Abstract

The modulus gradient of asphalt concrete (AC) layers is an important feature of flexible pavements. The variation of the modulus with depth results from the synthetical effect of material properties, the service time of pavements, loading and environmental conditions. Since the modulus gradient directly affects critical responses and performance of pavements, the determination of the modulus gradient of AC layers is necessary for the evaluation, maintenance and rehabilitation of flexible pavements. This paper aims to propose a method to obtain layer moduli of flexible pavements at different loading frequencies, which include a power function describing the modulus gradient of AC layers. The method utilizes results from a typical nondestructive test in the field applying the falling weight deflectometer and techniques of the fast Fourier transform, finite element model updating, kriging model and artificial intelligence. The method is validated by comparing layer moduli obtained from the proposed method and other backcalculation softwares.

Similar content being viewed by others

References

Lakes RS (2009) Viscoelastic materials. Cambridge University Press, Cambridge

Kim YR, Hibbs BO, Lee Y (1995) Temperature correction of deflections and backcalculated asphalt concrete moduli. In: Transportation research record 1473, TRB, National Research Council, Washington, D.C., pp 55–62

Nazarian S, Alvarado G (2006) Impact of temperature gradient on modulus of asphaltic concrete layers. J Mater Civ Eng 18(4):492–499

Buttlar WG, Paulino GH, Song SH (2006) Application of graded finite elements for asphalt pavements. J Eng Mech 132(3):240–249

Wang H, Al-Qadi IL (2010) Near-surface pavement failure under multiaxial stress state in thick asphalt pavement. Transp Res Rec 2154(1):91–99

Li Z, Dufalla N, Mu F, Vandenbossche JM (2013) Bonded concrete overlay of asphalt pavements mechanistic-empirical design guide (BCOA-ME). User’s Guide FHWA TFP Study 5:165

Houston WN, Mirza MW, Zapata CE, Raghavendra S (2005) Environmental effects in pavement mix and structural design systems. NCHRP Project 9-23. TRB, National Research Council, Washington, DC

Zapata CE, Houston WN (2008) Calibration and validation of the enhanced integrated climatic model for pavement design. NCHRP Report 602. TRB, National Research Council, Washington, DC

Barksdale RD (1971) Compressive stress pulse times in flexible pavements for use in dynamic testing. Highway Res Rec 345(4):32–44

Brown SF (1973) Determination of Young’s modulus for bituminous materials in pavement design. In: Highway research record, HRB, National Research Council, Washington, D.C., issue no 431, pp 38–49

McLean DB (1974) Permanent deformation characteristics of asphalt concrete. PhD Dissertation, University of California, Berkeley

Al-Qadi IL, Xie W, Elseifi MA (2008) Frequency determination from vehicular loading time pulse to predict appropriate complex modulus in MEPDG. Asphalt Paving Technol Proc 77:739

Ulloa A, Hajj EY, Siddharthan RV, Sebaaly PE (2013) Equivalent loading frequencies for dynamic analysis of asphalt pavements. J Mater Civ Eng 25(9):1162–1170

Wang H, Li M (2016) Comparative study of asphalt pavement responses under FWD and moving vehicular loading. J Transp Eng 142(12):04016069

Koohi Y, Lawrence JJ, Luo R, Lytton RL (2012) Complex stiffness gradient estimation of field-aged asphalt concrete layers using the direct tension test. J Mater Civ Eng 24(7):832–841

Yin F, Martin AE, Arámbula-Mercado E, Newcomb D (2017) Characterization of non-uniform field aging in asphalt pavements. Constr Build Mater 153:607–615

Luo X, Gu F, Ling M, Lytton RL (2018) Review of mechanistic-empirical modeling of top-down cracking in asphalt pavements. Constr Build Mater 191:1053–1070

Hu W (2018) Evaluation of intelligent compaction technology in asphalt pavement construction and laboratory compaction. PhD Dissertation, University of Tennessee, Knoxville

ARA-ERES (Applied Research Associates, Inc., ERES Consultants Division) (2004) Guide for mechanistic–empirical design of new and rehabilitated pavement structures. Final report, NCHRP Project 1-37A, Transportation Research Board, Washington, DC

Luo X, Gu F, Lytton RL (2015) Prediction of field aging gradient in asphalt pavements. Transp Res Rec 2507(1):19–28

Luo X, Gu F, Lytton RL (2019) Kinetics-based aging prediction of asphalt mixtures using field deflection data. Int J Pavement Eng 20(3):287–297

Das PK, Kringos N, Birgisson B (2015) Numerical study on the effect of mixture morphology on long-term asphalt mixture ageing. Int J Pavement Eng 16(8):710–720

Baek C, Underwood BS, Kim YR (2012) Effects of oxidative aging on asphalt mixture properties. Transp Res Rec 2296(1):77–85

Li Y, Nazarian S (1995) Evaluation of aging of hot-mix asphalt using wave propagation techniques. In: Engineering properties of asphalt mixtures and the relationship to their performance. ASTM Special Technical Publication 1265. ASTM, Philadelphia, PA, 166–179

Hagos ET (2008) The effect of aging on binder properties of porous asphalt concrete. PhD Dissertation, Delft University of Technology, Delft, Netherlands

AASHTO (1999) Provisional standards, Interim edn. American Association of State Highway and Transportation Officials, Washington, DC

Ling M, Luo X, Gu F, Lytton RL (2017) Time-temperature-aging-depth shift functions for dynamic modulus master curves of asphalt mixtures. Constr Build Mater 157:943–951

ASTM International (2017) Standard test methods for quantitative extraction of asphalt binder from asphalt mixtures. D2172/D2172M-17, West Conshohocken

Oliver JW (2009) Changes in the chemical composition of Australian bitumens. Road Mater Pavement Des 10(3):569–586

Lee SJ, Amirkhanian SN, Kim KW (2009) Laboratory evaluation of the effects of short-term oven aging on asphalt binders in asphalt mixtures using HP-GPC. Constr Build Mater 23(9):3087–3093

Luo R, Lytton RL (2010) Characterization of the tensile viscoelastic properties of an undamaged asphalt mixture. J Transp Eng 136(3):173–180

Ling M, Luo X, Gu F, Lytton RL (2017) An inverse approach to determine complex modulus gradient of field-aged asphalt mixtures. Mater Struct 50(2):138

Mirza MW, Witczak MW (1995) Development of a global aging system for short and long term aging of asphalt cements. J Assoc Asphalt Paving Technol 64:393–430

Zhang D, Birgisson B, Luo X, Onifade I (2019) A new short-term aging model for asphalt binders based on rheological activation energy. Mater Struct 52(4):68

Luo X, Birgisson B, Lytton RL (2020) Kinetics of healing of asphalt mixtures. J Clean Prod 252:119790

Zhang D, Birgisson B, Luo X, Onifade I (2019) A new long-term aging model for asphalt pavements using morphology-kinetics based approach. Constr Build Mater 229:117032

Xu B, Ranjithan SR, Kim YR (2002) New relationships between falling weight deflectometer deflections and asphalt pavement layer condition indicators. Transp Res Rec 1806(1):48–56

Horak E, Emery S (2006) Falling weight deflectometer bowl parameters as analysis tool for pavement structural evaluations. In: Research into practice: 22nd ARRB conference. ARRB, Canberra

Magnuson AH, Lytton RL, Briggs RC (1991) Comparison of computer predictions and field data for dynamic analysis of falling weight deflectometer data. Transp Res Rec 1293:61–71

Meier RW, Rix GJ (1994) Backcalculation of flexible pavement moduli using artificial neural networks. Transportation Research Record, 1448. National Research Council, Washington, DC

Hadidi R, Gucunski N (2010) Comparative study of static and dynamic falling weight deflectometer back-calculations using probabilistic approach. J Transp Eng 136(3):196–204

Kutay ME, Chatti K, Lei L (2011) Backcalculation of dynamic modulus mastercurve from falling weight deflectometer surface deflections. Transp Res Rec 2227(1):87–96

Li M, Wang H (2019) Development of ANN-GA program for backcalculation of pavement moduli under FWD testing with viscoelastic and nonlinear parameters. Int J Pavement Eng 20(4):490–498

Elseifi MA, Abdel-Khalek AM, Gaspard K, Zhang Z, Ismail S (2012) Evaluation of continuous deflection testing using the rolling wheel deflectometer in Louisiana. J Transp Eng 138(4):414–422

Muller W, Wix R (2014) Preliminary field validation of the updated traffic speed deflectometer (TSD) device. In: ARRB conference, Sydney

Ameri M, Yavari N, Scullion T (2009) Comparison of static and dynamic backcalculation of flexible pavement layers moduli, using four software programs. Asian J Appl Sci 2(3):197–210

Liu W, Scullion T (2001) Modulus 6.0 for Windows: User’s manual. No. FHWA/TX-05/0-1869-2. Texas Transportation Institute, Texas A&M University System

The Dynatest Group (2001) ELMOD pavement evaluation manual (Version 4.5), Dynatest

BAKFAA (2017) Retrieved from https://www.airporttech.tc.faa.gov/Products/Airport-Safety-Papers-Publications/Airport-Safety-Detail/ArtMID/3682/ArticleID/11/BAKFAA-version-2101

Magnuson AH (1988) Dynamic analysis of falling-weight deflectometer data. Report No. TX-89/1175-1. Texas Transportation Institute, Texas A&M University System, College Station

Uzan J (1994) Dynamic linear back calculation of pavement material parameters. J Transp Eng 120(1):109–126

Fernando EG, Liu W (1999) User’s manual for pavement dynamic back-calculation procedure with systems identification method (DBSID). Texas Transportation Institute, Texas A&M University, College Station

Varma S, Kutay ME (2016) Backcalculation of viscoelastic and nonlinear flexible pavement layer properties from falling weight deflections. Int J Pavement Eng 17(5):388–402

Deng Y, Luo X, Gu F, Zhang Y, Lytton RL (2019) 3D simulation of deflection basin of pavements under high-speed moving loads. Constr Build Mater 226:868–878

Cao H, Qian X, Chen Z, Zhu H (2017) Enhanced particle swarm optimization for size and shape optimization of truss structures. Eng Optim 49(11):1939–1956

Qin S, Zhang Y, Zhou YL, Kang J (2018) Dynamic model updating for bridge structures using the kriging model and PSO algorithm ensemble with higher vibration modes. Sensors 18(6):1879

Simulia (2012) Abaqus 6.12 documentation, Providence

Kim M (2007) Three-dimensional finite element analysis of flexible pavements considering nonlinear pavement foundation behavior. PhD Dissertation, University of Illinois, Urbana-Champaign, Urbana

Dave EV, Buttlar WG, Paulino GH, Hilton HH (2008) Graded viscoelastic approach for modeling asphalt concrete pavements. In: AIP conference proceedings, vol 973, No. 1. American Institute of Physics, pp 736–741

Dave EV, Buttlar WG, Paulino GH (2010) Asphalt pavement aging and temperature dependent properties through a functionally graded viscoelastic model, part II: applications. Mater Sci Forum 631–632:53–58

Martin JD, Simpson TW (2003) A study on the use of kriging models to approximate deterministic computer models. In: ASME 2003 International design engineering technical conferences and computers and information in engineering conference. American Society of Mechanical Engineers Digital Collection, pp 567–576

Simpson TW, Mauery TM, Korte JJ, Mistree F (1998) Comparison of response surface and kriging models for multidisciplinary design optimization. In: Proceedings of the 7th AIAA/USAF/NASA/ISSMO symposium on multidisciplinary analysis and optimization, St. Louis, MO, vol 1, pp 381–391

Kennedy J, Eberhart R (1995) Particle swarm optimization. In: Proceedings of ICNN’95-international conference on neural networks, Perth, vol 4, pp 1942–1948

Shabbir F, Omenzetter P (2015) Particle swarm optimization with sequential niche technique for dynamic finite element model updating. Comput Aided Civ Infrastruct Eng 30(5):359–375

Lytton RL (1989) Backcalculation of pavement layer properties. In: STP 1026, Nondestructive testing of pavements and backcalculation of moduli. ASTM, Philadelphia, pp 7–38

Funding

This work was supported by Changsha University of Science & Technology via Open Fund of National Engineering Laboratory of Highway Maintenance Technology (Grant Number: KFJ180104).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

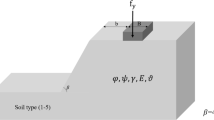

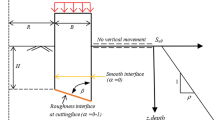

1.1 Determinations of the mesh size and model radius of the pavement

In the sensitivity analysis, structural parameters and material properties are the same as Fig. 2 of the manuscript. A standard FWD load was applied, of which the pressure magnitude is 565 kPa, the load cycle is 0.03 s and the load radius is 0.15 m. Figure 10 illustrates the model radius which was adjusted in the sensitivity analysis. For simplicity, the surface layer, base layer and subgrade were treated as elastic materials, of which the modulus are 2000 MPa, 500 MPa and 250 MPa, respectively. Table 3 shows the corresponding maximum deflection at the loading center when the model radius is 3 m, 4 m and 5 m. It shows that the maximum deflection at the loading center converges as the model radius increases. Since the relative error drops below 1% when the model radius is 5 m, this value was used in all FE models of this paper. Similarly, the sensitivity analysis was conducted on different meshes and results are presented in Table 4. The mesh setting in the case “Finer” was applied in all FE models of this paper.

1.2 Validation of the UMAT for the surface layer

Two comparisons were conducted in this section to validate the UMAT for the modulus gradient of the surface layer. The structural parameters, loading condition and material properties of the base layer and subgrade are the same as Sect. 4.1. In the first comparison, \(E_{b}\), \(E_{s}\) and \(n\) in the UMAT were set to 2000 MPa, 2000 MPa and 1, which represents no modulus change with the depth. It was compared with the case where the module “Elastic” in ABAQUS was set for the surface layer and the modulus value was set to 2000 MPa. In the second comparison, \(E_{b}\), \(E_{s}\) and \(n\) in the UMAT were set to 1000 MPa, 2000 MPa and 1, which represents a linear decrease in the modulus value with the depth. It was compared with the case where the surface layer was divided into 5 identical sublayers. From the top to bottom, the elastic modulus was set to 1900 MPa, 1700 MPa, 1500 MPa, 1300 MPa, 1100 MPa, respectively.

Figure 11 shows the results of two comparisons. The time histories of the deflection at the loading center were compared. From the graph, it can be seen that results of the cases using the UMAT are nearly the same as cases using the default module in ABAQUS, which proves the accuracy of the UMAT used in the manuscript.

1.3 Sensitivity analysis of layer modulus on deflections at sensor locations

Table 5 is the supplement of Fig. 3 of the manuscript. The loading condition, structural parameters and material properties except the modulus of the pavement are the same as Sect. 4.1. Table 5 shows the modulus of each layer and deflection magnitudes at four sensor locations. In Case 1–Case 10, only one property is adjusted and the rest are the same as Case 0.

Rights and permissions

About this article

Cite this article

Deng, Y., Luo, X., Zhang, Y. et al. Determination of complex modulus gradients of flexible pavements using falling weight deflectometer and artificial intelligence. Mater Struct 53, 100 (2020). https://doi.org/10.1617/s11527-020-01528-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-020-01528-2