of SAP on hydration and microstructure formation in ordinary cement pastes, some studies have been dedicated to alternative binders and blends with supplementary cementitious materials, e.g. [27, 60, 90, 91].

Few studies analyze the effect of SAP on the assemblage of hydration products. Esteves et al. [51] reported that for some SAP higher amounts of calcium hydroxide can be formed, most likely due to SAP’s ability to bind Ca2+ ions; see also [35]. If this were the case, one would expect also changes in stoichiometry of the C-S–H and other hydration products in the cement paste matrix. Further studies are necessary on this topic.

Justs et al. [66] observed massive precipitation of calcium hydroxide in the original SAP voids. Hence, it can be stated that SAP may in some cases affect the morphology of hydration products.

A numerical study by Wyrzykowski et al. [92] based on the experimental work [93] showed that water from SAP can readily be transported away from the SAP over distances as large as about 2–3 mm in the early stages of hydration. Esteves et al. [51] reported no significant effect of different size gradations of SAP on the hydration of cement. Hence, it can be concluded that paste containing SAP of less than 1 mm in its swollen state is readily protected from desiccation by the internal curing water.

Another concept that needs revision is the maximum degree of hydration that can be reached by using SAP in mixtures with low w/c. Based on Powers’ model of volume composition of hydrating cement paste, Jensen and Hansen estimated the amount of internal curing water as the minimum amount of water to compensate for chemical shrinkage, yet stopping short of self-desiccation [2]. Following the model, they proposed that the maximum hydration degree that can be reached in cement pastes with free access to internal curing water is higher than in a sealed system (a system with no access to curing water). Still, according to [2] and following the model of Powers, hydration will still stop prematurely when the hydration products use up all free space in their forming. This would be the case even if more water than is theoretically necessary to avoid self-desiccation were provided. On the contrary, recent studies [85] show that for higher volumes of internal curing water higher degrees of hydration can be achieved than the theoretical limit dictated by the lack of space for hydration products. In practice, the ultimate degree of hydration appears to depend only on the total w/c and not on space filling considerations. This unexpected result may be explained by the presence of additional space available in the SAP voids, in which crystalline hydration products, primarily calcium hydroxide, may grow [66, 94]. Ref. [94] reported that such mineral growth in pores was pronounced for hydrogels with higher proportions of acrylamide, but less intense with SAPs with higher proportions of acrylic acid. Calcium hydroxide was majorly formed, and, to a lower extent, calcium silicate hydrate (C–S–H).

4.2 Microstructure alterations by SAP

SAP can significantly alter the microstructure of concrete and, consequently, its properties in the hardened state.

First, macropores, the vacant remnants of the swollen SAP, are present in the microstructure [7, 57, 86, 90, 95,96,97]. The increased volume of macropores, whose volume can be specified by the amount of SAP and by their swelling potential, can be beneficial in improving the freeze–thaw resistance of concrete [7, 11]; see also Sect. 6.

An increase in macroporosity due to SAP in combination with polypropylene (PP) fibers has also been reported as enhancing the fire spalling resistance of high-performance, prestressed concrete [80]. As shown in Fig. 3, the reference concrete containing only PP fibers at a dosage of 2 kg/m3 was seriously damaged by exposure to fire. At the same time the concrete in which the PP fibers, at a dosage of 2 kg/m3, were combined with SAP at a dosage of 1.93 kg/m3 did not experience any fire spalling. It was suggested that the SAP and PP fibers in combination form an effective percolation system for reducing the fire spalling in thin-walled, prestressed, high-performance reinforced concrete slabs. Further, combining SAP and PP fibers should impair workability less than when fibers are used alone at an increased dosage necessary to reach sufficient resistance against fire spalling. Toropovs et al. [98] reported that spalling occurred in concrete with only SAP, whereas no spalling occurred when PP-fibers were introduced in addition to SAP. These results suggest that the increased moisture content of concretes internally cured with SAP may have negative effects if concrete is subject to high temperatures. In such a case the combination of SAP and PP fibers again appears to be beneficial.

Combining suitable SAP with functional mineral additives is a new direction for utilizing the unique functions of SAP in practice. For example, using SAP together with a calcium-sulfoaluminate-based expansive cement and shrinkage reducing admixture (SRA) seems an effective way to promote chemical prestressing, i.e., self-prestressing, and simultaneously enhancing the mechanical properties and durability of concrete [99, 100]. This is because SAP provide water for the formation of ettringite, the major component causing expansion.

It should be noted that the macropores may be to a large extent filled with calcium hydroxide [66, 94], in particular for the hydrogels with higher acrylamide amount [94] (see Sect. 4.1), reducing the freeze–thaw or fire spalling protection potential.

As long as SAP introduce additional macropores, they also promote cement hydration; see Sect. 4.1 This in turn leads to a denser cement paste matrix with lower capillary porosity, as suggested already in [2]. This was confirmed in the study by Snoeck et al. [101]. A reduction of capillary pores was reported also in [90], where later a relative bulk expansion triggered by deposition of secondary hydration products from SCM reactions facilitated by SAP water was observed in mortars. Furthermore, the hypothesis of the denser microstructure of the matrix in cement pastes with SAP has been confirmed by the reduced transport properties observed in some studies; see Sect. 4.3.

The properties of the matrix may change depending on the distance from the SAP. In [86, 94] increased porosity was observed around SAP voids within a distance of about 50–100 µm.

As a first approximation it can be expected that the total porosity of pastes with SAP is similar to those without SAP and having the same total w/c. In other words the final porosity depends only on the total volume of water used in the mix, see [46]. However, it should be noted that slightly increased air content in concretes with SAP was observed by some researchers in a RILEM inter-laboratory study [7]. This was likely due to the SAPs’ effect on workability, i.e., with reduced workability more air might have been entrapped in the concrete samples. Another reason might have been the presence of residuals of the polymerization process which had stabilized air in the fresh mix.

4.3 Transport properties

The changes in the variety of pore sizes can have a significant influence on the transport properties of cement pastes. It can be speculated that macropores introduced by SAP should have a small effect on the transport properties of cement paste so long as they form well-isolated, individual voids. At the same time, the reduced porosity of a matrix should in principle lead to reduced transport properties and enhanced durability of cement-based materials. This hypothesis was confirmed by the studies on permeability and capillary suction of concrete with SAP [102].

On the other hand, in [103] it was suggested that the increased connectivity of pores in systems with SAP caused a reduction in electrical resistivity, i.e., a proxy measurement for the assessment of transport properties. Hasholt and Jensen [79] reported that in concretes where addition of SAP resulted in an increase of the gel/space ratio the chloride ingress was reduced. Hence, this is so where SAP is added without extra water or if SAP is added together with extra water, leading to enhanced hydration. This was not a general statement about the positive effect of SAP on transport resistance, but a conditional statement where the positive effect was related to a densification of the microstructure. Reduced durability relevant transport properties in concretes or mortars with SAP were also reported in other studies [46, 70, 104].

5 Use of SAP for mitigation of shrinkage and shrinkage-induced cracking

This section describes the latest development in the field of the use of SAP for reducing shrinkage and shrinkage-induced cracking. The first part is devoted to drying shrinkage and creep, the second part to autogenous shrinkage, and the last part to plastic shrinkage and cracking.

5.1 Drying shrinkage and creep

Assmann and Reinhardt [105] studied total shrinkage of concretes drying at 65% relative humidity (RH). When concretes with SAP were compared to a reference with the same w/c (0.42) as the total w/c of internally cured concrete (0.36 + 0.06), the total shrinkage after 28 d was similar. Based on this and on previous studies it can be summarized that the overall effect of internal curing with SAP on total shrinkage will depend upon the total w/c of the mixture and the RH during drying and, hence, upon the proportion between the reduced autogenous and the enhanced drying shrinkage.

Few studies have been devoted to the effect of internal curing with SAP on the creep of cement-based materials. In [105], an almost twofold reduction of both basic and drying tensile creep was observed for a concrete of w/c 0.36 with SAP and additional water corresponding to an increase in w/c of 0.06 as compared to a reference concrete with the same w/c, 0.42. At the same time, the creep was similar to that of a reference concrete with the same basic w/c of 0.36. A significant reduction in tensile basic creep was also reported in [64], based on the stress development in a temperature-stress testing machine (TSTM). The reduction was higher for higher amounts of additional water and SAP. On the other hand, in [63] higher stress relaxation in restrained ring tests was observed for mixes with SAP and additional water, when compared to that of a reference mix with w/c equal to the basic w/c of the mixes with SAP.

5.2 Autogenous shrinkage

There have been many studies investigating the effectiveness of SAP in mitigating autogenous shrinkage at low water/cement ratios. Moreover, it is well recognized that SAP is effective in reducing autogenous shrinkage for various mixes, both with and without mineral admixtures such as blast furnace slag [90, 106]. Recently, the application of SAP to reduce autogenous shrinkage in alternative binders with very marked autogenous shrinkage, e.g., geopolymers or alkali-activated materials, was studied. The incorporation of SAP together with them was found to mitigate a significant portion of the autogenous shrinkage [107, 108]. In [108] it was reported that some part of the autogenous shrinkage could not be mitigated, suggesting mechanisms other than self-desiccation. Li et al. [108] also showed that mixture design of concrete with alternative binders and SAP can be based, as in the similar case of ordinary cement, on the desired reduction of chemical shrinkage and the predetermined free absorption potential of the SAP, e.g. with tea-bag method, while leading to limited adverse effects on mechanical properties.

Not all SAP can mitigate autogenous shrinkage effectively. As some SAP may show incontinent features, i.e. desorb quickly without an external trigger like the onset of self-desiccation or external drying, the internal curing purpose may be defeated even if the theoretical additional amount of water was added [35, 36, 41, 109]. In particular, it should be checked if the specific absorption and desorption kinetics of SAP do not impair hydration or other parameters too intensely.

On the other hand Zhong et al. [59] studied several types of SAP with different chemical structures featuring different behavior in free absorption tests ("retentive" vs. "releasing") with regard to their performance in reducing autogenous shrinkage. They reported that despite different free absorption characteristics, all the SAP tested could reduce autogenous shrinkage. Most interestingly, SAP with rapid liquid release after initial absorption during tea-bag tests performed well in reducing autogenous shrinkage.

5.3 Plastic shrinkage and cracking

A few recent publications detail the use of SAP alone or in combination with other preventive measures to mitigate plastic shrinkage cracking.

Serpukhov and Mechtcherine [110] reported that the addition of SAP led to slower evolution of capillary pressure in concrete exposed to harsh drying condition after setting. Consequently, early age shrinkage was reduced until final setting, whereas no significant effect was observed during later stages of drying. Thanks to the addition of SAP in mortars with Portland cement or blast furnace slag as binder, significant reduction of plastic shrinkage cracks could be reported by Almeida et al. [111].

Snoeck et al. [39] looked at the plastic shrinkage of cement paste, with and without SAP as an internal curing additive. They found a clear reduction in plastic shrinkage when SAP was added. They confirmed using NMR that the saturated SAP were releasing water to the cement paste during the drying phase. Olivier et al. [112] investigated the effect of nano-silica on plastic shrinkage cracking and as part of the investigation also looked at the effect of SAP on plastic shrinkage cracking. This was done alone but also in conjunction to other methods, e.g. nano-silica and polypropylene microfibers. SAP was found to be more effective in reducing plastic shrinkage cracking when compared to the case in using a typical dosage of polypropylene microfibers.

The largest study on plastic shrinkage cracking and SAP to date is the inter-laboratory study done under the auspices of RILEM TC 260-RSC to determine the influence of the addition of SAP on the plastic shrinkage cracking of concrete under severe drying conditions [14]. Six laboratories over three continents took part in this inter-laboratory test. The study concluded that using SAP in conventional concrete can significantly decrease plastic shrinkage cracking. It was also found that using SAP with the appropriate amount of extra water added to the concrete decreases plastic shrinkage cracking significantly, more so than is true when just the same amount of water is added without SAP. The concrete's bleeding is strongly influenced by the type of SAP used, with retentive SAP reducing the bleeding, whereas it increases when SAP with only short-term absorption capacity is used. Lastly, the compressive strengths of the conventional concrete were only slightly reduced, with a 3% reduction for the 0.15% bwoc SAP addition and a 10% reduction for the 0.30% bwoc SAP addition.

6 Effect of SAP on the mechanical properties and durability of hardened cementitious materials

In this section, emphasis is given to mechanical properties and durability-related issues. Recent reviews can be found in [113, 114]. Different modes of action of SAP leading to improved durability of concrete are schematically presented in Fig. 4.

The use of SAP a to change the microstructure, b to increase freeze–thaw resistance, c to induce sealing, and d to provide for healing characteristics in a cementitious material; the materials represented are shown as light grey SAP in a dark grey cementitious matrix with blue water and medium grey healing product formation

6.1 Mechanical properties

A general reduction in compressive strength can be found due to the macro-porosity formed by the SAP voids; see also Sect. 4.2 [35, 52, 101]. In a limited number of cases, an increase in strength is possible due to internal curing and enhanced cement hydration, as well as in the macro-pores [66], compensating the observed strength reduction caused by the higher porosity. These characteristics depend on the type of polymer, mixture composition, water-to-binder ratio, concrete versus mortar or paste, amount of SAP added, curing conditions, and testing age. Typical values are a decrease of 10–20% in compressive strength for acrylate-type SAP with a size of 300–500 µm and 30–50% for SAP with a size of 50–150 µm [52, 72, 115] when 0.2–0.5 m% of SAP are added. SAP releasing their stored water prematurely cause a more noteworthy decrease in strength when compared to water-retentive SAP with a comparable amount of additional water [35]. Zhong et al. [59] reported that for the net addition of SAP no significant effect on strength could be observed when mixtures both with and without SAP within the same water-to-cement ratio were compared.

As a solution for the loss in mechanical properties when adding high amounts of SAP of several mass-percentages, pH-sensitive SAP [18, 29, 31, 32, 53, 78] or coated SAP [67, 77] may be added to the mixture, in order to limit the absorption of mixing water in the initial stage. The strength can also be compensated by the addition of nanosilica or nanoclays [33, 116, 117].

The impact resistance of strain-hardening, cement-based composite (SHCC) increased as the SAP act as stress concentrators, and the material showed more ductile behavior when compared to a cementitious material without SAP [38]. For cellular concrete with SAP, this effect increases with increased strain rates [75].

In addition to reducing autogenous shrinkage, maintaining a higher RH has one additional beneficial effect, thanks to internal curing with SAP. Wyrzykowski and Lura [118, 119] investigated changes in the coefficient of thermal expansion (CTE) of concrete containing SAP. They showed that the incorporation of SAP effectively inhibits the increase in CTE at early ages. This contributes to the decrease in the risk of thermal cracking, which would be a serious problem in mass concrete.

6.2 Freeze–thaw resistance

After internal curing, the SAP leave behind macro-pores which are beneficial in respect of freeze–thaw resistance [7, 99, 120,121,122] as the induced macro-porosity resembles an air-entraining agent system [57] but may render a more stable mixture and better mechanical properties [7]. The addition of SAP in the range of 0.10–0.34% in relation to the mass of cement has been reported to promote a reduction of at least 50% in scaling after more than 25 freeze–thaw cycles in both cement mortars and concrete mixtures [121, 123]. The interlaboratory study on freeze–thaw resistance carried out by the RILEM TC 260-RSC [7] concluded the same. Adding the SAP as dry powder or pre-saturated particles also influences the behavior of the concrete during the freeze–thaw cycles. Although both scenarios were found to reduce the amount of scaled material, the use of pre-saturated SAP might lead to a higher loss of material in comparison to the use of dry SAP [11, 123].

Other sustainability—[124] or durability—related issues such as carbonation and chloride ingress are still topics for investigation. Beushausen et al. [46] found positive effects of SAP addition to repair mortars of relatively high w/b (0.55) on different durability indexes studied by means of accelerated carbonation and bulk diffusion testing, indicating a high potential for application in repair projects.

Due to their improvements in sealing and healing, in addition to improvement in terms of shrinkage mitigation, the SAP will show some influences in the long term properties, but microstructural changes may cause adverse effects. Currently, only results up to an age of eight-years are available for self-healing qualities. Additional information is needed to assess the long-term influences and the overall impact of SAP on the service life of concrete structures.

6.3 Self-sealing

As SAP are able to swell and retain water upon crack formation, they also may contribute to overall increase in durability and sustainability due to their immediate sealing ability and stimulated autogenous healing [113, 125, 126]. As the polymers swell and fill the crack spaces, they cause a decrease in water permeability [26, 53, 125, 127,128,129]. Swollen SAP could be visualized by means of cryofracture-scanning electron microscopy showing that SAP swell across voids into the crack, causing the physical sealing of the crack [54, 130]. The decrease in permeability can be enhanced further by the use of expansive agents [131]. All this information is currently used in three-dimensional mesoscale numerical models to simulate capillary absorption of water in sound and cracked cement-based materials containing SAP [54, 132, 133]. The experimental results are used as validation and will optimize the application of SAP and the practical applications.

6.4 Self-healing

On ingress of water, the water stored in SAP particles near the crack walls may also promote autogenous healing [134,135,136,137], even repeatedly [138]. Autogenous healing occurs only when liquid water is provided. Upon adding SAP, the availability of stored water or moisture extracted from the environment helps to overcome dry periods [50, 135, 139]. This water stimulates further hydration increases of up to 40% [140] and thus the formation of new calcium silicate hydrates, pozzolanic activity, and the formation of calcium carbonate crystals, as observed by means of X-ray tomography [136]. Next to polyacrylate-type SAP, the healing has also been studied in specimens containing pH-sensitive SAP or natural polymers in combination with a synthetic backbone [29, 30, 45, 78]. As the autogenous healing capacity of the cementitious matrix promoted by the SAP can heal cracks up to 100–150 μm in width, wider cracks cannot be closed completely. In order to further increase the amount of calcium carbonate in wide cracks, SAP can be combined with bacteria, taking advantage of microbiologically induced CaCO3 precipitation [61, 62]. The SAP serves as a protective carrier for the bacteria upon hardening and the water absorption capacity is beneficial to stimulate bacterial precipitation. Furthermore, SAP with synthetic microfibers can be combined to improve healing capacity even further [126, 135, 141], or with glass fibers [142] or with natural microfibers [143, 144], to limit crack widths. This healing in humid air or wet/dry cycling, is even stimulated by SAP in large-scale samples [145] and in samples aged eight years [21].

7 Large scale and field applications

When looking back on the development of research on SAP in concretes, it is evident that SAP have been, in essence, expected to perform the following functions:

-

to absorb water and form hydrogels,

-

to act as an internal water reservoir for certain periods, and

-

to create macropores.

Therefore, applications of SAP in practice consist in finding adequate uses in which these functions perform effectively while controlling any adverse effects.

Some projects applying SAP to large-scale concrete structures have been completed in China. For example, Liu et al. [27] developed a new type of SAP that was different from conventional SAP in molecular structure. They reported that a shear wall of concrete (20 × 50 × 0.85 m3) with the new SAP had not cracked at seven days, whereas a concrete using an expansion agent had cracked. They also used the same SAP in a concrete slab (12 × 8 × 0.12 m3) and column (0.5 × 0.5 × 3.5 m3). The authors reported that there were no cracks on the surfaces of those structures, even without curing regimens such as water supply and surface covering. Zhu et al. [146] reported that concrete internally cured with an SAP was successfully applied to a railway slab whose concrete volume was 8 × 105 m3. The crack ratio in concrete using the SAP was about 1/40 of that in the concrete without SAP. The authors concluded that their SAP can increase crack resistance in engineering practice.

Superabsorbent polymers were applied in the construction of the China Zun tower [147]. It was found that the SAP reduced shrinkage by 46% and that the later age compressive strength was not affected when 0.56 mass-% of SAP is added to the mixture.

Due to the recent commercial availability of SAP in the market, an increase of SAP applications in the field can be expected.

8 Summary and outlook

This paper provides an overview of the progress in research on application of SAP as a new concrete admixture introduced since the appearance of the RILEM State-of-the-Art report in 2012 [5]. The main conclusions are summarized here section by section.

Regarding the chemistry of SAP, covalently cross-linked, acrylate-based synthetic polymers are the prevailing class of molecules. For a long time, a majority of publications related to civil-engineering applications of SAP had not disclosed thorough details on their respectively distinct chemical compositions, fairly similar to the situation related to HRWRAs. However, in the last few years, several outstanding publications have contributed to establishing chemically oriented structure-efficiency relationships of SAP in cement-based composites, i.e., to understand their molecular working mechanisms. This has allowed for reaching far beyond qualitative descriptions of the mere performance of unspecified SAP materials, which had been prevailing until issuing the previous STAR [5]. Future research is highly encouraged to proceed in a cooperative manner among chemists, materials scientists, and civil engineers for targeted, tailor-made design of the most beneficial SAP structures respectively suited to a variety of applications [9]. From a chemical point of view, the basic substances for SAP synthesis should move beyond the petrochemical basis towards bio-based raw or precursor materials.

The effect of SAP addition on the rheological properties of fresh cement-based materials depends of the ab- and desorption properties of SAP used, which depend in turn on the chemical structure and grading as well as on the availability of free water in the mix and presence of finely dispersed substances such as silica fume. The Bingham parameters, yield stress and plastic viscosity, are, however, influenced to different extents. Loss of workability may be compensated by increasing the overall water content and/or by using a superplasticizer. On the other hand, rheological measurements may be used to assess the water-sorption behavior of SAP in concrete. SAP seemed to impair the formation of a lubricating layer in the SHCC during pumping and to change its properties, in this way leading to a steeper slope of the pressure-delivery rate curve. While rheology issues related to the use of SAP in concrete can be empirically mastered in most instances, more research is needed to be able to predict and control the effects of SAP addition on rheological properties and process characteristics (such as pumpability) of fresh concrete in a comprehensive manner.

Progress has been made in the use of SAP for the mitigation of plastic shrinkage cracking [14, 110]. More research is required to understand fully the mechanism of how SAP reduces the plastic shrinkage and the related cracking.

New work has been published also on autogenous shrinkage of low w/c ratio concrete with the addition of SAP [10]. It has been found that there is a need to improve the properties, pH-sensitivity as an example, of the SAP to optimize the reduction in autogenous shrinkage in certain applications. The use of SAP for the reduction of autogenous shrinkage in alkali-activated materials is also being investigated.

The addition of SAP also has its influence on the durability- and sustainability-related properties of concrete [7, 11]. As many properties such as self-sealing and self-healing with SAP have been studied only recently, additional research is still needed to look in detail and to have information on the properties over the long term. Additional modelling efforts are necessary to increase the applicability of SAP for durability-related applications to optimize both mixture and SAP addition. These properties need to be investigated while at the same time investigating the change in microstructure and the possibly related decrease in mechanical performance. The results and information obtained can be used to model the service life of concrete structures.

Despite of the large body of research and the bringing together of experts from many countries, there still exist open issues as regards SAP application in the construction industry. The examples of SAP application in the field show promising results, yet are still scarce at this stage. Addressing open questions related to the performance of concretes with SAP is of paramount importance in promoting the wider application of this promising additive in practice. One of such issues is how to deal with the reduction of workability without substantially increasing the content of water-reducing admixtures or the water content of the concrete. Another issue is the lack of standards regulating the application of SAP by concrete producers. Concerning this last aspect, the recommendations offered by RILEM [9,10,11] may pave a path toward formal regulation.

References

Tsuji M, Okuyama A, Enoki K, Suksawang S (1998) Development of new concrete admixture preventing from leakage of water through cracks. JCA Proc Cem Concr (Japan Cem Assoc) 52:418–423

Jensen OM, Hansen PF (2001) Water-entrained cement-based materials: I Principles and thoeritical background. Cem Concr Res 31(4):647–654

Jensen OM, Hansen PF (2002) Water-entrained cement-based materials II. Experimental observations. Cem Concr Res 32(6):973–978

Jensen OM (2007) Report 41: internal curing of concrete-state-of-the-art report of RILEM Technical Committee 196-ICC. RILEM publications.

Mechtcherine V, Reinhardt HW (eds) (2012) Application of super absorbent polymers (SAP) in concrete construction. State-of-the-Art Report Prepared by Technical Committee 225-SAP, Springer.

Mechtcherine V, Gorges M, Schroefl C, Assmann A, Brameshuber W, Ribeiro AB, Cusson D, Custodio J, da Silva EF, Ichimiya K, Igarashi S, Klemm A, Kovler K, Lopez AND, Lura P, Nguyen T, Reinhardt HW, Toledo RD, Weiss J, Wyrzykowski M, Ye G, Zhutovsky S (2014) Effect of internal curing by using superabsorbent polymers (SAP) on autogenous shrinkage and other properties of a high-performance fine-grained concrete: results of a RILEM round-robin test. Mater Struct 47(3):541–562

Mechtcherine V, Schröfl C, Wyrzykowski M, Gorges M, Lura P, Cusson D, Margeson J, De Belie N, Snoeck D, Ichimiya K, Igarashi S-I, Falikman V, Friedrich S, Bokern J, Kara P, Marciniak A, Reinhardt H-W, Sippel S, Bettencourt Ribeiro A, Custódio J, Ye G, Dong H, Weiss J (2016) Effect of superabsorbent polymers (SAP) on the freeze–thaw resistance of concrete: results of a RILEM interlaboratory study. Mater Struct 50(1):14

Mechtcherine V, Schroefl C (2014) Proceedings pro095: International RILEM conference on application of superabsorbent polymers and other new admixtures in concrete construction. RILEM Publications, Dresden, Germany

Snoeck D, Schröfl C, Mechtcherine V (2018) Recommendation of RILEM TC 260-RSC: testing sorption by superabsorbent polymers (SAP) prior to implementation in cement-based materials. Mater Struct 51(5):116

Wyrzykowski M, Igarashi S-I, Lura P, Mechtcherine V (2018) Recommendation of RILEM TC 260-RSC: using superabsorbent polymers (SAP) to mitigate autogenous shrinkage. Mater Struct 51(5):135

Mechtcherine V, Schröfl C, Reichardt M, Klemm AJ, Khayat KH (2019) Recommendations of RILEM TC 260-RSC for using superabsorbent polymers (SAP) for improving freeze–thaw resistance of cement-based materials. Mater Struct 52(4):75

Schröfl C, Snoeck D, Mechtcherine V (2017) A review of characterisation methods for superabsorbent polymer (SAP) samples to be used in cement-based construction materials: report of the RILEM TC 260-RSC. Mater Struct 50(4):197

Mechtcherine V, Snoeck D, Schröfl C, De Belie N, Klemm AJ, Ichimiya K, Moon J, Wyrzykowski M, Lura P, Toropovs N, Assmann A, Igarashi S-I, De La Varga I, Almeida FCR, Erk K, Ribeiro AB, Custódio J, Reinhardt HW, Falikman V (2018) Testing superabsorbent polymer (SAP) sorption properties prior to implementation in concrete: results of a RILEM Round-Robin Test. Mater Struct 51(1):28

Boshoff W, Mechtcherine V, Snoeck D, Schröfl C, De Belie N, Ribeiro AB, Cusson D, Wyrzykowski M, Toropovs N, Lura P (2020) The effect of superabsorbent polymers on the mitigation of plastic shrinkage cracking of conventional concrete, results of an inter-laboratory test by RILEM TC 260-RSC. Mater Struct 53(4):1–16

Jensen O, Mechtcherine V, Reinhardt H, Ding B, Miao C, Tang W, Zhou D, Brüdern A, Mechtcherine V, Czarnecki L (2010) International RILEM Conference on use of superabsorbent polymers and other new additives in concrete. RILEM Publications, Bagneux

Boshoff W, Combrinck R, Mechtcherine V, Wyrzykowski M (2020) 3rd International conference on the application of superabsorbent polymers (SAP) and other new admixtures towards smart concrete. Springer

Mechtcherine V, Schröfl C (2014) Chemical aspects of superabsorbent polymers for use in cement-based mortars: a review. In: Mechtcherine V, Schröfl C (Eds) RILEM Proceedings PRO 95: application of superabsorbent polymers and other new admixtures in concrete construction

Mignon A, Snoeck D, Dubruel P, Van Vlierberghe S, De Belie N (2017) Crack mitigation in concrete: superabsorbent polymers as key to success? Materials 10(3):237

Mignon A, De Belie N, Dubruel P, Van Vlierberghe S (2019) Superabsorbent polymers: A review on the characteristics and applications of synthetic, polysaccharide-based, semi-synthetic and ‘smart’derivatives. Eur Polymer J 117:165–178

Vandenhaute M, Snoeck D, Vanderleyden E, De Belie N, Van Vlierberghe S, Dubruel P (2017) Stability of Pluronic® F127 bismethacrylate hydrogels: reality or utopia? Polym Degrad Stab 146:201–211

Snoeck D, De Belie N (2019) Autogenous healing in strain-hardening cementitious materials with and without superabsorbent polymers: an 8-year study. Front Mater 6:48

Aday AN, Osio-Norgaard J, Foster KE, Srubar WV (2018) Carrageenan-based superabsorbent biopolymers mitigate autogenous shrinkage in ordinary portland cement. Mater Struct 51(2):37

Cunha TA, Agostinho LB, Silva EF (2019) Application of nano-silica particles to improve the mechanical properties of high performance concrete containing superabsorbent polymers. In: International conference on application of superabsorbent polymers and other new admixtures towards smart concrete. Springer, pp 211–221

Kang S-H, Hong S-G, Moon J (2018) The effect of superabsorbent polymer on various scale of pore structure in ultra-high performance concrete. Constr Build Mater 172:29–40

Kong X-M, Zhang Z-L, Lu Z-C (2015) Effect of pre-soaked superabsorbent polymer on shrinkage of high-strength concrete. Mater Struct 48(9):2741–2758

Lee H, Wong H, Buenfeld N (2016) Self-sealing of cracks in concrete using superabsorbent polymers. Cem Concr Res 79:194–208

Liu R, Sun Z, Ding Q, Chen P, Chen K (2017) Mitigation of early-age cracking of concrete based on a new gel-type superabsorbent polymer. J Mater Civ Eng 29(10):04017151

Mechtcherine V, Secrieru E, Schröfl C (2015) Effect of superabsorbent polymers (SAPs) on rheological properties of fresh cement-based mortars—development of yield stress and plastic viscosity over time. Cem Concr Res 67:52–65

Mignon A, Graulus G-J, Snoeck D, Martins J, De Belie N, Dubruel P, Van Vlierberghe S (2015) pH-sensitive superabsorbent polymers: a potential candidate material for self-healing concrete. J Mater Sci 50(2):970–979

Mignon A, Snoeck D, Schaubroeck D, Luickx N, Dubruel P, Van Vlierberghe S, De Belie N (2015) pH-responsive superabsorbent polymers: a pathway to self-healing of mortar. React Funct Polym 93:68–76

Mignon A, Snoeck D, D’Halluin K, Balcaen L, Vanhaecke F, Dubruel P, Van Vlierberghe S, De Belie N (2016) Alginate biopolymers: Counteracting the impact of superabsorbent polymers on mortar strength. Constr Build Mater 110:169–174

Mignon A, Vermeulen J, Snoeck D, Dubruel P, Van Vlierberghe S, De Belie N (2017) Mechanical and self-healing properties of cementitious materials with pH-responsive semi-synthetic superabsorbent polymers. Mater Struct 50(6):238

Pourjavadi A, Fakoorpoor SM, Hosseini P, Khaloo A (2013) Interactions between superabsorbent polymers and cement-based composites incorporating colloidal silica nanoparticles. Cem Concr Compos 37:196–204

Rodriguez CR, Deprez M, de Mendonca Filho FF, Van Offenwert S, Cnudde V, Schlangen E, Šavija B (2019) X-ray micro tomography of water absorption by superabsorbent polymers in mortar. In: International conference on application of superabsorbent polymers & other new admixtures towards smart concrete. Springer, pp 29–37.

Schröfl C, Mechtcherine V, Gorges M (2012) Relation between the molecular structure and the efficiency of superabsorbent polymers (SAP) as concrete admixture to mitigate autogenous shrinkage. Cem Concr Res 42(6):865–873

Schroefl C, Mechtcherine V, Vontobel P, Hovind J, Lehmann E (2015) Sorption kinetics of superabsorbent polymers (SAPs) in fresh Portland cement-based pastes visualized and quantified by neutron radiography and correlated to the progress of cement hydration. Cem Concr Res 75:1–13

Secrieru E, Mechtcherine V, Schröfl C, Borin D (2016) Rheological characterisation and prediction of pumpability of strain-hardening cement-based-composites (SHCC) with and without addition of superabsorbent polymers (SAP) at various temperatures. Constr Build Mater 112:581–594

Snoeck D, De Schryver T, De Belie N (2018) Enhanced impact energy absorption in self-healing strain-hardening cementitious materials with superabsorbent polymers. Constr Build Mater 191:13–22

Snoeck D, Pel L, De Belie N (2018) Superabsorbent polymers to mitigate plastic drying shrinkage in a cement paste as studied by NMR. Cem Concr Compos 93:54–62

Snoeck D, Van den Heede P, Van Mullem T, De Belie N (2018) Water penetration through cracks in self-healing cementitious materials with superabsorbent polymers studied by neutron radiography. Cem Concr Res 113:86–98

Snoeck D, Pel L, De Belie N (2019) Kinetics of SAPs during hardening, drying and healing in cementitious materials studied by NMR. In: International conference on application of superabsorbent polymers and other new admixtures towards smart concrete. Springer, pp 132–139.

Tangkokiat P, Thanapornpavornkul T, Muangkaew S, Siriwatwechakul W, Siramanont J, Snguanyat C (2019) Characterization of neutral versus anionic superabsorbent polymers (SAPs) in ion-rich solutions for their use as internal curing agents. In: International conference on application of superabsorbent polymers and other new admixtures towards smart concrete. Springer, pp 38–45

Filho JRT, de Araújo MAPG, Snoeck D, Mannekens E, De Belie N (2019) Exploring different choices of “time zero” in the autogenous shrinkage deformation of cement pastes containing superabsorbent polymers. In: 3rd international conference on the application of superabsorbent polymers (SAP) and other new admixtures towards smart concrete. Springer, p 106

Urgessa G, Choi K-B, Yeon JH (2018) Internal relative humidity, autogenous shrinkage, and strength of cement mortar modified with superabsorbent polymers. Polymers 10(10):1074

Wang C, Bu Y, Guo S, Lu Y, Sun B, Shen Z (2019) Self-healing cement composite: Amine-and ammonium-based pH-sensitive superabsorbent polymers. Cem Concr Compos 96:154–162

Beushausen H, Gillmer M, Alexander M (2014) The influence of superabsorbent polymers on strength and durability properties of blended cement mortars. Cem Concr Compos 52:73–80

Beushausen H, Gillmer M (2014) The use of superabsorbent polymers to reduce cracking of bonded mortar overlays. Cem Concr Compos 52:1–8

Bian X, Zeng L, Deng Y, Li X (2018) The role of superabsorbent polymer on strength and microstructure development in cemented dredged clay with high water content. Polymers 10(10):1069

Davis CR, Bose B, Alcaraz AM, Martinez CJ, Erk KA (2019) Altering the crosslinking density of polyacrylamide hydrogels to increase swelling capacity and promote calcium hydroxide growth in cement voids. In: International conference on application of superabsorbent polymers and other new admixtures towards smart concrete. Springer, pp 20–28.

Deng H, Liao G (2018) Assessment of influence of self-healing behavior on water permeability and mechanical performance of ECC incorporating superabsorbent polymer (SAP) particles. Constr Build Mater 170:455–465

Esteves LP, Lukošiūtė I, Čėsnienė J (2014) Hydration of cement with superabsorbent polymers. J Therm Anal Calorim 118(2):1385–1393

Farzanian K, Teixeira KP, Rocha IP, Carneiro LDS, Ghahremaninezhad A (2016) The mechanical strength, degree of hydration, and electrical resistivity of cement pastes modified with superabsorbent polymers. Constr Build Mater 109:156–165

Gruyaert E, Debbaut B, Snoeck D, Díaz P, Arizo A, Tziviloglou E, Schlangen E, De Belie N (2016) Self-healing mortar with pH-sensitive superabsorbent polymers: testing of the sealing efficiency by water flow tests. Smart Mater Struct 25(8):084007

Hong G, Choi S (2017) Rapid self-sealing of cracks in cementitious materials incorporating superabsorbent polymers. Constr Build Mater 143:366–375

Lee H, Wong H, Buenfeld N (2018) Effect of alkalinity and calcium concentration of pore solution on the swelling and ionic exchange of superabsorbent polymers in cement paste. Cem Concr Compos 88:150–164

Ma X, Liu J, Wu Z, Shi C (2017) Effects of SAP on the properties and pore structure of high performance cement-based materials. Constr Build Mater 131:476–484

Riyazi S, Kevern JT, Mulheron M (2017) Super absorbent polymers (SAPs) as physical air entrainment in cement mortars. Constr Build Mater 147:669–676

Oh S, Choi YC (2018) Superabsorbent polymers as internal curing agents in alkali activated slag mortars. Constr Build Mater 159:1–8

Zhong P, Wyrzykowski M, Toropovs N, Li L, Liu J, Lura P (2019) Internal curing with superabsorbent polymers of different chemical structures. Cem Concr Res 123:105789

Liu J, Ou Z, Mo J, Wang Y, Wu H (2017) The effect of SCMs and SAP on the autogenous shrinkage and hydration process of RPC. Constr Build Mater 155:239–249

Wang J, Snoeck D, Van Vlierberghe S, Verstraete W, De Belie N (2014) Application of hydrogel encapsulated carbonate precipitating bacteria for approaching a realistic self-healing in concrete. Constr Build Mater 68:110–119

Wang J, Mignon A, Snoeck D, Wiktor V, Van Vliergerghe S, Boon N, De Belie N (2015) Application of modified-alginate encapsulated carbonate producing bacteria in concrete: a promising strategy for crack self-healing. Front Microbiol 6:1088

Shen D, Shi H, Tang X, Ji Y, Jiang G (2016) Effect of internal curing with super absorbent polymers on residual stress development and stress relaxation in restrained concrete ring specimens. Constr Build Mater 120:309–320

Shen D, Jiang J, Zhang M, Yao P, Jiang G (2018) Tensile creep and cracking potential of high performance concrete internally cured with super absorbent polymers at early age. Constr Build Mater 165:451–461

Yang J, Wang F, He X, Su Y (2019) Pore structure of affected zone around saturated and large superabsorbent polymers in cement paste. Cem Concr Compos 97:54–67

Justs J, Wyrzykowski M, Bajare D, Lura P (2015) Internal curing by superabsorbent polymers in ultra-high performance concrete. Cem Concr Res 76:82–90

Pelto J, Leivo M, Gruyaert E, Debbaut B, Snoeck D, De Belie N (2017) Application of encapsulated superabsorbent polymers in cementitious materials for stimulated autogenous healing. Smart Mater Struct 26(10):105043

Ferfera‐Harrar H, Aiouaz N, Dairi N, Hadj‐Hamou AS (2014) Preparation of chitosan‐g‐poly (acrylamide)/montmorillonite superabsorbent polymer composites: studies on swelling, thermal, and antibacterial properties. J Appl Polym Sci 131(1)

AzariJafari H, Kazemian A, Rahimi M, Yahia A (2016) Effects of pre-soaked super absorbent polymers on fresh and hardened properties of self-consolidating lightweight concrete. Constr Build Mater 113:215–220

Dang J, Zhao J, Du Z (2017) Effect of superabsorbent polymer on the properties of concrete. Polymers 9(12):672

Hu Z, Hilaire A, Wyrzykowski M, Scrivener K, Lura P (2017) Elastic and visco-elastic behavior of cementitious materials at early ages. Poromechanics VI:1013–1020

De Meyst L, Mannekens E, Araújo M, Snoeck D, Van Tittelboom K, Van Vlierberghe S, De Belie N (2019) Parameter study of superabsorbent polymers (SAPs) for use in durable concrete structures. Materials 12(9):1541

Ma X, Yuan Q, Liu J, Shi C (2019) Effect of water absorption of SAP on the rheological properties of cement-based materials with ultra-low w/b ratio. Constr Build Mater 195:66–74

Ferrari G, Brocchi A (2012) Zero impact recycling of returned concrete. In: XVI ERMCO Congress, Verona, Italy, 21–22 June 2012, p 4.

Deng Z, Cheng H, Wang Z, Zhu G, Zhong H (2016) Compressive behavior of the cellular concrete utilizing millimeter-size spherical saturated SAP under high strain-rate loading. Constr Build Mater 119:96–106

Tenório Filho JR, Snoeck D, DeBelie N (2020) Mixing protocols for plant-scale production of concrete with superabsorbent polymers. Struct Concr. https://doi.org/10.1002/suco.201900443

Liu H, Bu Y, Sanjayan JG, Nazari A, Shen Z (2016) The application of coated superabsorbent polymer in well cement for plugging the microcrack. Constr Build Mater 104:72–84

Hu M, Guo J, Du J, Liu Z, Li P, Ren X, Feng Y (2019) Development of Ca2+-based, ion-responsive superabsorbent hydrogel for cement applications: self-healing and compressive strength. J Colloid Interface Sci 538:397–403

Hasholt MT, Jensen OM (2015) Chloride migration in concrete with superabsorbent polymers. Cem Concr Compos 55:290–297

Lura P, Terrasi GP (2014) Reduction of fire spalling in high-performance concrete by means of superabsorbent polymers and polypropylene fibers: Small scale fire tests of carbon fiber reinforced plastic-prestressed self-compacting concrete. Cem Concr Compos 49:36–42

Van Der Putten J, Azima M, Van den Heede P, Van Mullem T, Snoeck D, Carminati C, Hovind J, Trtik P, De Schutter G, Van Tittelboom K (2020) Neutron radiography to study the water ingress via the interlayer of 3D printed cementitious materials for continuous layering. Constr Build Mater 258:119587

Senff L, Modolo R, Ascensão G, Hotza D, Ferreira V, Labrincha J (2015) Development of mortars containing superabsorbent polymer. Constr Build Mater 95:575–584

Secrieru E, Schroefl C, Mechtcherine V (2014) Evolution of rheological properties of fresh concrete enriched with superabsorbent polymers (SAP) in time at various temperatures. In: Pro 095: International RILEM conference on application of superabsorbent polymers and other new admixtures in concrete 2014.

Lura P, Durand F, Loukili A, Kovler K, Jensen OM (2006) Compressive strength of cement pastes and mortars with superabsorbent polymers. In: Jensen OM, Lura P, Kovler K (eds) Volume changes of hardening concrete: testing and mitigation. RILEM Publications SARL, Lyngby (Denmark), pp 117–126

Justs J, Wyrzykowski M, Winnefeld F, Bajare D, Lura P (2014) Influence of superabsorbent polymers on hydration of cement pastes with low water-to-binder ratio. J Therm Anal Calorim 115(1):425–432

Wehbe Y, Ghahremaninezhad A (2017) Combined effect of shrinkage reducing admixtures (SRA) and superabsorbent polymers (SAP) on the autogenous shrinkage, hydration and properties of cementitious materials. Constr Build Mater 138:151–162

Miller AE, Barrett TJ, Weiss W (2014) Evaluation of superabsorbent polymers for use in cementitious systems for the purpose of mitigating autogenous shrinkage. In: International RILEM conference on the application of superabsorbent polymers and other new admixtures in concrete construction, Dresden, Germany, 2014.

Zhutovsky S, Kovler K (2013) Hydration kinetics of high-performance cementitious systems under different curing conditions. Mater Struct 46(10):1599–1611

Wyrzykowski M, Lura P (2016) Effect of relative humidity decrease due to self-desiccation on the hydration kinetics of cement. Cem Concr Res 85:75–81

Almeida FCR, Klemm AJ (2018) Efficiency of internal curing by superabsorbent polymers (SAP) in PC-GGBS mortars. Cem Concr Compos 88:41–51

Klemm AJ, Sikora KS (2013) The effect of superabsorbent polymers (SAP) on microstructure and mechanical properties of fly ash cementitious mortars. Constr Build Mater 49:134–143

Wyrzykowski M, Lura P, Pesavento F, Gawin D (2012) Modeling of water migration during internal curing with superabsorbent polymers. ASCE J Mater Civil Eng 24(8):1006–1016

Trtik P, Münch B, Weiss WJ, Herth G, Kaestner A, Lehmann E, Lura P (2010) Neutron tomography investigation of water release from superabsorbent polymers in cement paste. In: International conference on material science, Aachen, Germany

Krafcik MJ, Macke ND, Erk KA (2017) Improved concrete materials with hydrogel-based internal curing agents. Gels 3(4):46

Esteves LP (2011) On the hydration of water-entrained cement–silica systems: combined SEM. XRD and thermal analysis in cement pastes. Thermochim Acta 518(1):27–35

Olawuyi BJ, Boshoff WP (2014) 3D-void analysis of high performance concretes containing superabsorbent polymers (SAP). In: International RILEM conference on application of superabsorbent polymers and other new admixtures in concrete construction. Technische Universität Dresden, Dresden, Germany, PRO, pp 81–91

Snoeck D, Pel L, De Belie N (2019) Comparison of different techniques to study the nanostructure and the microstructure of cementitious materials with and without superabsorbent polymers. Constr Build Mater 223:244–253

Toropovs N, Lo Monte F, Wyrzykowski M, Weber B, Sahmenko G, Vontobel P, Felicetti R, Lura P (2015) Real-time measurements of temperature, pressure and moisture profiles in high-performance concrete exposed to high temperatures during neutron radiography imaging. Cem Concr Res 68:166–173

Wyrzykowski M, Terrasi G, Lura P (2018) Expansive high-performance concrete for chemical-prestress applications. Cem Concr Res 107:275–283

Wyrzykowski M, Terrasi G, Lura P (2020) Chemical prestressing of high-performance concrete reinforced with CFRP tendons. Compos Struct 239:112031

Snoeck D, Schaubroeck D, Dubruel P, De Belie N (2014) Effect of high amounts of superabsorbent polymers and additional water on the workability, microstructure and strength of mortars with a water-to-cement ratio of 0.50. Constr Build Mater 72:148–157

Reinhardt HW, Assmann A (2009) Enhanced durability of concrete by superabsorbent polymers. In: International symposium brittle matrix composites, pp 291–300. Woodhead Publishing, Warsaw

Kamali M, Ghahremaninezhad A (2017) An investigation into the influence of superabsorbent polymers on the properties of glass powder modified cement pastes. Constr Build Mater 149:236–247

Ouattara Coumoin C, Wang F, Yang J, Liu Z (2019) Effect of SAP on properties of high performance concrete under marine wetting and drying cycles. J Wuhan Univ Technol Mater Sci Ed 34(5):1136–1142

Assmann A, Reinhardt H (2014) Tensile creep and shrinkage of SAP modified concrete. Cem Concr Res 58:179–185

Snoeck D, Jensen OM, De Belie N (2015) The influence of superabsorbent polymers on the autogenous shrinkage properties of cement pastes with supplementary cementitious materials. Cem Concr Res 74:59–67

Tu W, Zhu Y, Fang G, Wang X, Zhang M (2019) Internal curing of alkali-activated fly ash-slag pastes using superabsorbent polymer. Cem Concr Res 116:179–190

Li Z, Wyrzykowski M, Dong H, Granja J, Azenha M, Lura P, Ye G (2020) Internal curing by superabsorbent polymers in alkali-activated slag. Cem Concr Res 135:106123

Snoeck D, Pel L, De Belie N (2017) The water kinetics of superabsorbent polymers during cement hydration and internal curing visualized and studied by NMR. Sci Rep 7(1):1–14

Serpukhov I, Mechtcherine V (2015) Early-age shrinkage of ordinary concrete and a strain-hardening cement-based composite (SHCC) in the conditions of hot weather casting. In: CONCREEP 102015, pp 1504–1513

Almeida FCR, Rostami R, Klemm AJ (2020) The effect of SAP on volumetric changes and microstructural alterations in PC-GGBS matrices. Springer, Cham, pp 97–105

Olivier G, Combrinck R, Kayondo M, Boshoff WP (2018) Combined effect of nano-silica, super absorbent polymers, and synthetic fibers on plastic shrinkage cracking in concrete. Constr Build Mater 192:85–98

Snoeck D (2018) Superabsorbent polymers to seal and heal cracks in cementitious materials. RILEM Tech Lett 3:32–38

He Z, Shen A, Guo Y, Lyu Z, Li D, Qin X, Zhao M, Wang Z (2019) Cement-based materials modified with superabsorbent polymers: a review. Constr Build Mater 225:569–590

Ding H, Zhang L, Zhang P (2017) Factors influencing strength of super absorbent polymer (SAP) concrete. Trans Tianjin Univ 23(3):245–257

Lefever G, Snoeck D, De Belie N, Van Vlierberghe S, Van Hemelrijck D, Aggelis DG (2020) The contribution of elastic wave NDT to the characterization of modern cementitious media. Sensors 20(10):2959

Lefever G, Tsangouri E, Snoeck D, Aggelis DG, De Belie N, Van Vlierberghe S, Van Hemelrijck D (2020) Combined use of superabsorbent polymers and nanosilica for reduction of restrained shrinkage and strength compensation in cementitious mortars. Constr Build Mater 251:118966

Wyrzykowski M, Lura P (2013) Controlling the coefficient of thermal expansion of cementitious materials—a new application for superabsorbent polymers. Cem Concr Compos 35(1):49–58